Micro-interface reaction system and method for petroleum resin hydrogenation

An interfacial reaction, petroleum resin technology, applied in the fields of mixing methods, petroleum industry, hydrotreating process, etc., can solve the problems of decreased intrinsic safety, high reaction pressure of trickle bed hydrogenation process, high equipment investment cost, and high operating cost , to achieve the effect of improving the dispersion and crushing effect, good product quality and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

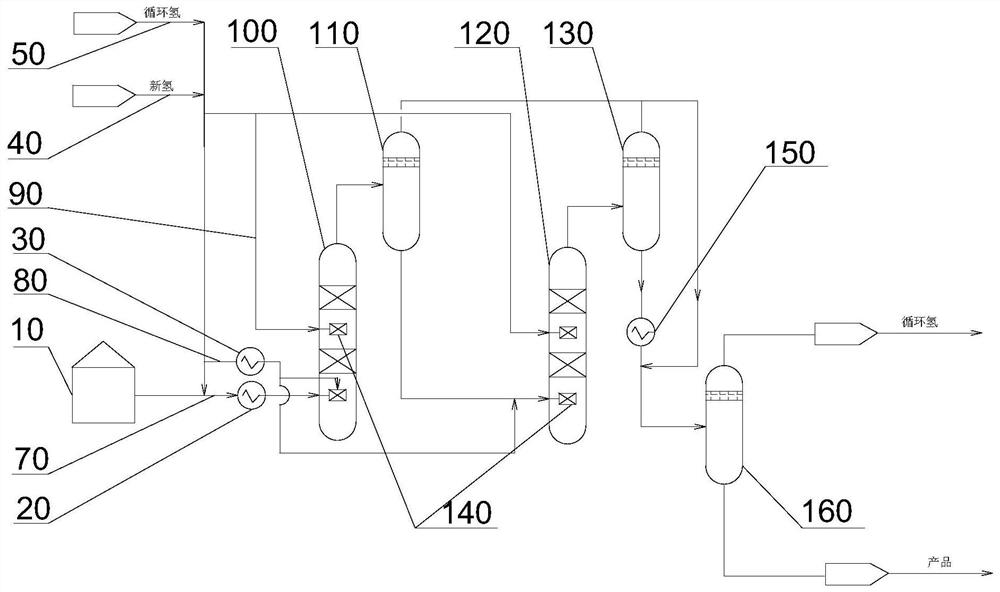

[0056] refer to figure 1 As shown, it is a micro-interface reaction system for petroleum resin hydrogenation according to an embodiment of the present invention, which mainly includes a pre-hydrogenation reactor 100 and a refining hydrogenation reactor 120;

[0057] The pre-hydrogenation reactor 100 is a fixed-bed reactor, and two catalyst beds are arranged inside it, and a micro-interface generator 140 is arranged between the catalyst bed and the bottom of the pre-hydrogenation reactor 100. The micro-interface generator 140 is two, and two catalyst beds are arranged in the refining hydrogenation reactor 120, and a micro-interface generator 140 is respectively arranged between the two catalyst beds and the bottom of the refining hydrogenation reactor 120 , the number of micro-interface generators 140 set inside the refining hydrogenation reactor 120 is the same as the number of micro-interface generators set inside the pre-hydrogenation reactor 100, both being two.

[0058] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com