Micro-interface oxidation system for preparing hydrogen peroxide and oxidation method thereof

An oxidation system, hydrogen peroxide technology, applied in the directions of peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of low product yield and inability to obtain Insufficient mixing, low oxygen utilization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

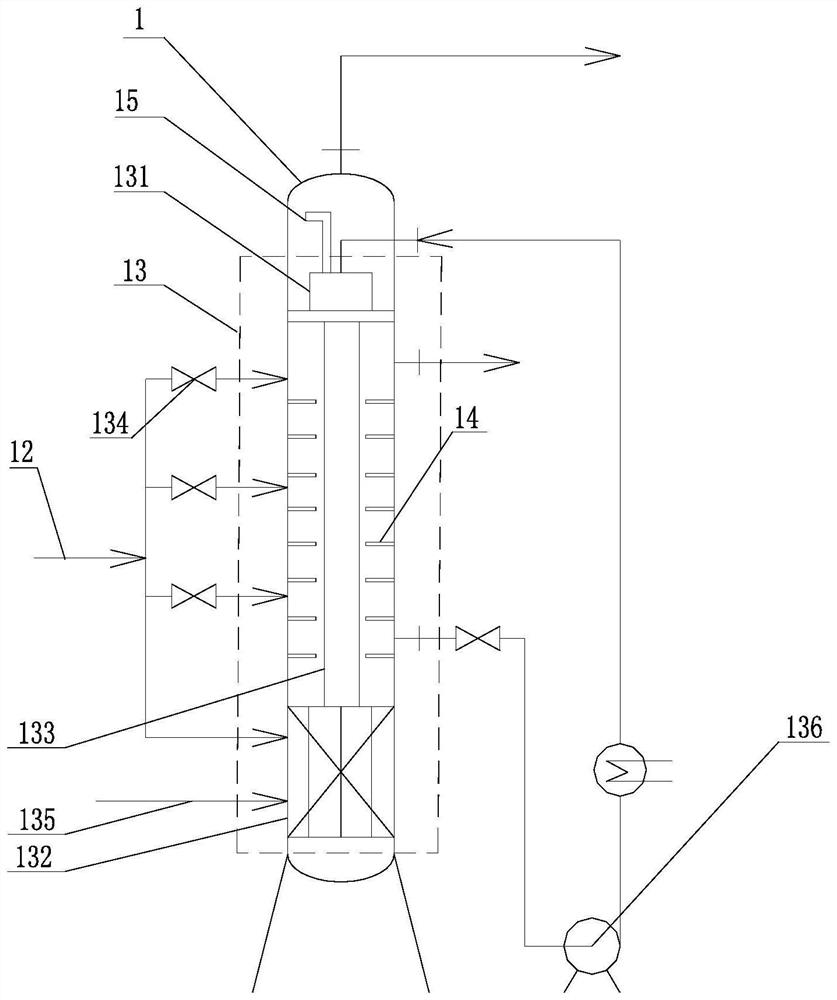

[0047] refer to figure 1 As shown, it is a micro-interface oxidation system for preparing hydrogen peroxide according to an embodiment of the present invention, which mainly includes an oxidation reaction tower 1 and a mixed micro-interface unit 13 arranged inside the oxidation reaction tower 1. In the oxidation reaction tower 1, mainly hydrogenated anthracene The oxidation reaction between quinone and air produces hydrogen peroxide. In order to improve the oxidation effect, grids 14 are arranged on both sides of the gas-liquid emulsion channel to improve the reaction effect, and the grids 14 are arranged symmetrically on the left and right.

[0048] The hybrid micro-interface unit 13 of this embodiment includes an upper-mounted micro-interface generator 131 and a lower-mounted micro-interface generator 132 that are connected up and down. A gas-liquid emulsion channel 133 is arranged between them, and the gas-liquid emulsion channel 133 is connected with a gas-liquid emulsion ...

Embodiment 2

[0060] Other operating steps are consistent with Example 1, except that the oxidation heating constant temperature is 45° C., and the reaction pressure of oxidation reaction tower 1 is 0.25 MPa. Analysis results: the conversion rate of hydrogenated anthraquinone is 96%, and the utilization rate of oxygen is 96%.

Embodiment 3

[0062] Other operating steps are consistent with Example 1, except that the oxidation heating constant temperature is 55° C., and the reaction pressure of oxidation reaction tower 1 is 0.35 MPa. Analysis results: the conversion rate of hydrogenated anthraquinone is 96%, and the utilization rate of oxygen is 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com