Fermented grains discharging device for liquor making

A liquor and vertical shaft technology, which is applied to the field of liquor solid-state jar fermentation and wine-making machinery, can solve the problems of damage to the pottery fermented grain jar, affecting liquor production, high labor intensity, etc. Solve the effect of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

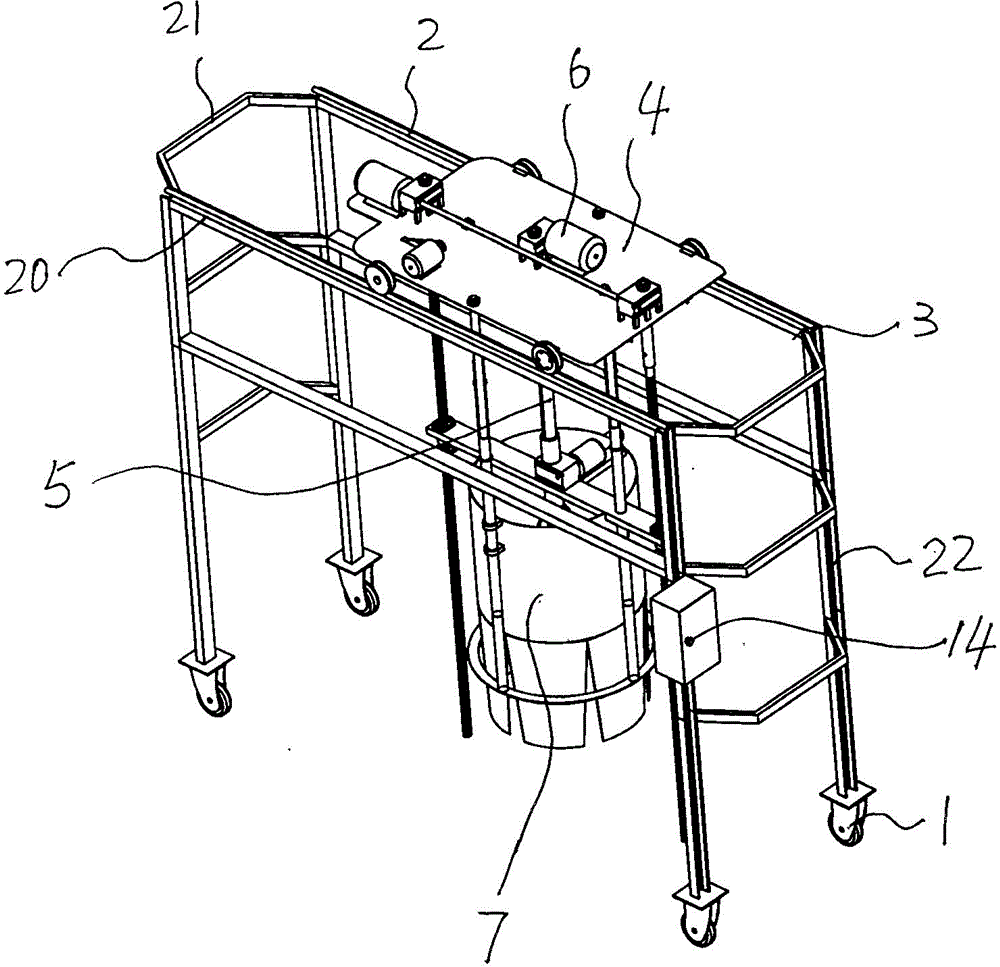

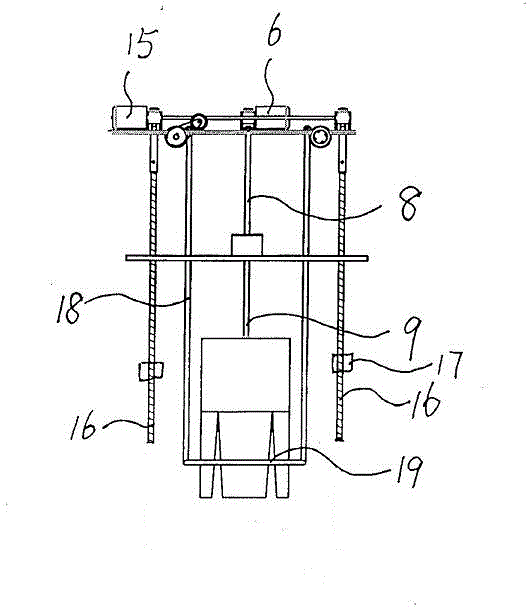

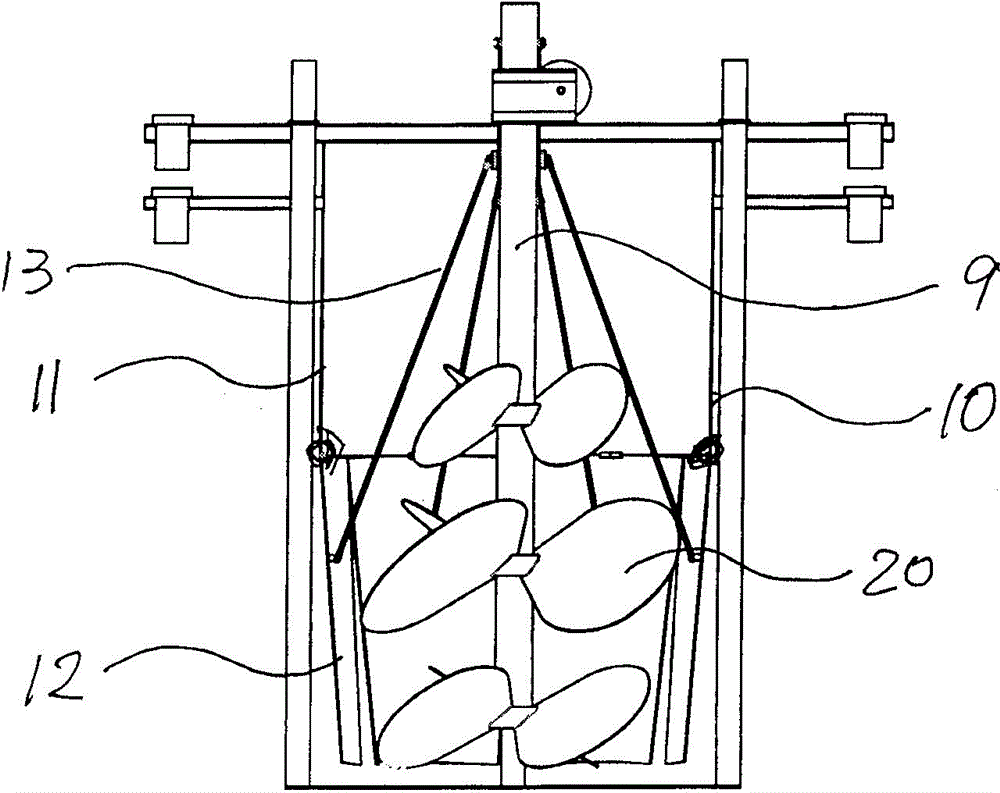

[0027] Such as figure 1 Shown is a schematic structural view of a fermented grains discharging device for making liquor provided by the present invention. The structure constituting the unstrained spirits device includes a frame 3 composed of crossbeams 20, side beams 21 and pillars 22. Mobile rollers 1 are arranged at the bottom of the frame, and guide rails 2 are arranged on the top crossbeam. The guide rail 2 is provided with a trolley mechanism 4 that can move along it; on the lower side of the trolley mechanism and is located in the frame body, there is a grain storage unit that is connected with the power transmission mechanism 6 that is arranged on the trolley mechanism through a vertical shaft 5. Material mechanism 7, the unloading grain receiving mechanism 7 can move on the guide rail 2 with the pulley mechanism controlled by the power transmission mechanism 6, and at the same time, the elongation or shortening of the vertical axis 5 is controlled by the power transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com