Micro-interface reaction system and method for preparing ethylene glycol by oxalate method

A reaction system and interface reaction technology, applied in the preparation of nitrite, the preparation of carbon monoxide or formate, and the chemical method of reacting liquid and gas medium, etc. high temperature problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

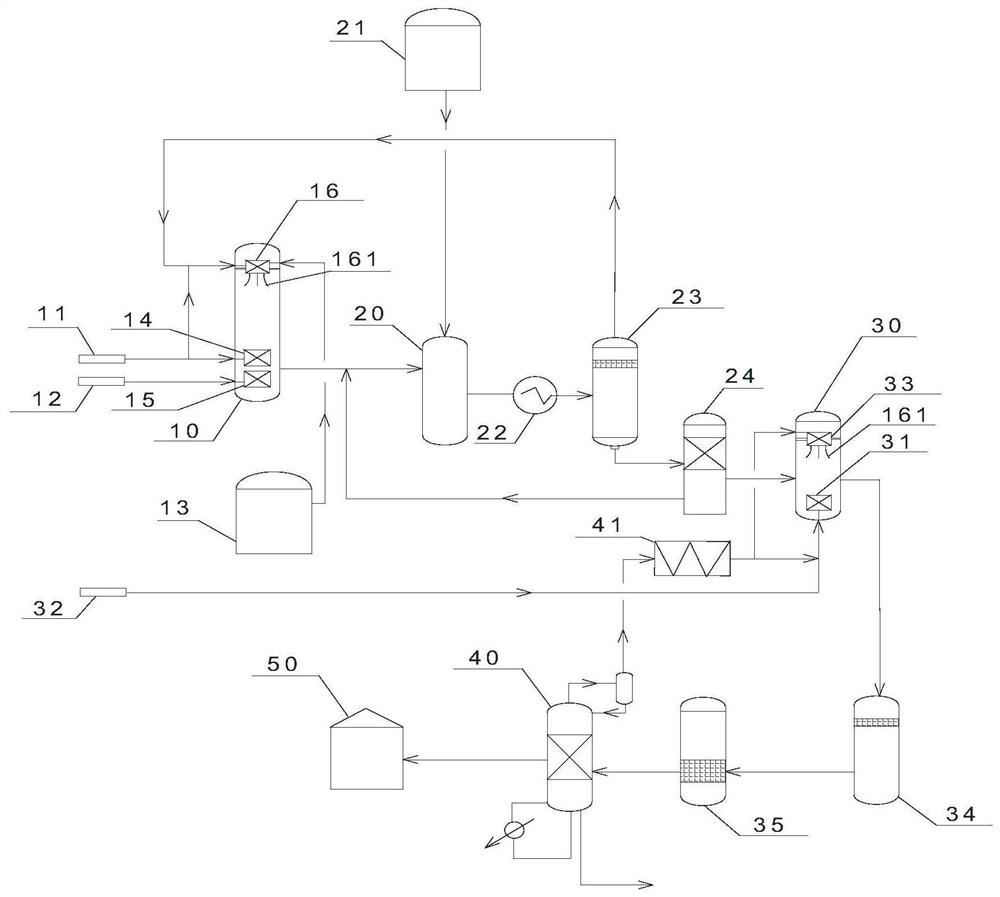

[0055] refer to figure 1 As shown, the microinterface reaction system for the preparation of ethylene glycol by the oxalate ester method provided by the embodiment of the present invention mainly includes a first reaction tank 10, an oxygen inlet pipeline 11, a nitric oxide inlet pipeline 12, and a methanol storage tank 13. An upper micro-interface generator 14, a lower micro-interface generator 15, a first split type micro-interface generator 16, a hydrogenation reaction tank 30, a hydrogenation micro-interface generator 31, a hydrogen inlet pipe 32, a second Split-type micro-interface generator, rectification column 40 and ethylene glycol storage tank 50.

[0056] The side wall of the first reaction tank 10 is provided with an oxygen inlet, a nitric oxide inlet and a methanol inlet, the oxygen inlet pipeline 11 is connected to the upper micro-interface generator 14 through the oxygen inlet, and the oxygen passes through the upper micro-interface The generator 14 is broken a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com