Reaction system and method for hydrofining crude terephthalic acid

A crude terephthalic acid and reaction system technology, applied in the field of crude terephthalic acid purification, can solve the problems of uneven hydrogen distribution, equipment investment costs, high operating costs, and low mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

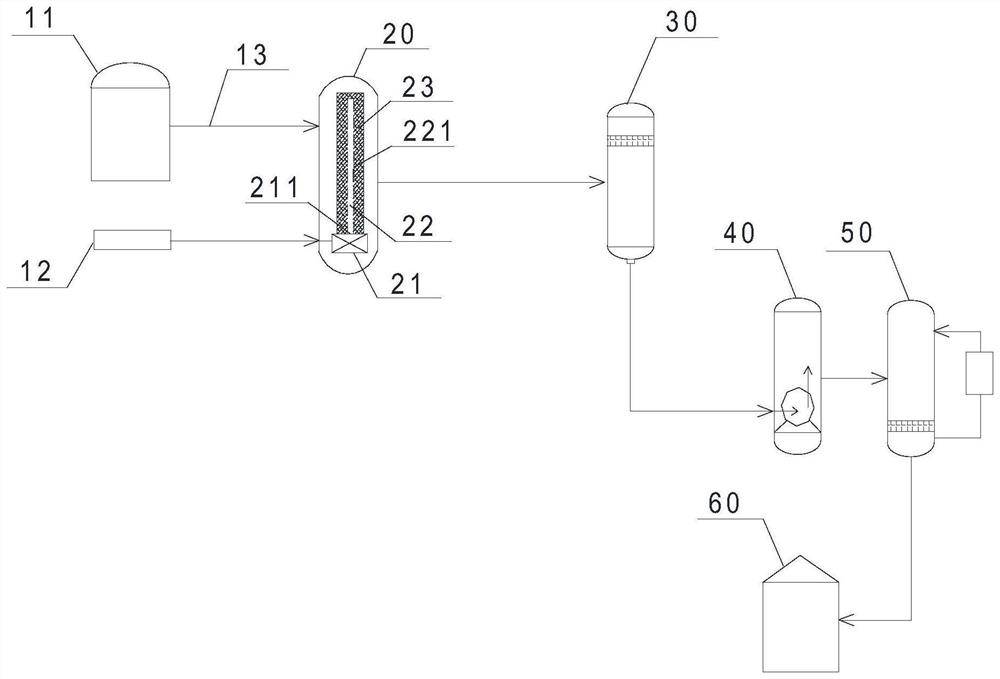

[0046] refer to figure 1 As shown, the crude terephthalic acid hydrogenation and refining reaction system provided by the embodiment of the present invention mainly includes a crude terephthalic acid raw material tank 11, a hydrogen gas inlet pipeline 12, a hydrogenation reactor 20, a crystallization tower 30, Centrifugal separator 40 , dryer 50 and collection tank 60 . The crude terephthalic acid raw material tank 11 is connected to the hydrogenation reactor 20 through a crude terephthalic acid pipeline 13 so that the crude terephthalic acid enters the hydrogenation reactor 20 . The hydrogenation reactor 20 is internally provided with a hydrogen micro-interface generator 21, a gas distribution pipeline 22 and a palladium-carbon catalyst bed 23, and the hydrogen gas inlet pipeline 12 passes through the side wall of the hydrogenation reactor 20 and the hydrogen micro-interface generator 21 connected.

[0047] The hydrogen micro-interface generator 21 is arranged at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com