Automobile steering device gear case transmission aluminum alloy shell and preparation method thereof

A technology of automobile steering gear and gearbox, which is applied to belts/chains/gears, mechanical equipment, transmission parts, etc. It can solve the problems of low product qualification rate, slow production cycle, waste of raw materials, etc., and achieve high product qualification rate, The effect of reducing labor intensity and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

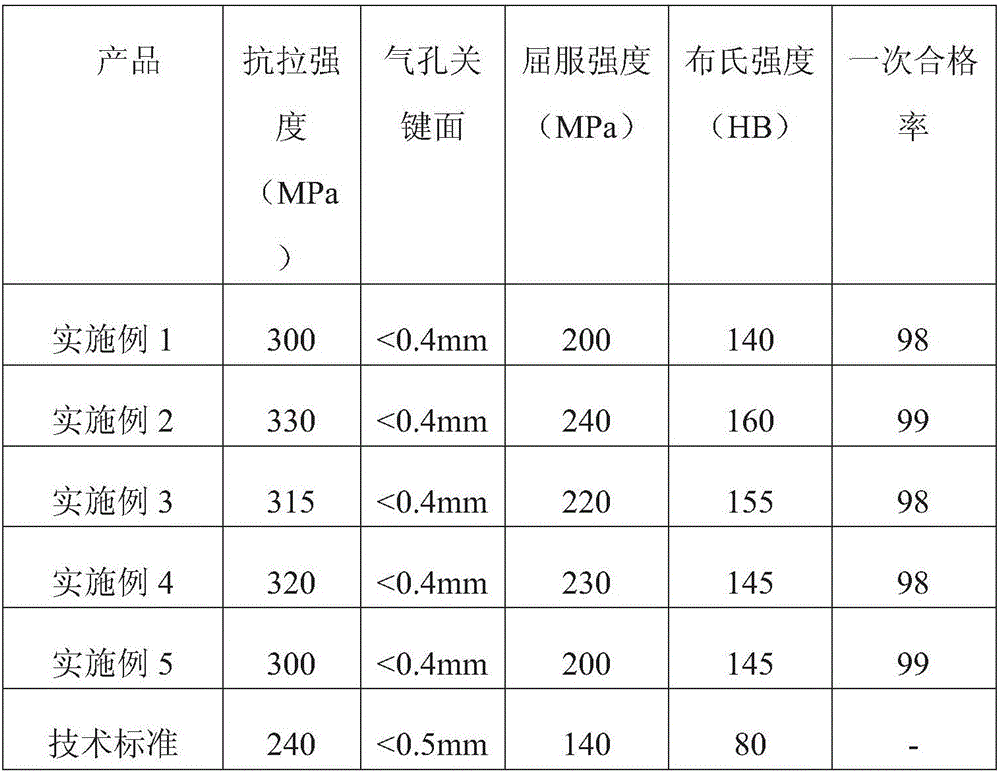

Embodiment 1

[0028] An aluminum alloy casing for an automobile steering gear gearbox transmission, consisting of the following components in weight percentage: 9.5% silicon, 1.0% iron, 3.5% copper, 0.18% magnesium, 0.5% zinc, 0.05% chromium, 0.15% nickel, Tin 0.27%, titanium 0.3%, lead 0.45%, manganese 0.65%, and the balance is aluminum.

[0029] The smelting furnace is heated to above 600°C, and silicon, iron, copper, magnesium, zinc, chromium, nickel, tin, titanium, lead, manganese and aluminum are added into the furnace according to the above-mentioned weight ratio. Continue to heat the above mixed material, and when the temperature of the mixed material rises to 720°C±10°C, add a three-in-one refining agent with an amount of 0.1%-0.8% of the mixed material for low-temperature refining, and use a bell jar to put the three-in-one refining agent Press into the mixed material liquid and perform circular stirring for 5-15 minutes, use 99.99% argon for degassing operation for 3-15 minutes, a...

Embodiment 2

[0033] In this embodiment, the aluminum alloy casing of the automobile steering gear gearbox transmission is composed of the following components in weight percentage: 9.5% silicon, 1.4% iron, 4.0% copper, 0.6% magnesium, 1.2% zinc, 0.14% chromium, Nickel 0.33%, tin 0.26%, titanium 0.2%, lead 0.3%, manganese 0.65%, and the balance is aluminum. .

[0034] The above-mentioned aluminum alloy casing of the automobile steering gear gearbox transmission is obtained by the same method as in Example 1.

[0035]Compared with the existing automobile steering gear gearbox transmission aluminum alloy shell products, the automobile steering gear gearbox transmission aluminum alloy casing prepared in this embodiment passes through modern simulation means (mold flow analysis), and the first pass rate of the product is 99% , After the aluminum liquid undergoes metamorphic treatment, the porosity and mechanical properties of the product are 8% better than the same product in the market, and t...

Embodiment 3

[0037] In this embodiment, the aluminum alloy casing of the automobile steering gear gearbox transmission is composed of the following components in weight percentage: 8% silicon, 1.2% iron, 2.5% copper, 0.15% magnesium, 0.5% zinc, 0.05% chromium, 0.05% nickel, 0.05% tin, 0.1% titanium, 0.1% lead, 0.05% manganese, and the balance is aluminum. .

[0038] The above-mentioned aluminum alloy casing of the automobile steering gear gearbox transmission is obtained by the same method as in Example 1.

[0039] Compared with the existing aluminum alloy casing products of automobile steering gear gearbox transmission, the aluminum alloy casing of automobile steering gear gearbox transmission prepared in this embodiment has passed modern simulation means (mold flow analysis), and the first pass rate of the product is 98%. , After the aluminum liquid undergoes metamorphic treatment, the porosity and mechanical properties of the product are 7% better than the same product in the market, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com