Reinforced micro-interface preparation system and method of polyglycolic acid

A preparation system, polyglycolic acid technology, applied in the field of enhanced micro-interface preparation system of polyglycolic acid, can solve the problems of high reaction pressure, high hydrogen-ester ratio, low liquid hourly space velocity, etc., and achieve the effect of strengthening the hydrogenation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

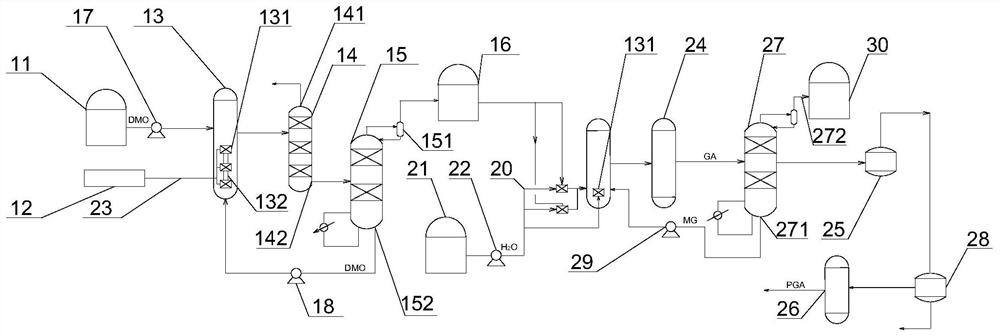

[0071] refer to figure 1 As shown, it is an enhanced micro-interface preparation system for polyglycolic acid according to an embodiment of the present invention, which mainly includes a hydrogenation reactor 13, a hydrogen feed pipeline 23, a hydrolysis reactor 19, and a water vapor feed pipeline 20. Hydrogen catalyst is filled in the hydrogenation reactor 13 in advance, and the side wall of hydrogenation reactor 13 is also provided with oxalate feed pipe, is provided with micro-interface unit in hydrogenation reactor 13, and micro-interface unit consists of A plurality of micro-interface generators 131 are arranged sequentially from top to bottom, preferably three micro-interface generators 131, and a group of liquid reciprocal channels 132 are arranged between adjacent micro-interface generators 131, and the liquid reciprocal channels 132 realizes the circulation of gas and liquid in the micro interface generator 131. In this way, the hydrogen feed pipe 23 passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com