Device for eliminating internal stress of U-shaped bent pipe by performing heating and annealing

A technology of bending pipe heating and U-shaped pipe, applied in heat treatment furnaces, furnace types, heat treatment equipment, etc., can solve the problems of poor quality, oxidation of the inner wall of the U-shaped pipe bend, and difficulty in reaching high-precision stainless steel pipes, etc. Achieve the effect of improving product quality, solving low production efficiency, and preventing heating and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

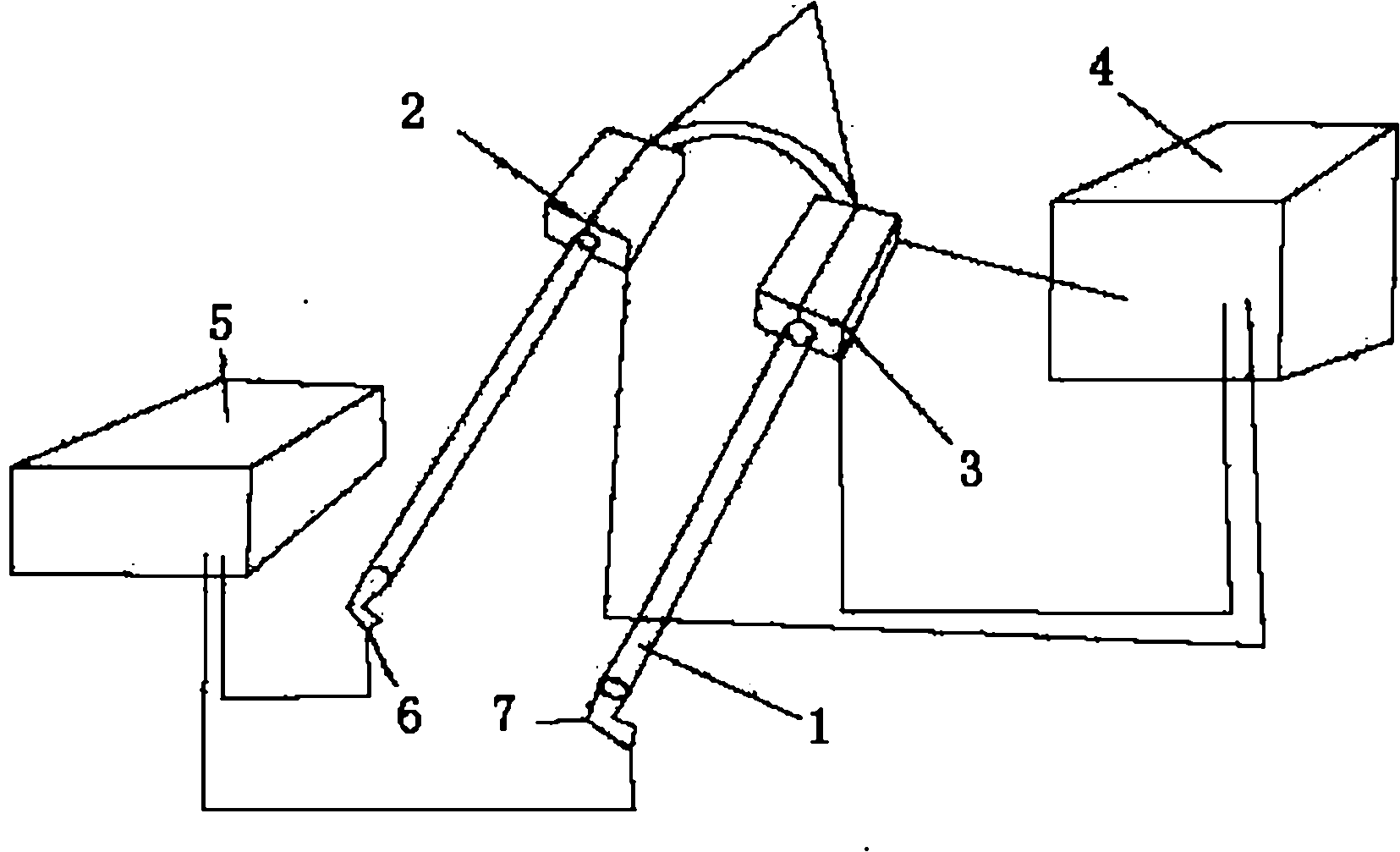

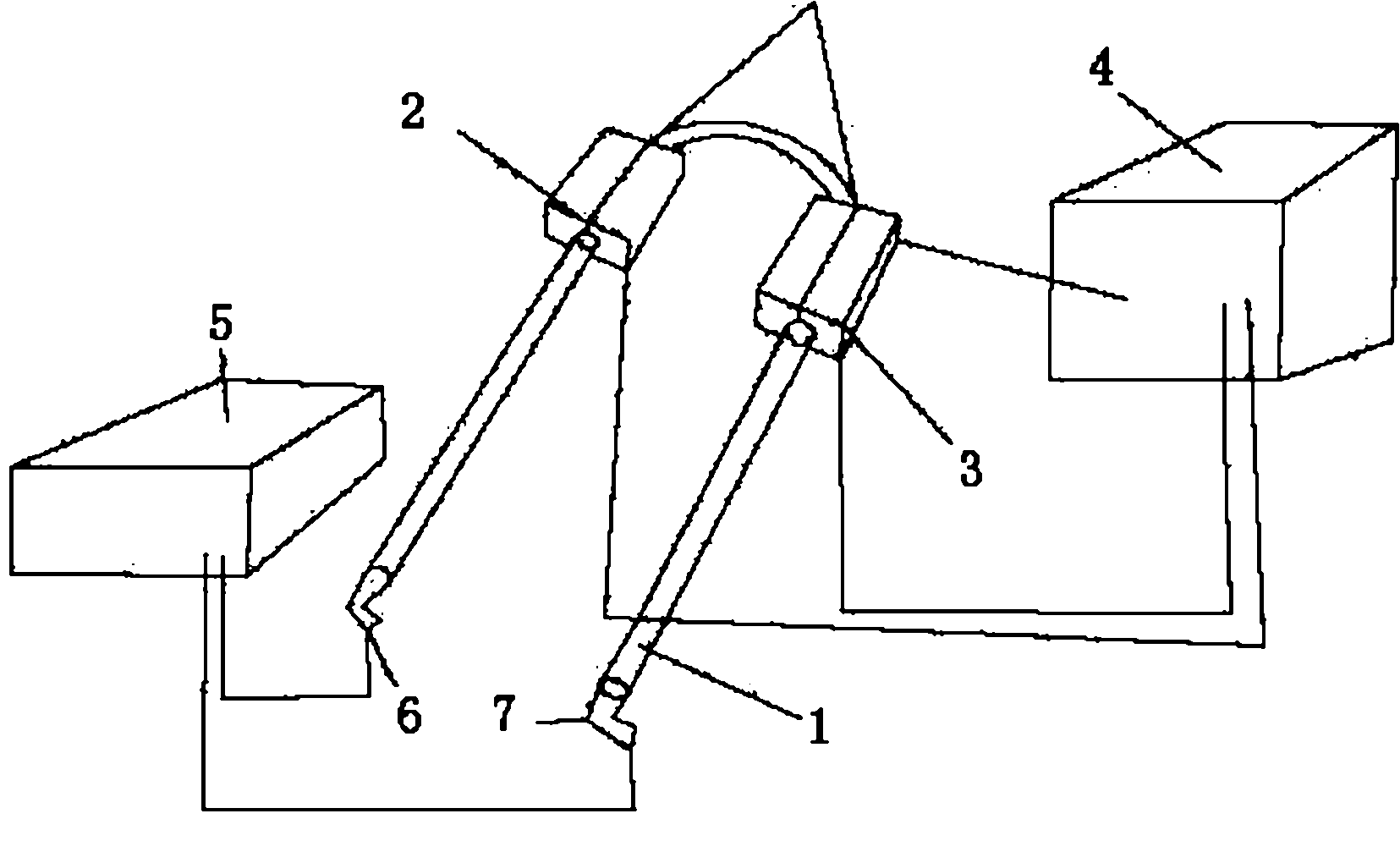

[0010] Depend on figure 1 It can be seen that the present invention includes: U-shaped pipe 1; also includes: parallel first guide rail 2 and second guide rail 3; the chuck on the top of the first guide rail 2 is in contact with the top of the bend of the U-shaped pipe 1 , the chuck on the top of the second guide rail 3 is in contact with the root of the bend of the U-shaped pipe 1; the first guide rail 2 and the second guide rail 3 are respectively connected with the high-frequency heater 4 to form a heating circuit.

[0011] Also includes: a protective gas device 5, a first air gun 6 and a second air gun 7; one end of the first air gun 6 and the second air gun 7 is connected to the protective gas device 5 respectively, the first air gun 6 and the second air gun 7 The other end of the tube is inserted into the two ends of the U-shaped pipe 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com