Reinforced micro-interface preparation system and method of cyclic carbonate

A cyclic carbonate and preparation system technology, applied in chemical instruments and methods, organic chemistry, chemical recovery, etc., can solve the problems of low efficiency of the reaction system and inability to fully mix, so as to improve the fusion effect and increase the phase boundary Mass transfer area, enhancing the effect of carboxylation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

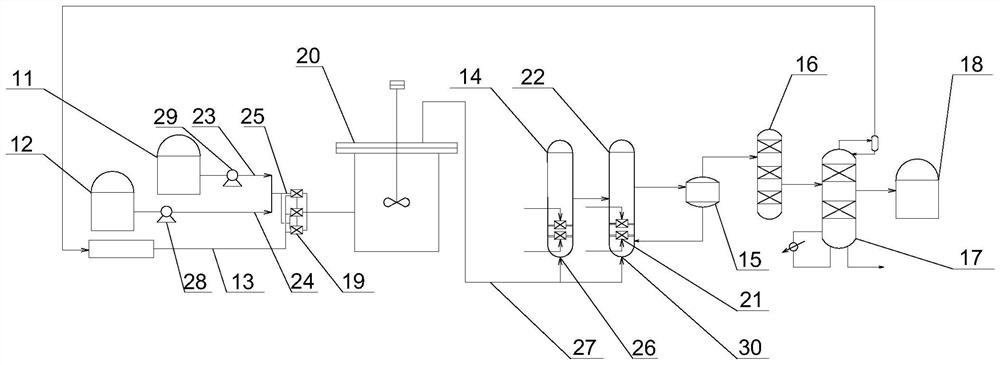

[0062] refer to figure 1 As shown, it is an enhanced micro-interface preparation system for cyclic carbonates according to an embodiment of the present invention, which mainly includes a stirred tank 20, a first carboxylation reactor 14, and a second carboxylation reactor 22, and the side of the stirred tank 20 is provided with Micro-interface unit, the micro-interface unit is composed of several external micro-interface generators 19, the external micro-interface generators 19 are arranged in sequence from top to bottom along the vertical direction, the bottom surface between adjacent external micro-interface generators 19 and Connecting rods for fixing are connected between the top surfaces, and the number of external micro-interface generators 19 is preferably three.

[0063]The main pipeline 25 leading to the micro-interface unit is connected with the oxidant delivery pipeline 24 and the two branch pipelines of the olefin delivery pipeline 23, and is connected with the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com