Heavy-load grinding wheel and preparation method thereof

A heavy-duty grinding wheel and sintered corundum technology, which is applied in the field of abrasive tools, can solve the problems of small grinding ratio, poor toughness, and weak impact resistance, so as to increase the cutting ratio, improve the bonding force and toughness, and improve the impact resistance. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with embodiment.

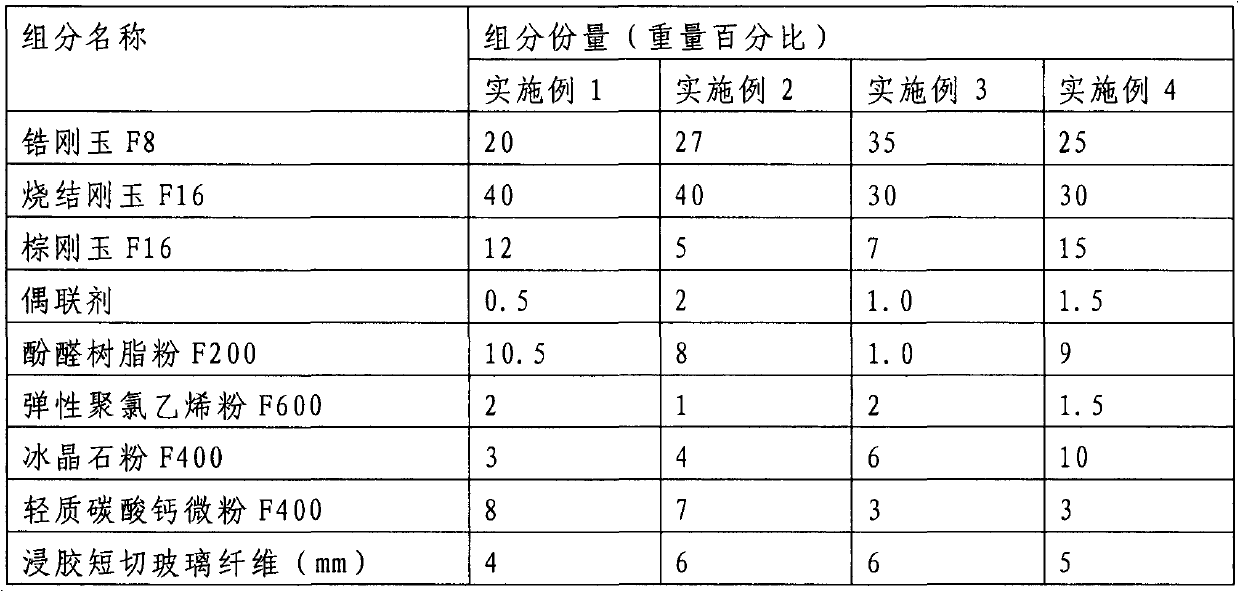

[0035] The components of the heavy-duty grinding wheel are measured by percentage as follows: 30% to 40% of sintered corundum, 20% to 35% of zirconium corundum, 5% to 15% of brown corundum, 0.5% to 2% of coupling agent, and 8% to phenolic resin powder 10%, elastic polyvinyl chloride powder 1%-2%, cryolite powder 3%-10%, light calcium carbonate powder 3%-8%, impregnated chopped glass fiber 4%-6%. In the present invention, the particle size numbers of the granular materials of each component are different, sintered corundum F14~F16, zirconium corundum F8~F10, brown corundum F16~F20, phenolic resin powder F200~F220, elastic polyvinyl chloride powder F550~F600, cryolite powder F380-F400, light calcium carbonate micropowder F380-F400, the length of the dipped chopped glass fiber is 4mm-6mm. The coupling agent is any one of isopropyl titanate, tetrabutyl titanate or isopropyl trihydroxyac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com