Patents

Literature

259results about How to "Solve low production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

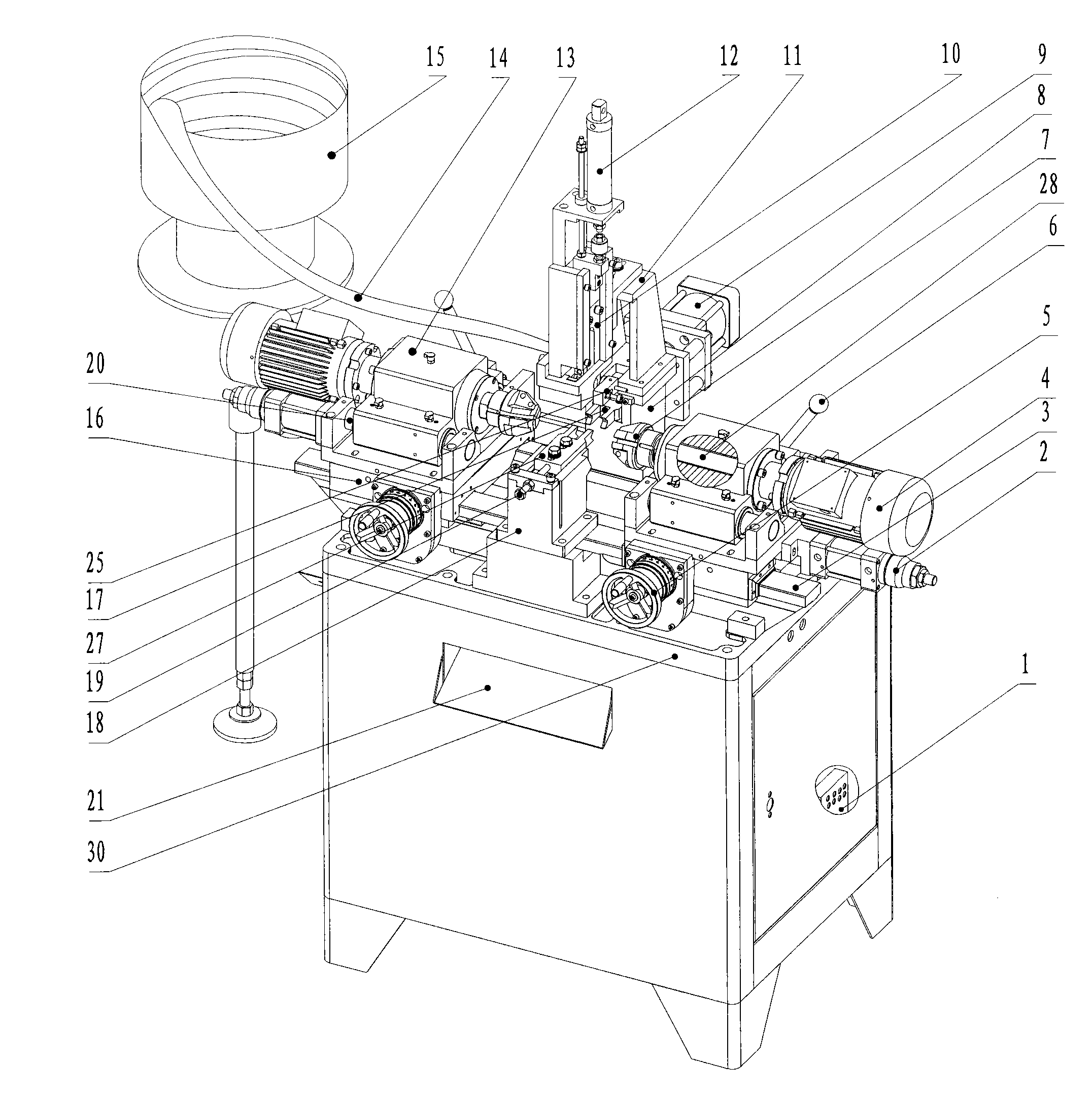

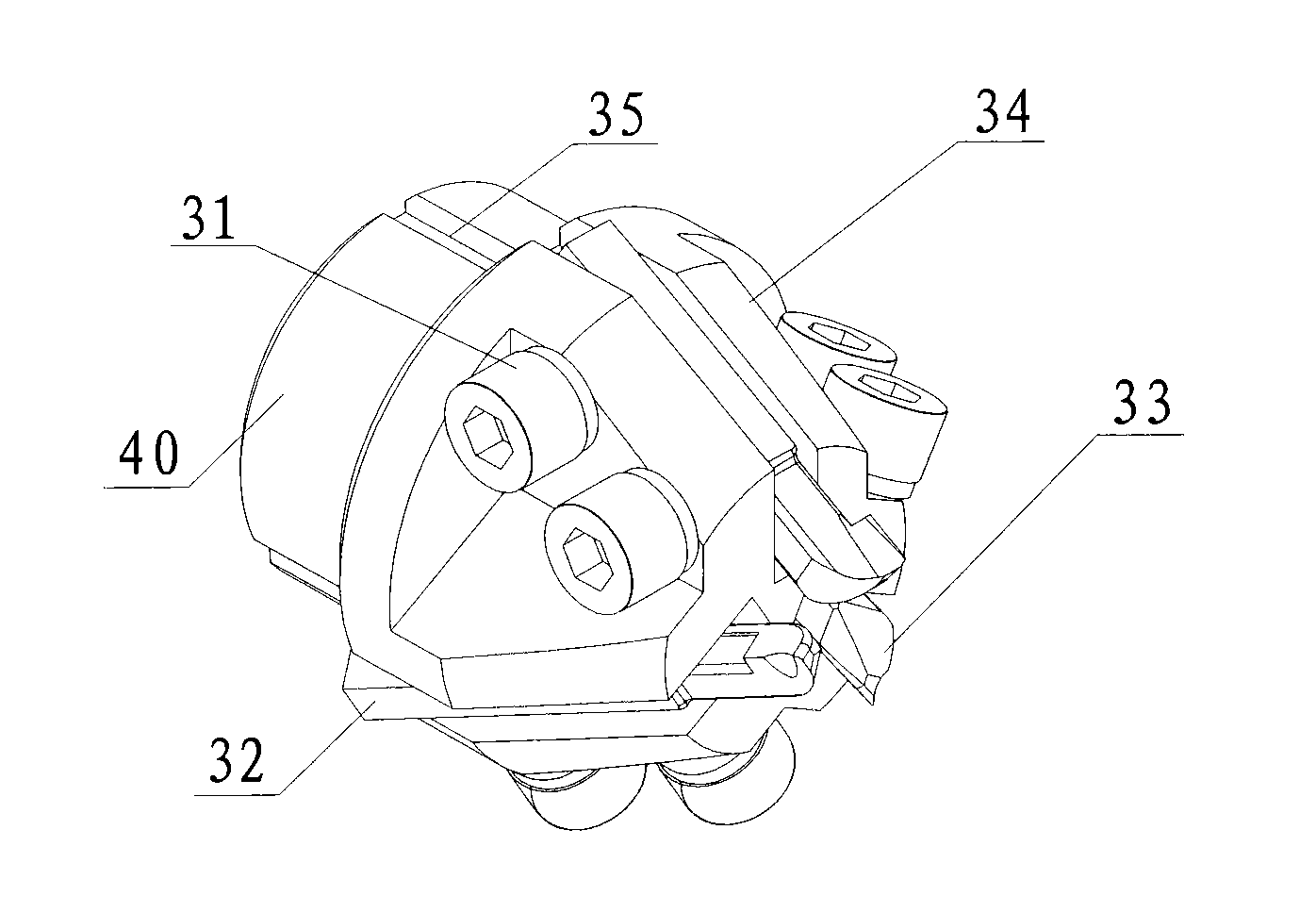

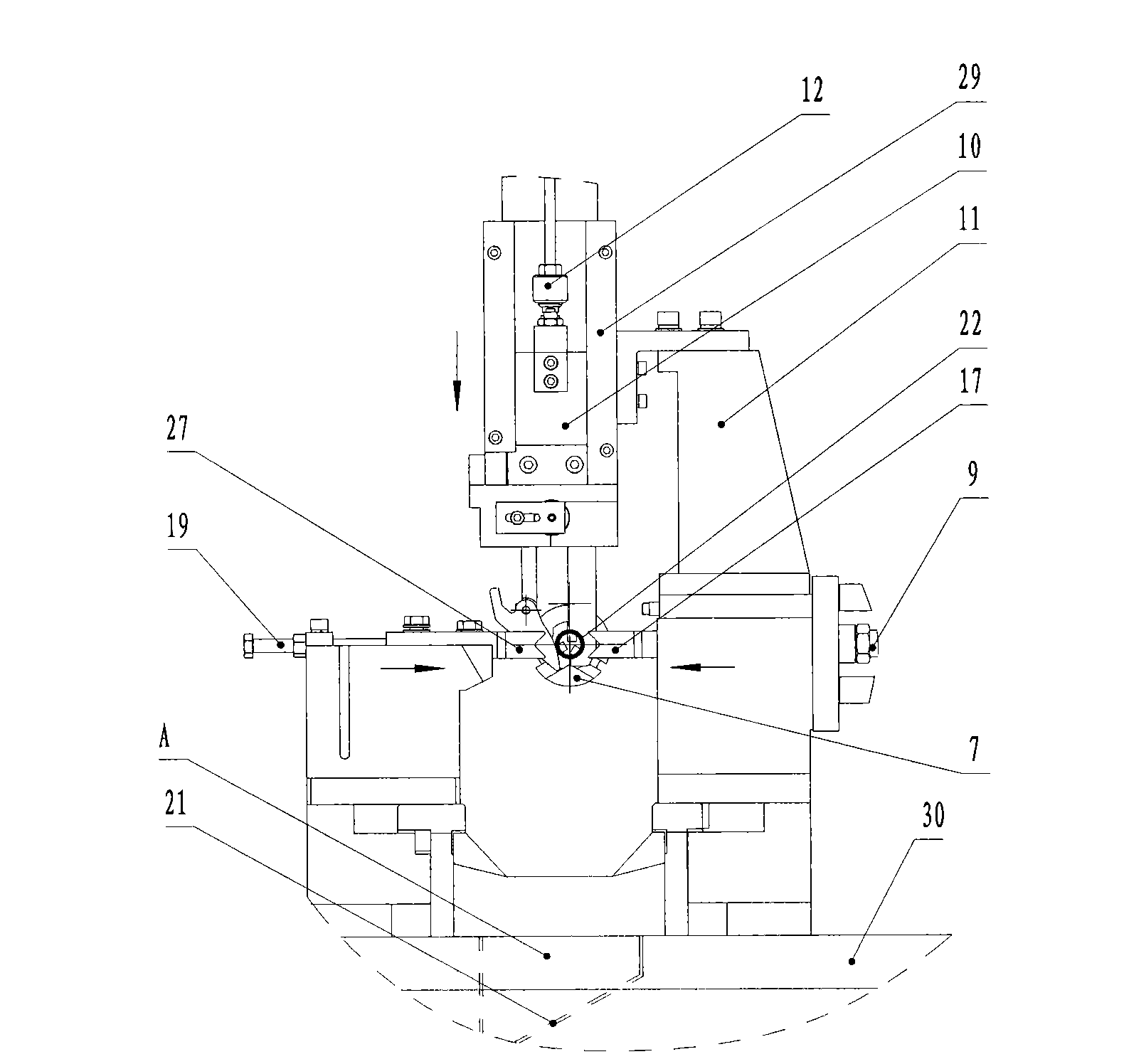

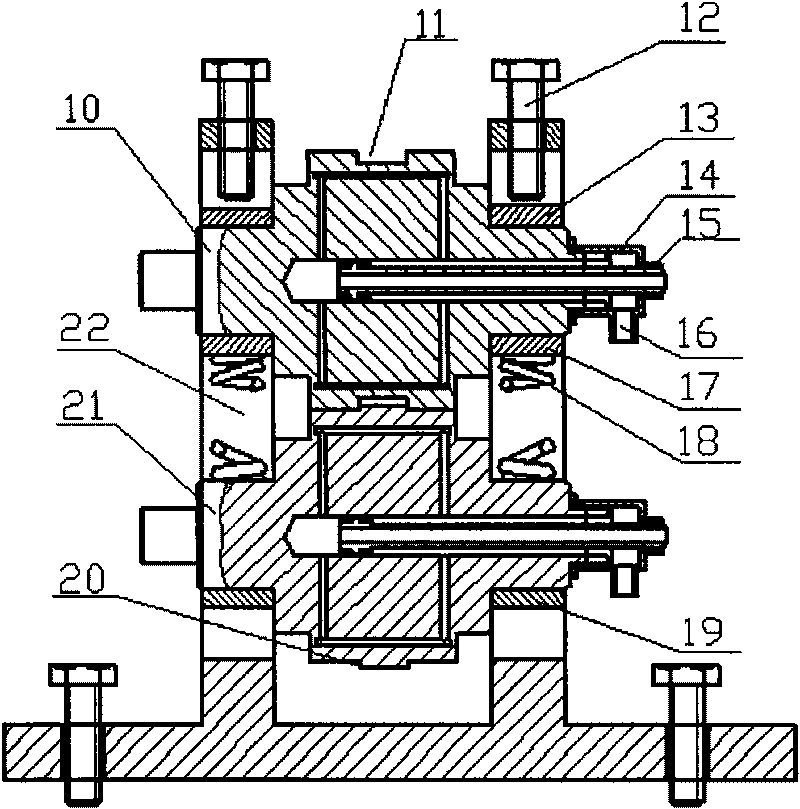

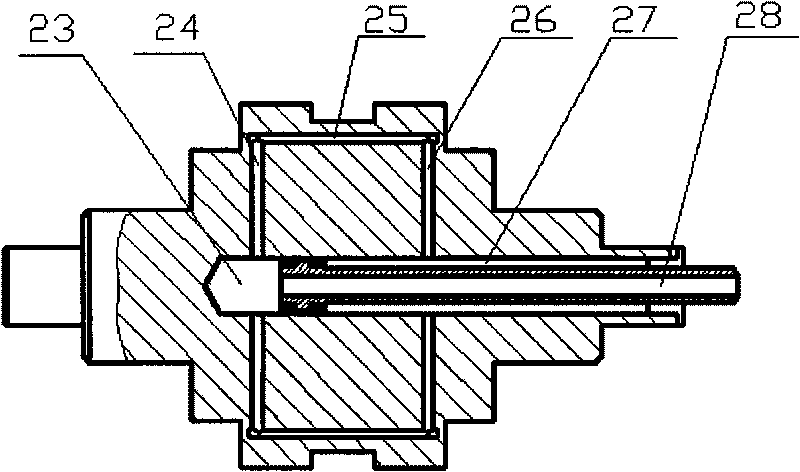

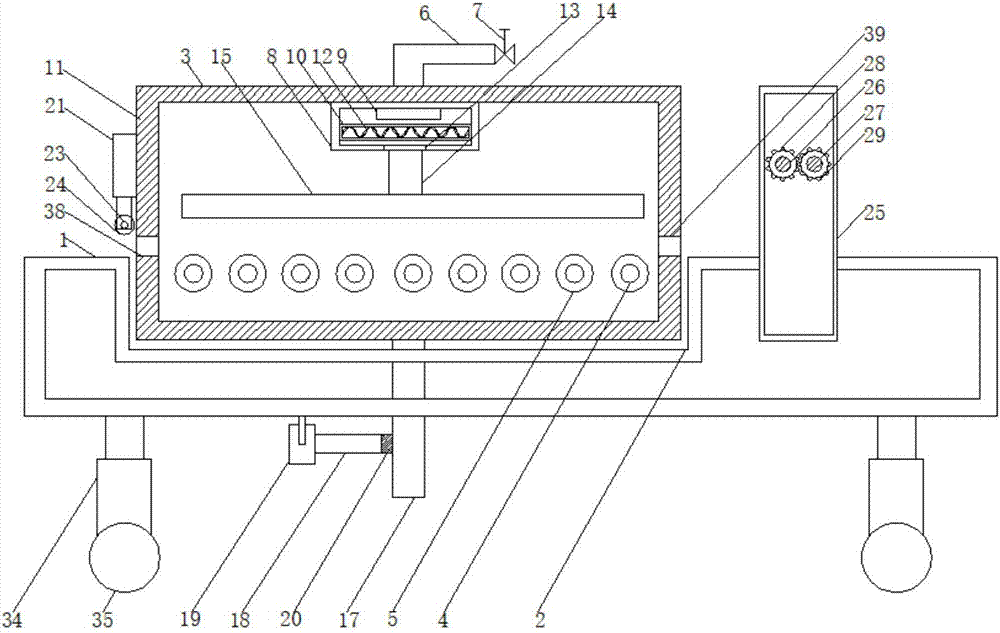

Full-automatic chamfering machine

InactiveCN102601614ASolve low production efficiencyOther manufacturing equipments/toolsMetal working apparatusProgrammable logic controllerMachining

The invention relates to a full-automatic chamfering machine, which comprises a rack that is internally provided with a programmable logic controller, wherein a large rack bottom plate is arranged on the top surface of the rack, a blanking hole is arranged in the center of the large rack bottom plate, a feeding clamp is arranged at the rear side of the middle part of the large rack bottom plate and is driven by a feeding air cylinder arranged above the feeding clamp, the feeding air cylinder is fixed on the large rack bottom plate by a trapezoid feeding base plate, a fixed clamp and a movable clamp are arranged oppositely front and back and are respectively positioned at the front side and the rear side of the blanking hole of the large rack bottom plate, a cylindrical workpiece and the large rack bottom plate are clamped by the fixed clamp and the movable clamp in parallel, the left side and the right side of the large rack bottom plate are respectively provided with a guide rail that is in parallel to the cylindrical workpiece, and a pair of workpiece machining mechanisms are respectively connected with one guide rail in a sliding way. The full-automatic chamfering machine integrates automatic feeding, material clamping, chamfering and blanking, end surface chamfering and end surface cutting are carried out on the cylindrical workpiece, and therefore, the full-automatic chamfering machine can realize the simultaneous machining of a plurality of machining stations.

Owner:ZHEJIANG SHUNXIN MACHINERY

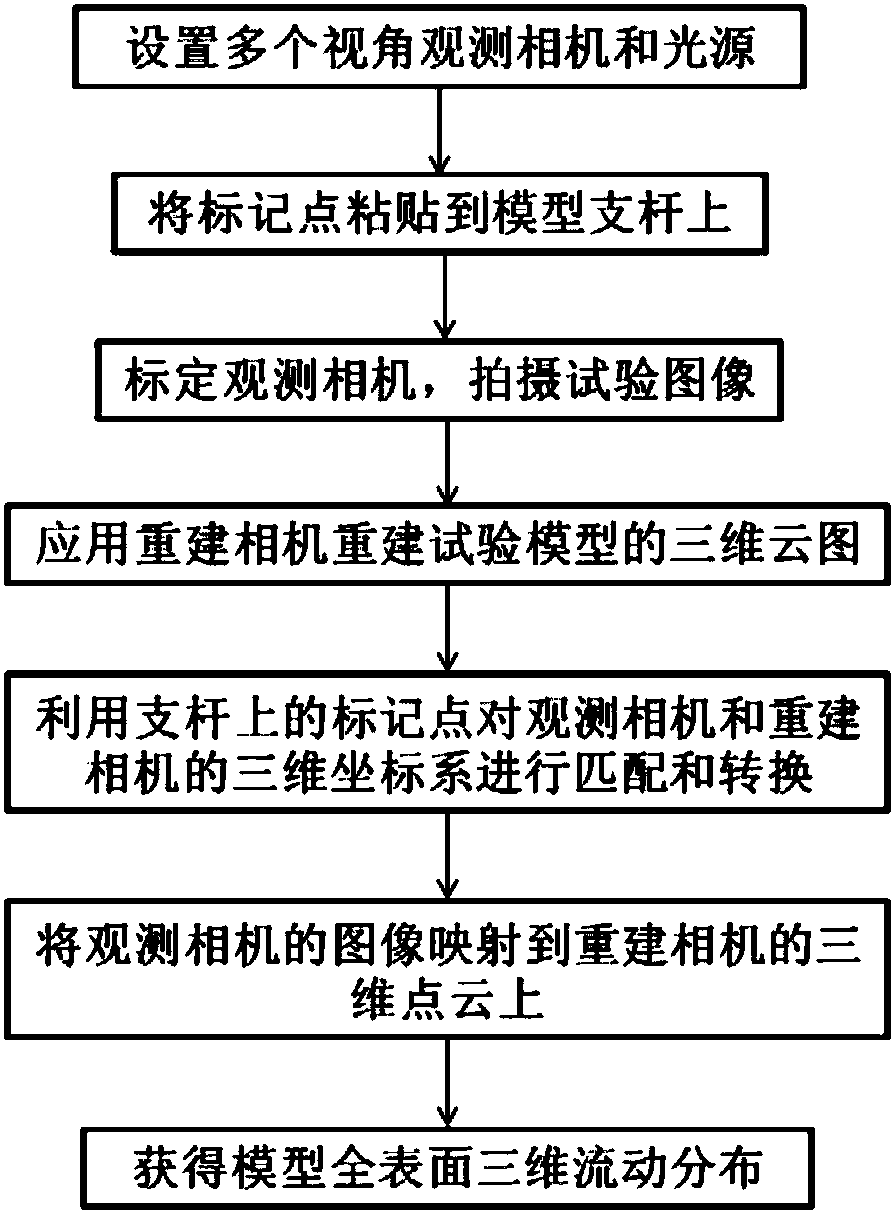

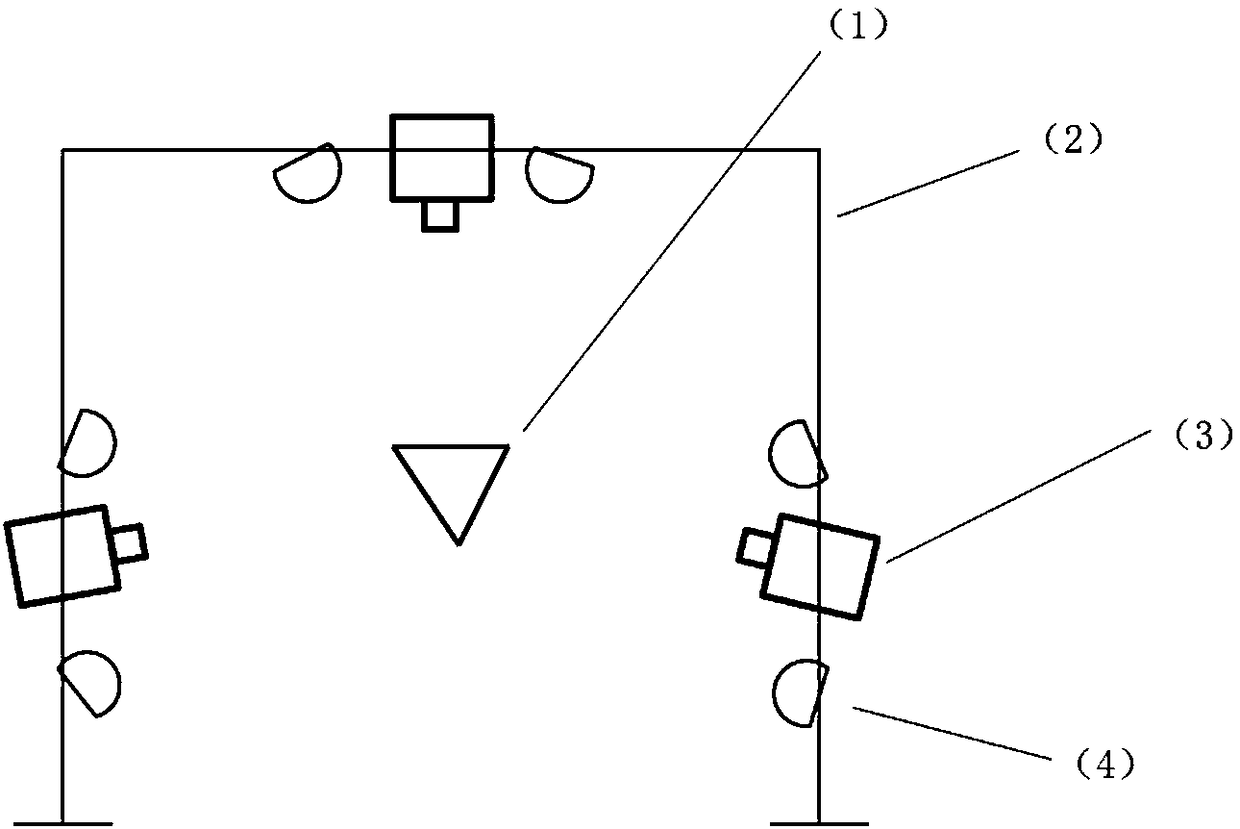

Aircraft three-dimensional surface flow distribution wind tunnel measurement method

ActiveCN108398229AAccurate distributionSolve the mapping problemAerodynamic testingPoint cloudSystem transformation

The invention relates to an aircraft three-dimensional surface flow distribution wind tunnel measurement method. A structured light-based binocular vision three-dimensional point cloud reconstructionsystem and a multi-view image acquisition system are used for wind tunnel three-dimensional flow distribution measurement. Firstly, the binocular vision system is used to reconstruct the surface of awind tunnel test model. According to the aircraft three-dimensional surface flow distribution wind tunnel measurement method, the binocular vision system is utilized to perform the three-dimensional reconstruction of the surface of the wind tunnel test model; a small number of marking points are distributed on the model or at the periphery of the model; and point cloud splicing processing is carried out, so that the point cloud information of the surface of the wind tunnel test model is obtained. In a wind tunnel test, a plurality of cameras are adopted to perform multi-angle shooting on the model, so that the surface flow information of the model under different visual angles can be obtained; and image-to-three-dimensional point cloud coordinate system transformation is carried out through the information of the marking points arranged on the model or at the periphery of the model, so that a two-dimensional flow image can be mapped onto three-dimensional point cloud, and therefore, the three-dimensional full-surface flow distribution of an aircraft can be obtained.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

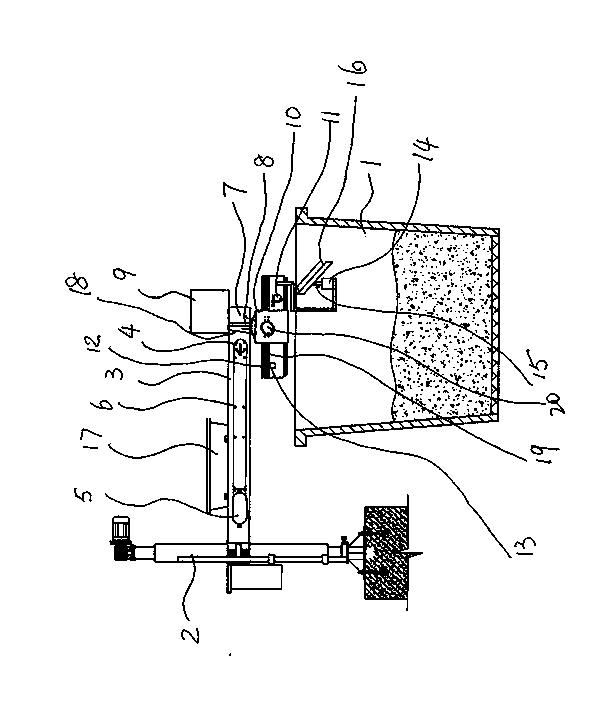

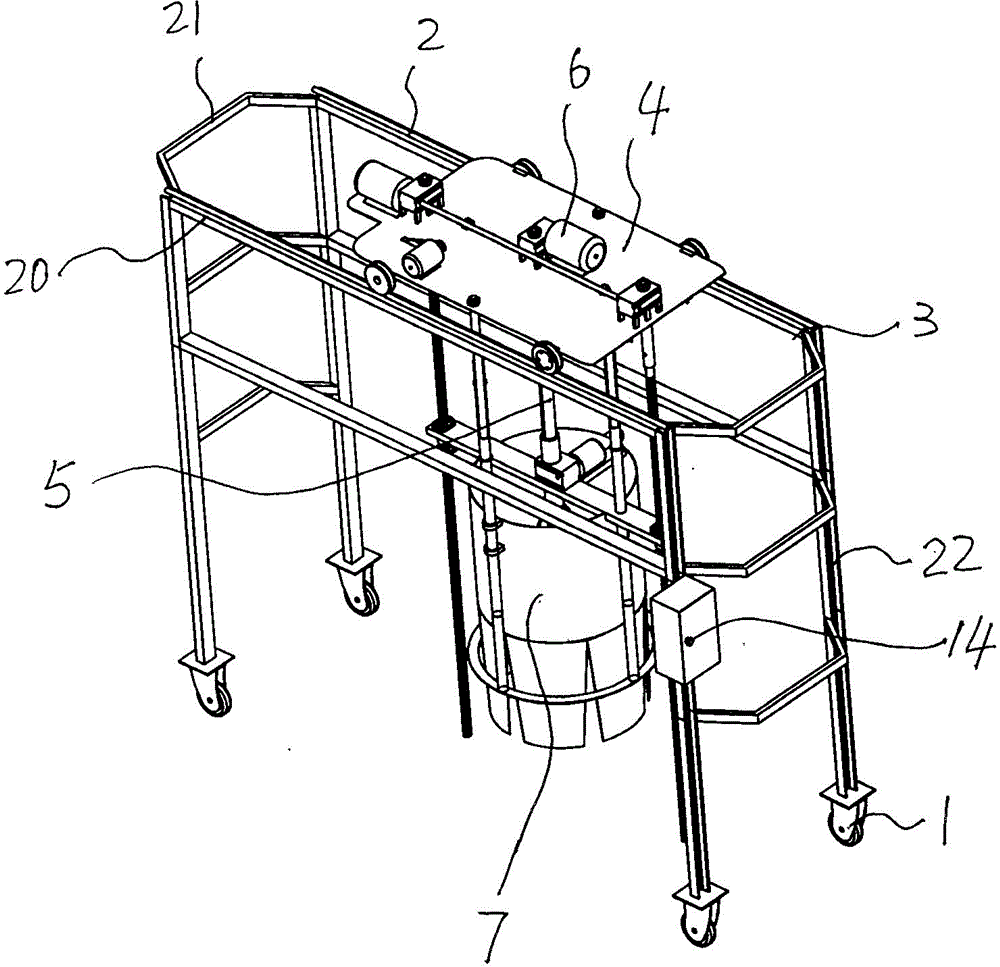

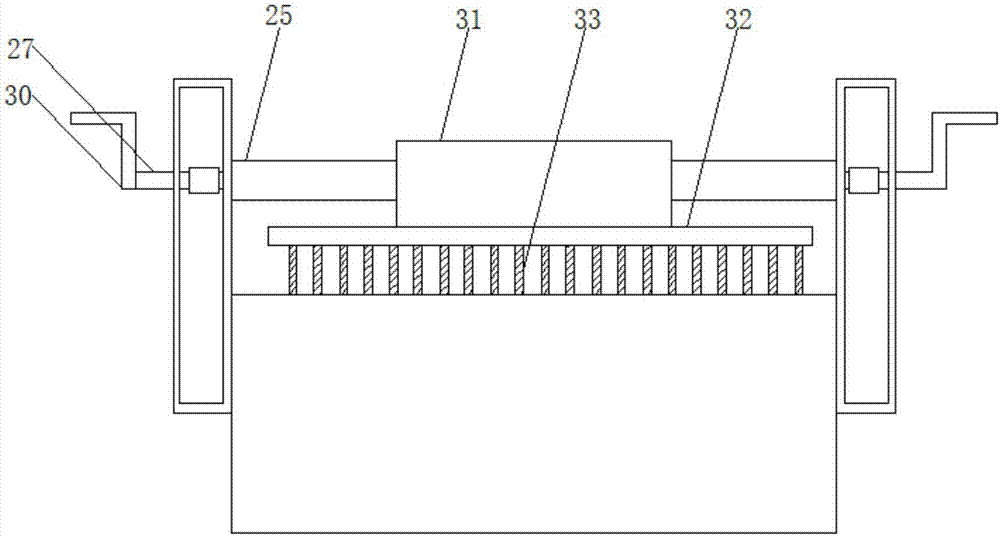

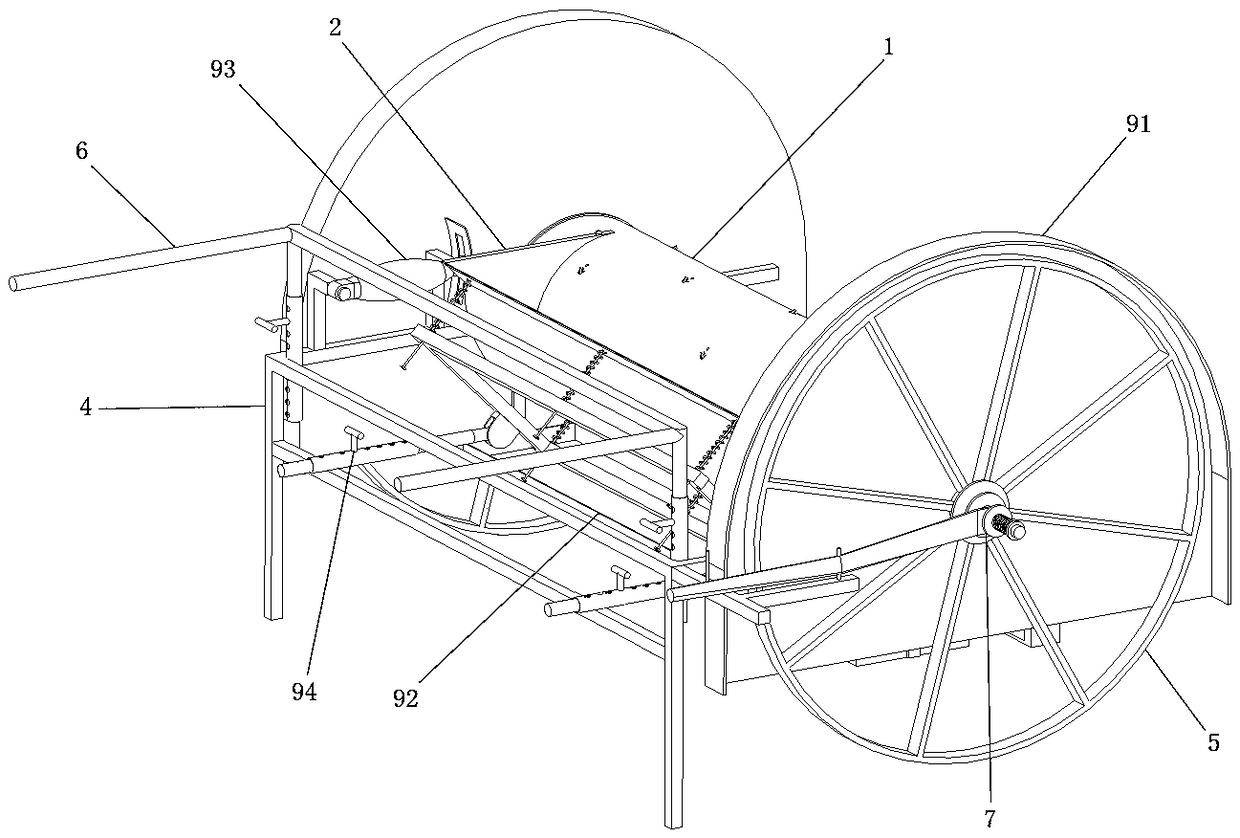

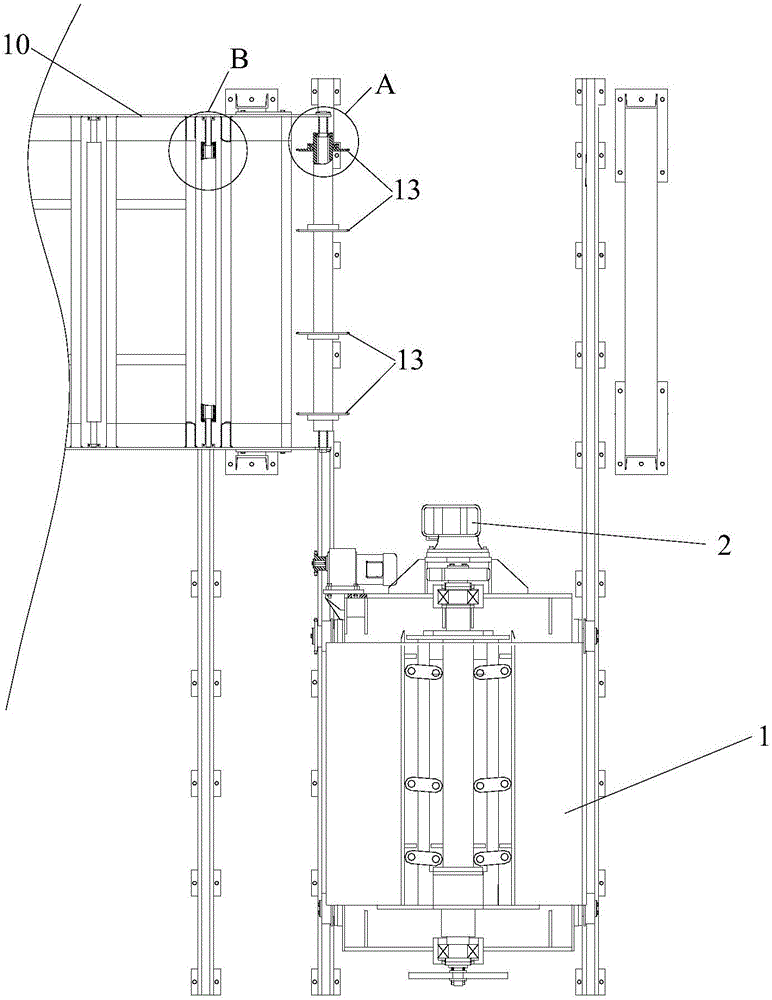

Retort filling distributing device for making white spirit

InactiveCN103625950AEasy to realize patchingFulfill the requirements of "quasi"Loading/unloadingDistillationUltimate tensile strength

The invention belongs to the technical field of wine making machinery, and discloses a retort filling distributing device for making white spirit. According to the technical scheme, the retort filling distributing device mainly comprises a lifting rack, an upper swing arm, a fixed rack and a material inlet, wherein the lifting rack is relatively fixed on a retort barrel; the upper swing arm is arranged on the rack, can rotate around the rack, and is provided with a material conveying mechanism composed of a roller wheel mechanism and a conveying belt; the end part of the upper swing arm can be stably arranged on the center of the retort barrel and is provided with a power mechanism; the fixed rack, which is driven to rotate around an axis by the power mechanism, is arranged on the lower side of the upper swing arm, and is provided with a second material conveying mechanism composed of a second roller wheel mechanism and a second conveying belt, and the lower side of the end part of the second material conveying mechanism is provided with a retort filling dustpan; the material inlet is arranged in the material conveying mechanism. According to the invention, the labor intensity can be relieved greatly, the labor force can be saved, and the favorable retort filling and distillation effects are ensured.

Owner:YUFENG IND HEBEI

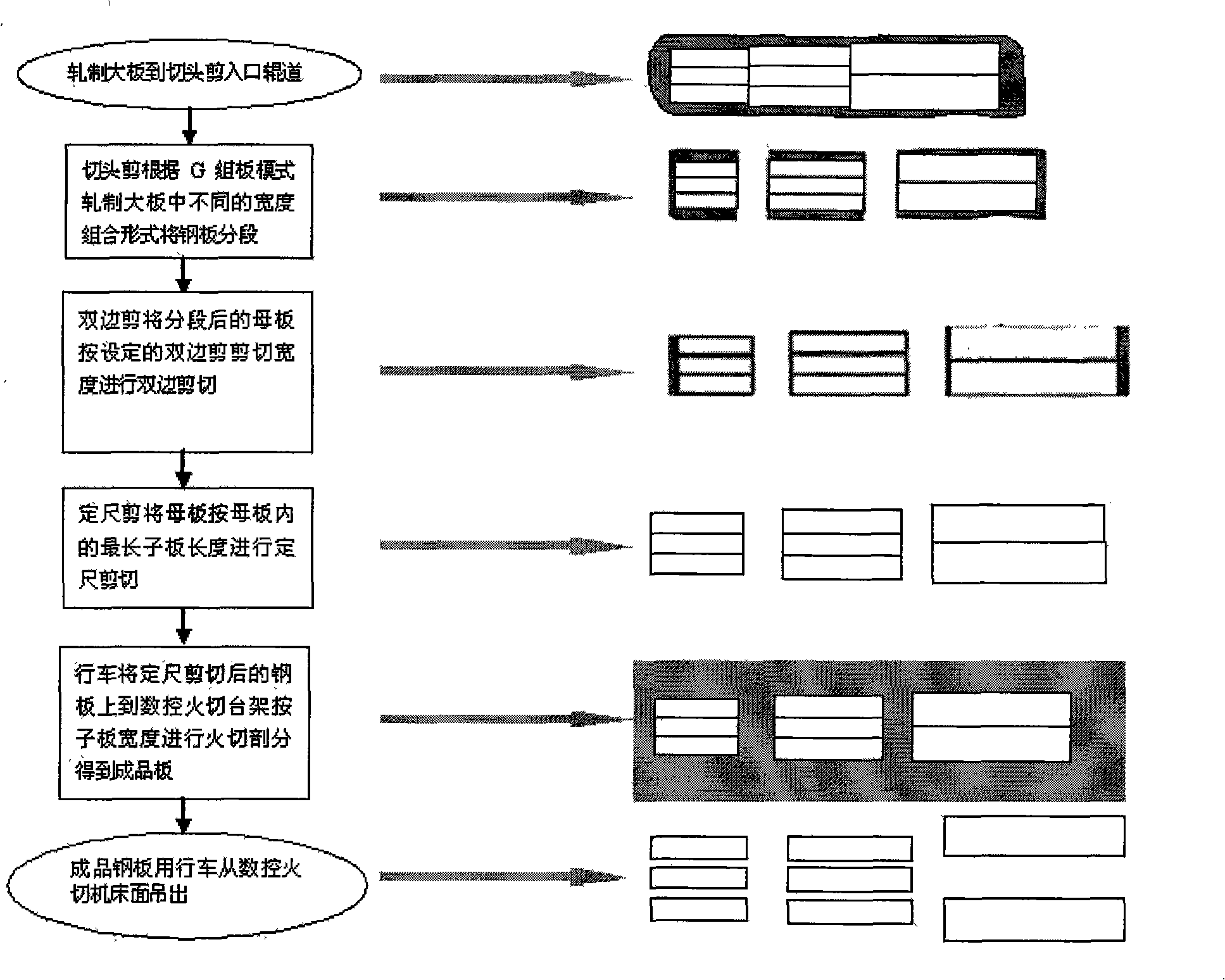

Method for producing G group plate mode steel plate by the combination of digital control torch cutter and shears

InactiveCN101327558ASolve low production efficiencyCutting cycle time reductionShearing machinesOther manufacturing equipments/toolsSheet steelEngineering

The present invention discloses a production method which utilizes a numerically controlled flame cutter and a shearer to produce G-group plate mode steel plates. The method adopts the numerically controlled flame cutter and the shearer assembly (a pair of crop shears, a pair of double-side shears, a pair of slitting shears and a pair of cut-to-length shears) to produce G-group plate mode steel plates. The process includes steel plate segmentation, width cut-to-length shearing, length cut-to-length shearing and slitting. On the premise of ensuring the dimensional precision of the length and the width of a steel plate, the method effectively resolves the problem of low working efficiency in the production of G-group plate mode steel plates, the cutting period of a single G-group plate mode steel plate can be reduced by about one hour, and the total cutting time can be decreased by 40 percent. The method is adapted to the production of thick steel plates.

Owner:BAOSHAN IRON & STEEL CO LTD

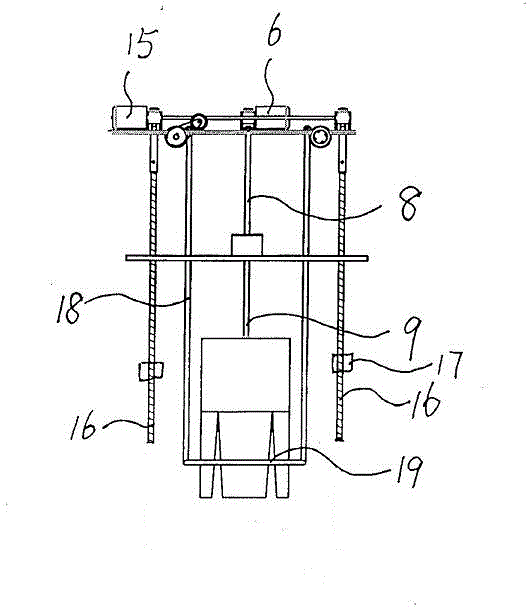

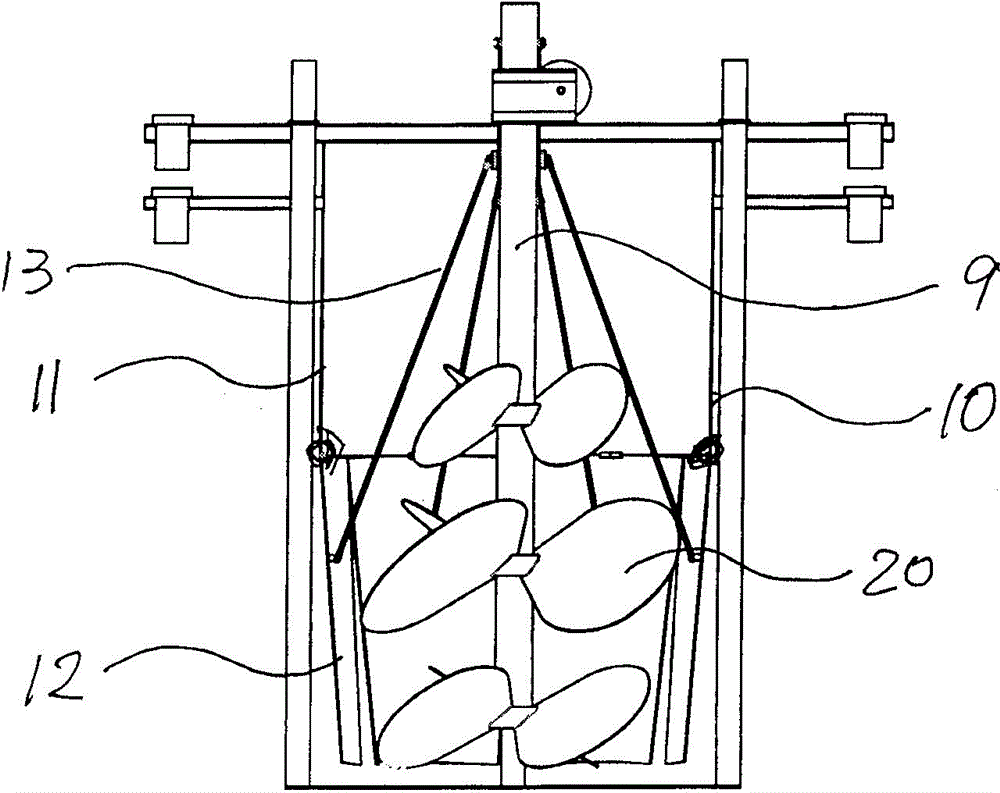

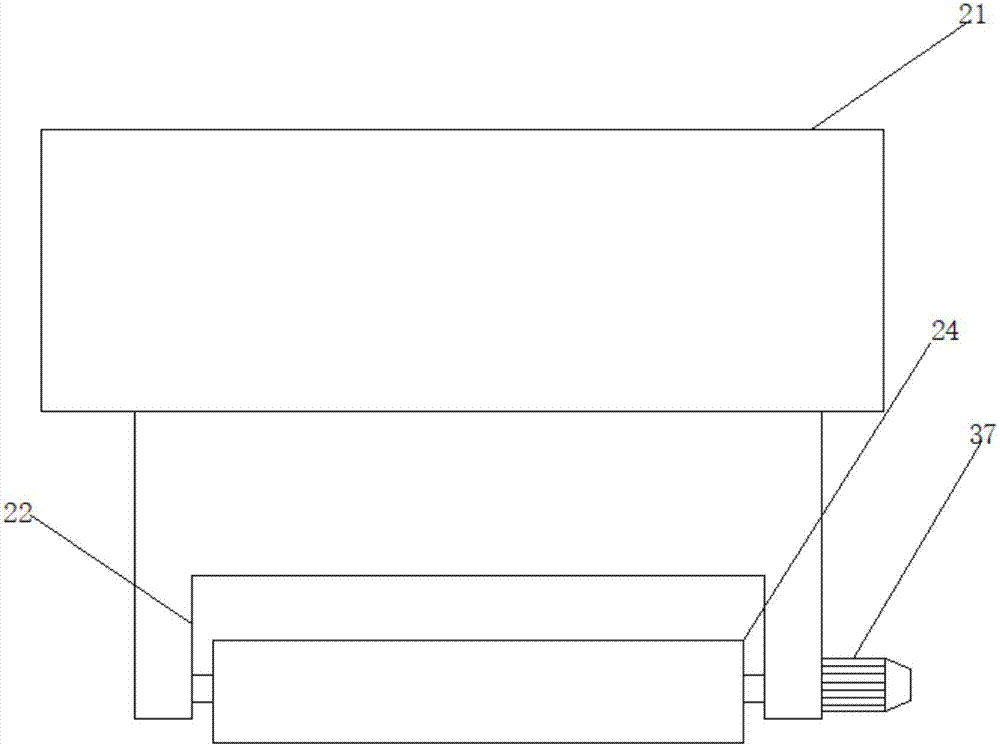

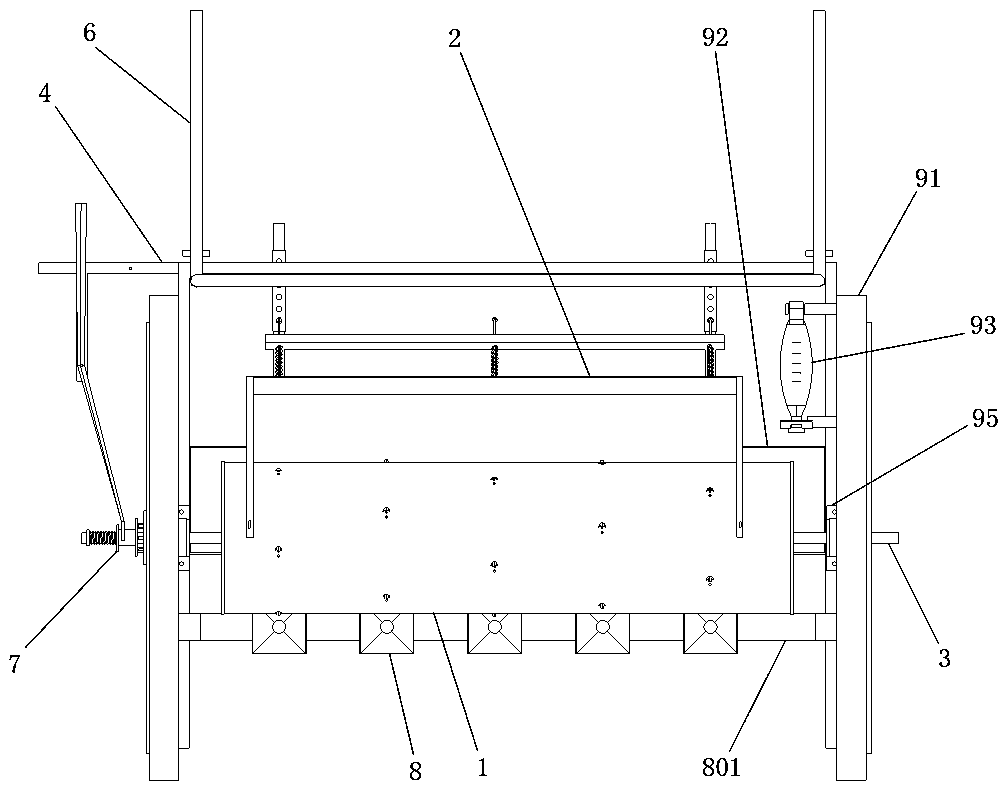

Fermented grains discharging device for liquor making

ActiveCN102978071AReduce labor intensitySolve low production efficiencyAlcoholic beverage preparationPulp and paper industryPulley

The invention belongs to the technical field of liquor making machinery, and discloses a fermented grains discharging device for liquor making. The main technical scheme comprises a machine frame, a pulley mechanism, a fermented grains discharging and collecting mechanism and a control mechanism, wherein the bottom of the machine frame is provided with a moving roller mechanism; the top of the machine frame is provided with a guide rail mechanism; the pulley mechanism is arranged on the top of the machine frame; the fermented grains discharging and collecting mechanism and the control mechanism are fixed at the lower side of the pulley mechanism; the pulley mechanism is provided with a power transmission mechanism which can control the pulley mechanism to move along the guide rail mechanism and control the fermented grains discharging and collecting mechanism to move vertically; the fermented grains discharging and collecting mechanism is composed of a vertical shaft and a fermented grains digging mechanism; the vertical shaft is connected with the power transmission mechanism and can make a rotary and telescopic movement; and the fermented grains digging mechanism is fixed at the lower end of the vertical shaft. According to the invention, a fermented grains cylinder can be moved, and fermented grains in the fermented grains cylinder can be dug out, so that the automation of fermented grains discharging is realized, thereby greatly relieving the labor intensity of fermented grains discharging workers in a liquor making workshop and solving the problem of low production efficiency.

Owner:张晓光

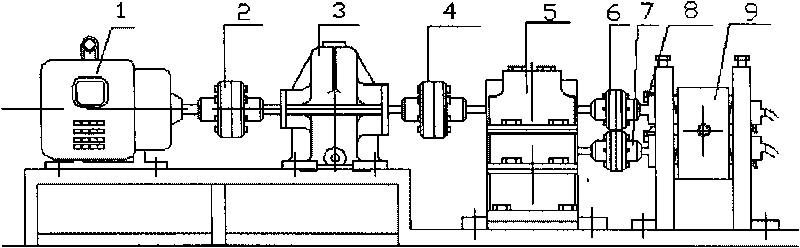

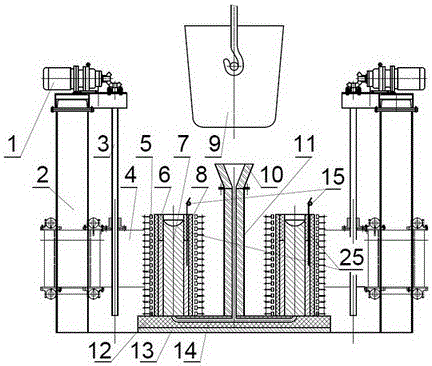

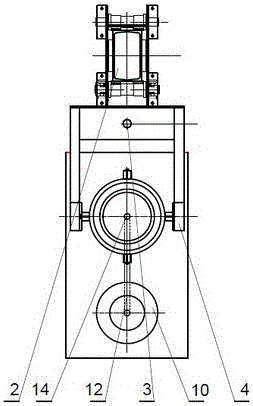

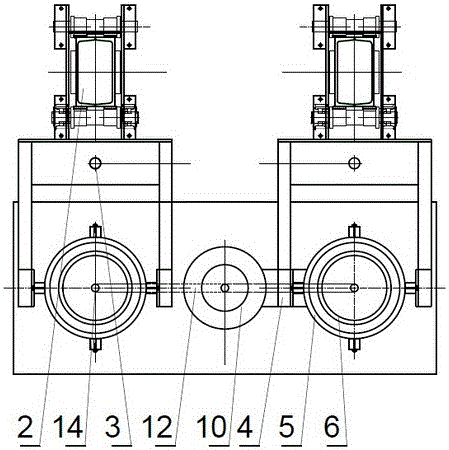

Multi-purpose double-roll continuous rheological forming device for liquid metal

InactiveCN101690941AIncrease productivitySolve low production efficiencyMetal rolling arrangementsLiquid stateCoupling

The invention discloses a multi-purpose double-roller continuous rheological forming device for liquid metal, which is mainly used for double-roller continuous rheological forming of plates, strips, pipes, profiles, wires, composite materials and wrapping materials. The device consists of a motor, a half coupling, a decelerator, a gear box, a main machine, a cooling water tank and a coiling machine, wherein the main machine consists of a stander, an upper working roller, a lower working roller, a feeding shoe, an extrusion shoe, a die in a cavity of the extrusion shoe, and rotating speed sensors at shaft heads of the upper working roller and the lower working roller of the main machine. An annular groove of the upper working roller is mutually matched with an annular lug boss of the lower working roller. The feeding shoe is arranged at the feeding end of the main machine, and the feeding shoe and the annular groove of the upper working roller form a feeding cavity. A metal material enters into a roller gap between the two working rollers through the feeding cavity. When producing pipes, profiles, wires and wrapping materials, the extrusion shoe is arranged at the discharging end of the main machine, and an extrusion forming die can be arranged in the cavity of the extrusion shoe. The device can realize quick continuous rheological forming of the liquid metal, and can also be used for direct forming of a semi-solid metal material.

Owner:NORTHEASTERN UNIV

Epoxy resin-based carbon fibre compound material formed by using high polymer (HP)-resin transfer molding (RTM) process quickly

InactiveCN102675827AExpand application form and scopeSolve low production efficiencyEpoxy resin compositeDefoaming Agents

The invention discloses an epoxy resin-based carbon fibre compound material formed by using a high polymer (HP)-resin transfer molding (RTM) process quickly, which is obtained by forming an epoxy resin composition and a carbon fibre reinforced fabric through high-pressure resin transfer molding; the resin injection pressure is 50 to 300par; and the epoxy resin composition contains an A component and a B component, wherein the A component comprises epoxy resin, a diluting agent, a defoaming agent, a coupling agent and an antioxidant, and the B component is a curing agent. According to the epoxy resin-based carbon fibre compound material formed by using the HP-RTM process quickly, the compounding of traditional RTM and a mould pressing process is realized by utilizing a novel process form of HP-RTM, the application form and the application range of carbon fibre are greatly expanded, the problems of low production efficiency and poor dimensional stability of the processes of the traditional RTM and the like are effectively solved, and the obtained epoxy resin-based carbon fibre compound material has extensive application form and application range and good dimensional stability. The compound material has low manufacturing cost, and the diversification and the complication of the structure are realized.

Owner:江苏兆新材料科技

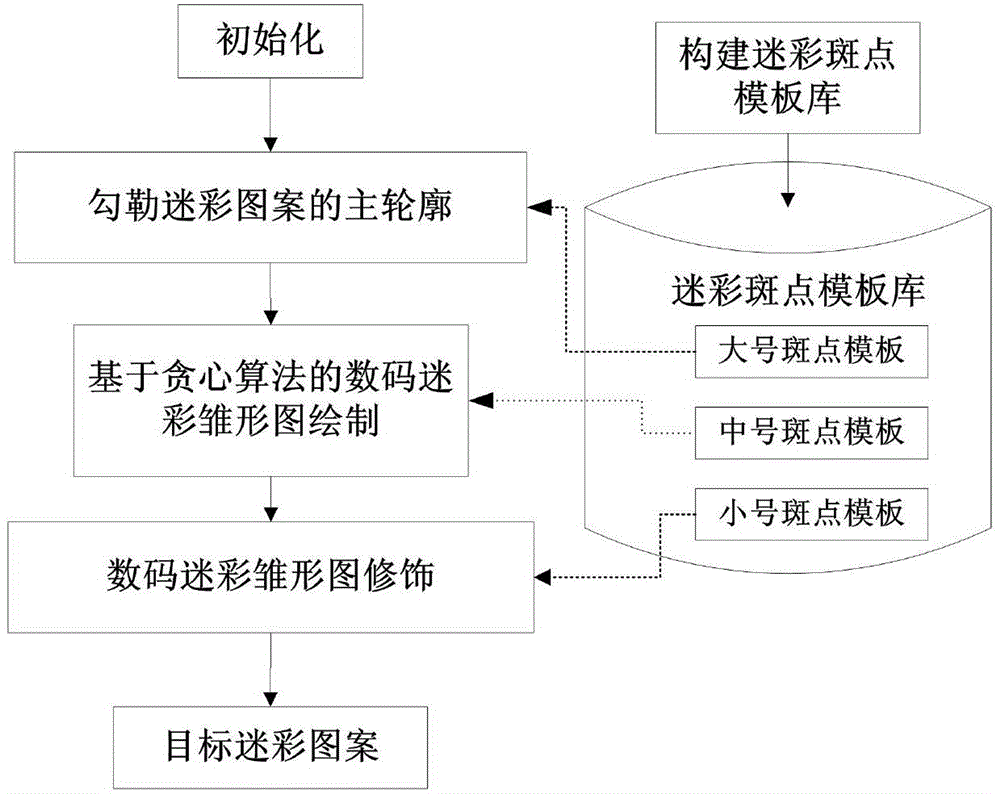

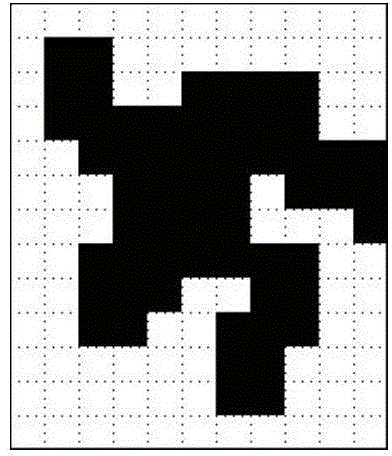

Digital camouflage design method based on spot template automatic combination

ActiveCN104463925AImprove design efficiencyImprove efficiency2D-image generationComputer scienceDesign methods

The invention discloses a digital camouflage design method based on spot template automatic combination. The digital camouflage design method is characterized by including the first step of designing camouflage spot templates and forming a camouflage spot template bank, the second step of initializing a digital camouflage pattern, the third step of drawing a main outline of the digital camouflage pattern, the fourth step of drawing a camouflage pattern rudiment drawing and the fifth step of drawing a target camouflage pattern. According to the digital camouflage design method based on the spot template automatic combination, the design efficiency of the digital camouflage pattern and the production efficiency of the digital camouflage pattern in the actual air brush process can be improved, and the stability of the quality of the digital camouflage pattern can be guaranteed.

Owner:黄山市开发投资集团有限公司

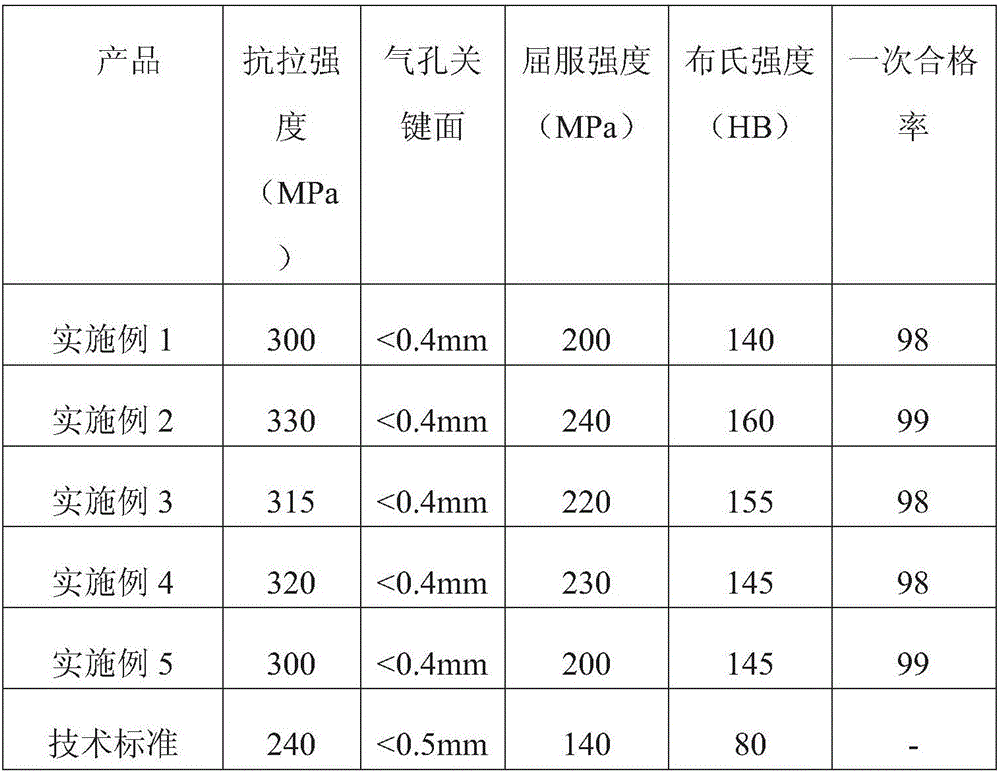

Automobile steering device gear case transmission aluminum alloy shell and preparation method thereof

InactiveCN106119625ASolve the problem of easy deformation of high temperature core pullingGuaranteed purityGearing detailsPorosityManganese

The invention relates to an automobile steering device gear case transmission aluminum alloy shell and a preparation method thereof. Raw materials of silicon, iron, copper, magnesium, zinc, chromium, nickel, tin, titanium, lead, manganese and aluminum are mixed according to the weight proportion, a product is taken out of a die-casting machine through smelting and die casting, edge cutting, manual cleaning, X flaw detection, shot blasting, ECM deburring, final cleaning and drying, final checking, packaging and delivery are carried out, and the product is obtained. By means of modern simulation means (mold flow analysis), the development cost is greatly reduced, and the product yield is high; molten aluminum is subjected to modification, porosity and the mechanical performance of the product are higher than those of the same product in the market by 5% or above, and the strength of extension breaks through 300 Mpa; and by means of the reasonable mold process design, the mold filling process of the product is stable, quality is improved, and meanwhile the service life of the mold is prolonged to a large degree. The fist pas yield of the product is 98%.

Owner:TAICANG HAIJIA VEHICLE FITTINGS

Composite cellulose viscose filament yarn with composite cellulose pulp as raw materials made of cotton, wood, hemp and bamboo mixture, and preparation method thereof

InactiveCN1865547AShinyGood air permeabilityConjugated cellulose/protein artificial filamentsSpinning solutions preparationManufacturing efficiencyNatural fiber

The invention discloses a composite fiber viscose filament and preparing method, which adopts the following random two or more combination as raw material: cotton velvet, hemp, wood, bamboo, straw and crust. The preparing method comprises the following steps: blending pulp; immersing; squeezing; grinding; etiolating; adhering glue to grind; dissolving; grinding; filtering; ripening; debubbling; spinning; refining; drying to make cylinder. The invention reduces cost to improve manufacturing efficiency with excellent paintability, elasticity, desiccating and air permeability, which is better than kinds of synthesizing fiber.

Owner:YIBIN GRACE

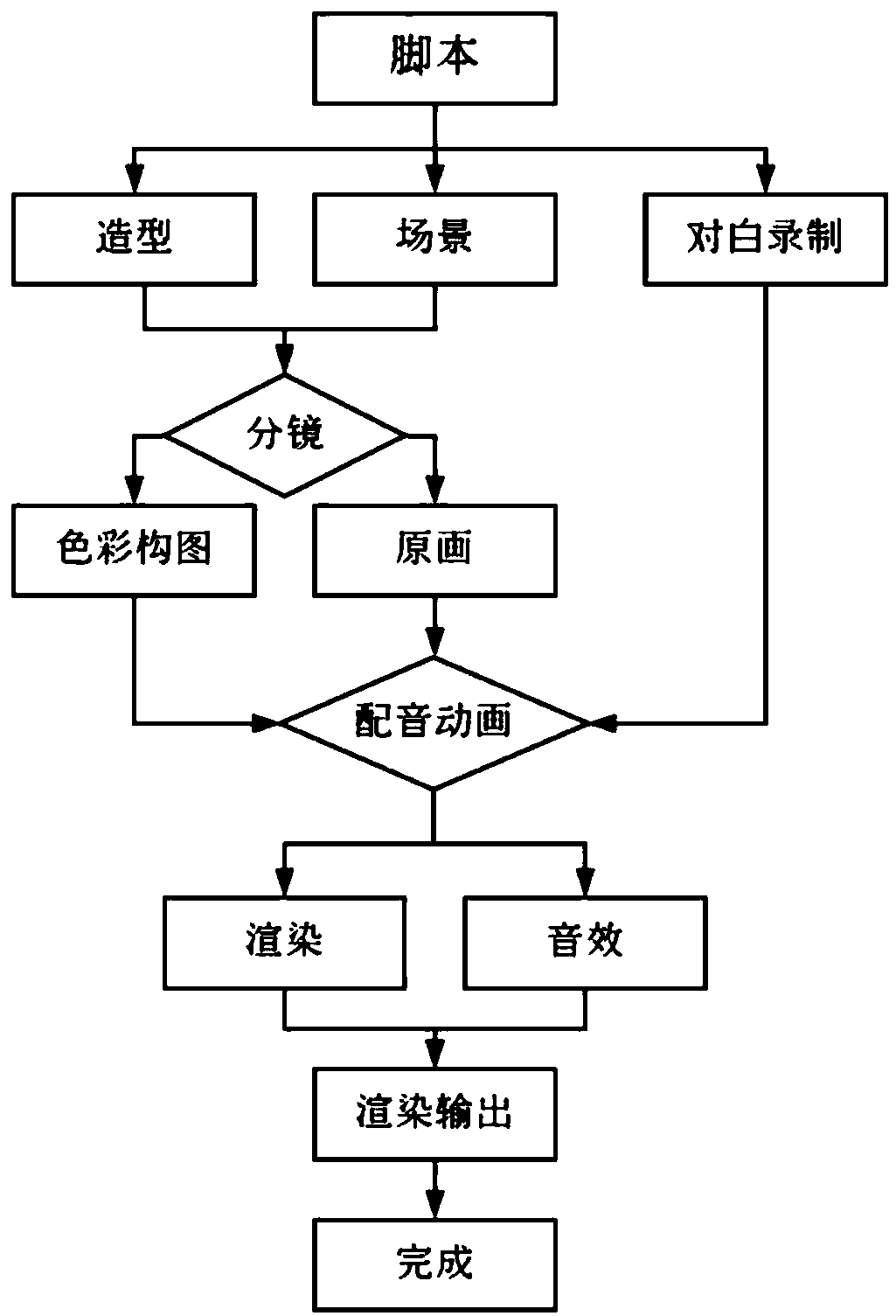

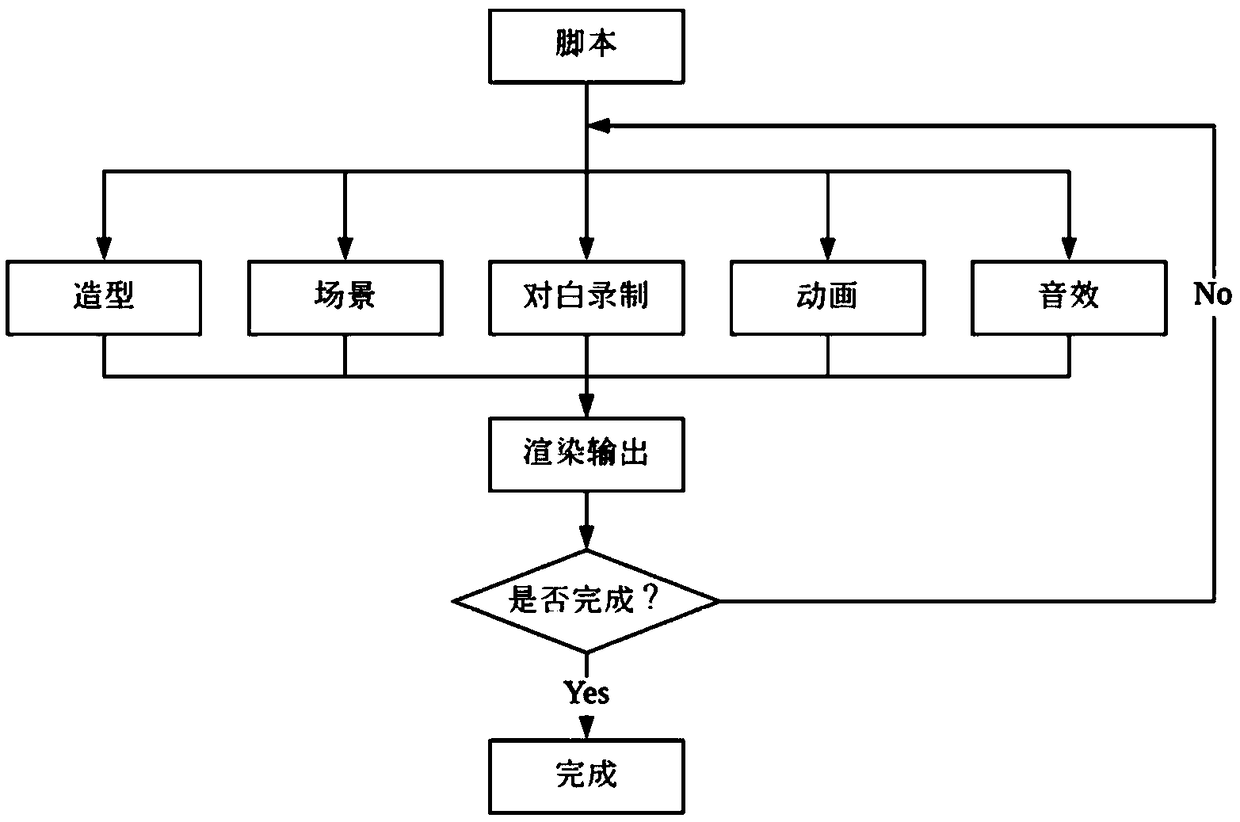

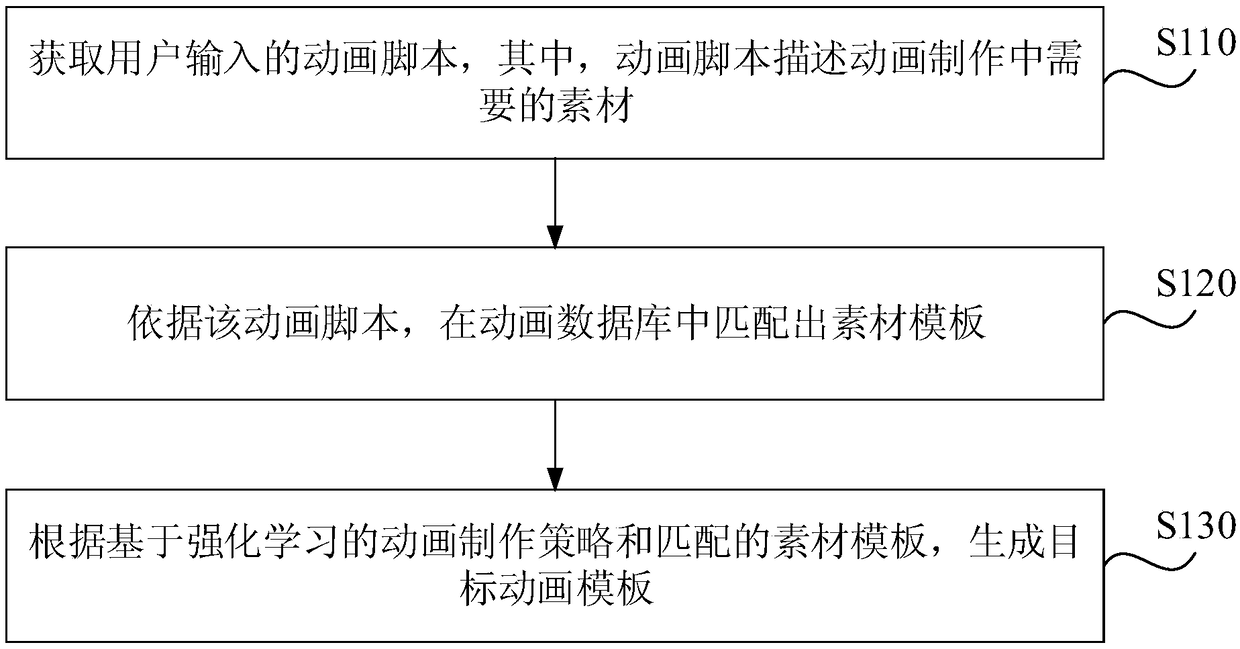

Animation make method, device, terminal and medium

ActiveCN109300179ASolve low production efficiencyImprove production efficiencyAnimationManufacturing computing systemsLearning basedUser input

The embodiment of the invention discloses an animation making method, a device, a terminal and a medium, wherein, the method comprises the following steps: obtaining an animation script input by a user, wherein, the animation script describes materials needed in the animation making; According to the animation script, the material template is matched in the animation database. According to the reinforcement learning-based animation strategy and material template, the target animation template is generated. In the embodiment of the invention, the user only needs to pay attention to the animation script continuously inputted by the user, thus solving the problem of low animation production efficiency and improving the animation production efficiency. At that same time, the process of animation production is simplified, and the barrier of animation production is reduced; And, based on reinforcement learning, the accuracy of animation production is ensured.

Owner:南京蜜宝信息科技有限公司

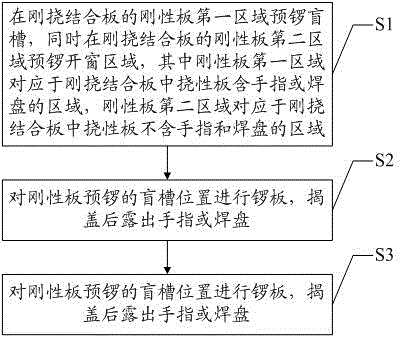

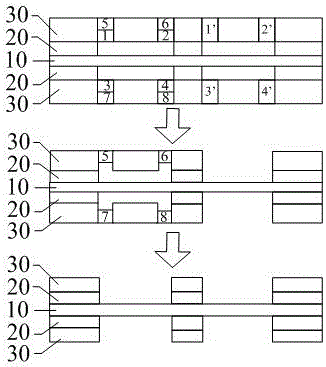

Rigid-flexible combination board and manufacturing method thereof

ActiveCN106535466ASolve low production efficiencyMultilayer circuit manufactureConductive pattern layout detailsEngineeringManufacturing efficiency

The invention discloses a rigid-flexible combination board and a manufacturing method thereof. The manufacturing method comprises the steps of A, pre-forming a blind groove in a first region of a rigid board of the rigid-flexible combination board, and pre-forming a windowing area in a second region of the rigid board of the rigid-flexible combination board at the same time, wherein the first region of the rigid board corresponds to a region, which contains a finger or a bonding pad, of a flexible board in the rigid-flexible combination board, and the second region of the rigid board corresponds to a region, which does not contain a finger and a bonding pad, of the flexible board in the rigid-flexible combination board; B, performing lamination processing on the rigid board and the flexible board of the rigid-flexible combination board; and C, performing routing at the position of the pre-formed blind groove of the rigid board, and exposing the finger or the bonding pad after uncovering. According to the invention, two manufacturing methods such as an uncovering method and a windowing method are simultaneously applied to products containing a finger or a bonding pad and products without a finger or a bonding pad. The manufacturing method can solve problems that an uncovering region is too small and that uncovering is difficult to be performed. Meanwhile, the manufacturing method can solve a problem that a single method is low in manufacturing efficiency.

Owner:SHENZHEN KINWONG ELECTRONICS

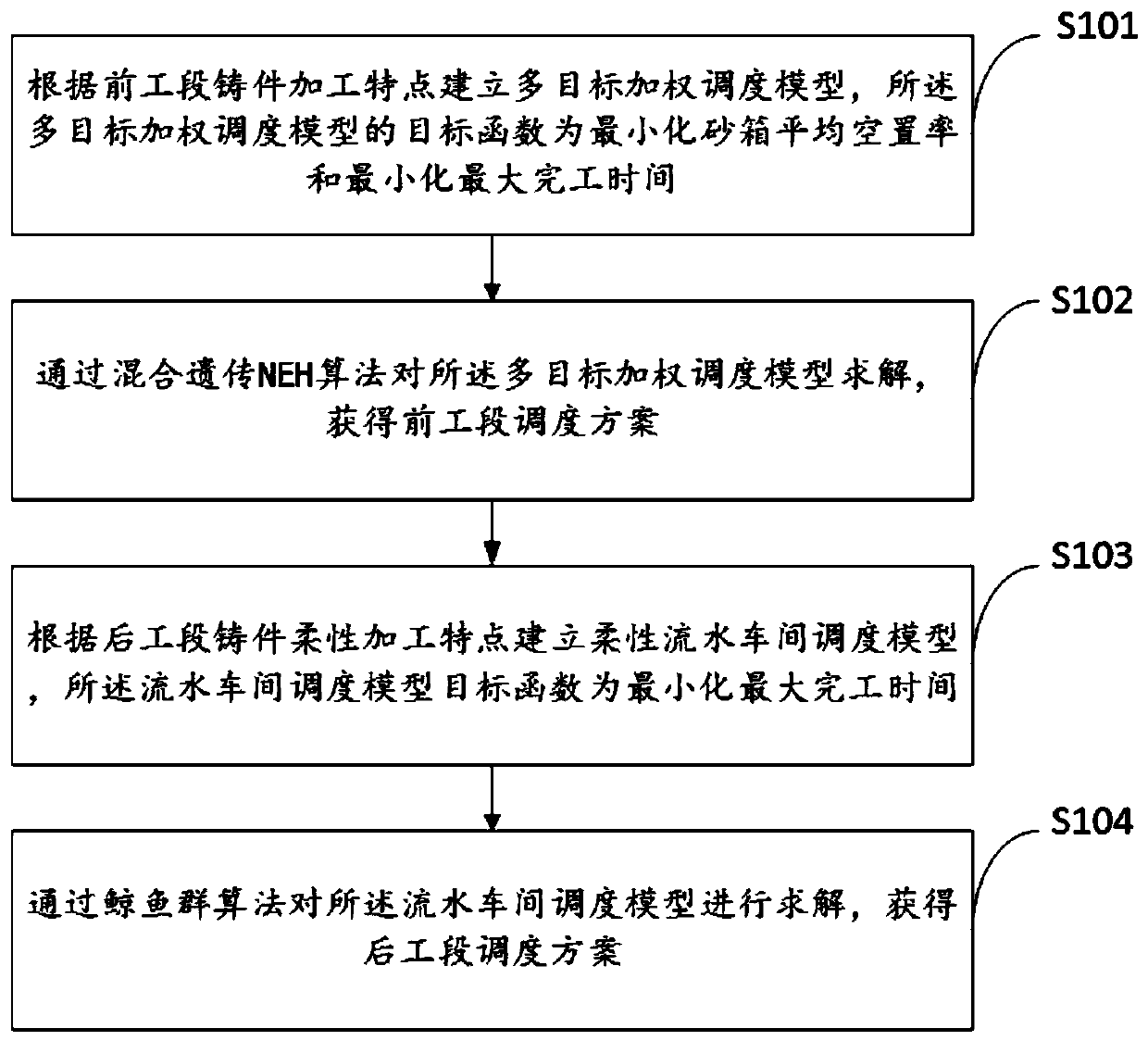

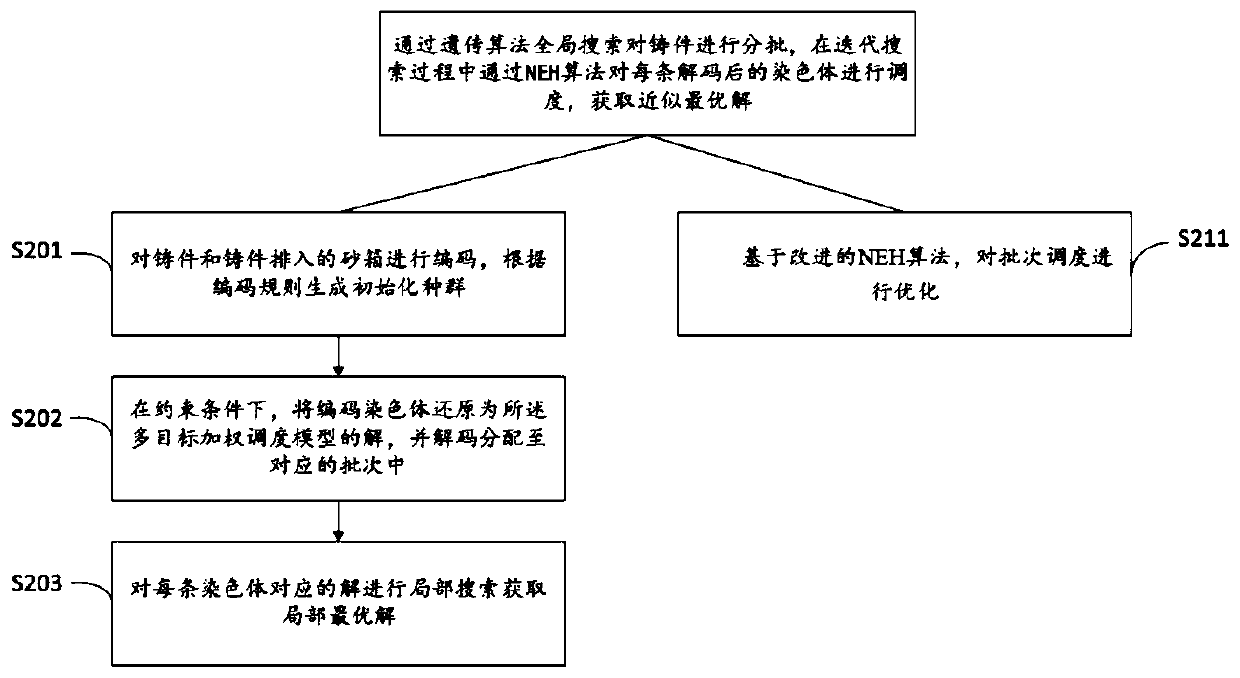

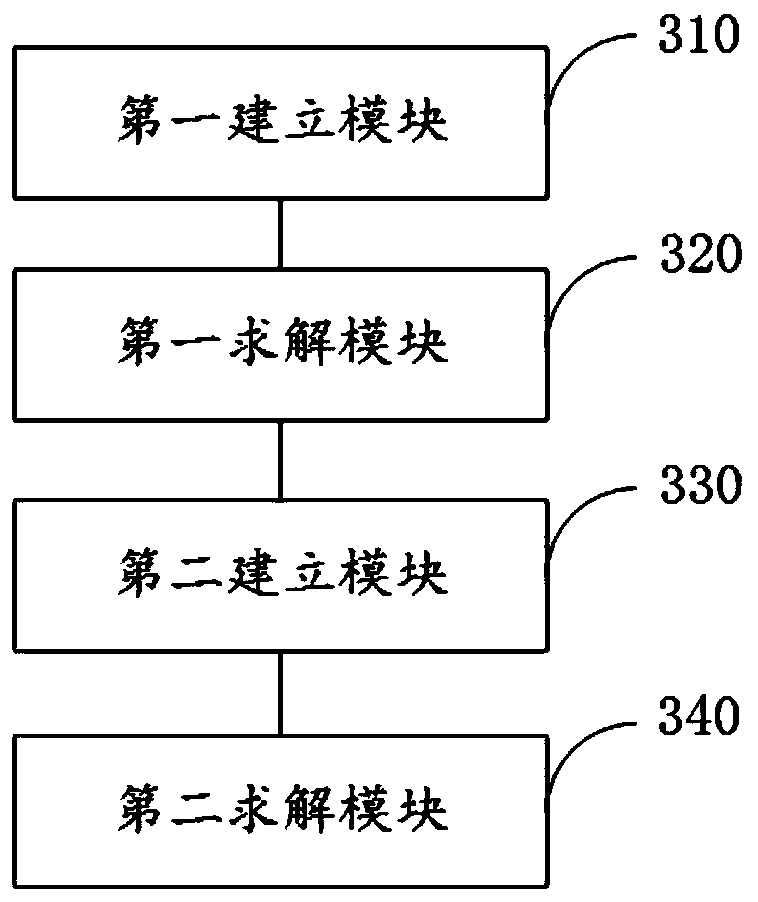

Casting production scheduling method and system

ActiveCN110782085ASolve low production efficiencyFacilitate automated fine-grained controlForecastingArtificial lifeCompletion timeResource utilization

The invention provides a casting production scheduling method and system, and the method comprises the steps: building a multi-objective weighted scheduling model according to the processing characteristics of a casting at a previous section, wherein an objective function of the multi-objective weighted scheduling model is the minimization of the average vacancy rate of a sand box and the minimization of the maximum completion time; solving the multi-objective weighted scheduling model through a hybrid genetic NEH algorithm to obtain a front workshop section scheduling scheme; establishing a flexible flow shop scheduling model according to the flexible machining characteristics of the castings in the later working section, wherein the objective function of the flow shop scheduling model isthe minimum maximum completion time; and solving the flow shop scheduling model through a whale swarm algorithm to obtain a rear workshop section scheduling scheme. According to the scheme, the problem of low casting production efficiency is solved, the production efficiency and the resource utilization rate are effectively improved, and integrated refined management and control are facilitated.

Owner:武汉晨曦芸峰科技有限公司

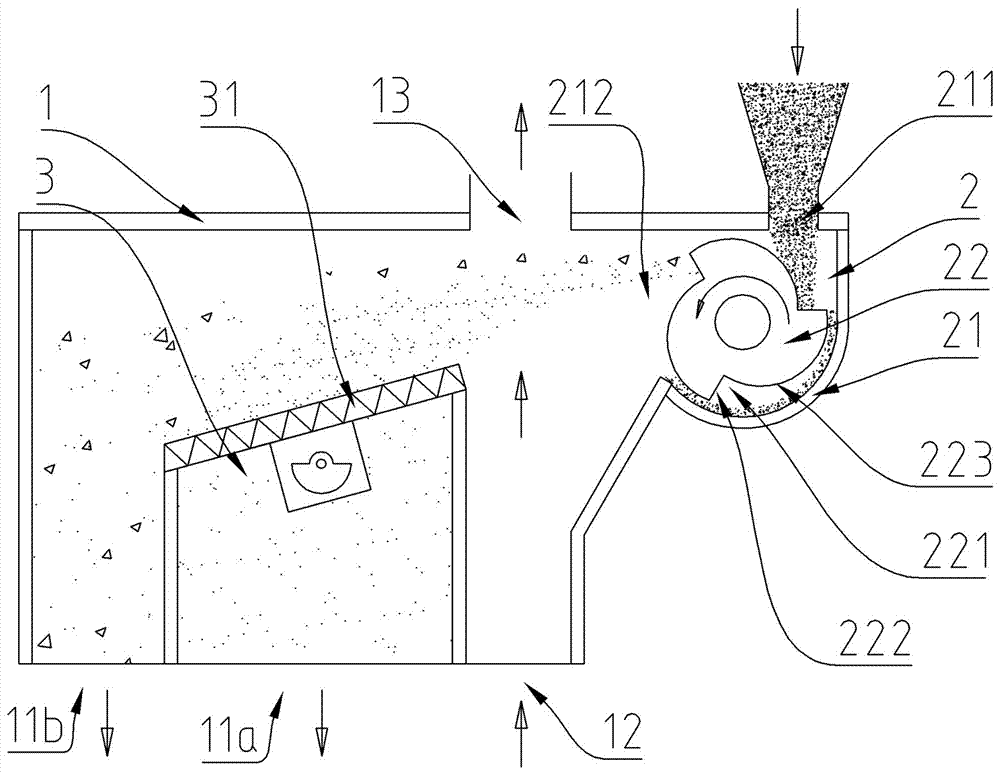

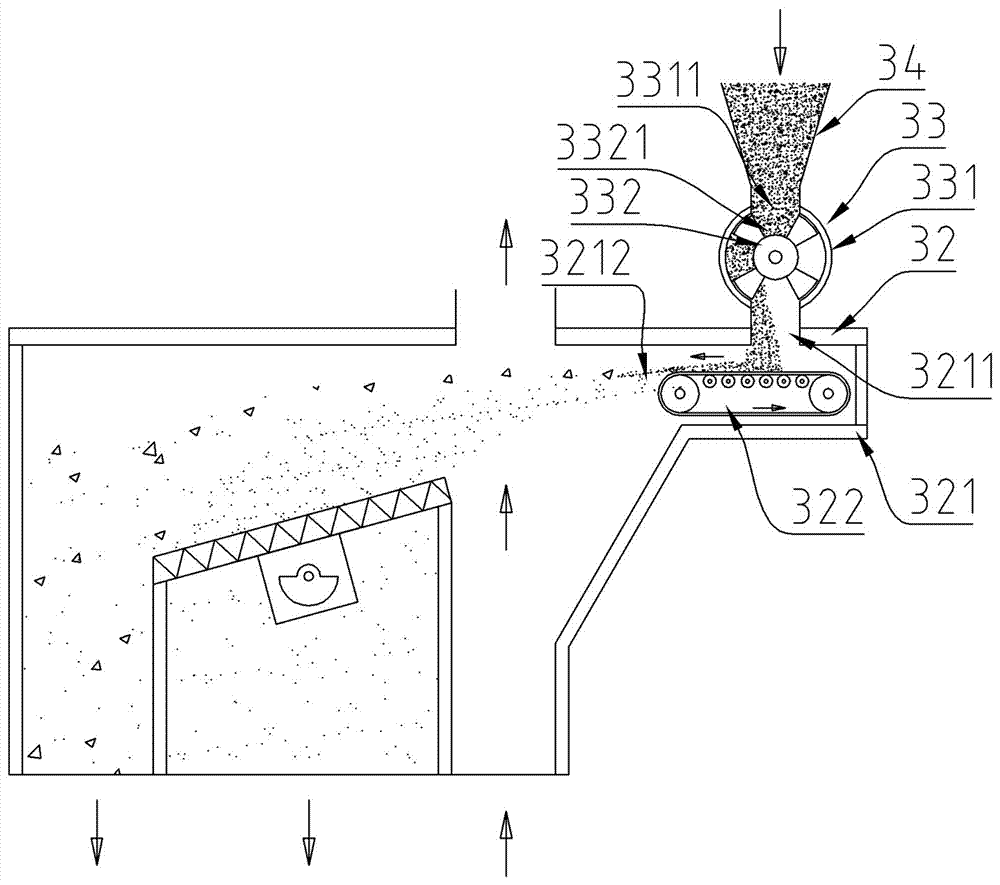

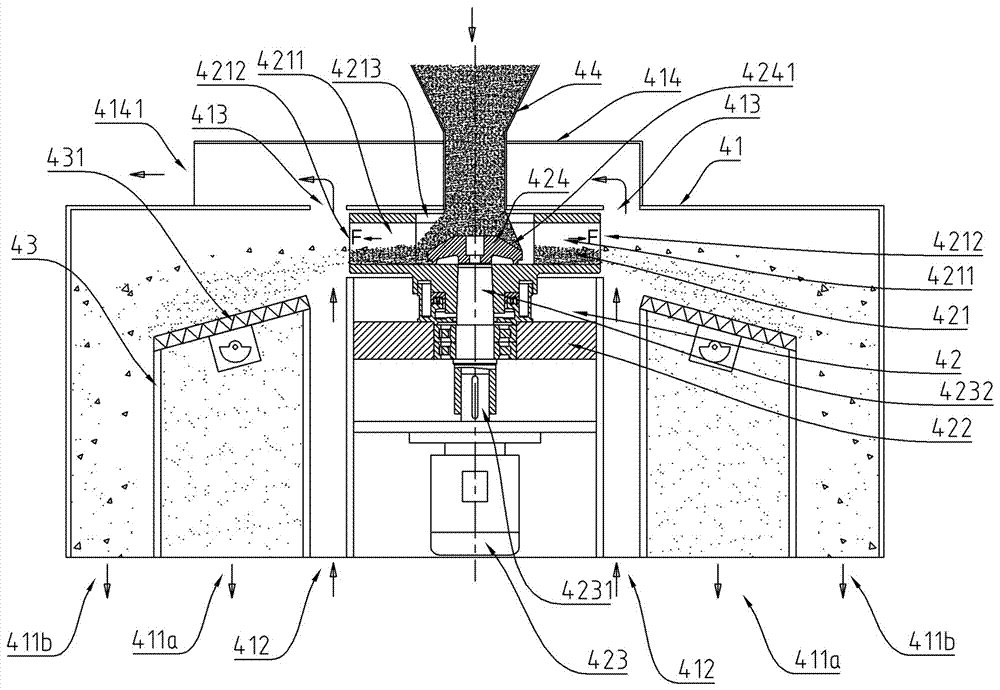

Cast type material separation method and device and separation bin

ActiveCN106984544AReduce work intensityReduced Power RequirementsSievingGas current separationCasting typesMixed materials

The invention relates to the field of material sorting equipment, in particular to a cast type material separation method and device and a separation bin. The cast type material separation method comprises the steps that at least one collecting area is provided with a screening device, a mixed material is cast through a cast device, the material falling into the collecting area where the screening device is located is screened through the screening device so that the material meeting the grain size requirement can be obtained. Compared with an existing material separation method, according to the cast type material separation method, the mixed material is preliminarily separated through the cast device, the screening device is arranged in the collecting area so as for further screen the material entering the collecting area, the effect that the grain size of the material obtained after screening is in the required range is guaranteed, and the problem that according to an existing cast type material separation method, due to the fact that further screening operation needs to be conducted, the production efficiency is low is solved.

Owner:ZHENGZHOU SANHE HYDRAULIC MACHINERY

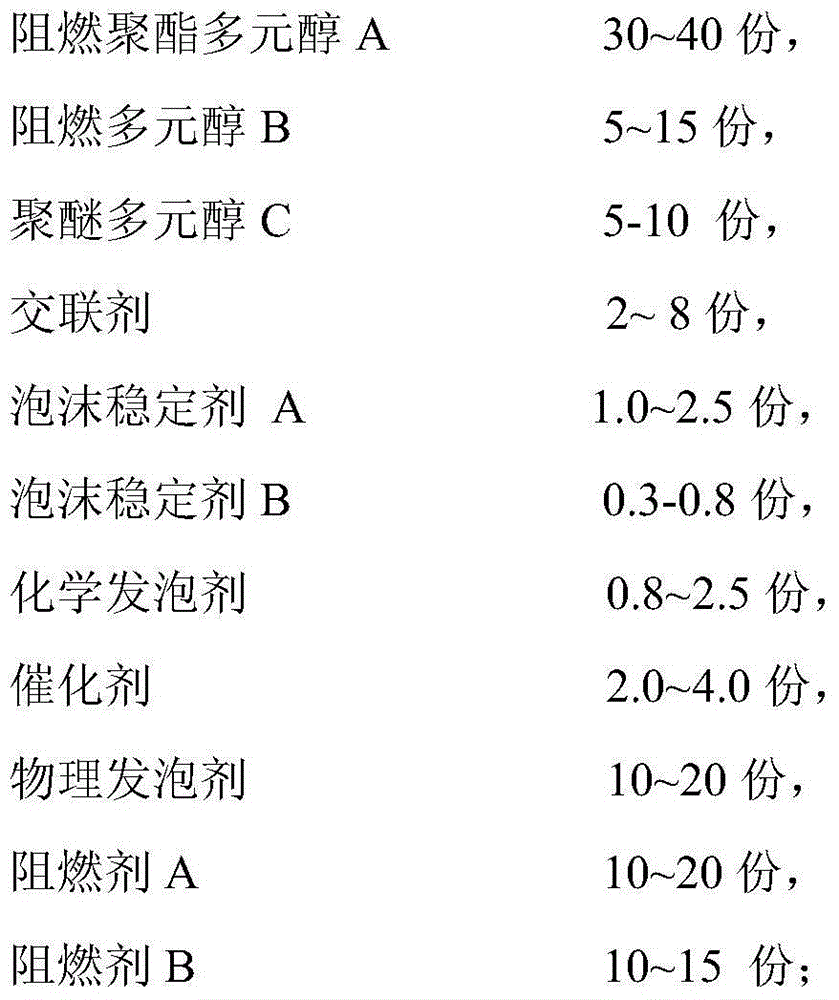

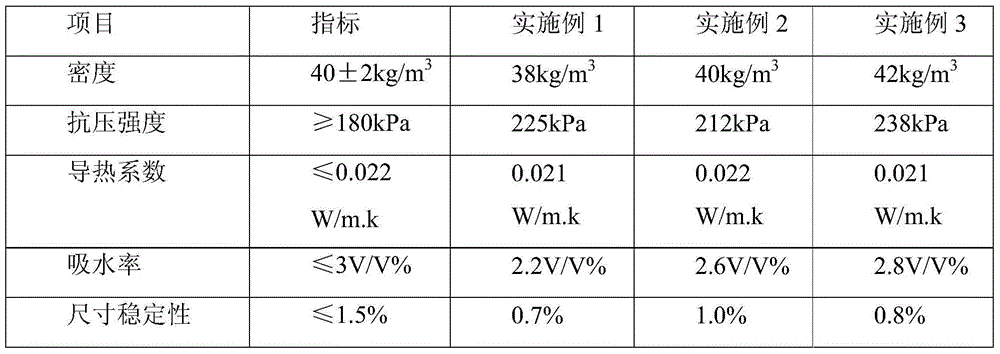

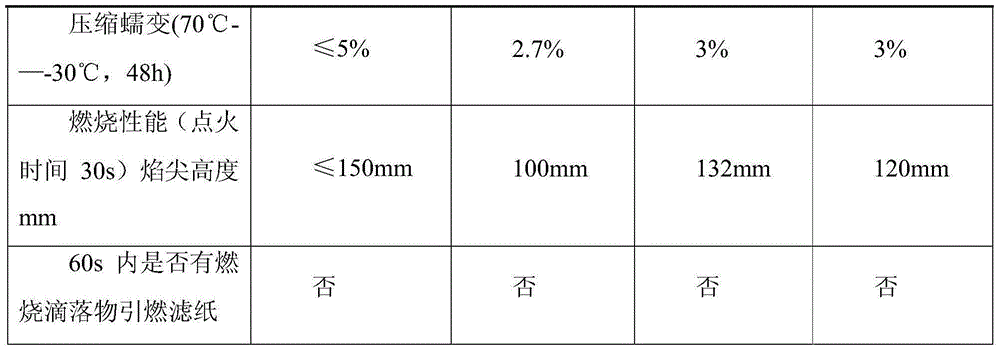

Combined polyether for flame-retardant bulk rigid polyurethane foams and application method of combined polyether

The invention relates to combined polyether for flame-retardant bulk rigid polyurethane foams and an application method of the combined polyether and belongs to the technical field of the combined polyether. The combined polyether for the flame-retardant bulk rigid polyurethane foams is prepared from the following components including flame-retardant polyester polyol A, flame-retardant polyester polyol B, flame-retardant polyester polyol C, a crosslinking agent, a foam stabilizer A, a foam stabilizer B, a chemical foaming agent, a catalyst, a physical foaming agent, a flame retardant A and a flame retardant B. The combined polyether for the flame-retardant bulk rigid polyurethane foams is wide in raw material source and is low in cost. With the adoption of the combined polyether, the flame-retardant bulk rigid polyurethane foams prepared by the combined polyether are good in flame retardancy, low in thermal conductivity, good in airtightness and stable in quality performance. The invention also provides the application method of the combined polyether for the flame-retardant bulk rigid polyurethane foams. The application method is simple in process, is easily operated, is low in volatilization and is high in production efficiency without three wastes.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Metallurgical bonding double-metal stainless steel cladding reinforcing steel bar and preparation process thereof

InactiveCN106825515AHas comprehensive mechanical propertiesHigh strengthInduction heaterSS - Stainless steel

The invention discloses a metallurgical bonding double-metal stainless steel cladding reinforcing steel bar and a preparation process thereof. The metallurgical bonding double-metal stainless steel cladding reinforcing steel bar comprises a carbon steel core part and a stainless steel cladding. The composite forming process comprises the following steps: integrally heating an outer-layer stainless steel pipe to 600 to 1000 DEG C by using an induction heater, pouring into inner-layer carbon steel, performing metal liquid casting and manufacturing an interface metallurgical bonding cladding type double-metal composite blank; hot-rolling the cast double-metal blank to form cladding double-metal round steel and threaded steel. The metallurgical bonding interface of the stainless steel layer and the carbon steel core is formed by casting, and the advantages of high bonding strength, excellent processing property, dense structure, high quality, few procedures, low cost, high efficiency and the like are achieved. The integral stainless steel reinforcing steel bar is replaced by the double-metal reinforcing steel bar, so on the premise of guaranteeing the corrosion-resistant characteristic of the reinforcing steel bar, the stainless steel material is saved, the engineering cost is reduced, the strength of the reinforcing steel bar is effectively improved, waste of resource and energy and environmental pollution are reduced, and a wide application prospect is achieved.

Owner:丹阳恒庆复合材料科技有限公司

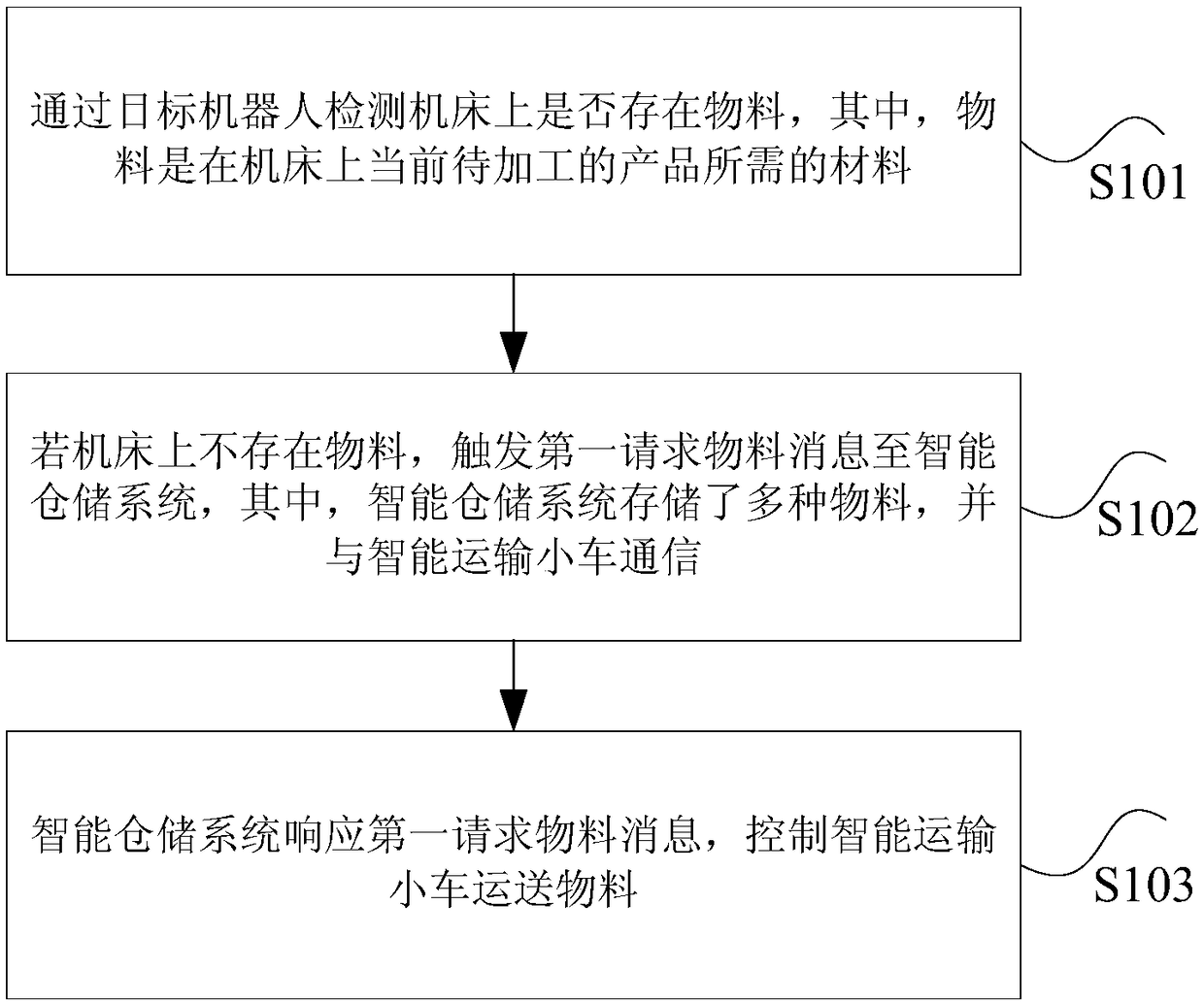

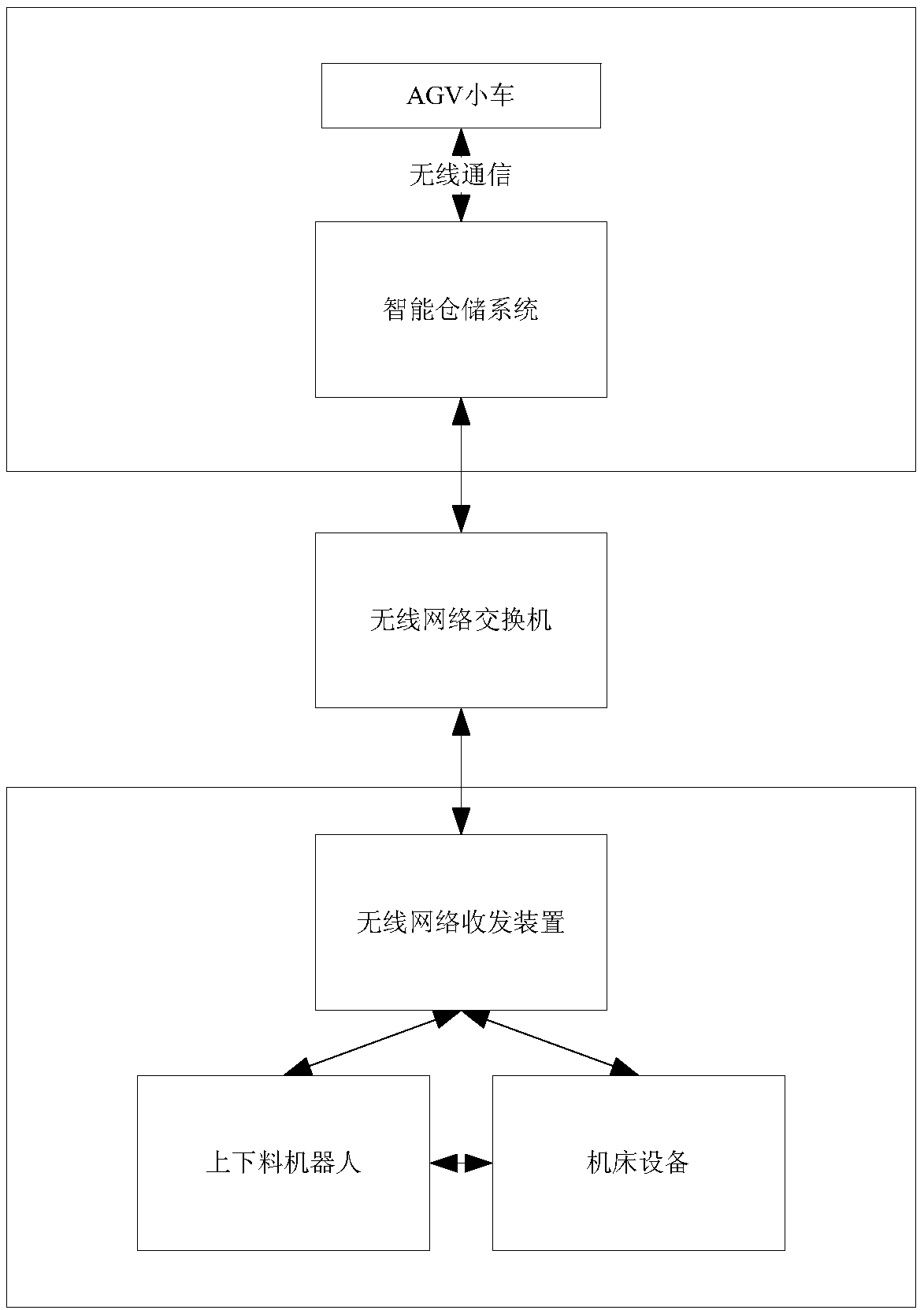

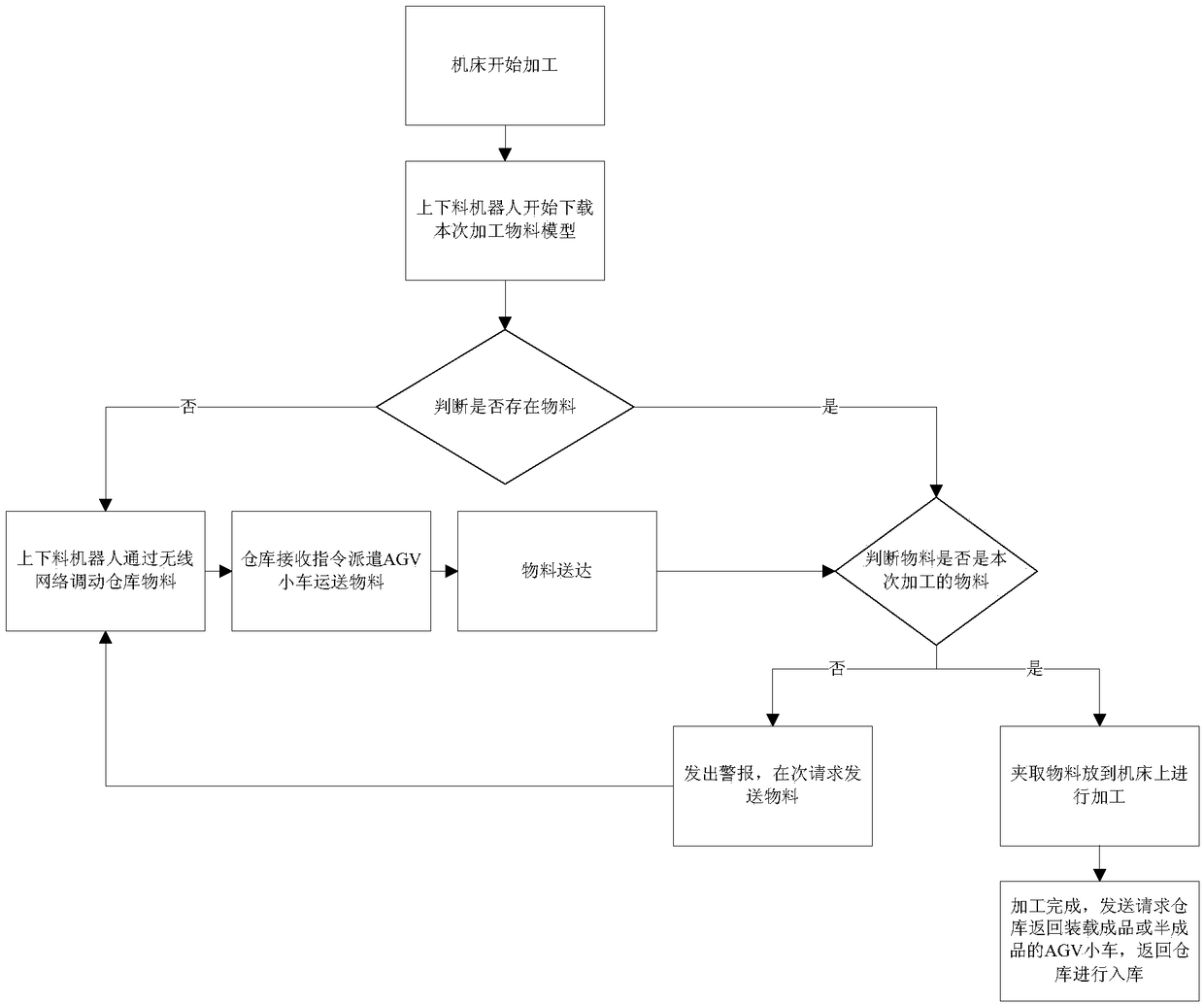

Loading and unloading treatment method and device

ActiveCN108838732ASolve artificial ginsengSolve efficiency problemsMeasurement/indication equipmentsMetal working apparatusSystems managementMachine tool

The invention discloses a loading and unloading treatment method and device. The method comprises the following steps of: detecting whether materials are on a machine tool or not by a target robot, wherein the materials are to-be-processed materials on the machine tool; if the materials are not on the machine tool, trigging first request material information to an intelligent storage system, wherein various materials are stored in a warehouse controlled by the intelligent storage system, and the warehouse communicates with an intelligent transport trolley; and enabling the intelligent storagesystem to respond to the first request material information, and controlling the intelligent transport trolley to transport the materials. The loading and unloading treatment method solves the problemthat production efficiency is relatively low as manual work is required for transporting the materials during machine tool processing in related technologies.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

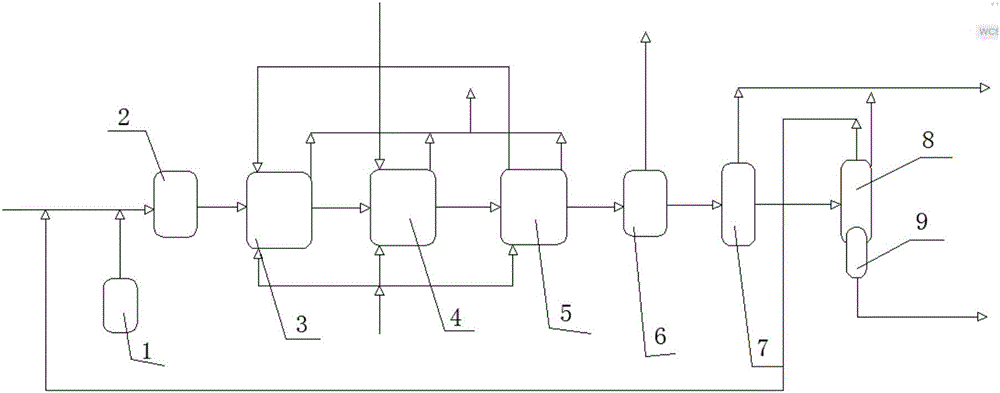

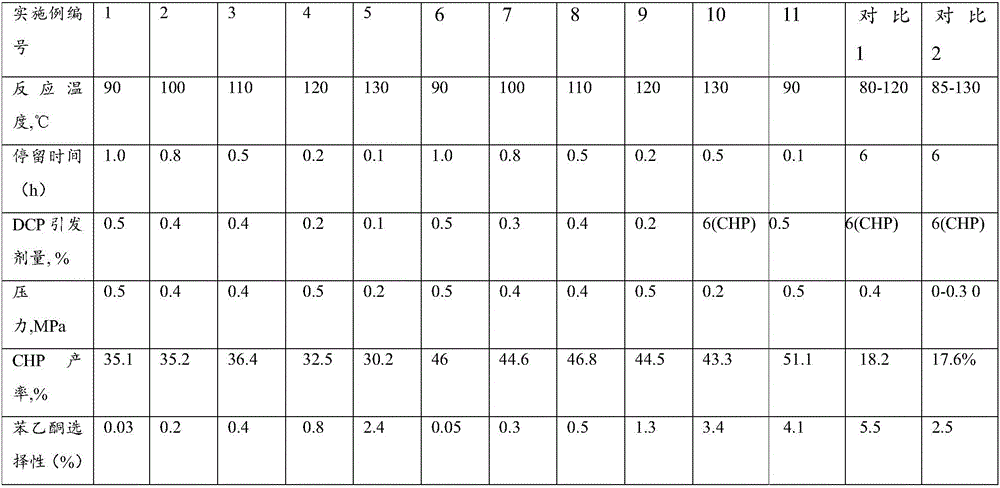

Method and device for preparing cumene hydroperoxide through cumene oxygenation

ActiveCN106588734ALarge specific surface areaIncrease reaction rateOrganic compound preparationChemical/physical/physico-chemical microreactorsMicroreactorReaction temperature

The invention provides a method and a device for preparing cumene hydroperoxide through cumene oxygenation. The method is characterized in that in a microreactor group formed by one microreactor or more microreactors connected in series, cumene and an initiating agent are supplied to a first microreactor in the first microreactor group, then a reaction product obtained after oxidizing reaction flows into a second microreactor in the first microreactor group for the oxidizing reaction, continuous flow type oxidizing reaction is carried out sequentially through recurrence till the reaction product finally flows into the last one microreactor for the oxidizing reaction, and purification is carried out finally; in every oxidizing reaction process, oxygen is supplied to all microreactors, and a mole ratio of cumene supplied to the first microreactor to the total oxygen supplied to all microreactors is 0.1:5. The problems that the reaction temperature fluctuation of the traditional technology is large, and the production efficiency and the productivity are low are solved.

Owner:SINOPEC ENG GRP CO LTD

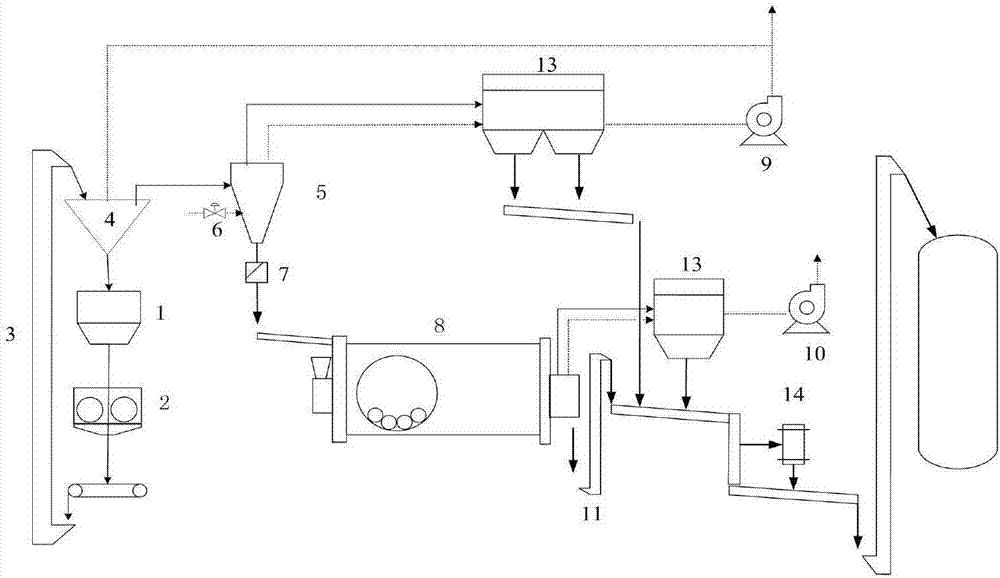

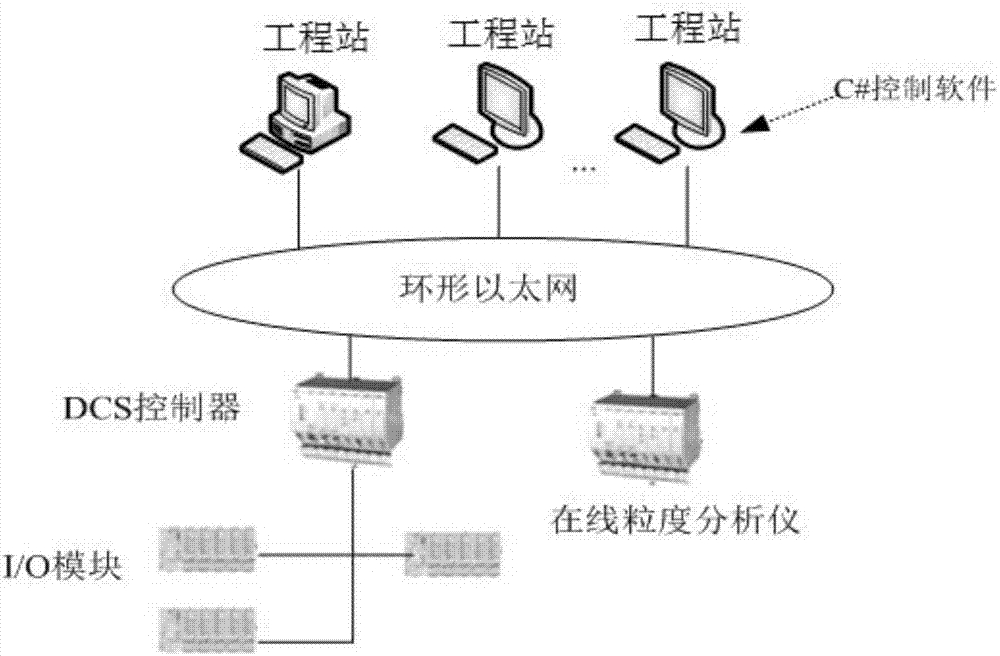

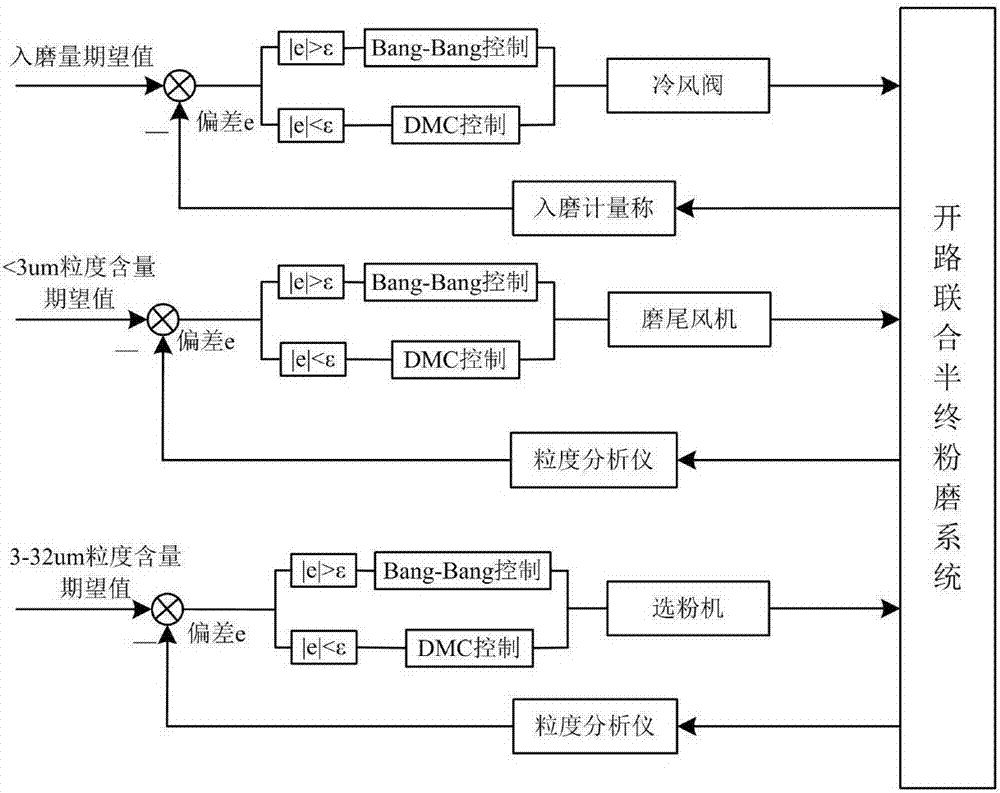

Open circuit cement combined and semi-final grinding automatic control method and system based on C#

ActiveCN106886150AEffective controlControl Performance IndicatorsGrain treatmentsAdaptive controlAutomatic controlGranularity

The invention discloses an open circuit cement combined and semi-final grinding automatic control method based on C#. The method comprises the steps of completing the data exchange of a DCS system and an online granularity analyzer through OPC communication by using C#, (2) allowing the online granularity analyzer to feed a detected granularity parameter to an engineering station in real time to judge the working condition of a grinding system, and (3) allowing the engineering station to control the grinding system in real time. The invention also discloses a control system with the use of the open circuit cement combined and semi-final grinding automatic control method based on C#.

Owner:临沂中联水泥有限公司

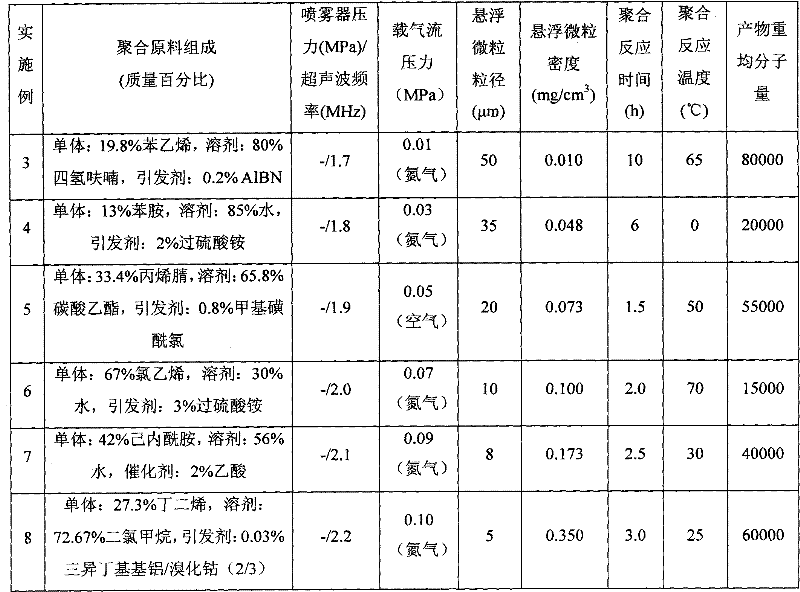

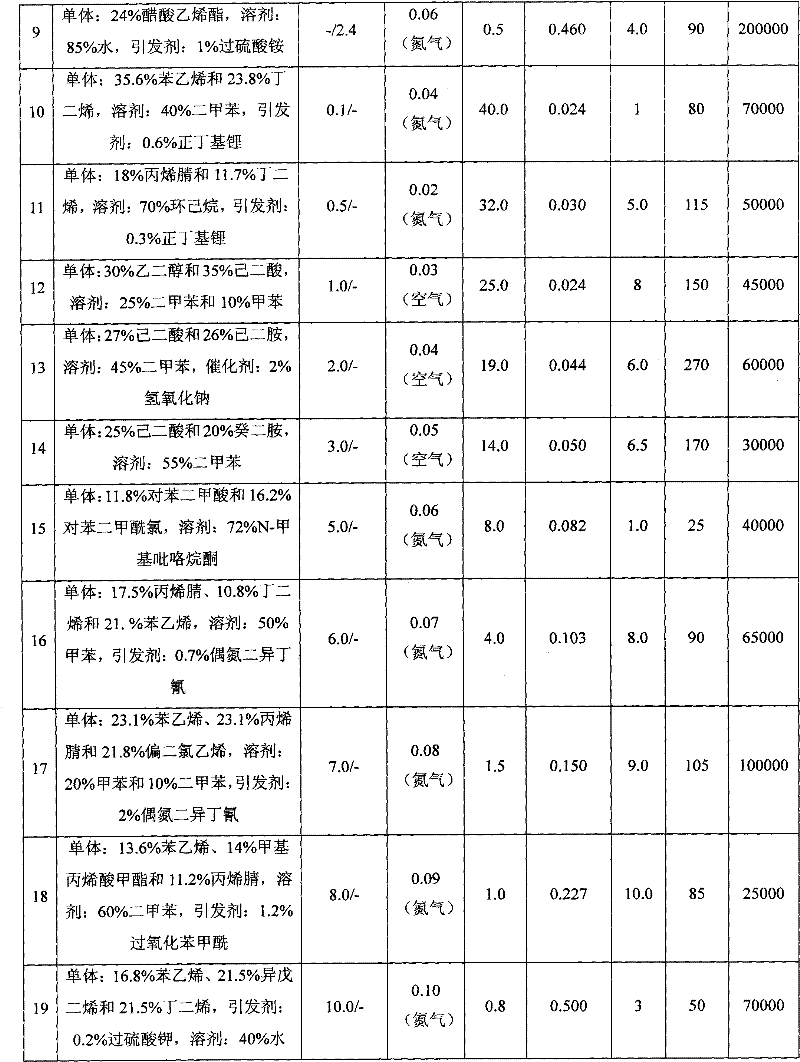

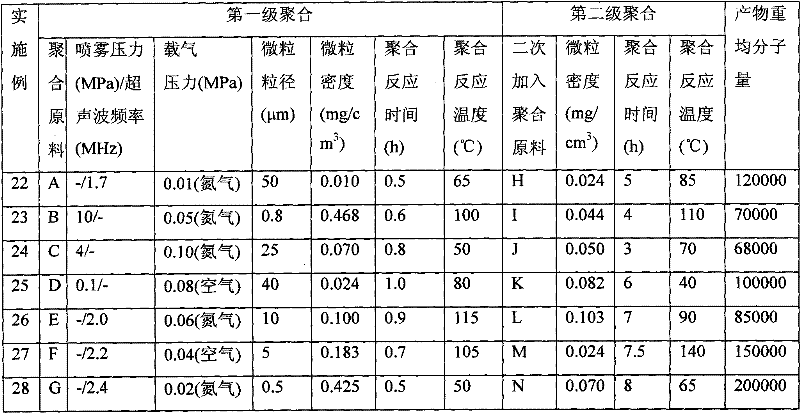

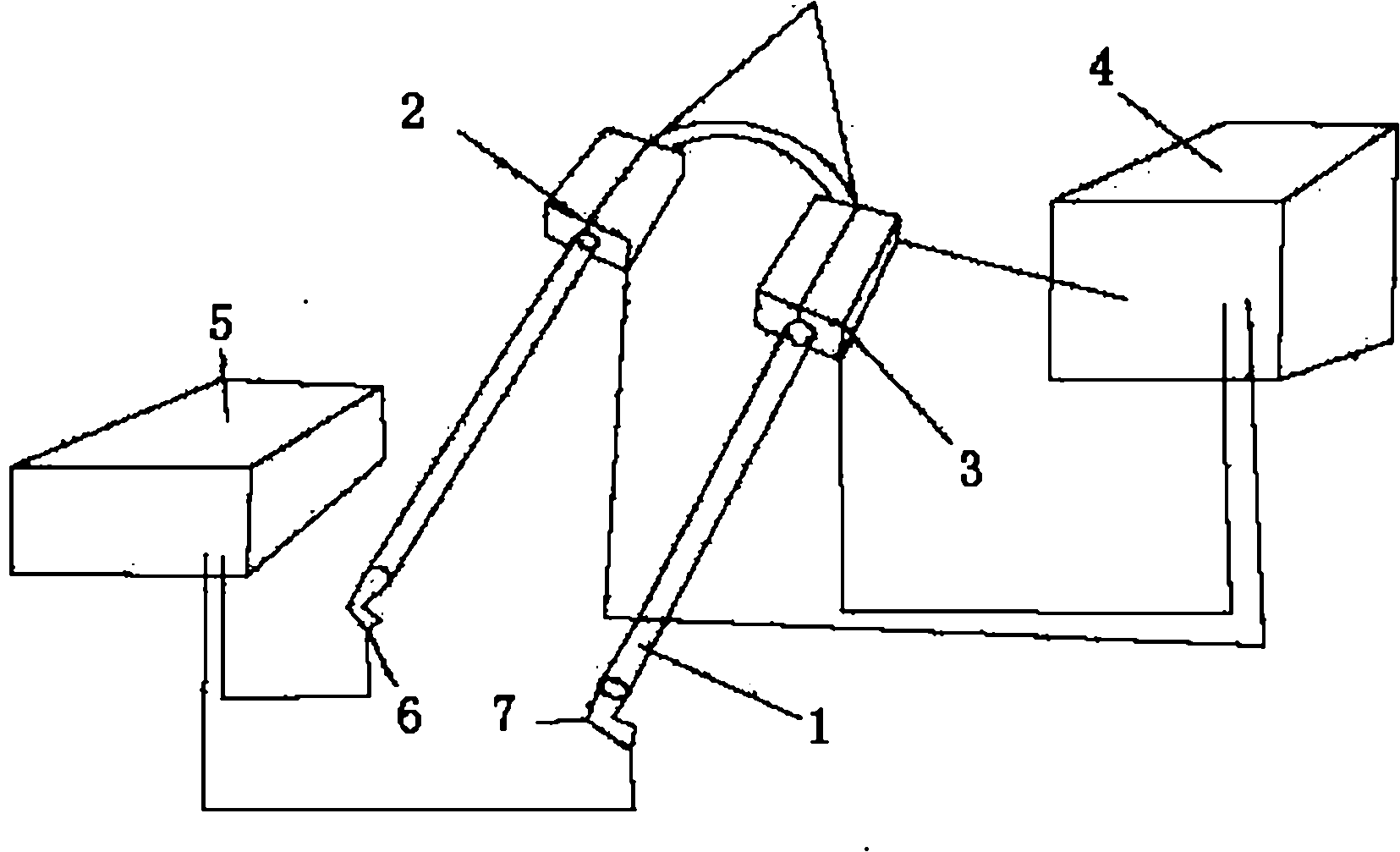

Method for preparing organic polymer through particle phase polymerization reaction

InactiveCN102212194AUniform molecular weight distributionGood monodispersityParticulatesPolymer science

The invention relates to a method for preparing an organic polymer through a particle phase polymerization reaction. The particle phase polymerization reaction comprises the following steps of: atomizing at least one or more than one polymerization raw material respectively to form suspended particulates with the particle sizes of between 0.5 and 50mu m, bringing one or more than one kind of suspended particulates into a reaction zone formed by serially connecting reaction bins by the airflow with the pressure of between 0.01 and 1.0MPa, and performing one or more than one stage of polymerization reaction to form the organic polymer, wherein the reaction temperature is -15 to 270 DEG C. The method for preparing the organic polymer through the particle phase polymerization reaction is different from the traditional polymerization reaction method; the method is efficient, reliable, simple and easy, the cost is low, and the applicable range is wide; an organic polymer product prepared bythe method has the advantages that: a unit sequence has a controllable structure, the molecular weight is high, the molecular weight distribution is uniform, the monodispersity is high, and the variety is rich; and the product can meet the needs of multi-component composite materials and special shaped materials.

Owner:WUHAN TEXTILE UNIV

Device for eliminating internal stress of U-shaped bent pipe by performing heating and annealing

InactiveCN102080150ASimple and safe operationSolve low production efficiencyFurnace typesHeat treatment furnacesInternal stressCollet

The invention relates to a device for eliminating internal stress of a U-shaped bent pipe by performing heating and annealing. The device comprises the U-shaped bent pipe, a first guide rail and a second guide rail, wherein the first guide rail is parallel with the second guide rail; a collet on the top of the first guide rail contacts with the top end of a bending part of the U-shaped bent pipe; a collet on the top of the second guide rail is in contact with the root part of the bending part of the U-shaped bent pipe; and the first guide rail and the second guide rail are connected with a high-frequency heater respectively to form a heating loop. The device has the advantages of solving the problem of low production efficiency, improving yield and quality of products, preventing heating oxidation by introducing protective gas and guaranteeing the quality of the inner walls of the products, along with simpleness and safety in operation.

Owner:上海华钢不锈钢有限公司

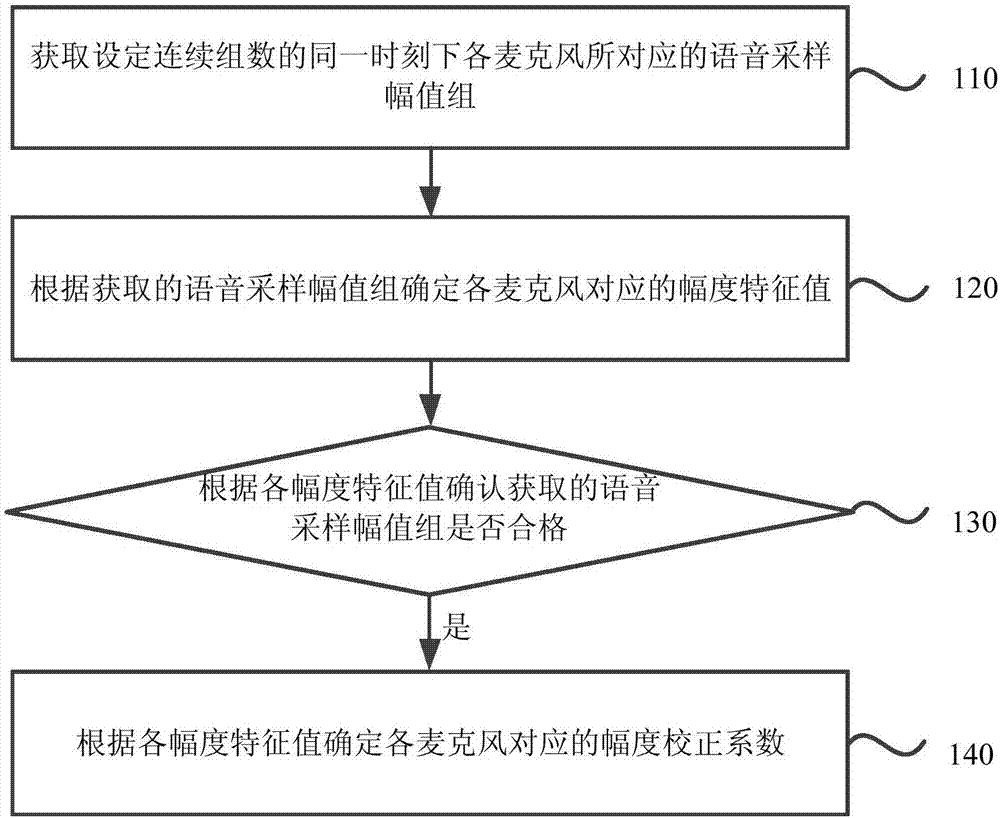

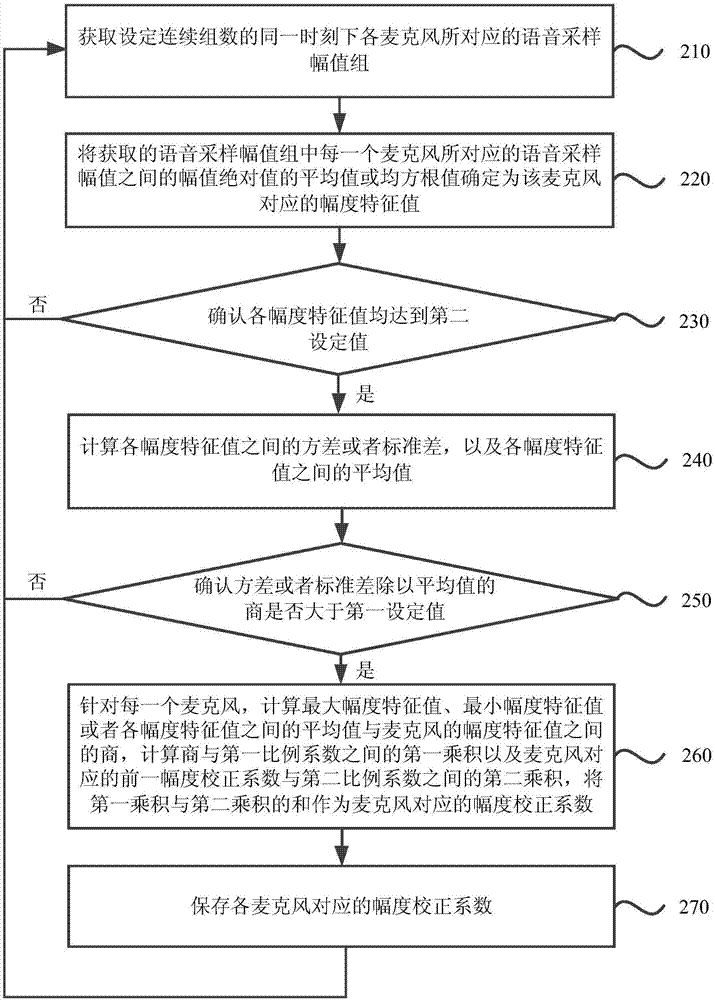

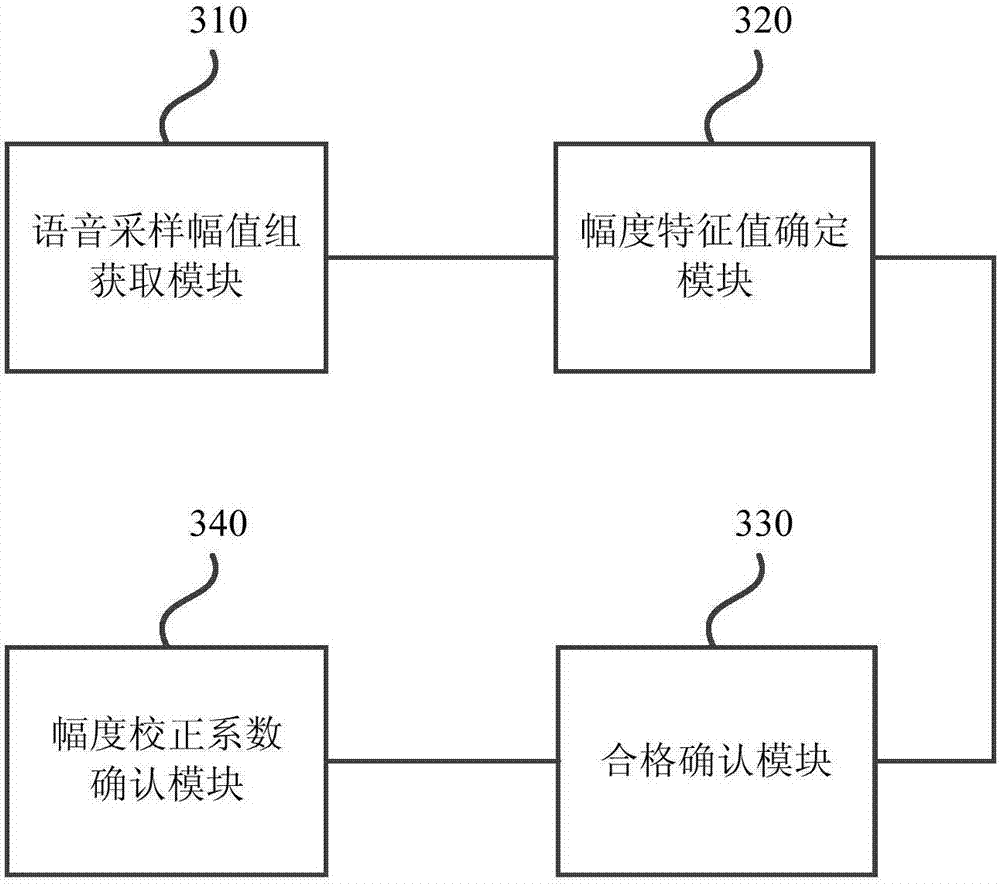

Correction method and device for array microphone, equipment and storage medium

ActiveCN107509155AIncrease productivitySolve low production efficiencyElectrical apparatusCorrection methodMicrophone

The invention discloses a correction method and device for an array microphone, equipment and a storage medium. The method comprises the steps of: acquiring a set continuous group number of voice sampling amplitude groups corresponding to each microphone at the same moment; according to the acquired voice sampling amplitude groups, determining an amplitude feature value corresponding to each microphone; according to each amplitude feature value, determining whether the acquired voice sampling amplitude groups are qualified; and if determining that the acquired voice sampling amplitude groups are qualified, according to each amplitude feature value, determining an amplitude correction coefficient corresponding to each microphone. According to the method provided by the invention, amplitude correction on the array microphone in the production process of the array microphone can be avoided, acquisition on the voice amplitude correction coefficient corresponding to each microphone in the using process of the array microphone is implemented, and production efficiency of the array microphone is improved.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

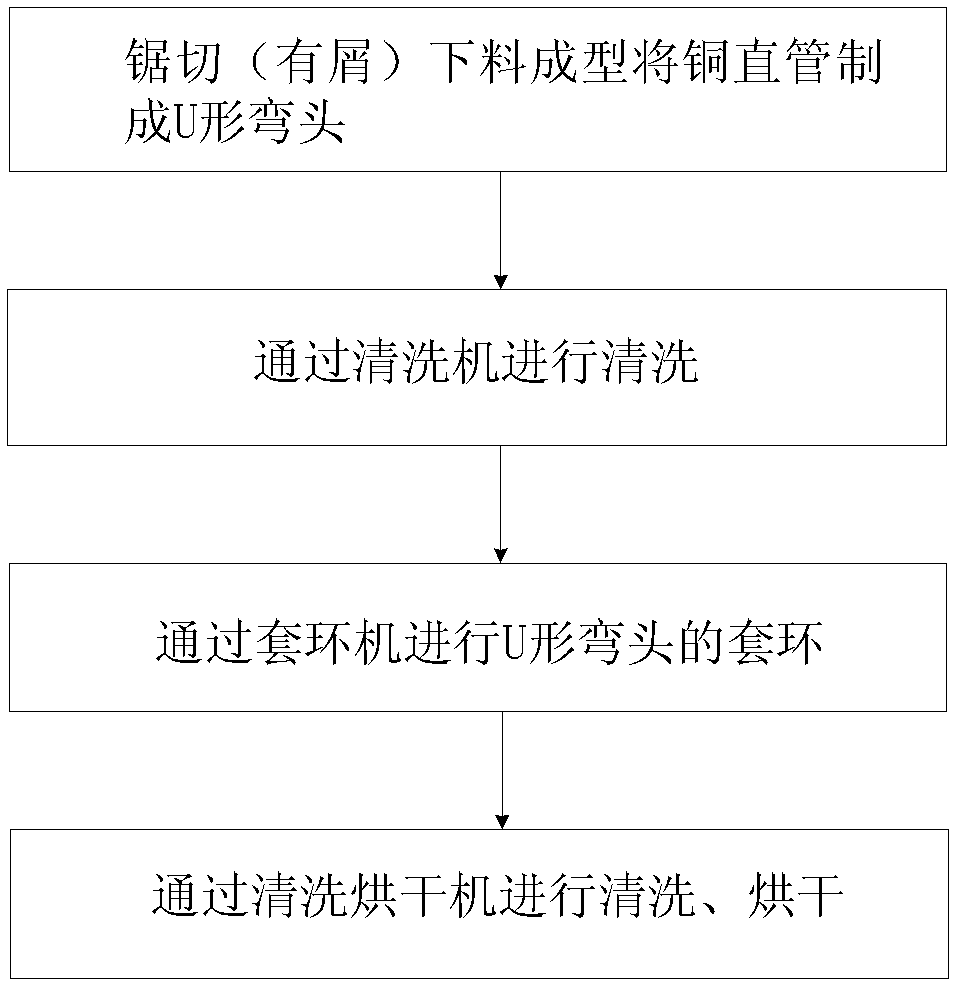

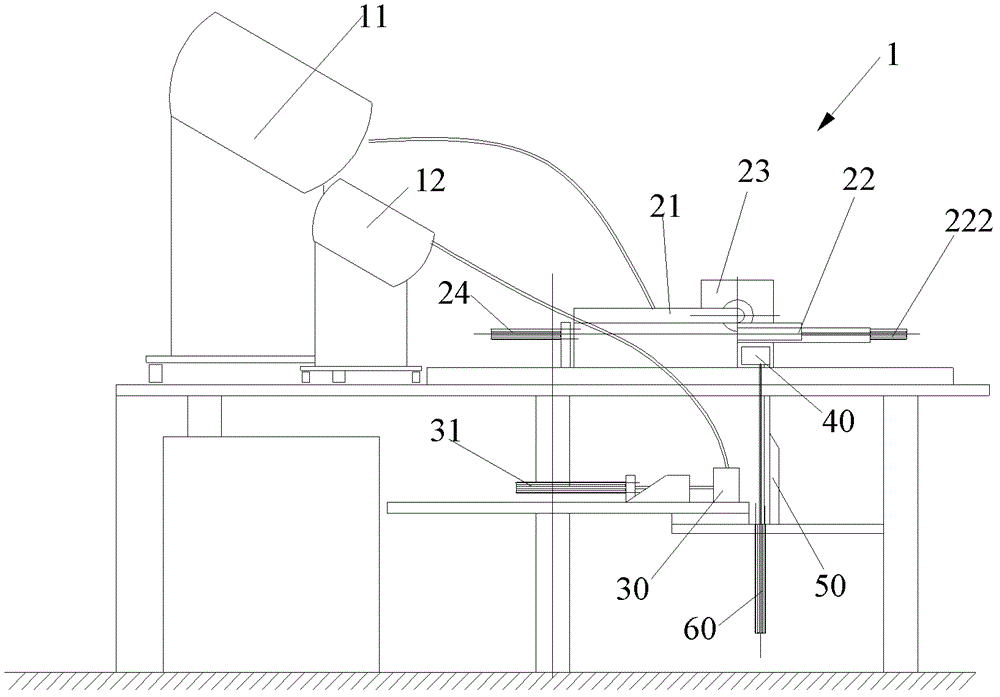

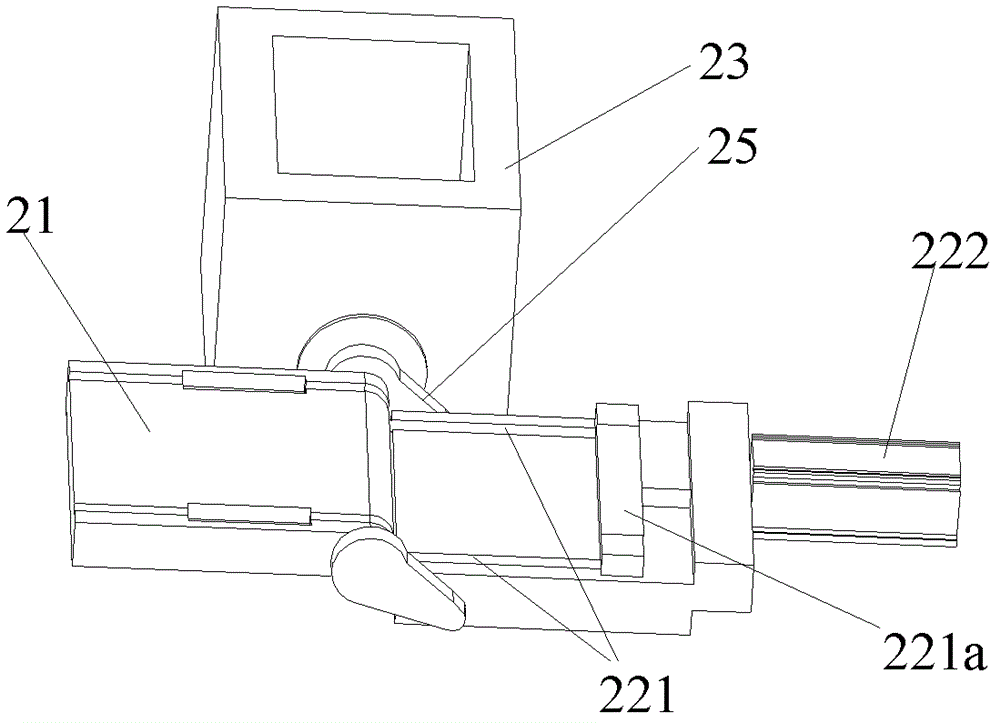

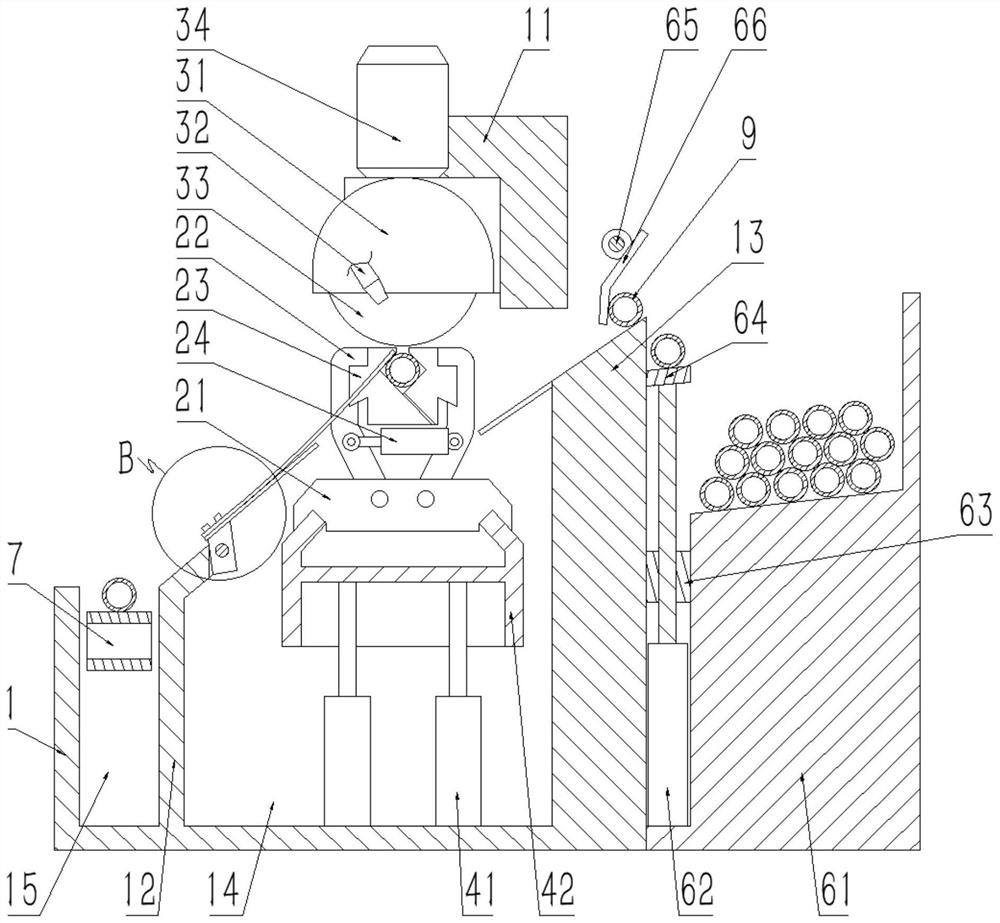

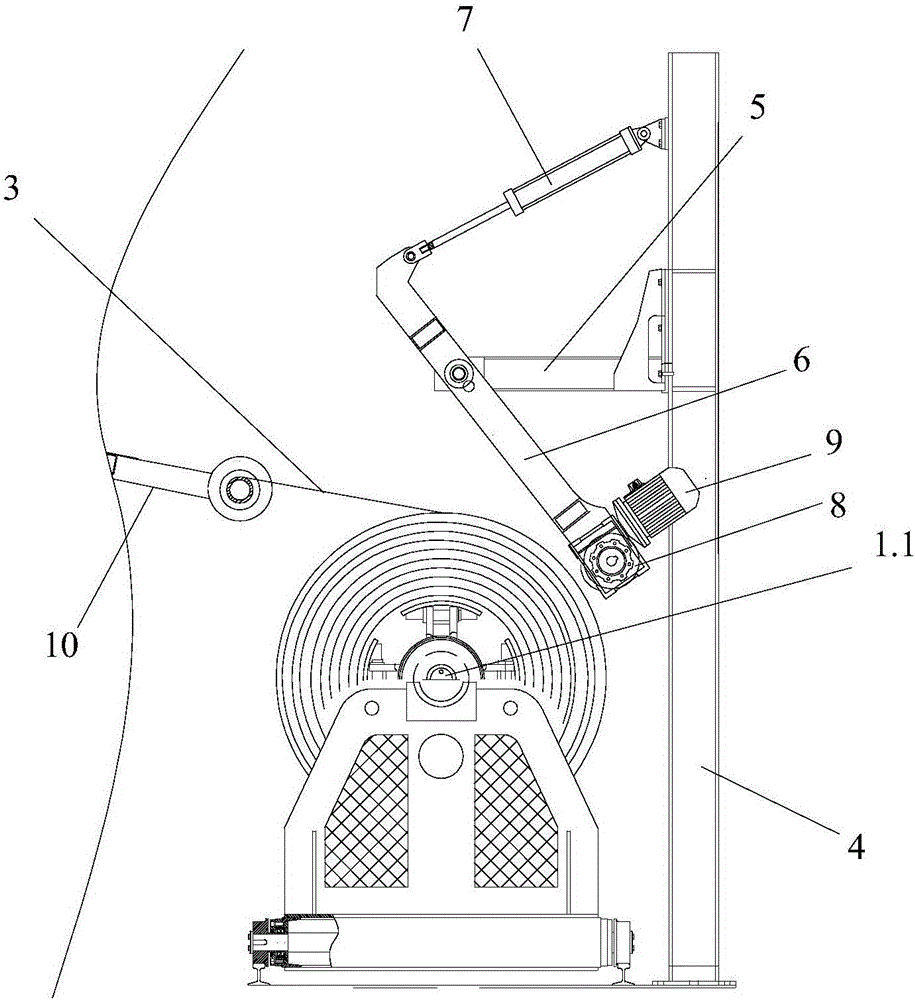

Elbow molding lantern ring all-in-one machine, and technique of elbow molding lantern ring

The invention provides an elbow molding lantern ring all-in-one machine, and a technique of the elbow molding lantern ring all-in-one machine, wherein the elbow molding lantern ring all-in-one machine comprises an elbow molding mechanism, a lantern ring mechanism and a converter, wherein a straight copper tube is bended as a U-shaped elbow by the elbow molding mechanism; the lantern ring mechanism is positioned below the elbow molding mechanism; welding rings are sleeved on outer sides of the end parts of two free ends of the U-shaped elbow by the lantern ring mechanism; the converter is movably arranged between the elbow molding mechanism and the lantern ring mechanism; and the U-shaped elbow is conveyed to the lantern ring mechanism from the elbow molding mechanism by the converter. The elbow molding lantern ring all-in-one machine disclosed by the invention has a simple structure and effectively solves the problem about low production efficiency caused by long technological process in the prior art.

Owner:GREE ELECTRIC APPLIANCES INC

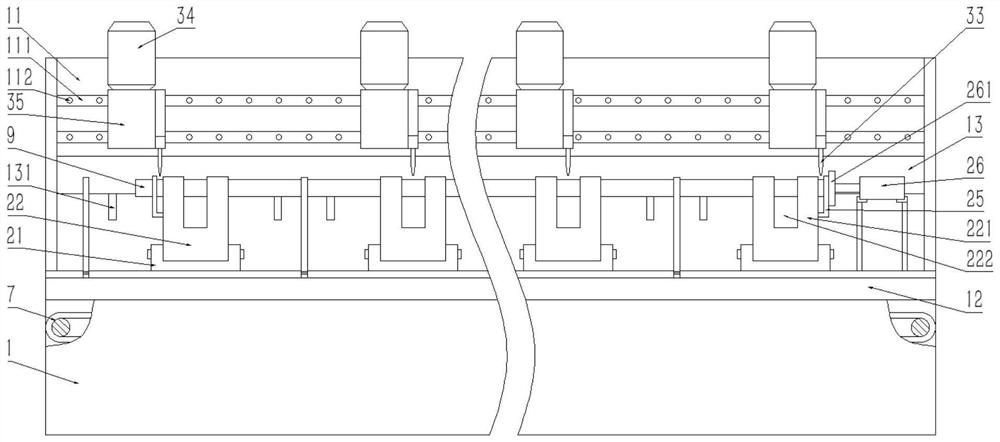

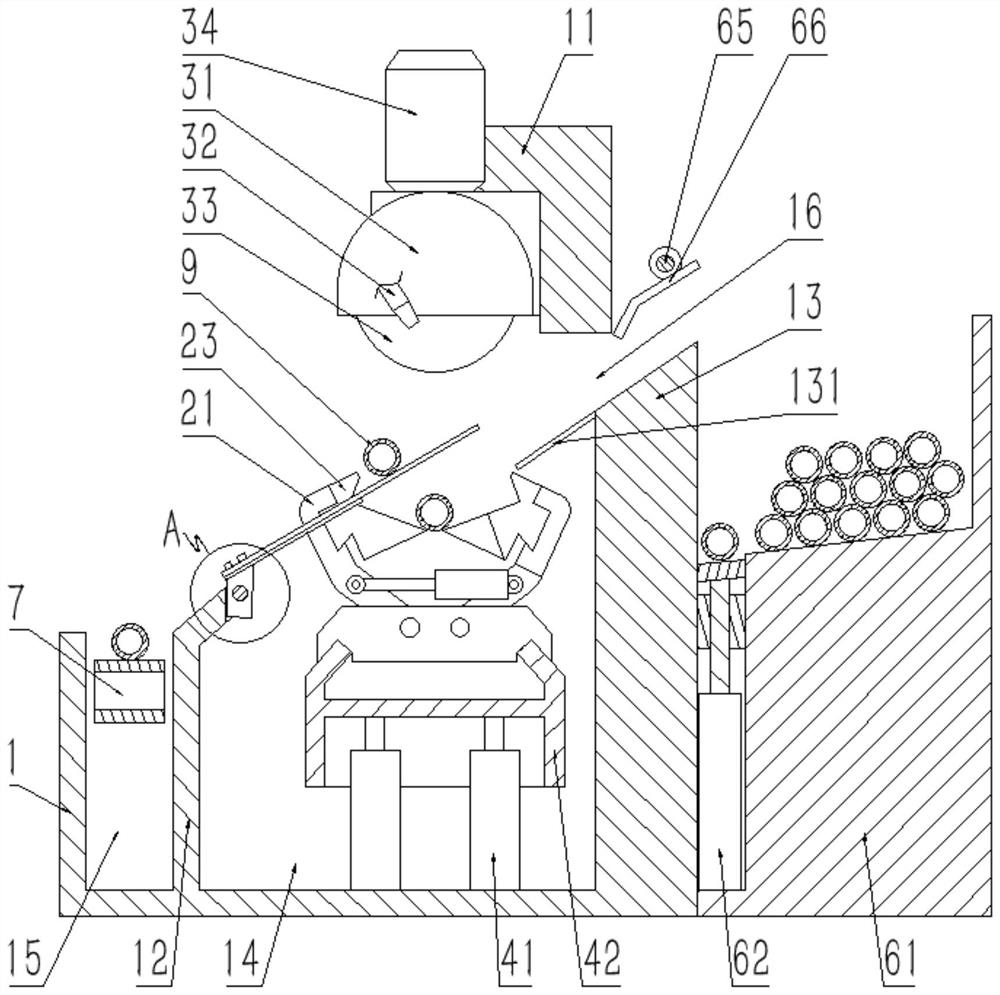

Full-automatic steel pipe cutting equipment and using method thereof

ActiveCN112916946ASolve the problem of the decline of cutting accuracySolve low production efficiencyWork clamping meansTube shearing machinesConveyor beltSteel tube

The invention relates to full-automatic steel pipe cutting equipment and a using method thereof. A steel pipe cutting assembly is fixedly mounted on a rack and used for cutting steel pipes; a steel pipe clamping assembly is used for clamping and fixing the steel pipes; and a driving assembly drives the steel pipe clamping assembly to move relative to the steel pipe cutting assembly. According to the full-automatic steel pipe cutting equipment, the steel pipes are automatically conveyed into the rack through an input assembly, the steel pipes are automatically clamped through the steel pipe clamping assembly, and the steel pipes fall onto an elastic plate of a conveying assembly after being cut, roll to conveyor belts under the gravity and finally leave the rack, so that manual participation in feeding, discharging and clamping is not needed; the problem of low production efficiency due to the fact that existing equipment needs manual feeding and discharging is solved; and the cutting assembly does not move, the steel pipes are driven by the driving assembly to move towards cutting knives, and the cutting knives do not need to move, so that the problem that the cutting accuracy of the steel pipes is reduced due to movement of the cutting knives is solved.

Owner:青岛沃明汽车管制造有限公司

Drying apparatus for flocking production

InactiveCN107388787ATo achieve the purpose of rolling reinforcement treatmentSolve the problem of easy hair lossDrying gas arrangementsDrying machines with progressive movementsAgricultural engineeringExhaust pipe

The invention discloses a drying apparatus for flocking production, comprising a base; a drying chamber is connected in a cavity in a penetrating manner, a heating chamber is connected to the inner top of the drying chamber, a heating pipe is connected in the heating chamber, a heating wire is arranged an inner cavity of the heating pipe, a radiating plate is connected to the bottom of the drying pipe, an exhaust pipe is connected to the bottom of the drying chamber in a penetrating manner, a suction fan is connected to the left of the suction pipe, a strainer is connected to the right side of the suction pipe, and a telescopic rod is connected to the left of the drying chamber. Through the use of an intake pipe, an air flow valve, the heating chamber, an intake fan, the heating pipe, the heating wire, an intake hole, heat-dissipating holes and the radiating plate, the problem that fluffs easily drop due to non-uniform heating in drying is solved; through the use of the drying chamber, the exhaust pipe, the suction pipe, the suction fan and the strainer, the problem that environmental pollution is caused by fluffs floating in air is solved.

Owner:梁留伟

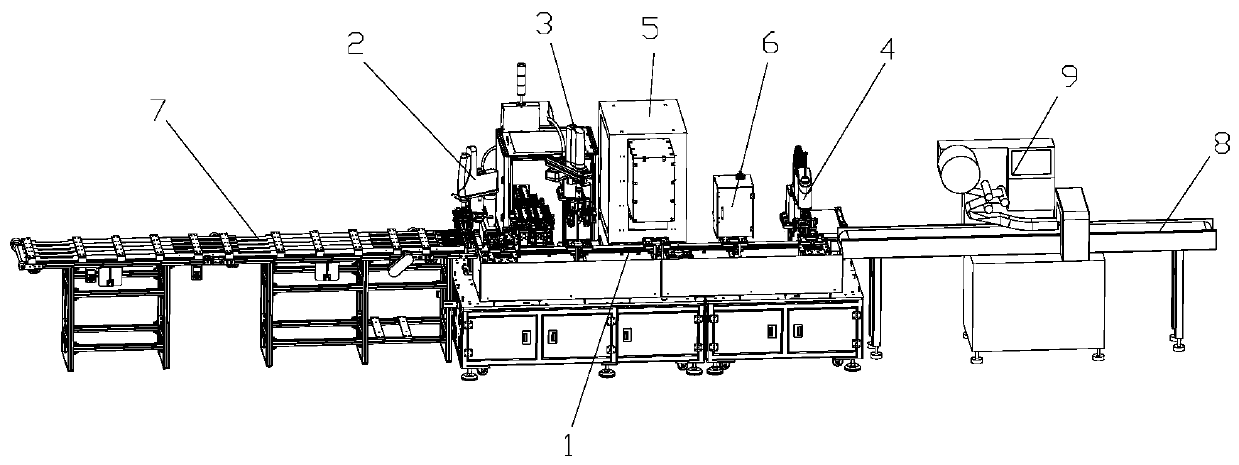

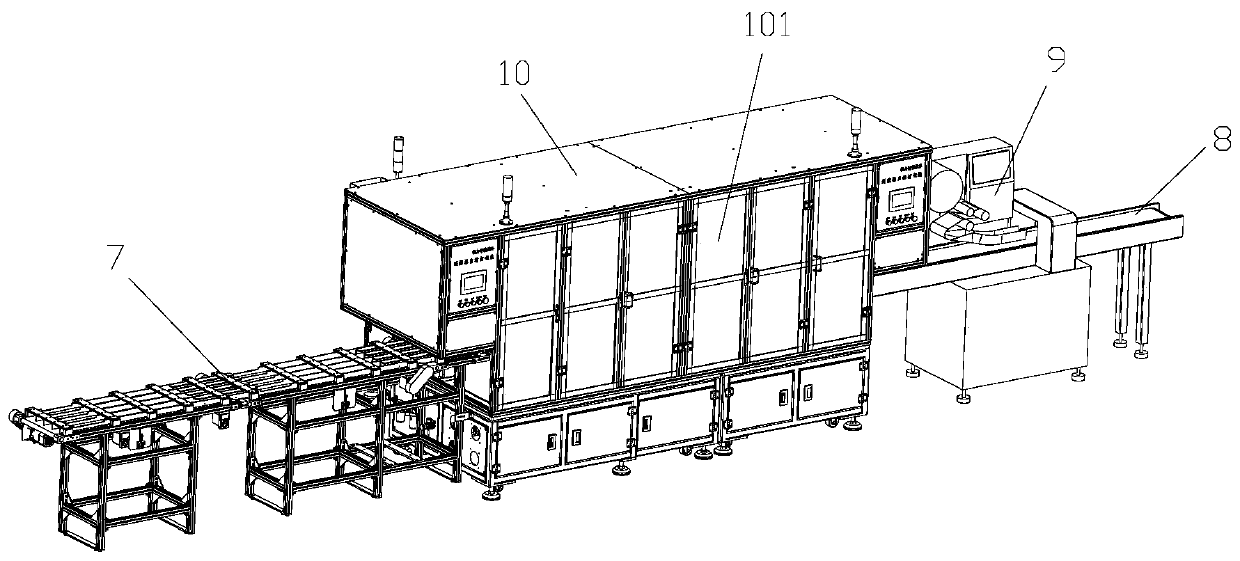

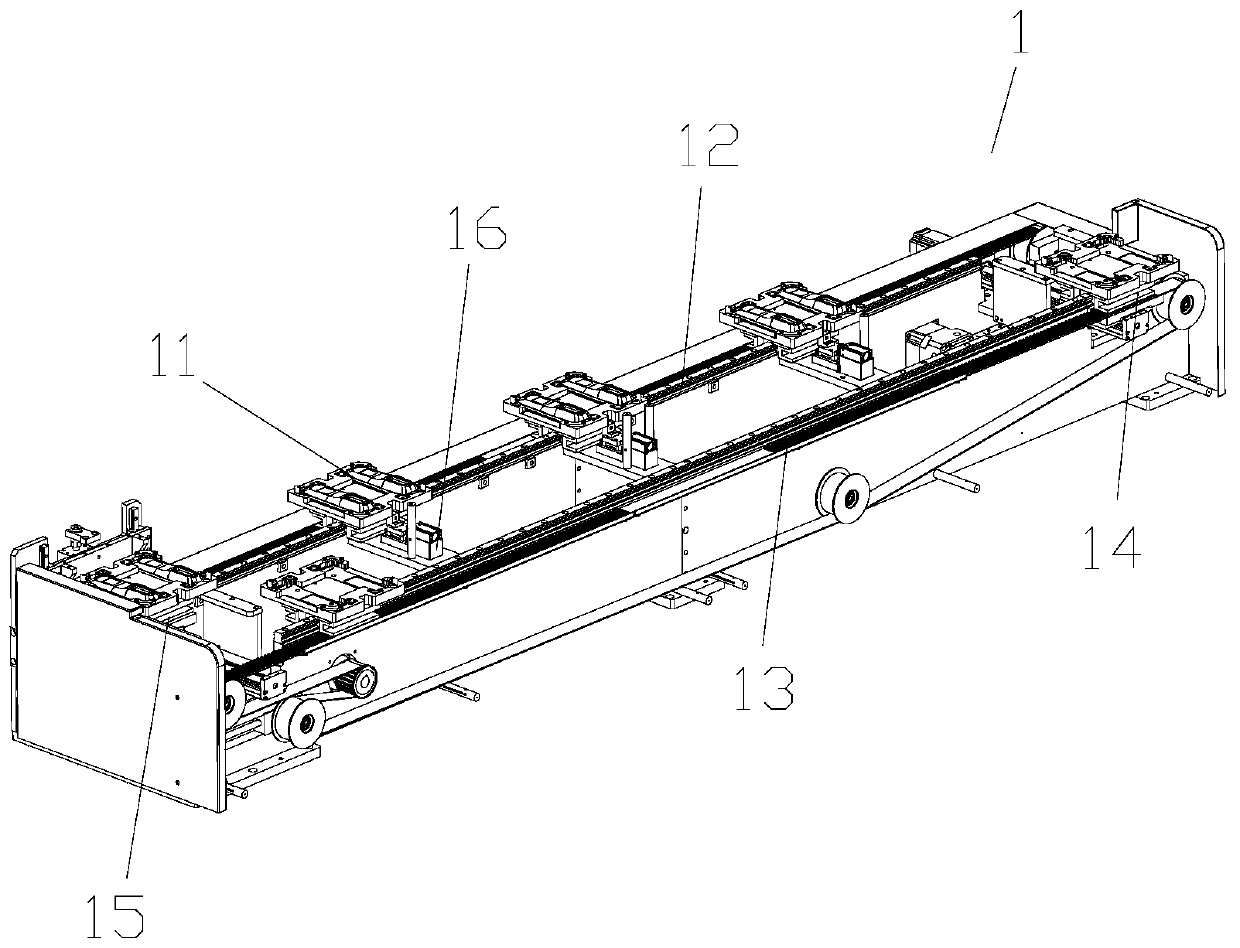

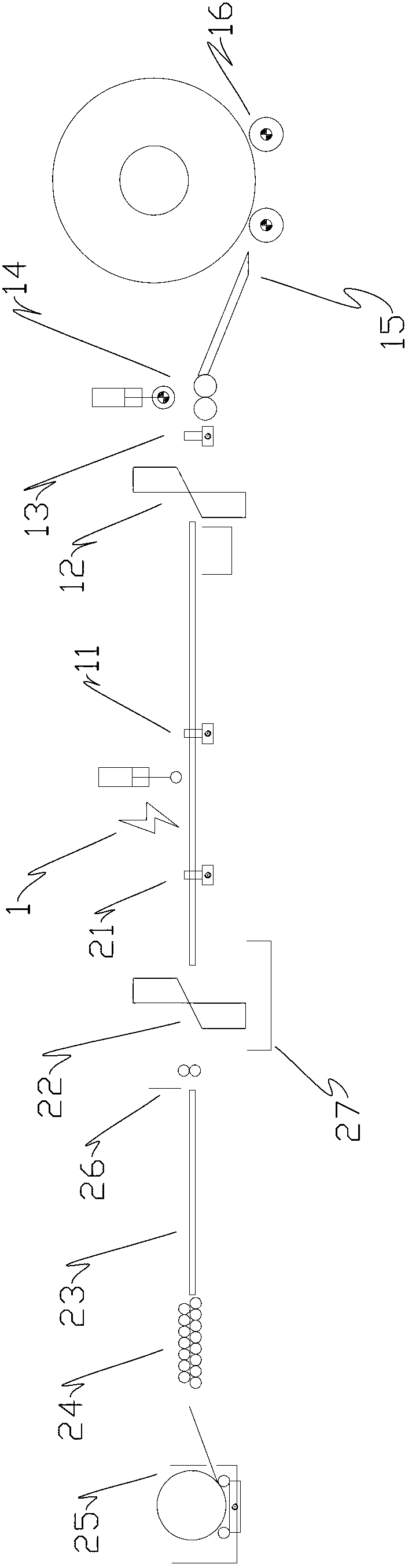

Production line

InactiveCN111002023ASolve low production efficiencyAssembly machinesMetal working apparatusEngineeringManufacturing line

The invention provides a production line. The production line comprises: a conveying structure comprising a plurality of workpiece bearing devices for bearing first workpieces, wherein the conveying structure comprises a first conveying part and a second conveying part, the first conveying part is used for conveying all the workpiece bearing devices to a discharging station from a feeding station,and the second conveying part is used for conveying the workpiece bearing devices to the feeding station from the discharging station; a feeding structure used for transferring the first workpieces to the corresponding workpiece bearing device; an assembling structure located at one side of the first conveying part, and when the first conveying part drives the corresponding workpiece bearing device to move to an assembling station, the assembling structure assembles a second workpiece to the first workpieces; and a discharging structure used for transferring the first workpieces and the second workpiece which are assembled together to a preset position. The production line solves the problem of low production efficiency of the production line in the prior art.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

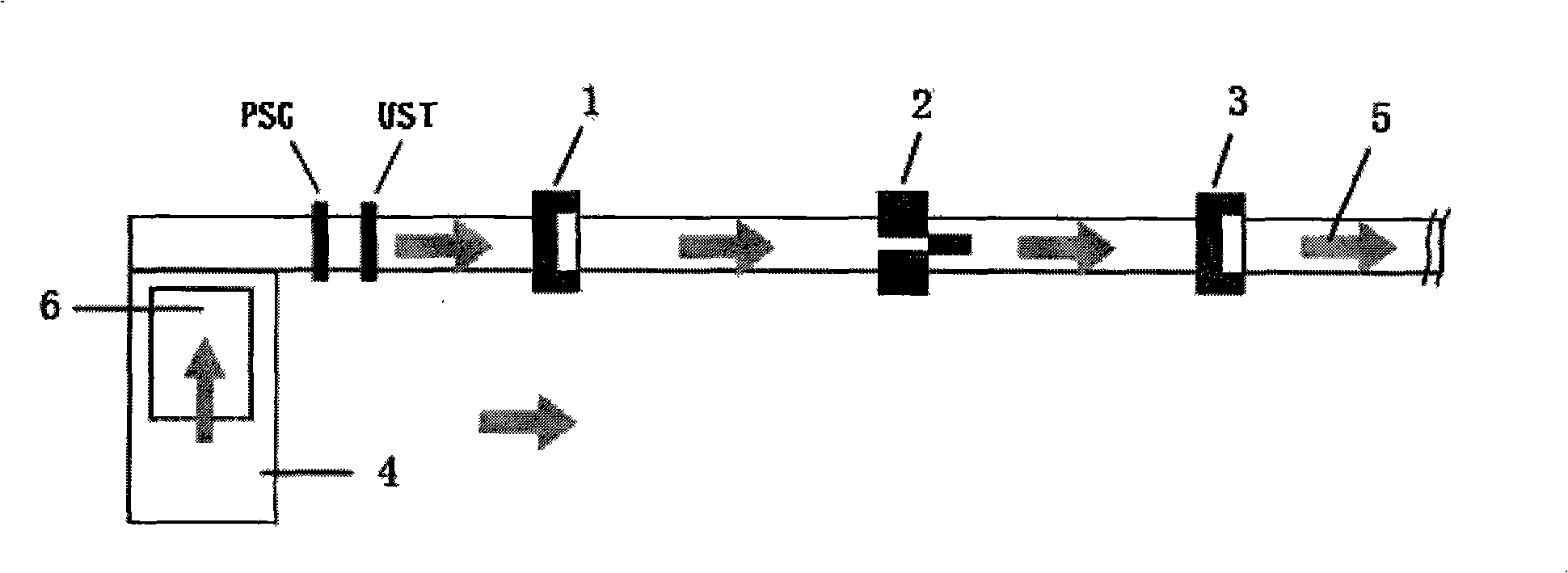

Roll core and waste and defective steel coil integrated use production line and technology

InactiveCN103341490AHigh degree of automationSolve low production efficiencyMetal rolling arrangementsProduction lineEngineering

The invention provides a roll core and waste and defective steel coil integrated use production line, and discloses a technology as for integrated use development of roll cores and waste and defective steel coils. The production line comprises a welding device, a first centering vertical roller, a first crosscutting plate shearing machine, a second centering vertical roller, a three-roller straightening pinch roll, a guide board platform and a raw material coil uncoiler, wherein the welding device is located in the middle, the first centering vertical roller, the first crosscutting plate shearing machine, the second centering vertical roller, the three-roller straightening pinch roll, the guide board platform and the raw material coil uncoiler are sequentially arranged on one side of the welding device from inside to outside, and the raw material coil uncoiler has the uncoiling function and the coiling function. A third centering vertical roller, a second crosscutting plate shearing machine, a feeding frame, a decoiler machine and an uncoiling device are sequentially arranged on the other side of the welding device from inside to outside. According to the production line and the technology, the roll cores are leveled and wound on the raw material coil uncoiler on the right side, and the leveling purpose is achieved. The roll cores are reused, meanwhile, the thickness transition sections of the roll cores are decoiled, and waste steel is changed into decoiling plates to be reused to achieve appreciation.

Owner:JIGANG GRP

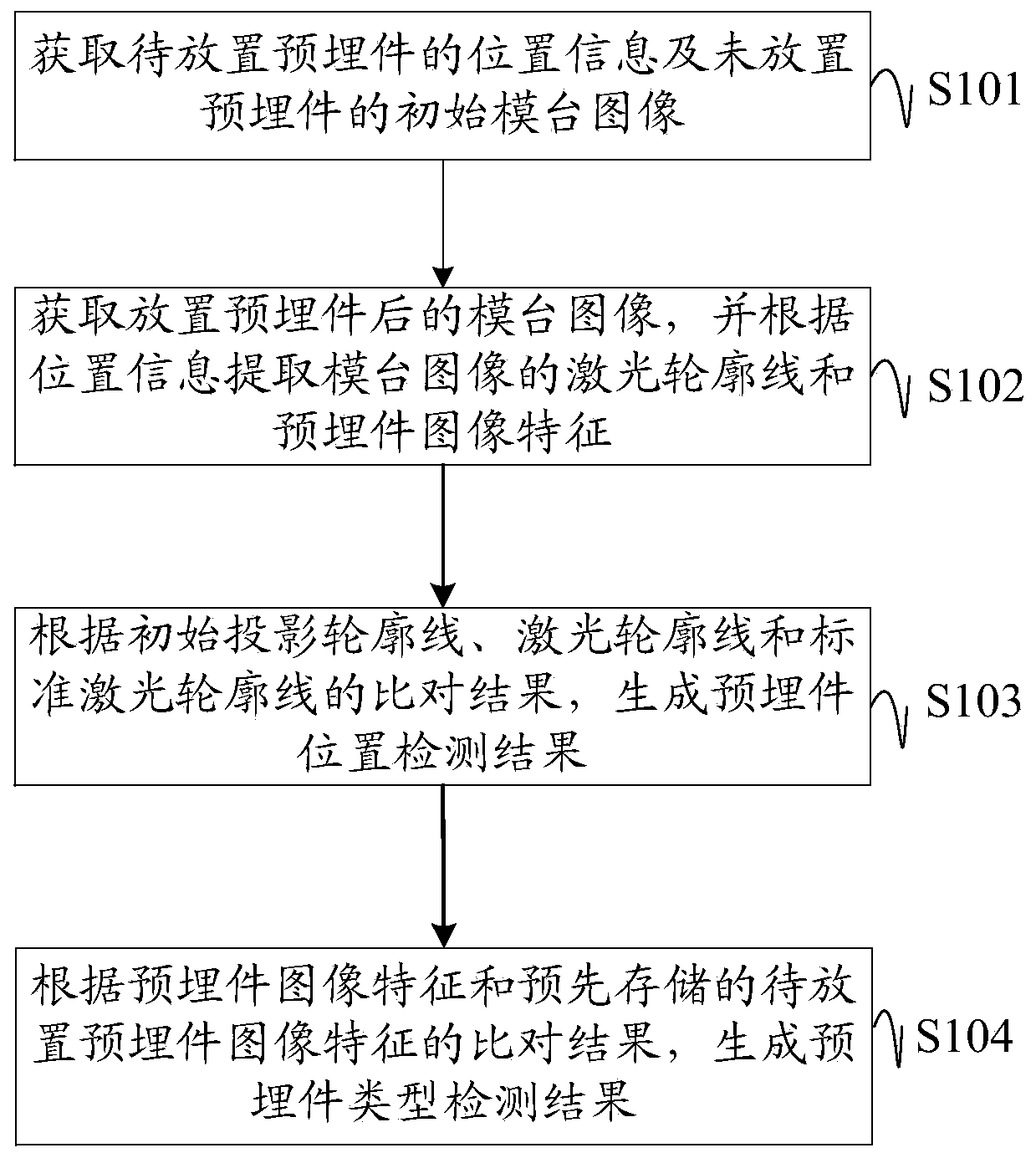

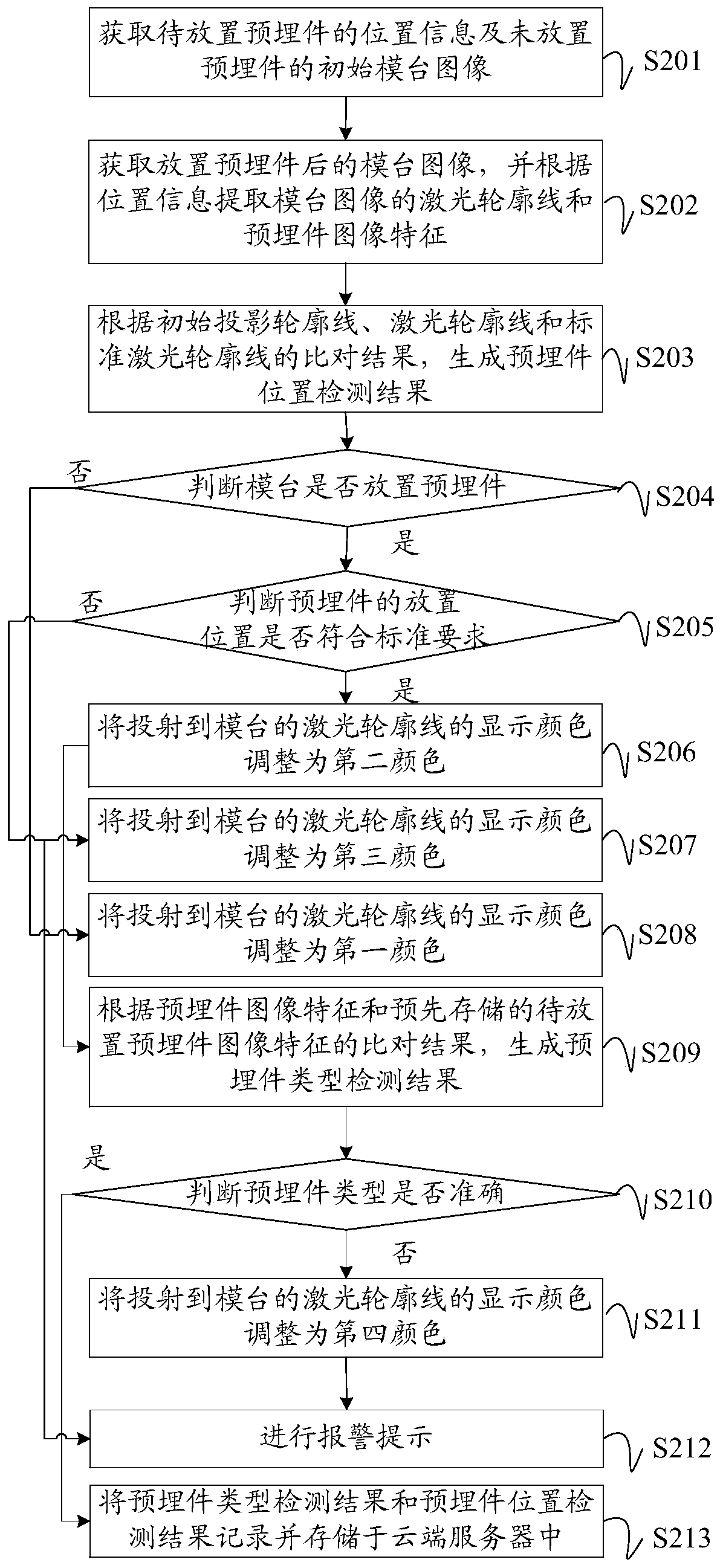

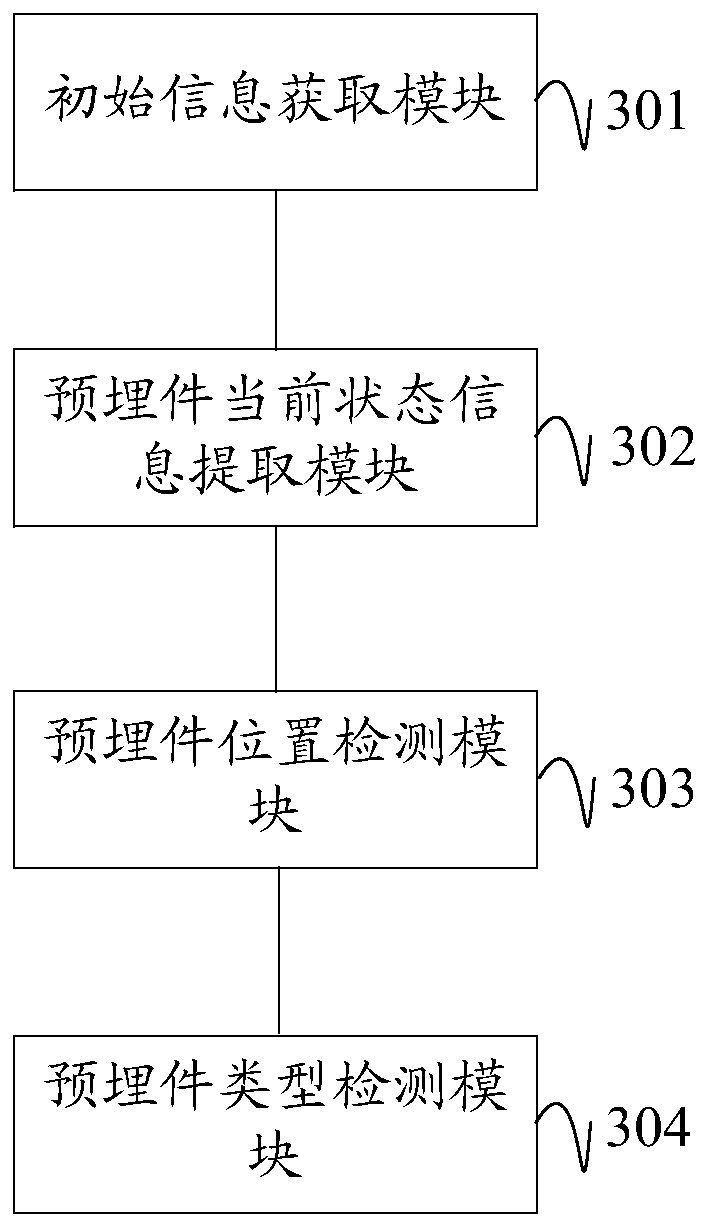

Embedded part detection method, device, equipment and system of component production line

The embodiment of the invention discloses an embedded part detection method, device, equipment and system of a component production line, wherein the method comprises the steps of: obtaining the position information of an embedded part to be placed, an initial mould platform image that an embedded part is not placed, and a mould platform image that the embedded part is placed; according to the position information, extracting the initial projection contour line in the initial mould platform image, the laser contour line in the mould platform image and the image characteristics of the embeddedpart; according to a comparison result of the initial projection contour line, the laser contour line and the standard laser contour line, generating an embedded part position detection result, wherein the standard laser contour line is a laser contour line when the placement position of the embedded part to be placed on the mould platform accords with the standard requirement; and, according to acomparison result of the image characteristics of the embedded part and the image characteristics of the embedded part to be placed, generating an embedded part type detection result; thereby, rapidand accurate detection on the placement position and the type of the embedded part can be realized; the automation degree and the production efficiency of a prefabricated part are improved; and the manual labour workload is reduced.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

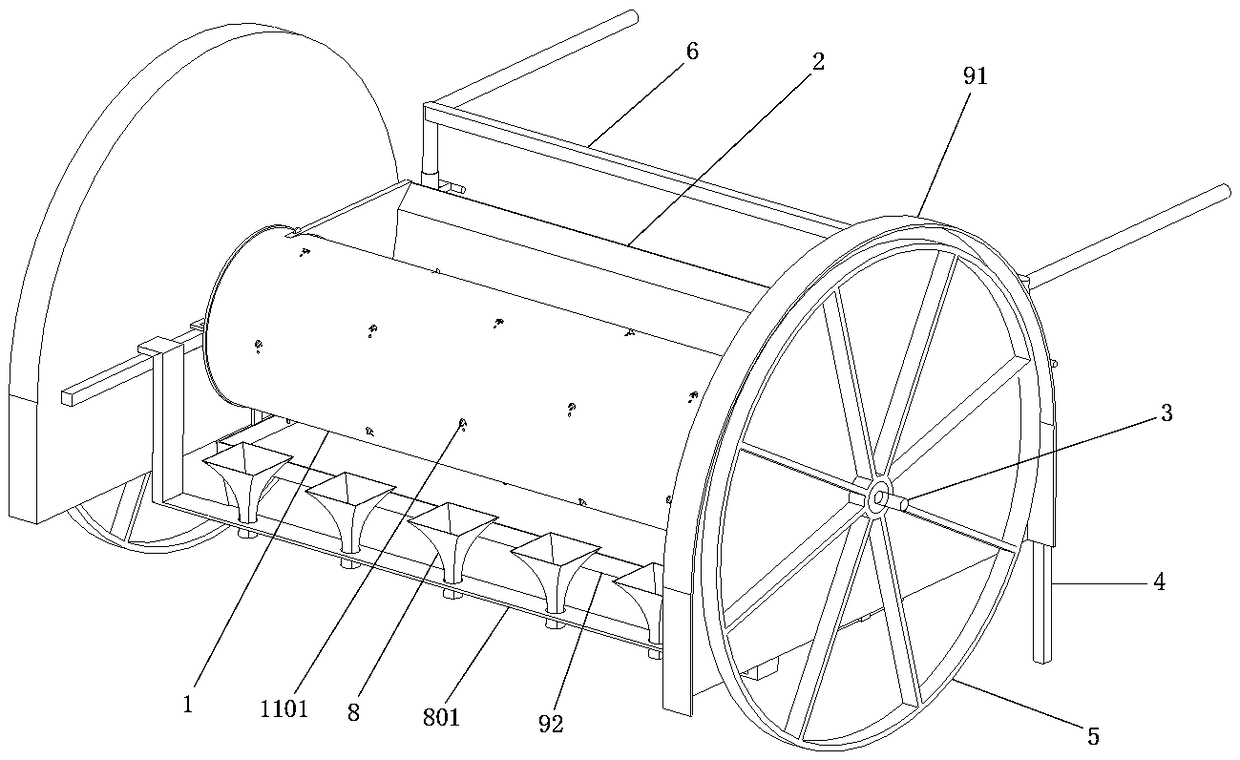

planter

ActiveCN107155467BPromotes even spreadingIncrease productivitySeed depositing seeder partsRegular seed deposition machinesAgricultural engineeringGrain quality

The invention provides a seeder. The seeder comprises a frame, road wheels, a handle, a rotating shaft, clutch devices, a roller, a four-wheel bucket and funnels, the rotating shaft is arranged at the middle of the frame, the handle is arranged at the rear end of the frame, the rotating shaft is connected with the road wheels through the clutch devices, the rotating shaft is fixedly provided with the roller, and the roller is in rolling connection with the four-wheel bucket, wherein the roller comprises basting spoons, the basting spoons can scoop up seeds in the four-wheel bucket with the rotating of the roller, and pour the seeds into the funnels, and the seeds fall to the ground from the funnels. The gaps and the quantities of the basting spoons are determined as demanded, so the spacing of the seeds falling to the ground can be controlled. The seeds are scooped up by the basting spoons and then fall to the ground without directly depending on the gravity, and the grain qualities of the seeds scooped up by the basting spoons every time are consistent, so the grains quality during seeding can be controlled. The seeder is operated manually, is suitable for continuous seeding in hilly areas, and can improve the production efficiency and the yield of rice.

Owner:吴之旺

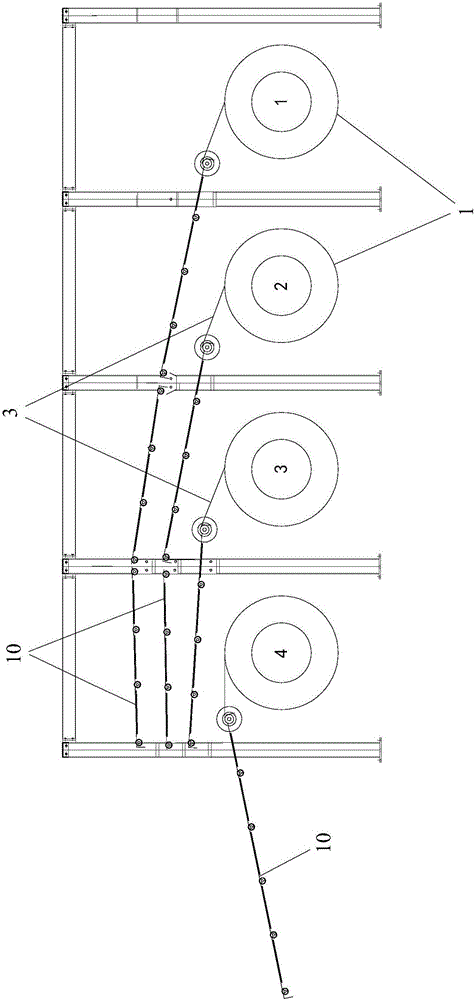

Multi-coiled panel veneer simultaneous feeding and automatic quick converting equipment and quick converting method thereof

The invention provides multi-coiled panel veneer simultaneous feeding and automatic quick converting equipment which comprises at least two metal coiled panel veneer feeding units and a metal coiled panel veneer converting mechanism; each metal coiled panel veneer feeding unit comprises an uncoiling machine used for leveling the metal coiled panel veneer, a driving device, a coiling device used for pushing the metal coiled panel veneer and delivery platforms; the metal coiled panel veneer converting mechanism comprises a lifting platform, a connection rack and a delivery standard plane; the connection rack is provided with delivery wires with the number the same as that of the delivery platforms; and one end of the connection rack is connected with the delivery platform, and the other end is connected with the lifting platform and is opposite to the delivery standard plane, thus realizing lifting of the connection rack under the driving of the lifting platform so as to achieve butt joint of the delivery wires with the delivery standard plane. The equipment not only can save a large quantity of manpower and time, but also can greatly improve the production efficiency and reduce the production cost. The invention further provides a multi-coiled panel veneer quick converting method, and the method can realize quick and accurate conversion of fed metal coiled panel veneers of different specifications.

Owner:佛山市三水雄金机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com