Enhanced micro-interface reaction system and method for preparing lactide from lactic acid

A reaction system and lactide technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, separation methods, etc., can solve the problem of reducing the yield of lactide products, low separation system efficiency, and many by-products. and other problems, to achieve the effect of reducing reaction temperature and catalyst usage, increasing mass transfer area, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

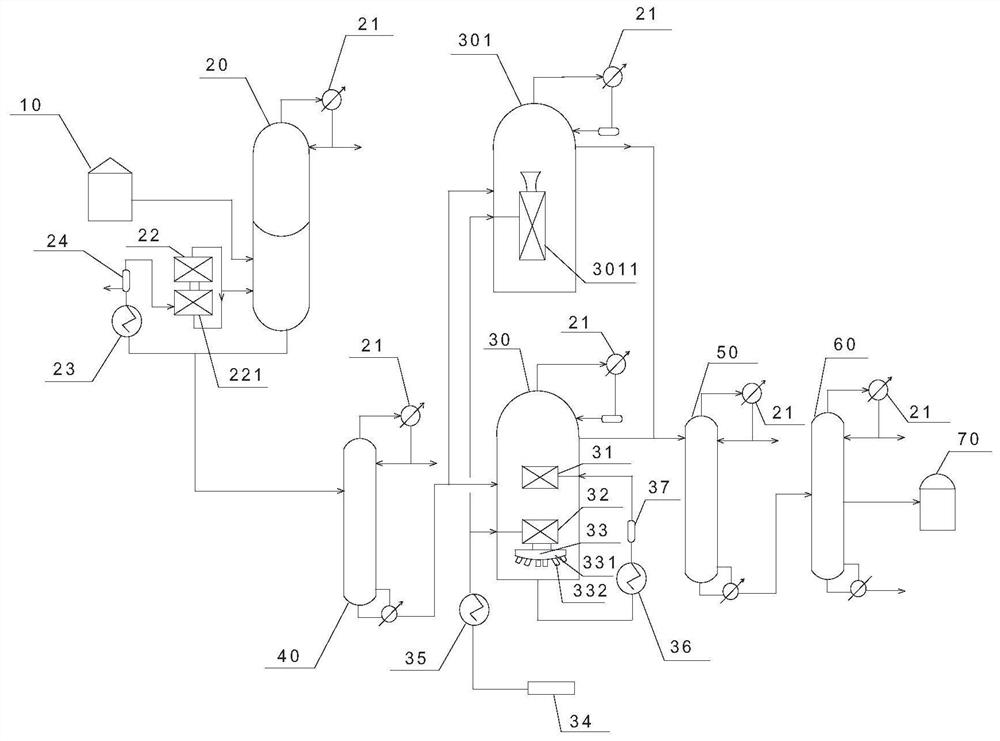

[0061] refer to figure 1 As shown, it is a schematic structural diagram of an enhanced micro-interface reaction system for preparing lactide from lactic acid provided in an embodiment of the present invention, which mainly includes a lactic acid raw material tank 10, an oligomerization rectification reactor 20, a reactive rectifier 40, a first propane Lactide rectification reactor 30 , second lactide rectification reactor 301 , first rectification tower 50 , second rectification tower 60 and lactide storage tank 70 . The lactic acid solution in the lactic acid raw material tank 10 enters the oligomerization rectification reactor 20 for oligomerization. Wherein the mass composition of the lactic acid solution is: 88-92% lactic acid, and the rest is composed of water.

[0062] The upper half of the oligomerization rectification reactor 20 is the rectification section of the oligomerization rectification reactor 20 , and the lower half of the oligomerization rectification reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com