A hydraulic rock drill anti-skid buffer system

A technology of buffer system and rock drilling machine, which is applied in the direction of reciprocating drilling rig, percussion drilling, fluid pressure actuation device, etc. It can solve the problems of insufficient impact distance, limited buffering and vibration reduction effect of air defense system, and low work efficiency. Achieve enhanced wear and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

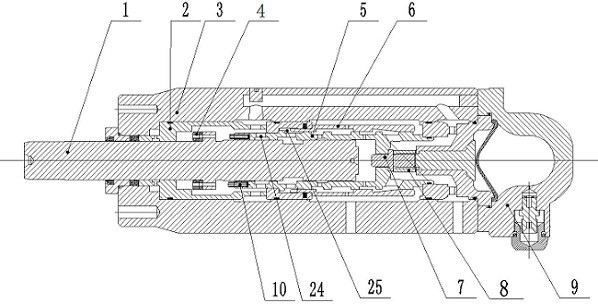

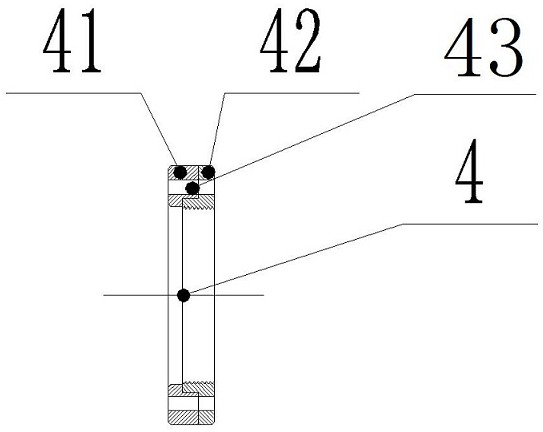

[0042] Example: see Figure 1-4 , a hydraulic rock drill anti-runaway buffer system, including a cylinder body 3, a reciprocating piston 1 is arranged in the cylinder body 3, and a stroke buffer device for preventing the occurrence of lost strike when the piston 1 strokes is arranged on the piston 1, so The rear of the cylinder body 3 is provided with a return stroke buffer device to prevent the piston from being lost during its return stroke.

[0043] The inner cylinder 5 is coaxially assembled on the piston 1 inside the cylinder body 3 , and a slide valve 6 for regulating the flow direction of high-pressure water is provided on the outer sliding side of the inner cylinder 5 .

[0044] A front sleeve 2 is arranged in the front portion of the inner cylinder 5 in the cylinder body 3 , and the front section of the inner cylinder 5 cooperates with the shoulder of the front sleeve 2 to fix the position of the inner cylinder 5 .

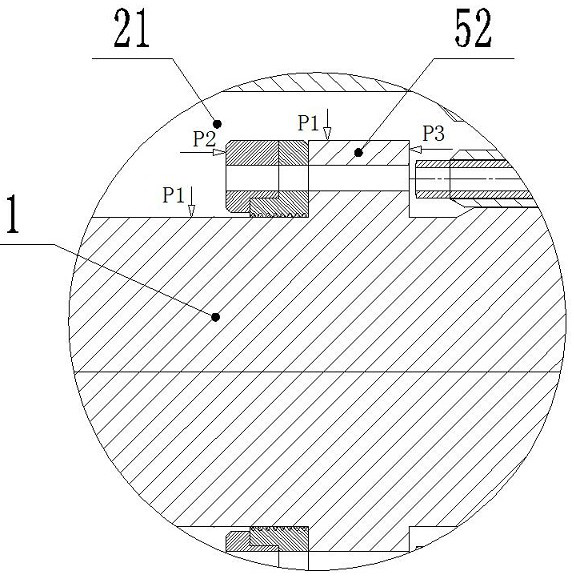

[0045] A piston front cavity 21 and a piston rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com