Ultra-efficient low-pressure gas source micro-interface enhanced biological fermentation device and method

A bio-fermentation, ultra-efficient technology, applied in enzymology/microbiology devices, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problem of low utilization rate of fermentation raw materials, large area of fermentation tanks, and waste of land resources. and other problems, to achieve the effect of increasing the mass transfer area of the phase boundary, reducing the floor space and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

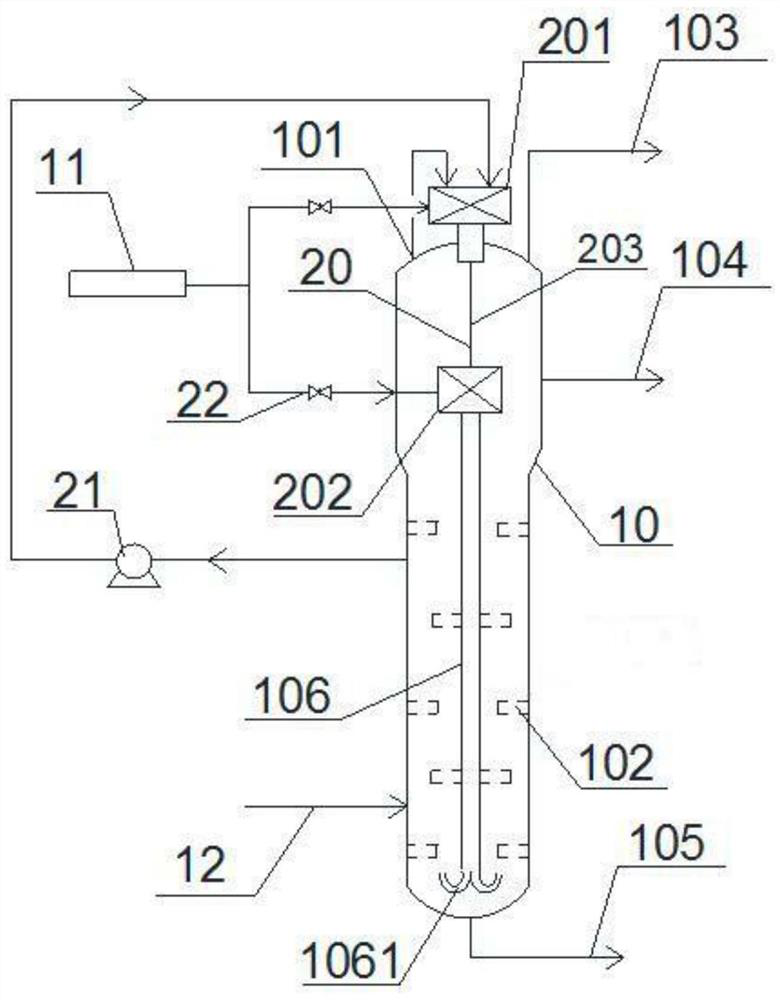

[0051] refer to figure 1 As shown, it is a schematic structural diagram of an ultra-high-efficiency low-pressure air source micro-interface enhanced bio-fermentation device provided by the embodiment of the present invention. It includes a fermenter 10, a compound micro-interface generator 20, the compound micro-interface generator 20 is arranged on the top of the fermenter 10, the compound micro-interface generator 20 includes a hydraulic micro-interface generator 201 and a pneumatic micro-interface generator 202, the liquid The dynamic micro-interface generator 201 is arranged outside the top of the fermenter 10, the pneumatic micro-interface generator 202 is arranged on the inside of the top of the fermenter 10, the pneumatic micro-interface generator 202 and the liquid-dynamic micro-interface generator 201 are connected through a communication pipe 203, And the hydraulic micro-interface generator 201 is directly above the pneumatic micro-interface generator 202 . The reas...

Embodiment 1

[0062] The reaction materials and process of embodiment 1, comparative example 1 and comparative example 2 are all identical, at first the fermentation raw material that chooses is stalk 10kg, dries, cuts and pulverizes, soaks 24h with 100ml0.01mol / L sulfuric acid solution, temperature is At 40°C, add calcium carbonate to adjust the pH to 5.2.

[0063] During the fermentation process, Clostridium was selected for fermentation, and Clostridium was added to the biofilm on the sieve plate for fermentation. At this time, the temperature was adjusted to a fermentation temperature of 38°C, the pH value was adjusted to 6.2, and the live bacteria of Clostridium were The number is 0.4×10 9 CFU / g. At this time, it is suitable for the fermentation of clostridia, and it is fermented for 2 days.

[0064] The ethanol that embodiment 1 and comparative example 1, comparative example 2 generate are compared, obtain following data:

[0065] The amount of ethanol produced kg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com