Patents

Literature

34results about How to "Solve the problem of low production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

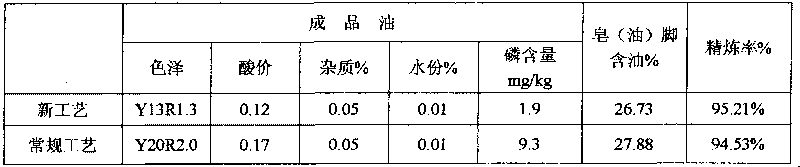

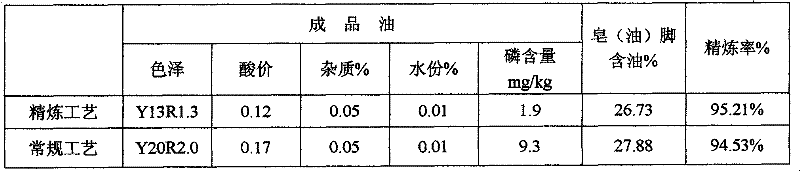

Novel process for refining oil-tea camellia seed crude oil

ActiveCN101735886AReduce side effectsLow reaction temperatureFatty-oils/fats refiningOil and greaseVegetable oil

The invention discloses a novel process for refining oil-tea camellia seed crude oil, which belongs to the technical field of grease refining in the fine and further processing of farm and sideline products. A process flow comprises the following steps: filtering the oil-tea camellia seed crude oil to eliminate impurities; performing a first low temperature acid reaction; performing low temperature alkali refining; removing soap; performing water washing after first acid adding; performing second water washing; and de-coloring and deodorizing the obtained product to obtain first-level oil-tea camellia seed oil. The novel process is characterized by improving the oil obtaining rate of refining, lowering production cost, improving product quality and stability and the like, and is used for refining the oil-tea camellia seed crude oil and refining rap oil, peanut oil and other vegetable oil.

Owner:HUNAN XINJINHAO TEA OIL

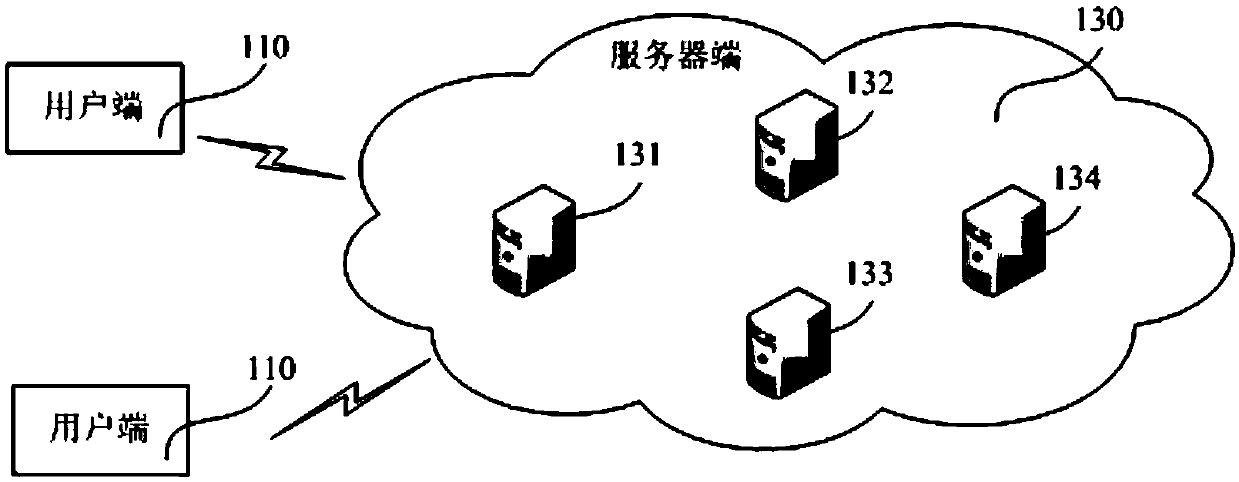

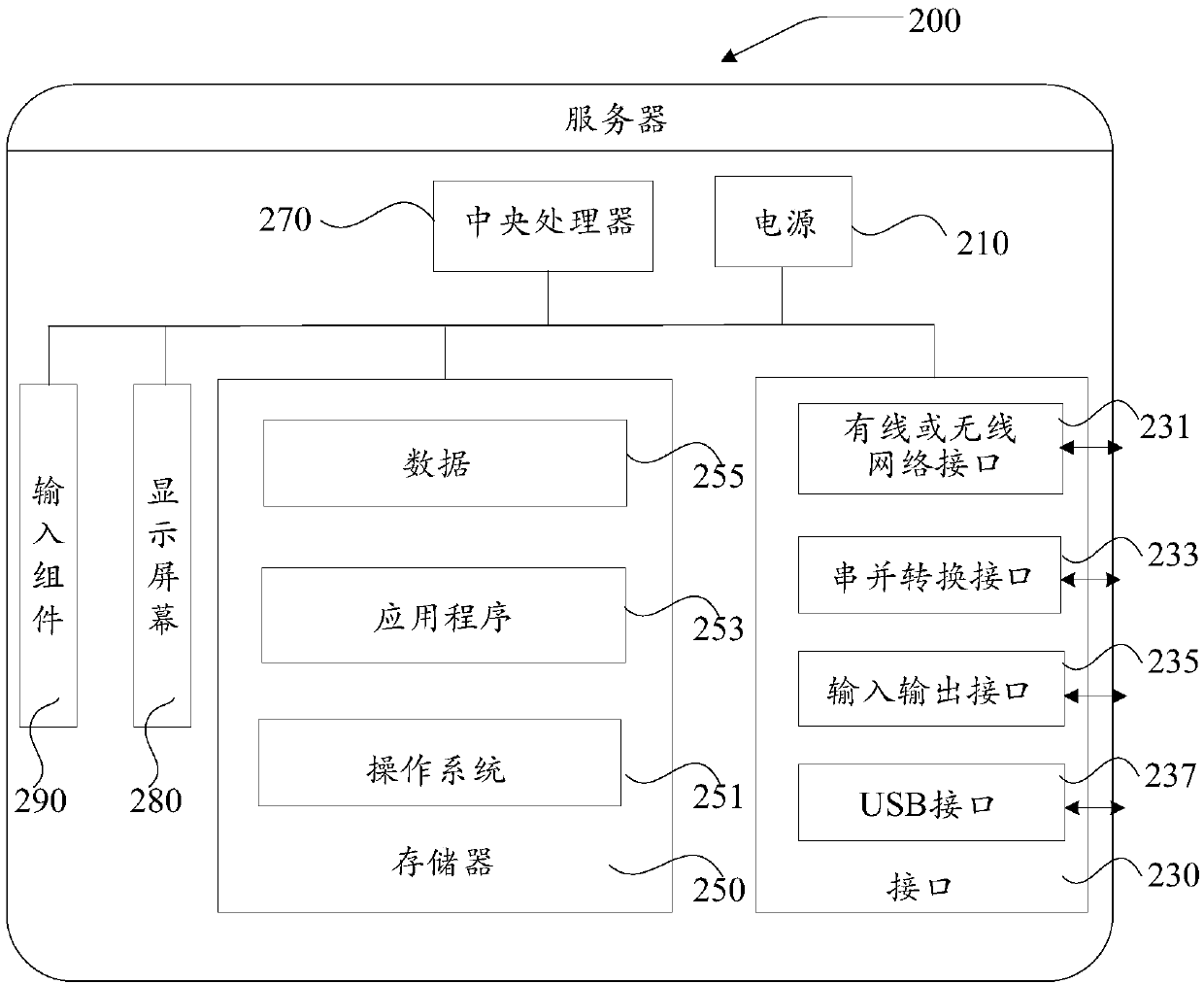

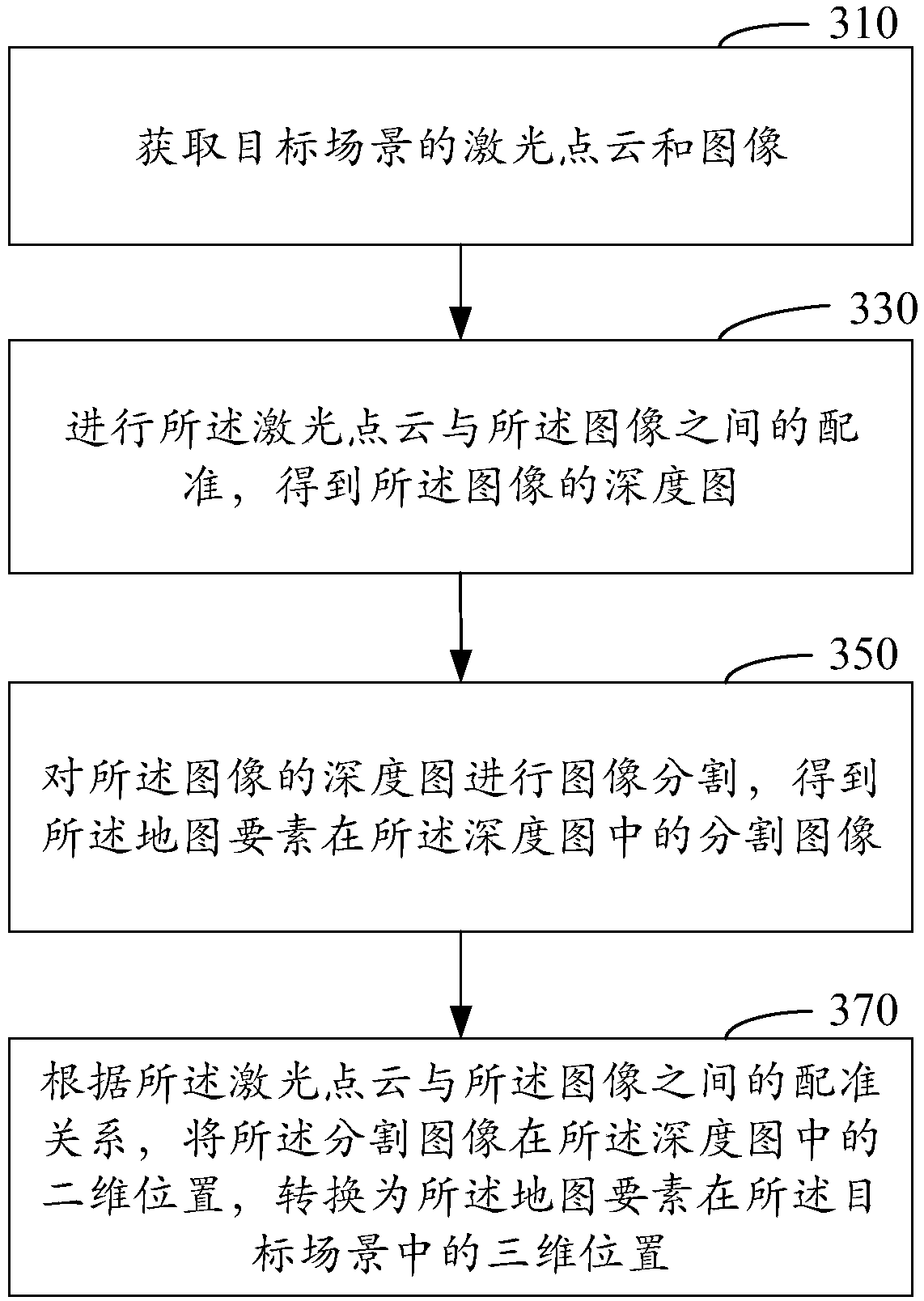

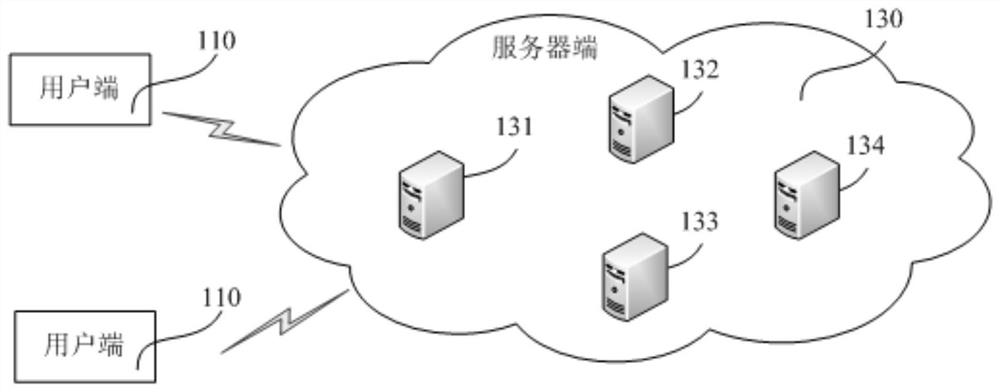

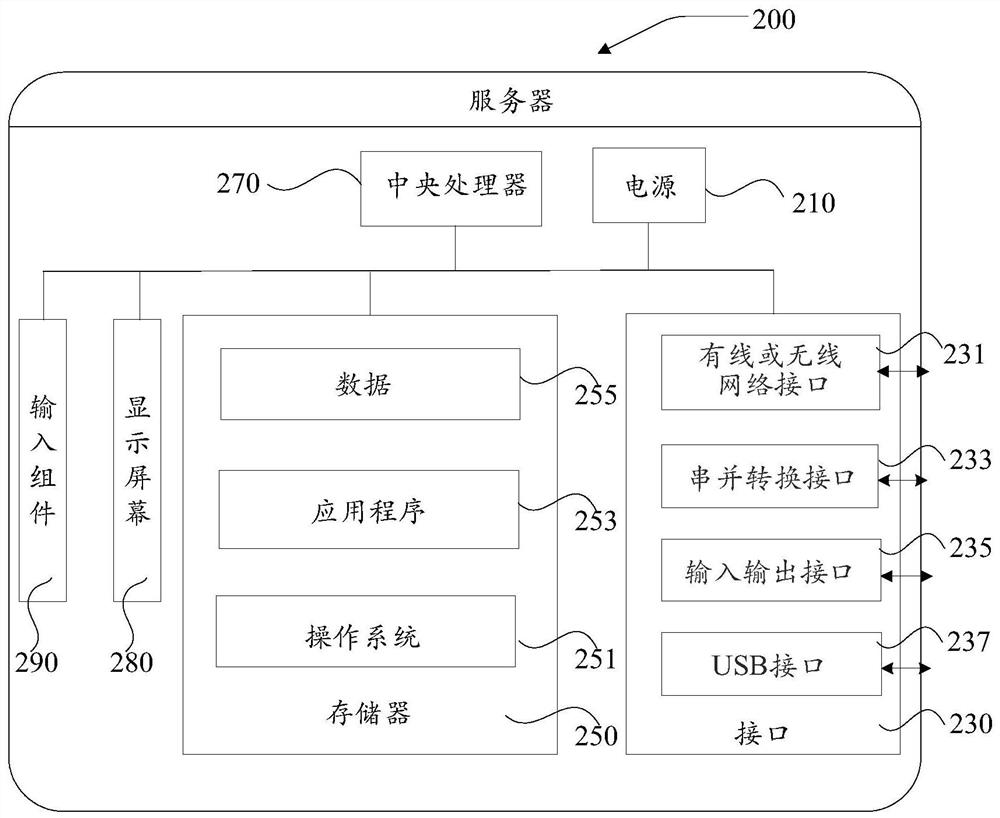

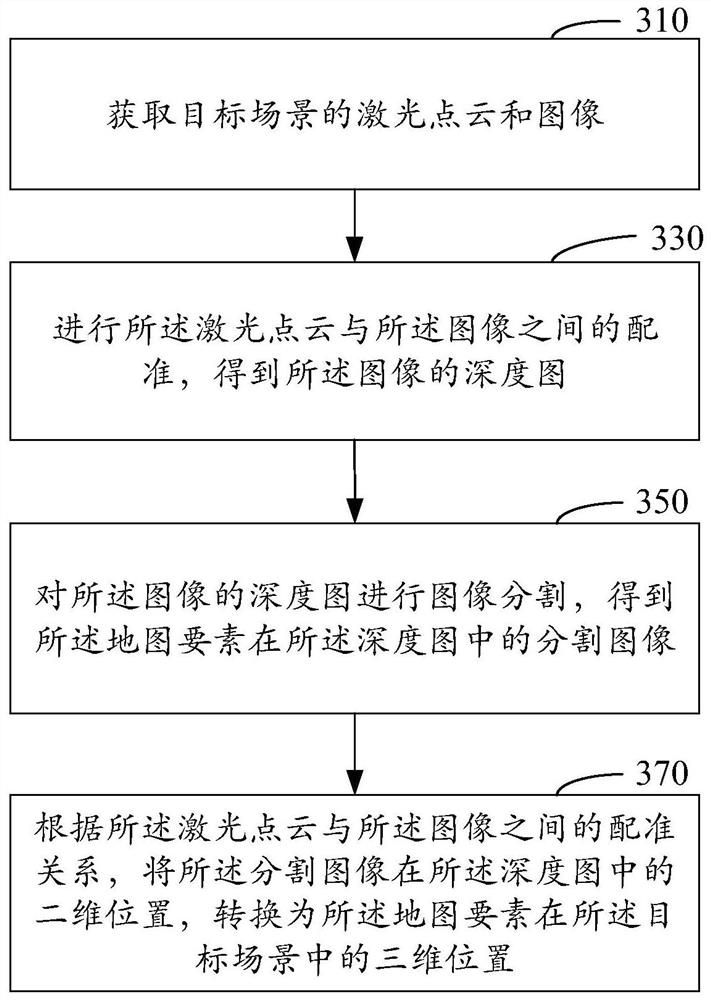

Map element extraction method and device and server

ActiveCN110160502AImage Segmentation AccurateGuaranteed accuracyImage enhancementImage analysisPoint cloudImage segmentation

The invention discloses a map element extraction method and device and a server. The map element extraction method includes the following steps: obtaining a laser point cloud and an image of a targetscene, wherein the target scene includes at least one element entity corresponding to map elements; registering the laser point cloud and the image to obtain a depth map of the image; performing imagesegmentation on the depth image of the image to obtain a segmented image of the map elements in the depth map; and converting a two-dimensional position of the segmented image in the depth map to three-dimensional positions of the map elements in the target scene according to a registration relationship between the laser point cloud and the image. The map element extraction method and device andthe server provided by the invention are used to solve the problem of low production efficiency of a high-precision map in the prior art.

Owner:TENCENT TECH (SHENZHEN) CO LTD

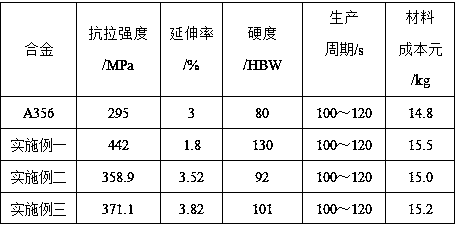

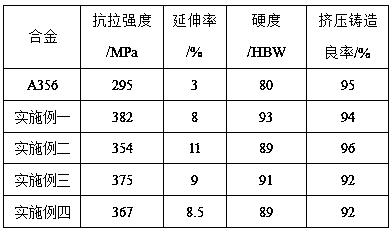

Rare earth aluminum alloy material and preparation method thereof

ActiveCN110885940AGood casting performanceReduce dendrite spacingCastabilityUltimate tensile strength

On one hand, the invention provides a rare earth aluminum alloy material comprising the following components by mass: 6%-8% of Si, 1.5%-4.5% of Cu, 0.2%-0.5% of Mg, 0.3%-0.8% of Mn, 0.2%-0.5% of Re, 0.1%-0.2% of Ti, 0.01%-0.05% of Sr and 80%-89% of Al; the Re is mischmetal containing Ce and La, and the Ti, Si, Ce and La rare earth elements are introduced into aluminum alloy; the castability of thealuminum alloy is improved effectively, and the freezing range and dendrite arm spacing of the alloy are reduced; the rare earth aluminum alloy material is higher in strength and plasticity; the component requirements of the rare earth aluminum alloy material are lower, and high purity Al ingots and expensive Zr, V and Y alloys are not required; the production cost is low, and the rare earth aluminum alloy material is high in industrial value. On the other hand, the invention provides a preparation method of the rare earth aluminum alloy material, and an indirect extrusion casting process isadopted; and the industrial production is achieved, and the preparation method has huge development potential in the fields of lightweight automobiles, intelligent robots, aerospace and the like.

Owner:KA FUNG IND TECH HUIZHOU CO LTD

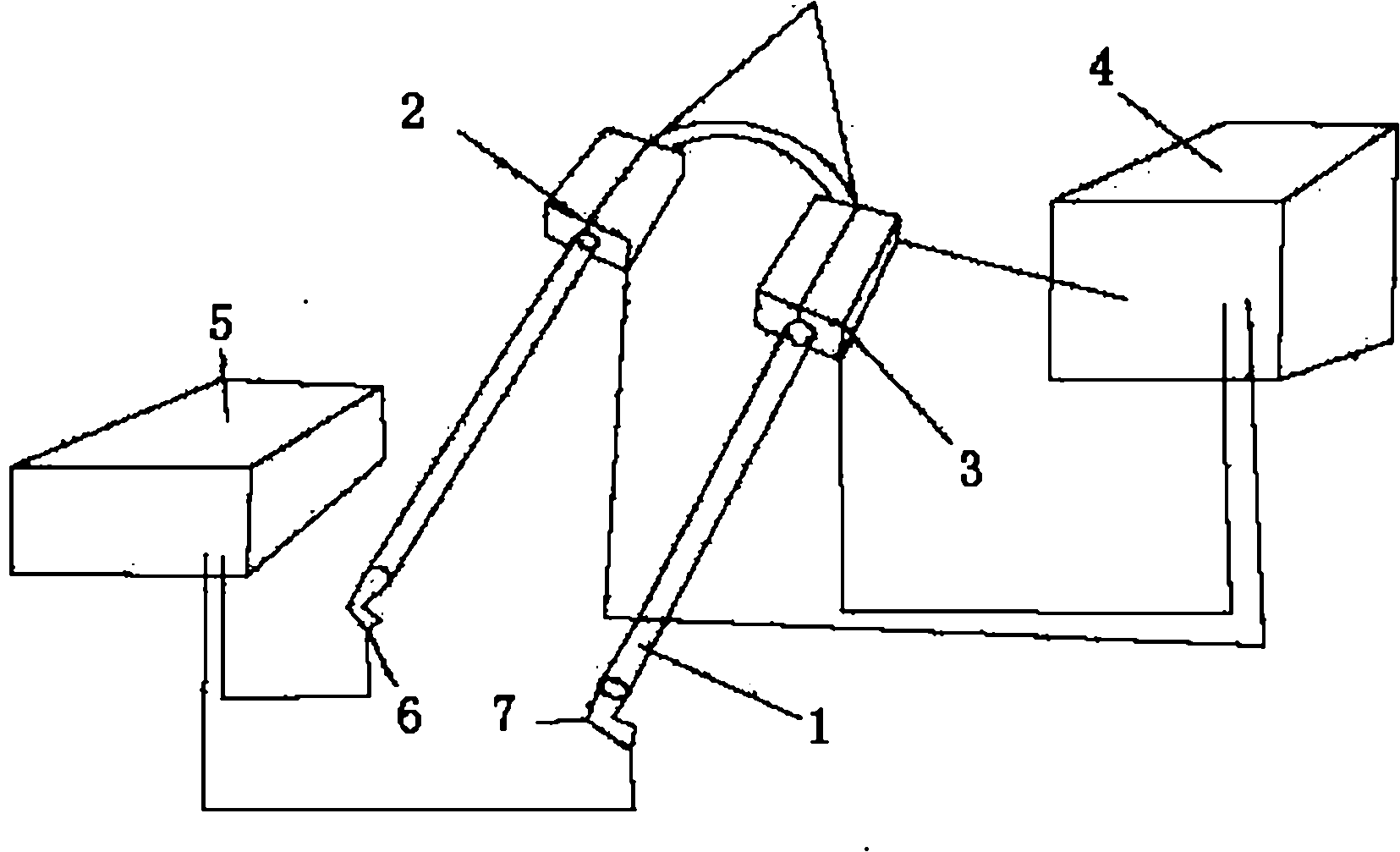

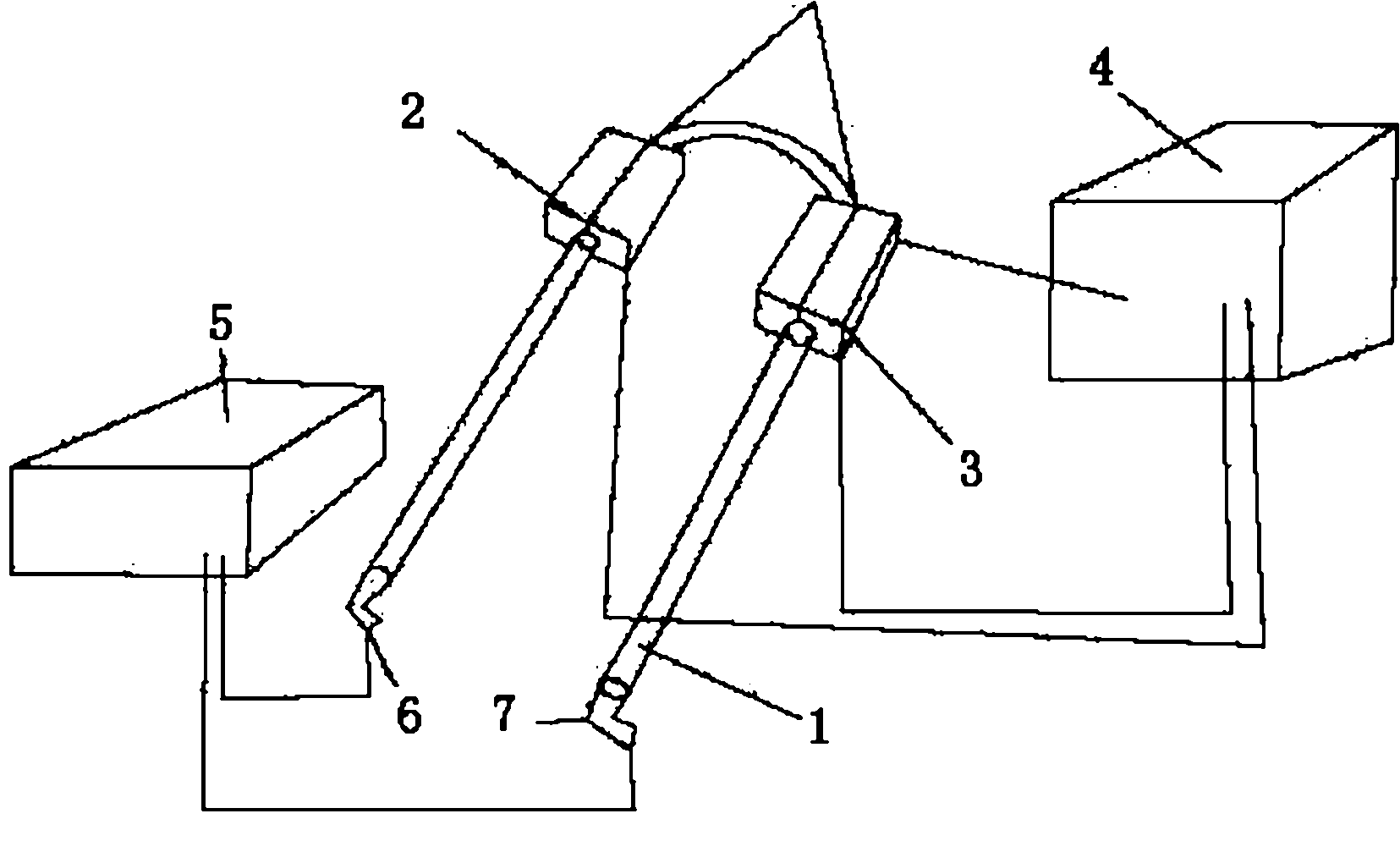

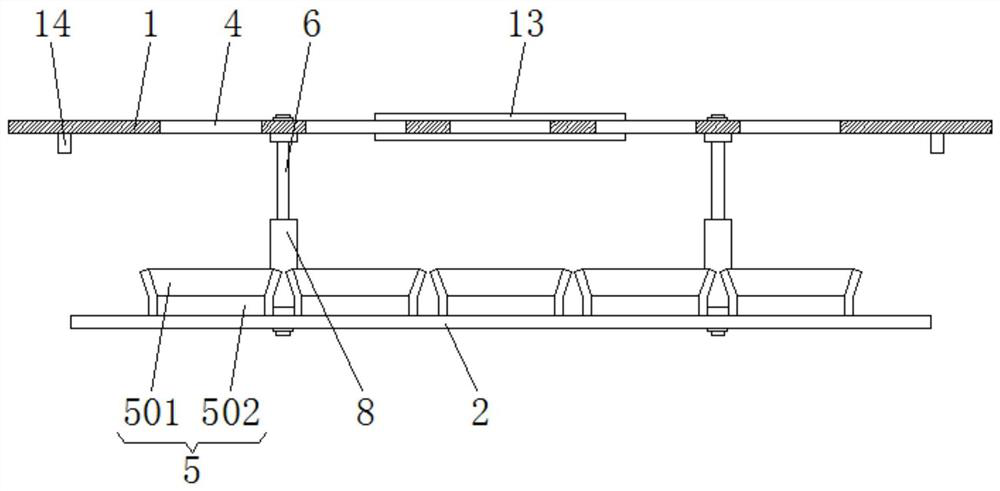

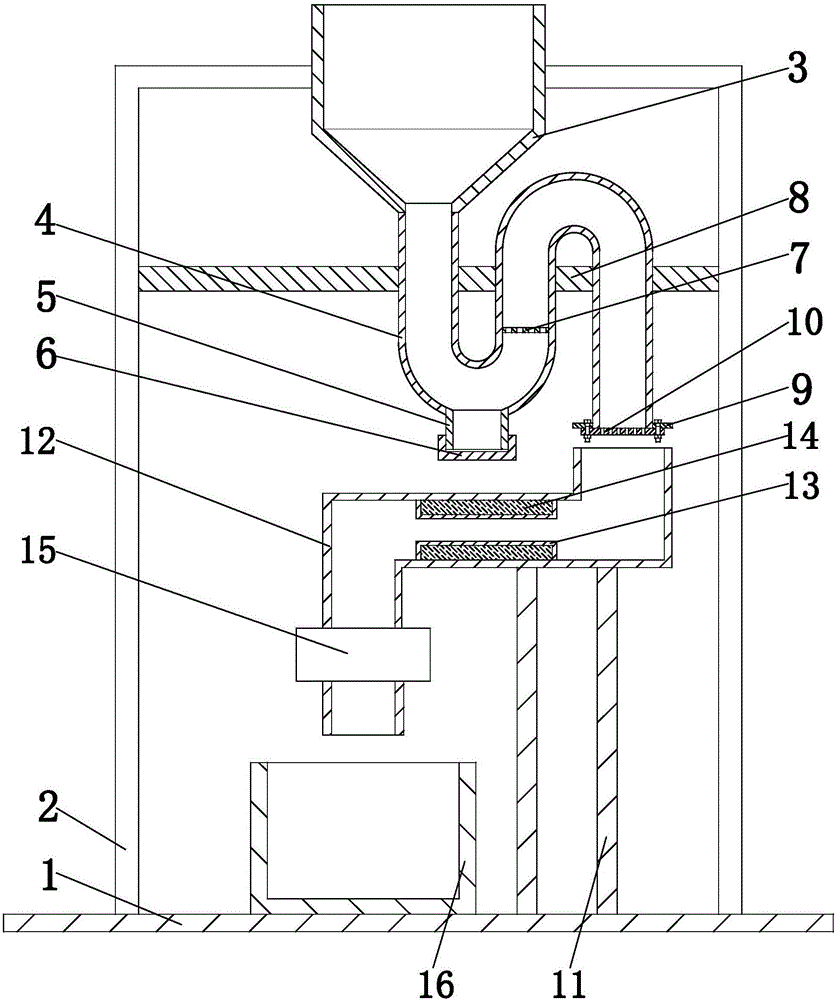

Device for eliminating internal stress of U-shaped bent pipe by performing heating and annealing

InactiveCN102080150ASimple and safe operationSolve low production efficiencyFurnace typesHeat treatment furnacesInternal stressCollet

The invention relates to a device for eliminating internal stress of a U-shaped bent pipe by performing heating and annealing. The device comprises the U-shaped bent pipe, a first guide rail and a second guide rail, wherein the first guide rail is parallel with the second guide rail; a collet on the top of the first guide rail contacts with the top end of a bending part of the U-shaped bent pipe; a collet on the top of the second guide rail is in contact with the root part of the bending part of the U-shaped bent pipe; and the first guide rail and the second guide rail are connected with a high-frequency heater respectively to form a heating loop. The device has the advantages of solving the problem of low production efficiency, improving yield and quality of products, preventing heating oxidation by introducing protective gas and guaranteeing the quality of the inner walls of the products, along with simpleness and safety in operation.

Owner:上海华钢不锈钢有限公司

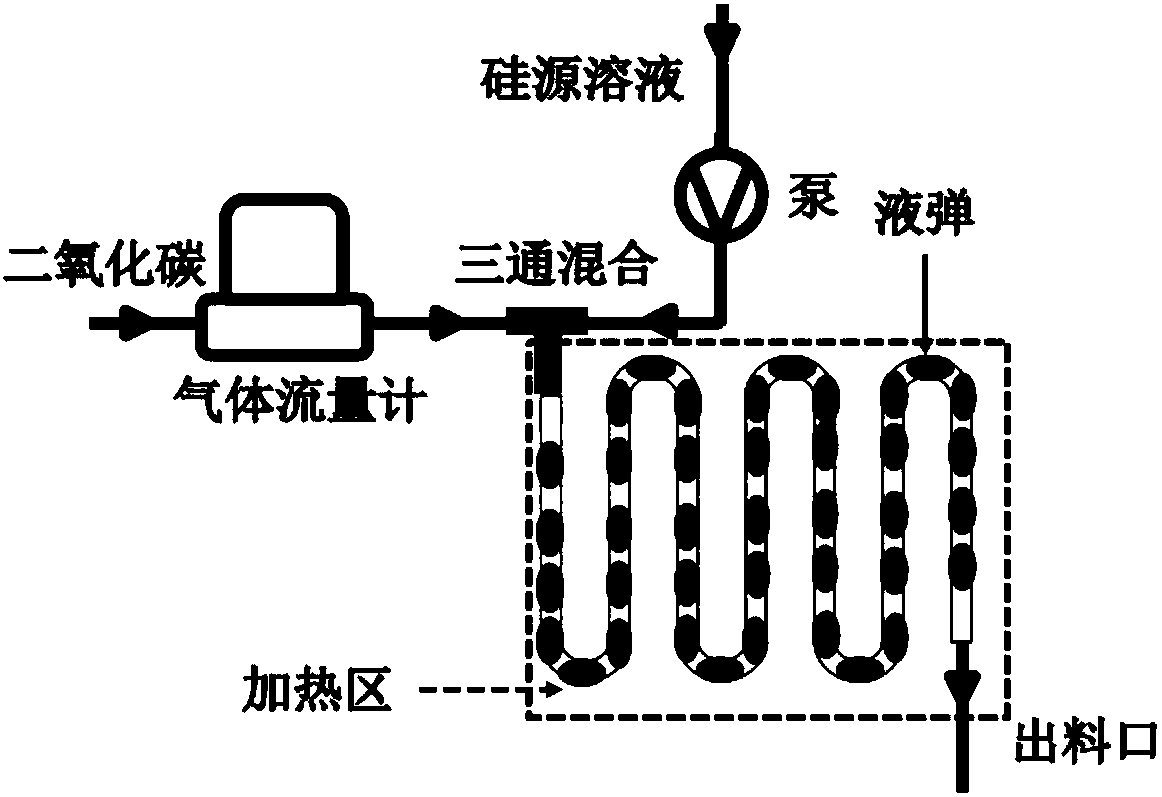

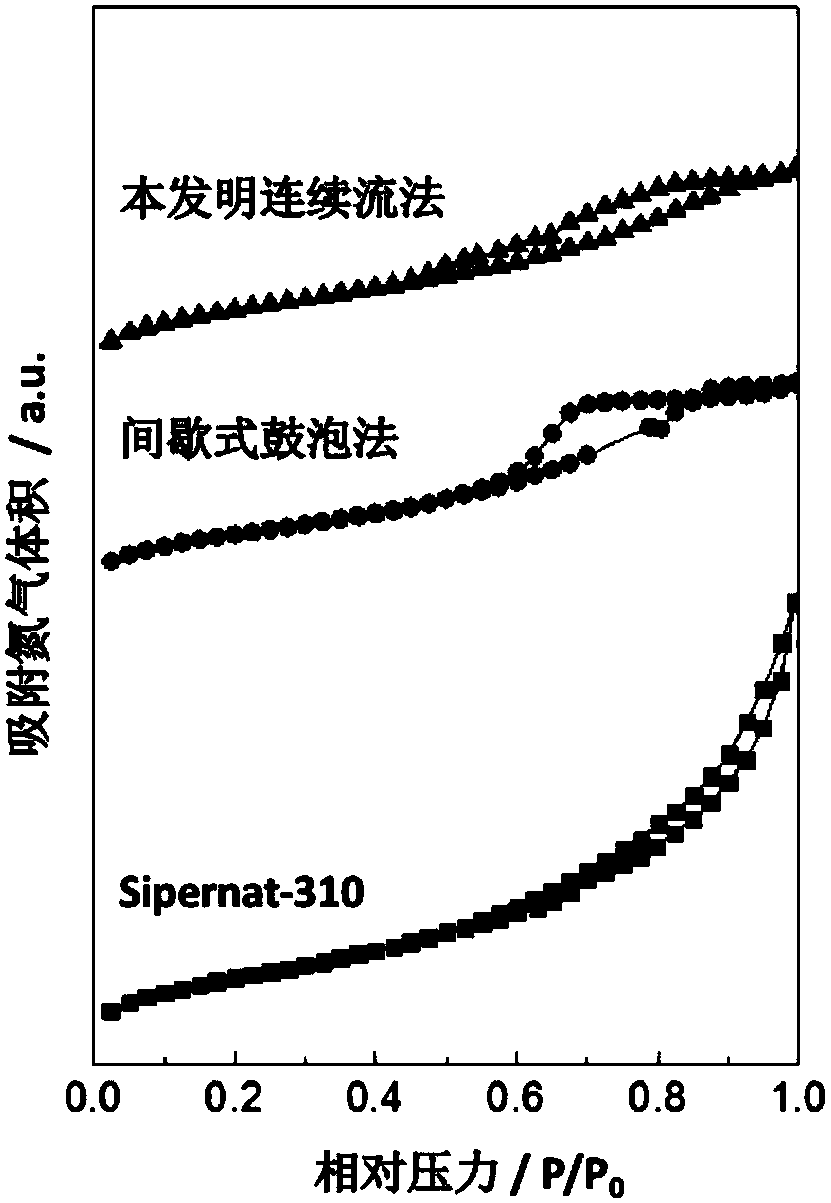

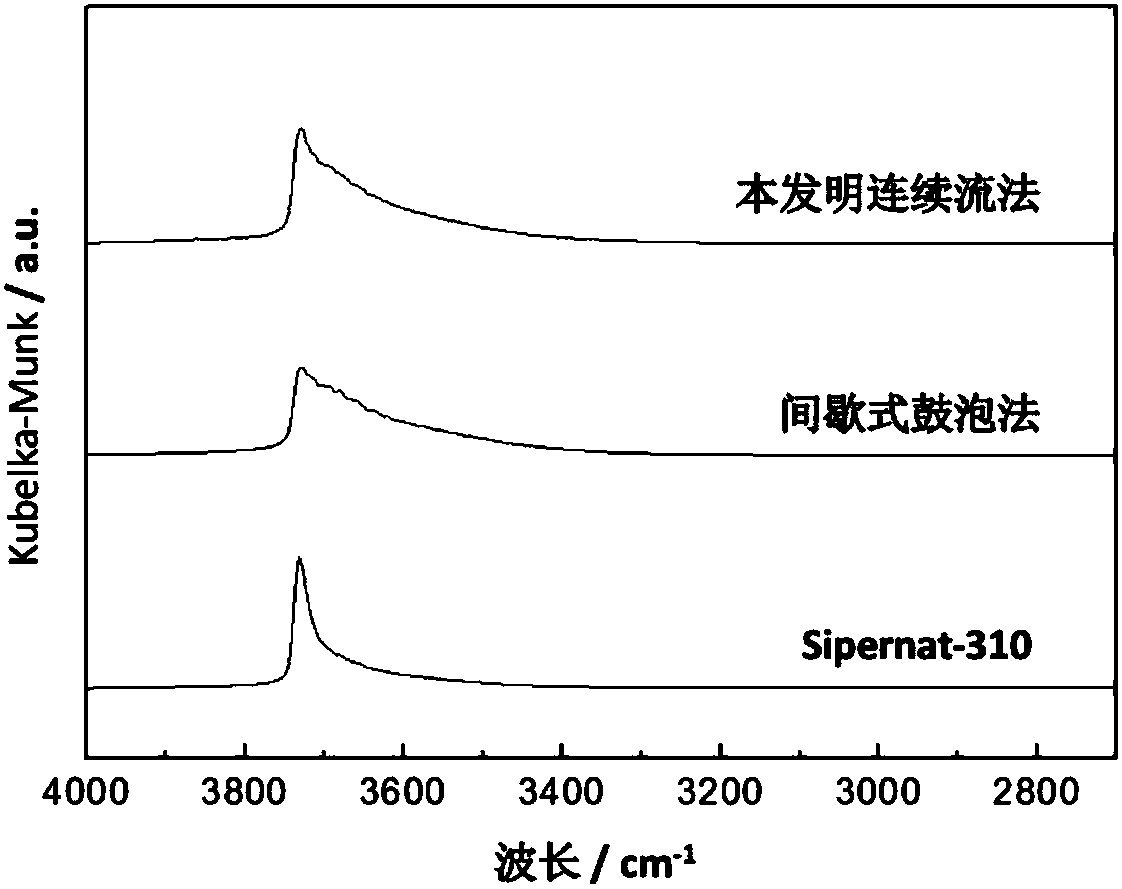

Method for preparing silicon dioxide with high specific surface area by using tubular continuous flow method

The invention discloses a method for preparing silicon dioxide with high specific surface area by using a tubular continuous flow method, and develops a novel precipitation method based on a small tube diameter tubular continuous flow method. The method is used for producing the silicon dioxide with high specific surface area, wherein a raw material for producing white carbon black is sodium silicate, silica sol or a mixed solution of sodium silicate and silica sol, and carbon dioxide gas serving as an acidifying agent goes through a gas-liquid alternating section flow formed by the tubular continuous flow method, so that the problem of mass and heat transfer on micro level is solved fundamentally. Therefore, according to the method disclosed by the invention, silicon dioxide with high specific surface area, small particles and stable product quality can be produced continuously.

Owner:合肥星巢环保科技有限公司

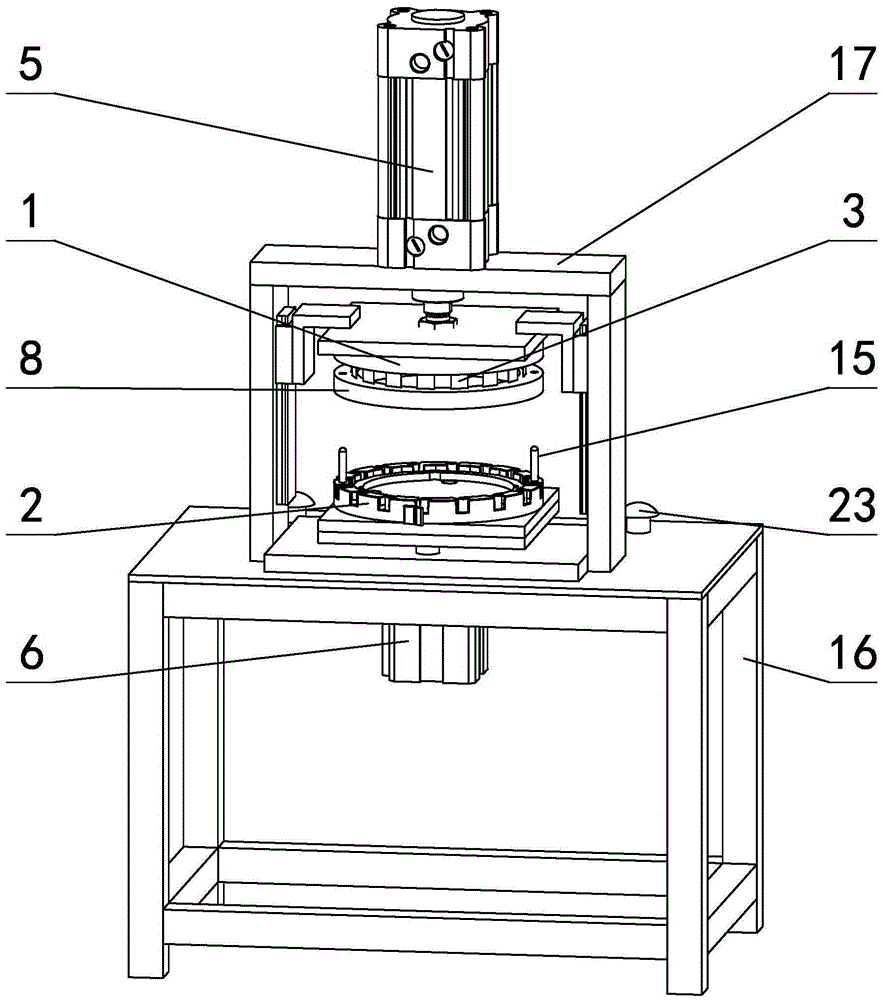

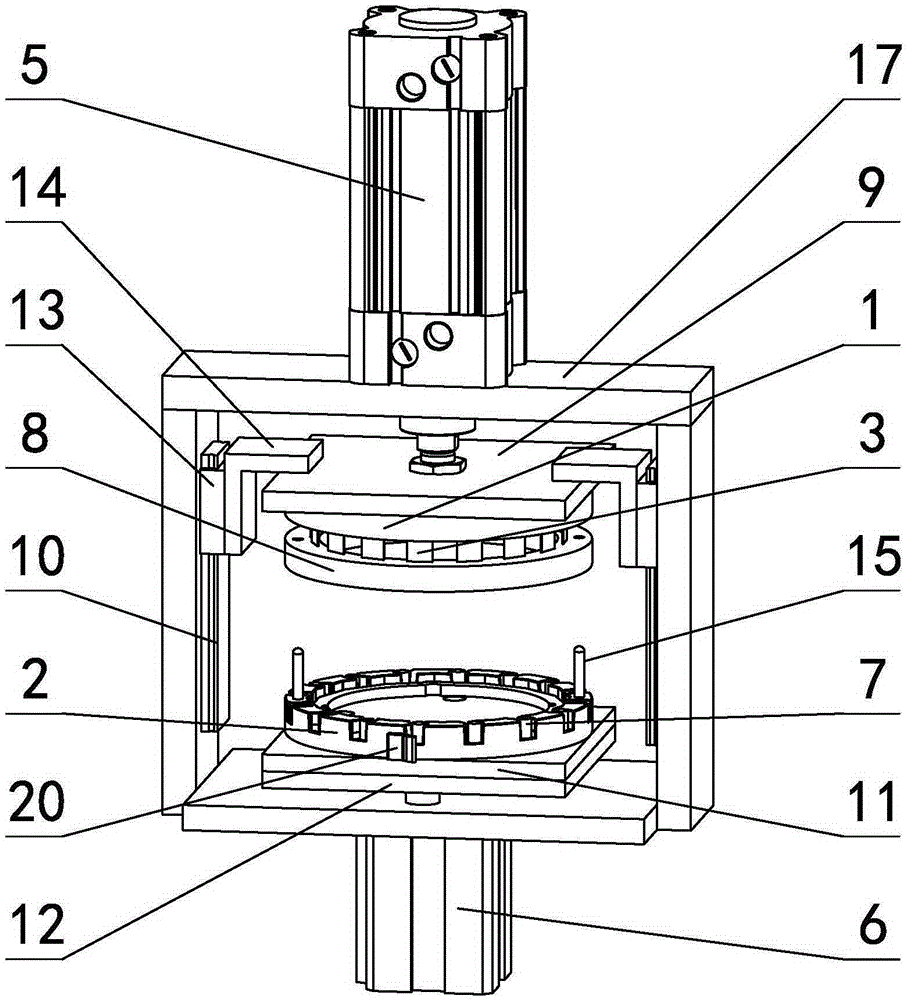

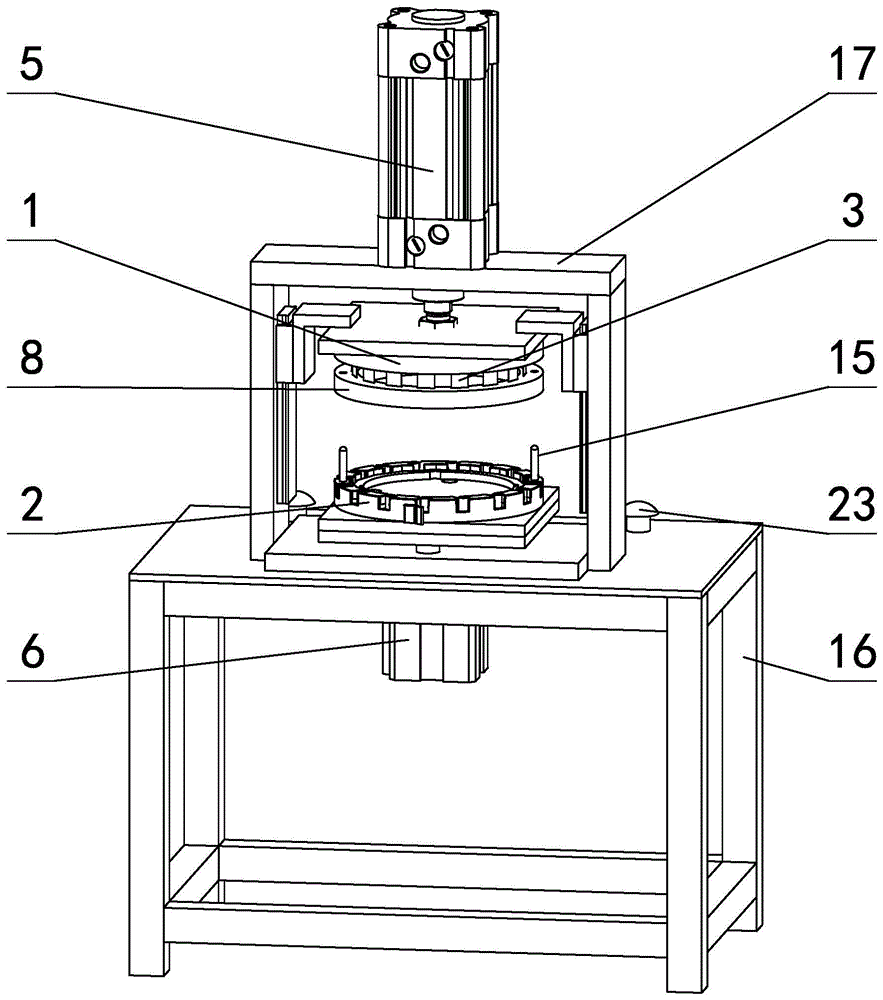

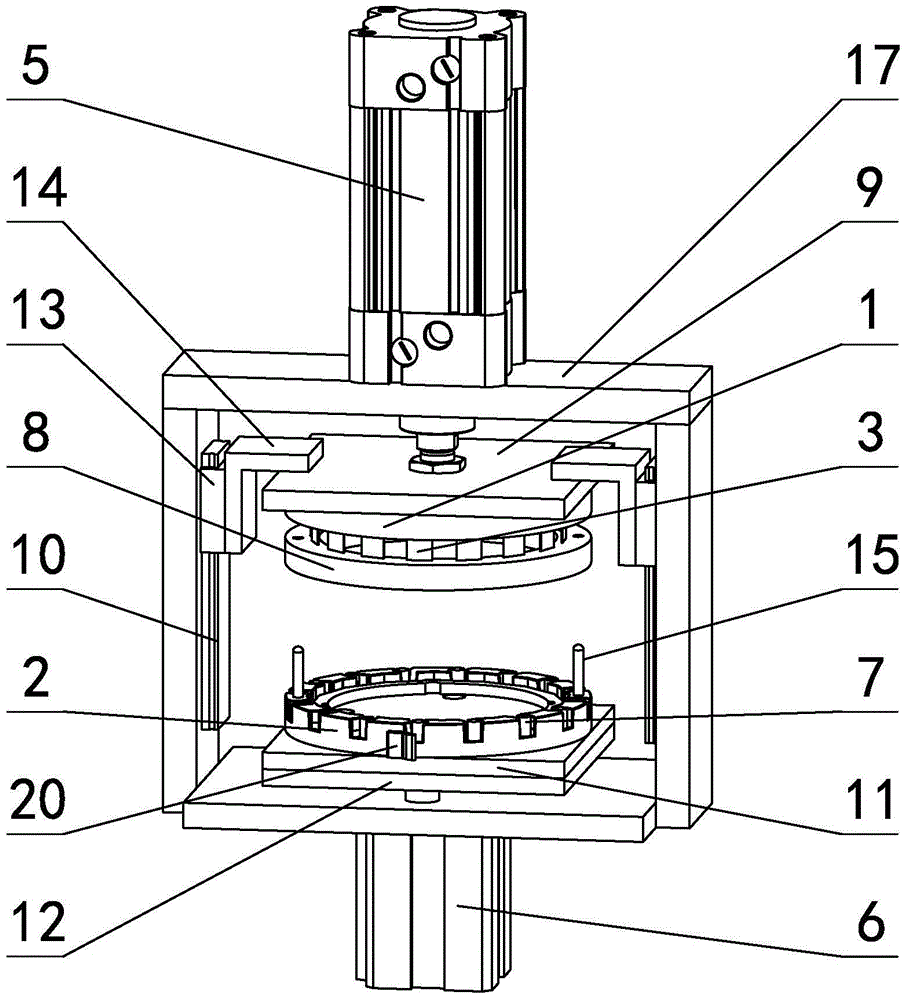

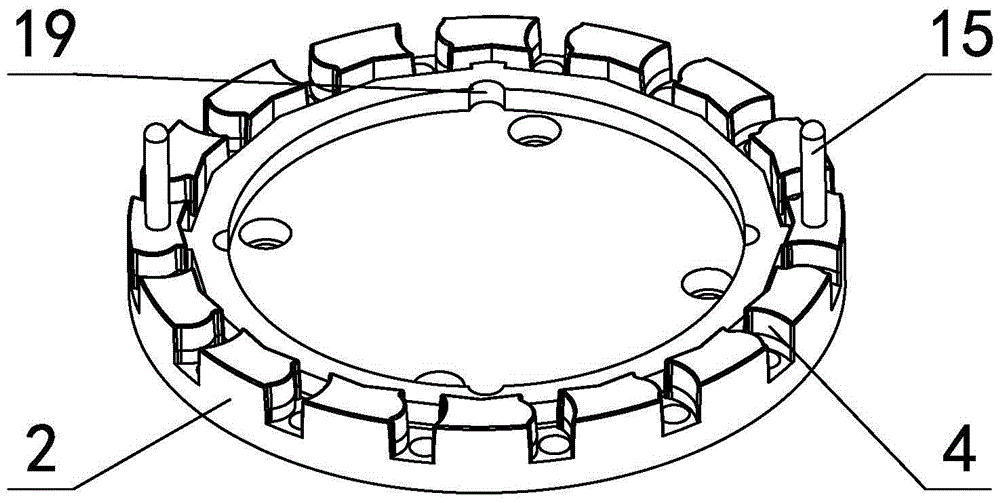

Stub bar punching device

ActiveCN105382883ASolve the problem of low production efficiencyIncrease productivityMetal working apparatusPunchingEngineering

The invention discloses a stub bar punching device. A rack is provided with an upper die seat and a lower die seat. The bottom face of the upper die seat is provided with multiple punching dies annularly arranged. The top face of the lower die seat is provided with workpiece grooves corresponding to the punching dies. The portion, above the upper die seat, of the rack is provided with a punching air cylinder connected with the upper die seat. The portion, below the lower die seat, of the rack is provided with an ejection air cylinder. The ejection air cylinder is connected with ejector rods arranged in the workpiece grooves. By means of the stub bar punching device, the problems that the manner in which a single workpiece is punched multiple times is adopted and production efficiency is very low in the prior art are solved effectively; and multiple workpieces can be separated through one-time punching, production efficiency is high, the uniformity of products is good, and the stub bar punching device has very high practical value.

Owner:宁波拓普电器有限公司

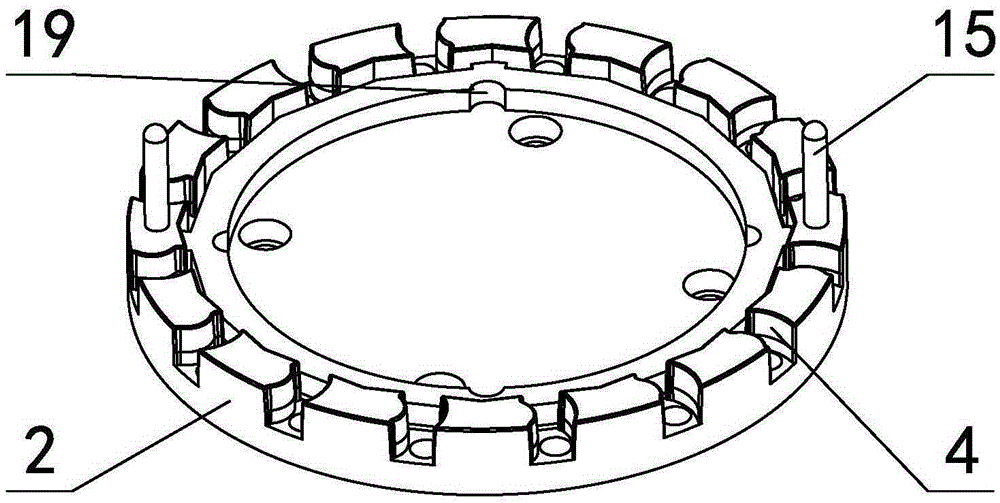

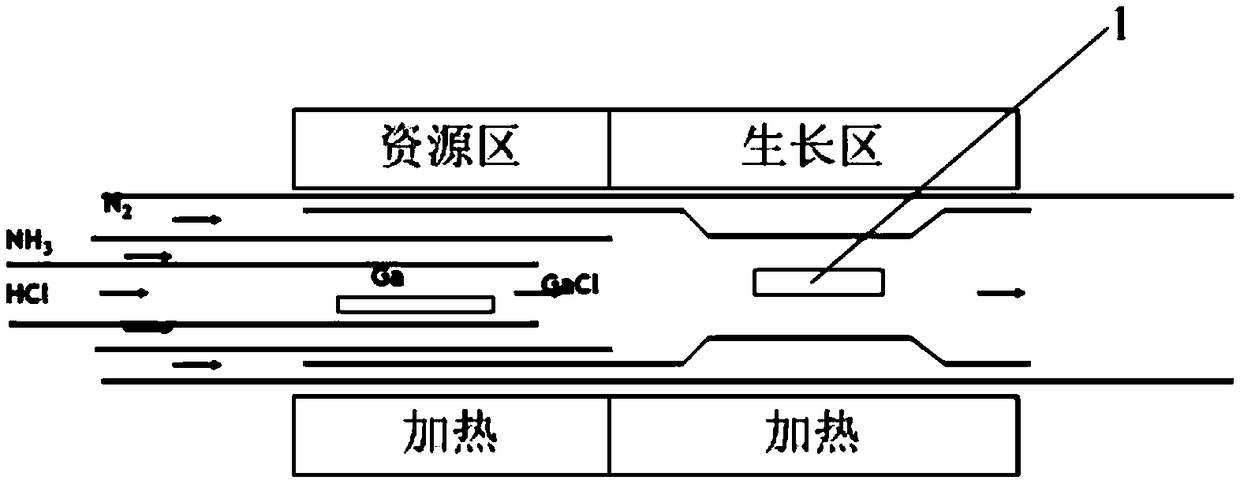

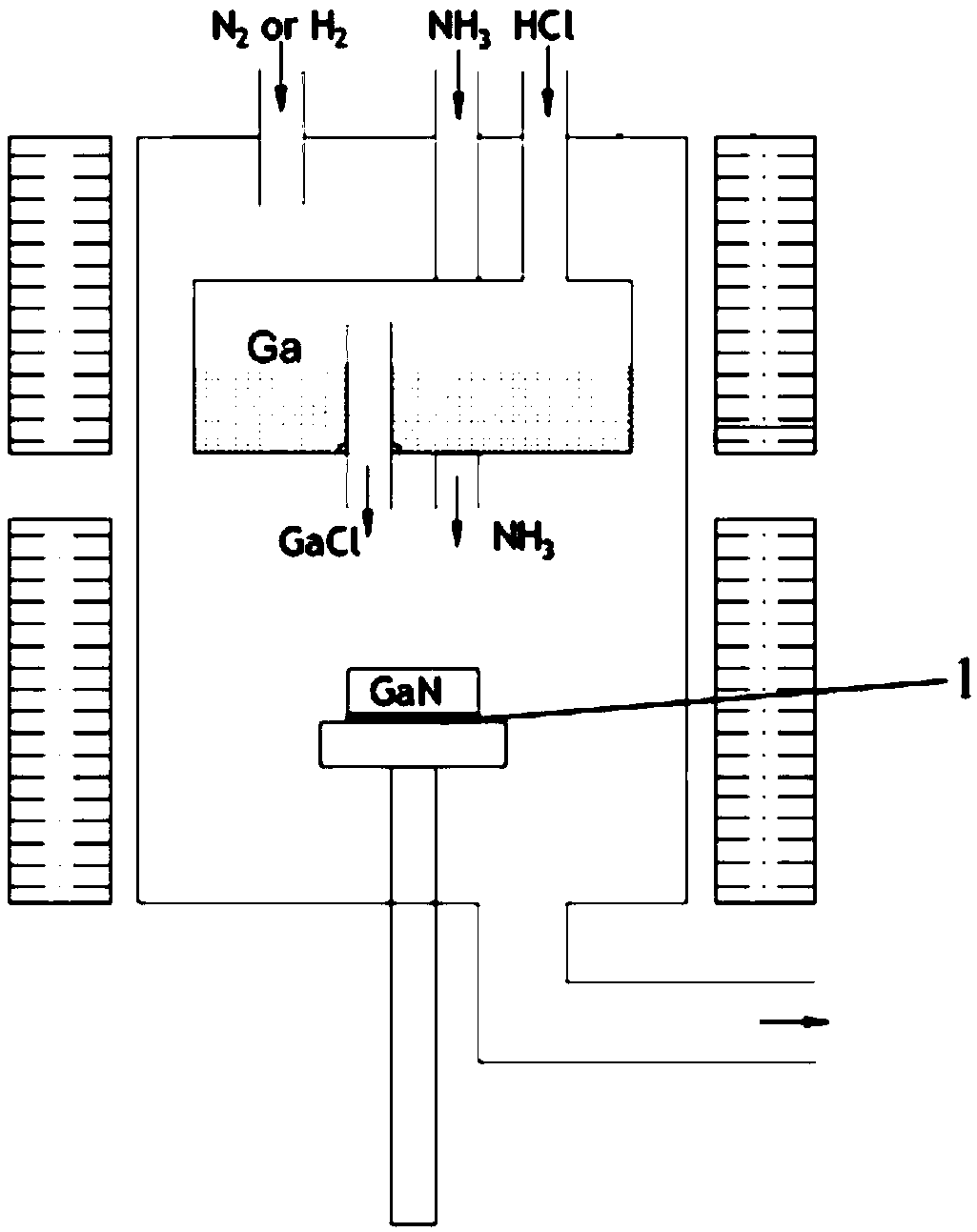

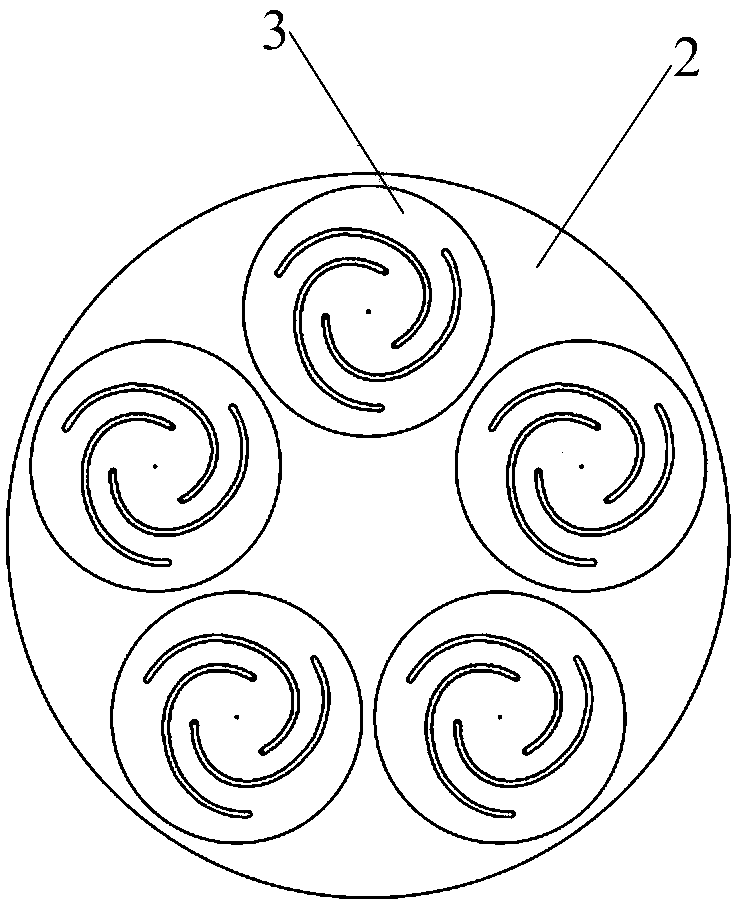

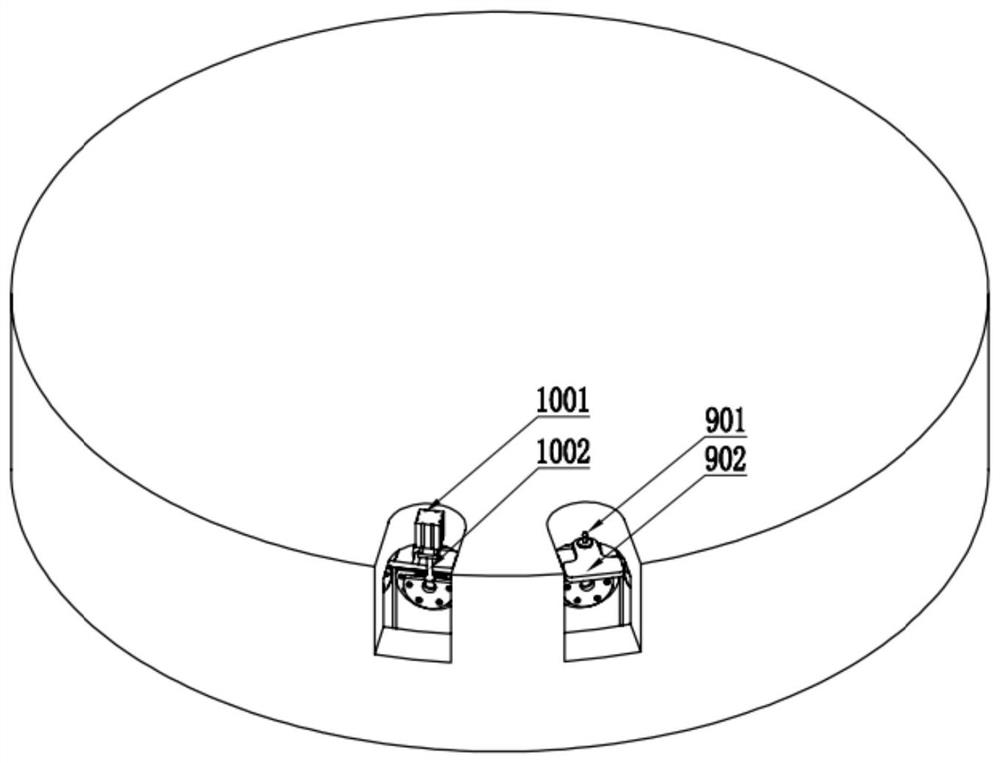

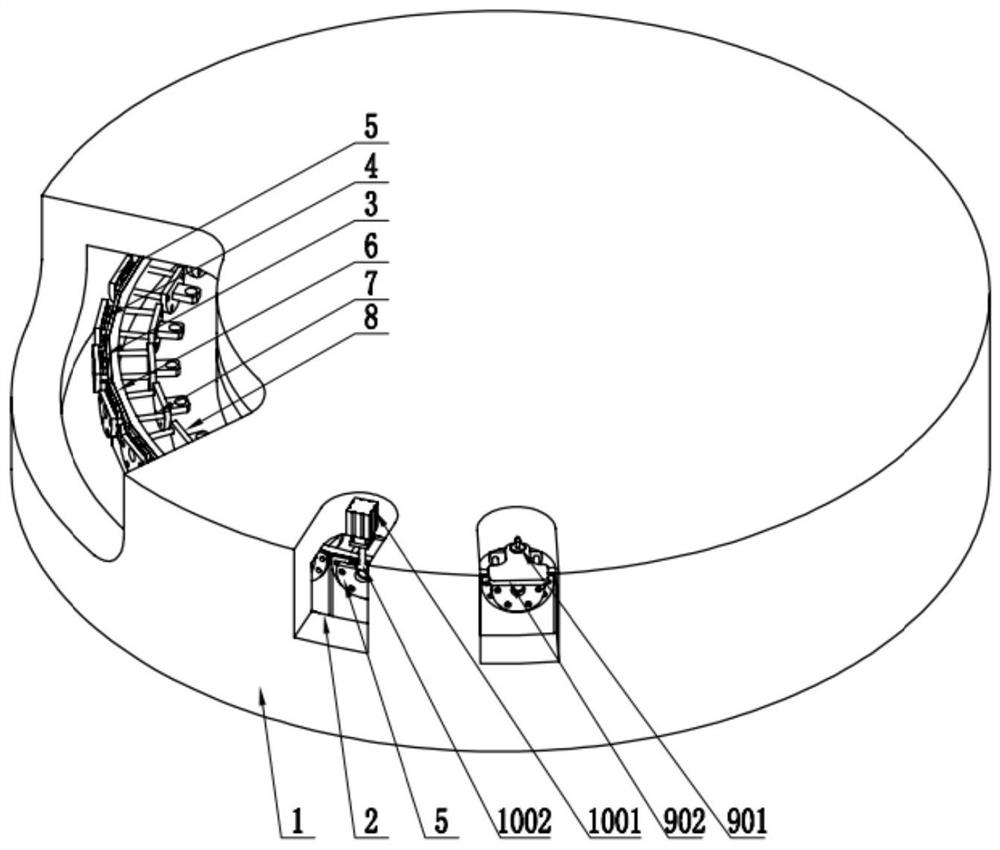

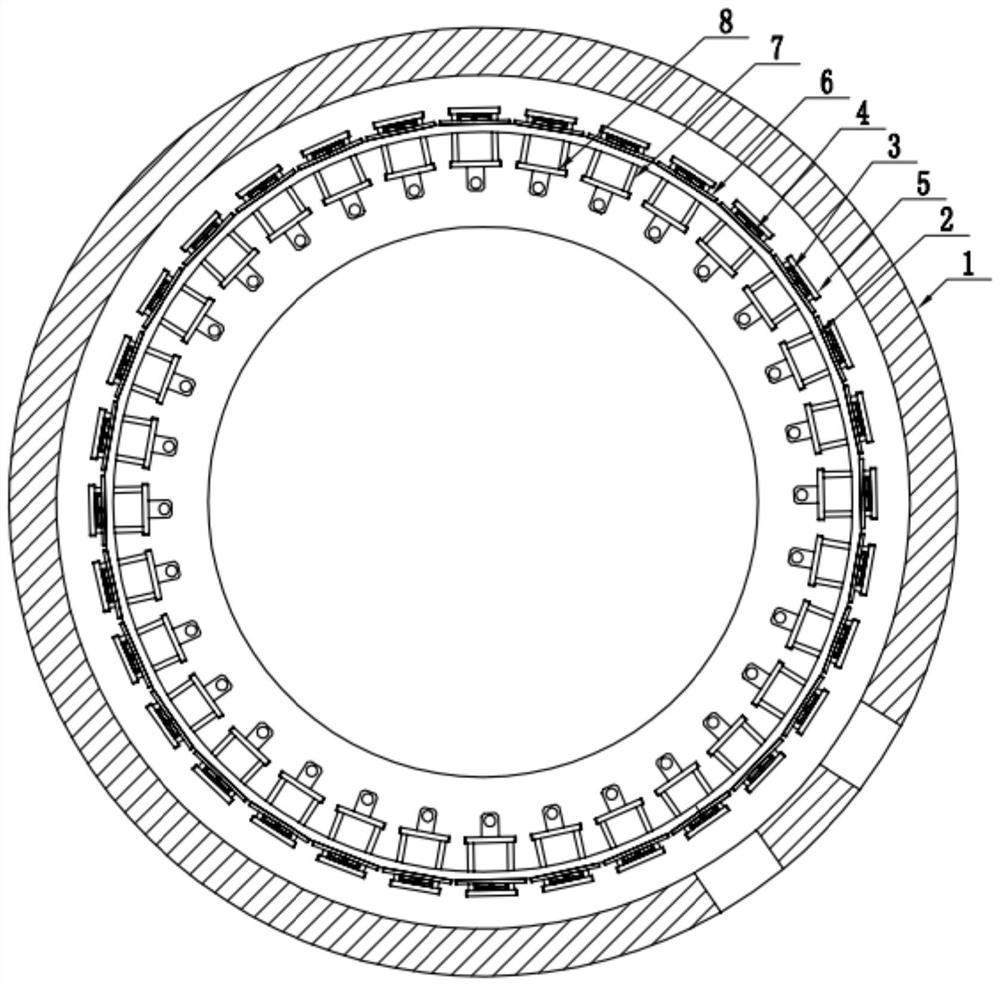

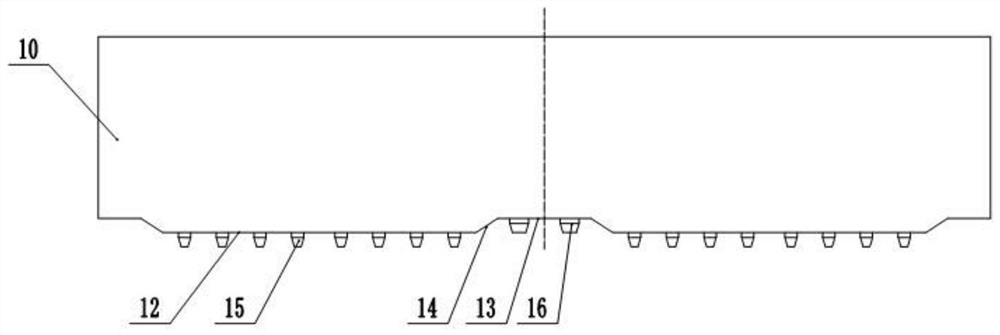

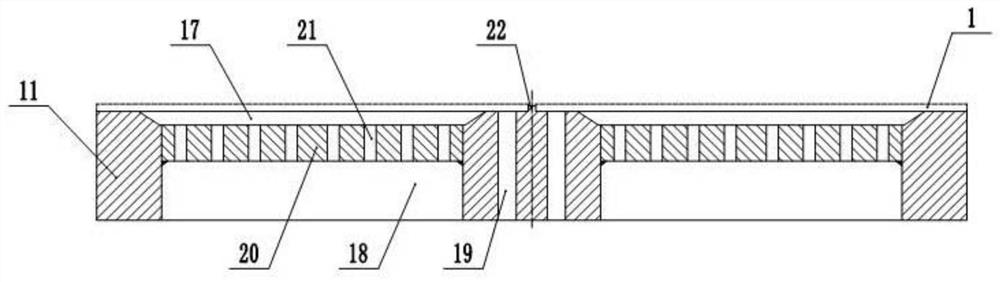

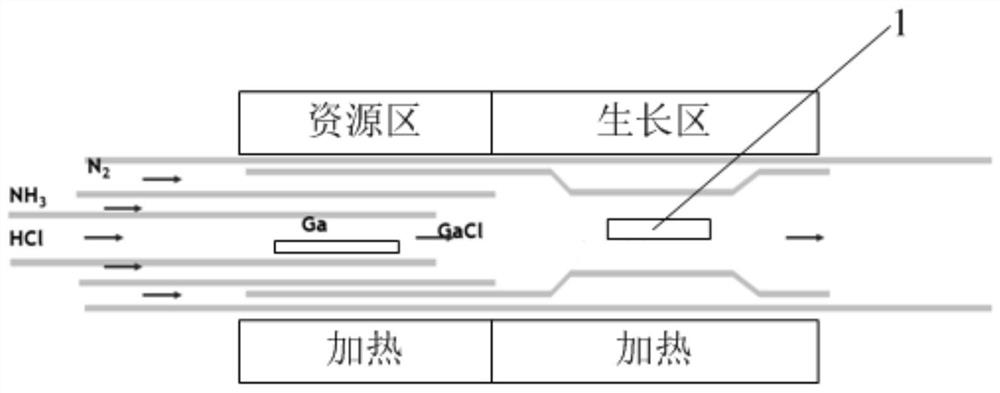

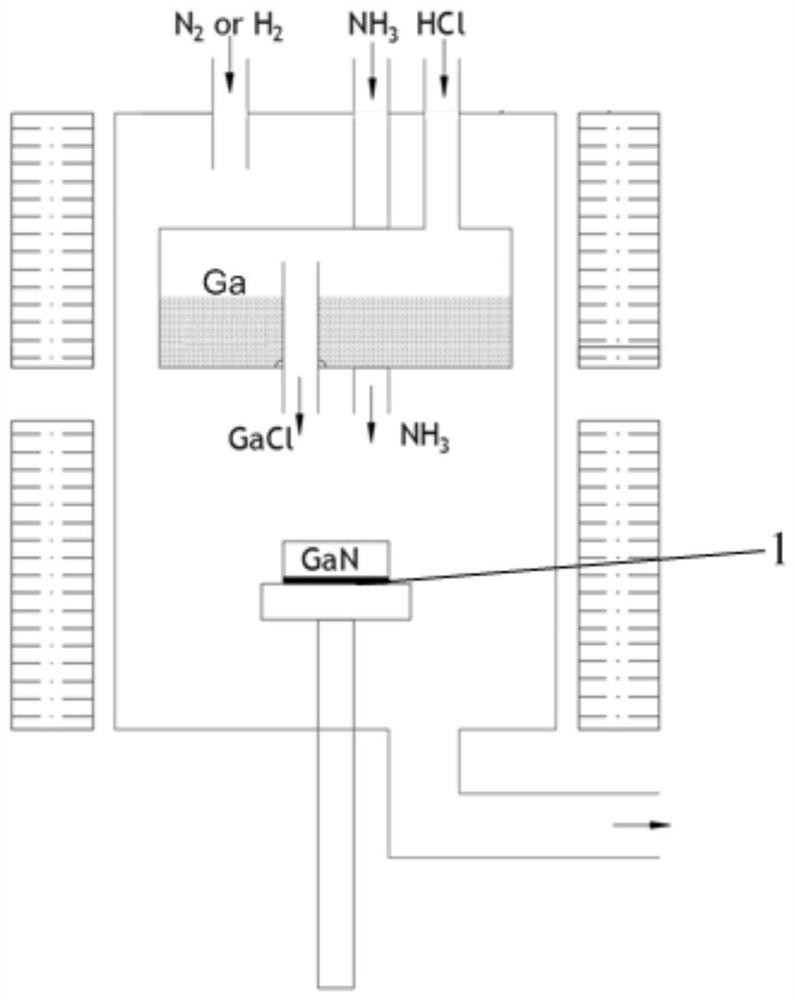

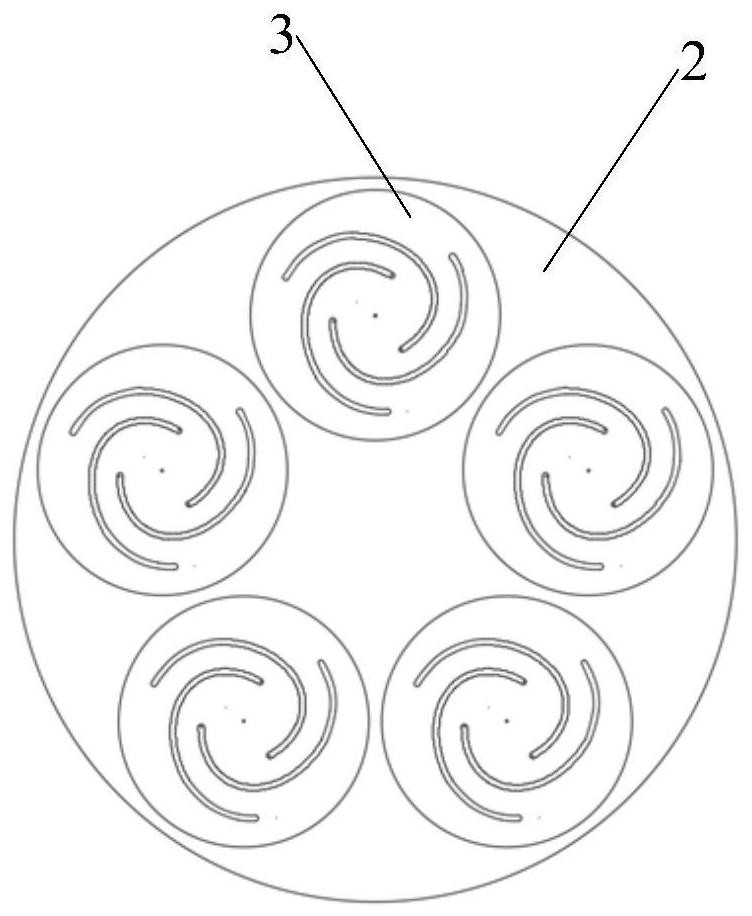

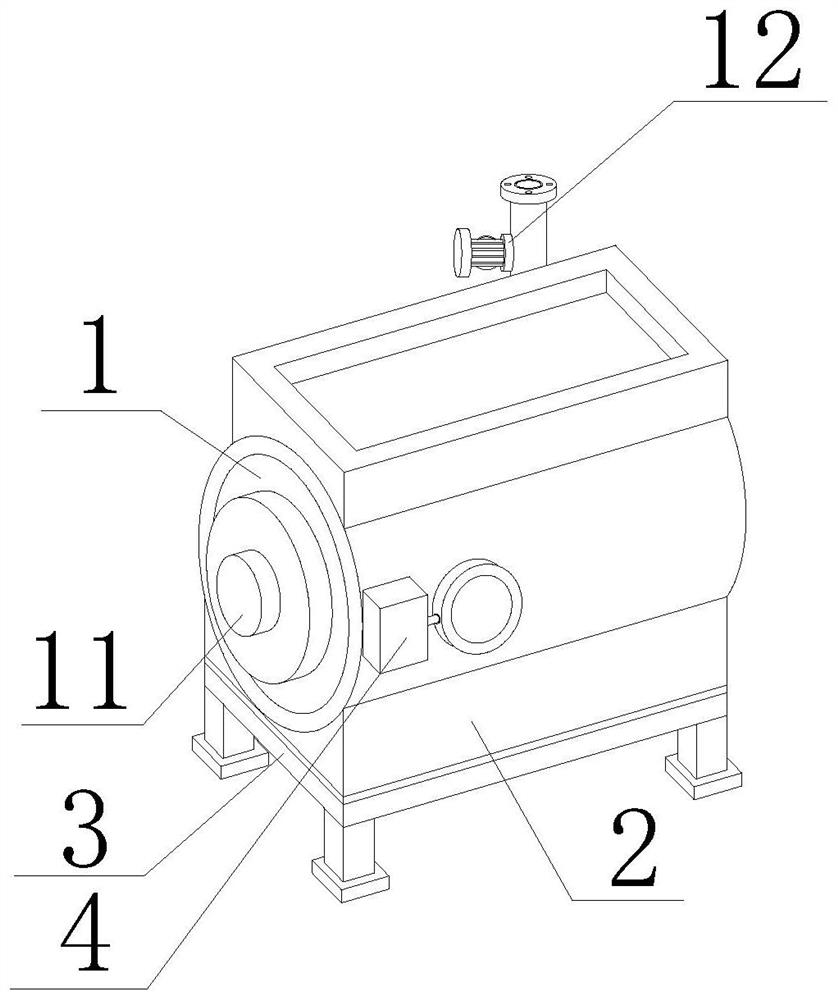

Hydride vapor phase epitaxy (HVPE) device capable of producing gallium nitride in batches

ActiveCN108914202ASolve the problem of not enough to completely cover the substrate sheetSolve the problem of low production efficiencyPolycrystalline material growthFrom chemically reactive gasesSemiconductor materialsHigh volume manufacturing

The invention relates to the technical field of semiconductor materials, and particularly discloses a hydride vapor phase epitaxy (HVPE) device capable of producing gallium nitride in batches. The device comprises a gas source chamber and a growth chamber; two gas inflow channels are arranged in the gas source chamber; one end of each of the two gas inflow channels communicates with the upper partof the gas source chamber, so that gases enter the growth chamber from the gas source chamber and are mixed in the growth chamber; a main support plate and a plurality of auxiliary support plates arranged on the main support plate are arranged in the middle of the growth chamber; and the auxiliary support plates are used for containing substrates. In the device, the gas inflow channels are transversely arranged, and the plate surface of the main support plate is horizontally placed, so that gases transversely enter the growth chamber and vertically contact the substrates, and then gallium nitride grows. According to the invention, the transverse gas source chamber and the vertical growth chamber are respectively arranged, gas inflow of resource gases and growth of gallium nitride crystalsare separated, so that the problems of insufficient auxiliary support plates and insufficient resource gases are solved, and therefore large-scale production of the gallium nitride crystals is realized.

Owner:北京镓数智能科技有限公司

Kitchen knife blade manufacturing process

ActiveCN103317302ASolve the problem of low production efficiencyFurnace typesHeat treatment furnacesKnife bladesMachining process

The invention provides a kitchen knife blade manufacturing process and aims at solving the problem that the production efficiency in the prior art is not high. The kitchen knife blade manufacturing process comprises the following steps of smelting an iron raw material to obtain molten iron, pouring the molten iron into a knife blade mould to obtain a near net shape knife blade, and machining the near net shape knife blade to obtain a finished knife blade. The near net shape knife blade. The manufacture of the near net shape knife blade is performed by means of a casting process, and compared with a traditional machining process, production procedures are decreased, and the efficiency is improved.

Owner:如东县东广物流有限公司

Novel process for refining oil-tea camellia seed crude oil

ActiveCN101735886BReduce side effectsLow reaction temperatureFatty-oils/fats refiningOil and greaseCamellia oleifera

The invention discloses a process for refining oil-tea camellia seed crude oil, which belongs to the technical field of grease refining in the fine and further processing of farm and sideline products. A process flow comprises the following steps: filtering the oil-tea camellia seed crude oil to eliminate impurities; performing a first low temperature acid reaction; performing low temperature alkali refining; removing soap; performing water washing after first acid adding; performing second water washing; and de-coloring and deodorizing the obtained product to obtain first-level oil-tea camellia seed oil. The novel process is characterized by improving the oil obtaining rate of refining, lowering production cost, improving product quality and stability and the like, and is used for refining the oil-tea camellia seed crude oil and refining rap oil, peanut oil and other vegetable oil.

Owner:HUNAN XINJINHAO TEA OIL

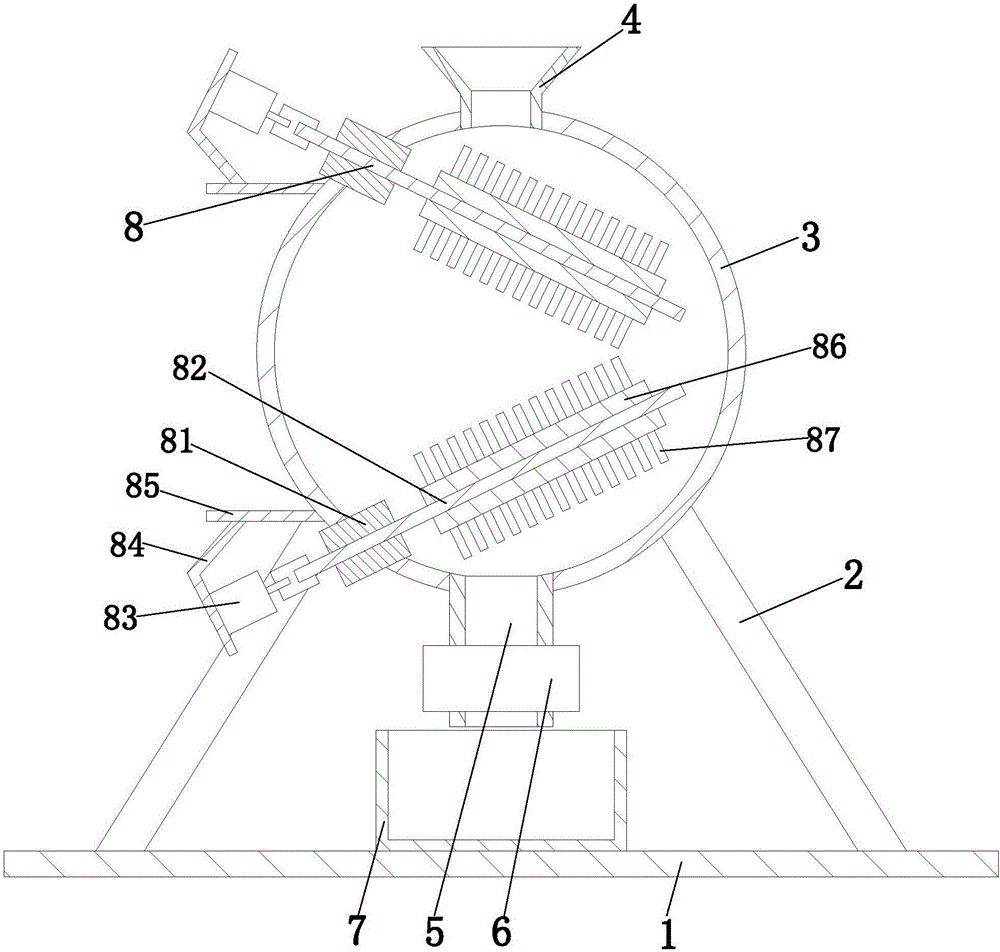

Rapid paint mixing device

InactiveCN106552525ASolve the problem of low production efficiencyIncrease productivityRotary stirring mixersTransportation and packagingSolenoid valveEngineering

The invention relates to a rapid paint mixing device which comprises a base plate. Four support columns are symmetrically installed on the upper end face of the base plate in an inclined manner, paint mixing balls are welded to the upper ends of the four support columns, the four support columns play a role in supporting the paint mixing balls, feeding hoppers are arranged at the upper ends of the paint mixing balls, various oil paint raw materials are put into the paint mixing balls through the feeding hoppers to be machined, discharging pipes are communicated to the lower ends of the paint mixing balls, solenoid valves are installed on the discharging pipes, and the opening and closing states of the discharging pipes are controlled through the solenoid valves; a collecting box is installed at the middle portion of the upper end face of the base plate and located under the discharging pipes, and oil paint can right enter the collecting box through the discharging pipes to be collected after paint mixing is finished; and the upper end and the lower end of each paint mixing ball are symmetrically provided with two paint mixing mechanisms. According to the rapid paint mixing device, on the premise that the cost is low, the rapid paint mixing function can be achieved; and the rapid paint mixing device has the beneficial effects of being simple in structure, low in cost, high in paint mixing efficiency and the like, and the oil paint production efficiency is greatly improved.

Owner:ANHUI MEILIN BUILDING MATERIAL

A high-tannase-yield strain and a preparing method thereof

InactiveCN104263650AImprove fermentation yieldSolve the problem of low production efficiencyFungiHydrolasesMicroorganismPrimary screening

Owner:曹庸

High-ductility high-strength rare earth aluminum alloy material and preparation method thereof

On the one hand, the invention provides a high-ductility high-strength rare earth aluminum alloy material. The rare earth aluminum alloy material comprises the following components of, in percentage by mass, 2.0% - 3.5% of Si, 3.5% - 5.0% of Cu, 0.5% - 0.9% of Mn, 0.1% - 0.5% of Re, 0.1% - 0.2% of Ti, 0.005% - 0.05% of Sr and 80% - 92% of Al, wherein the Re is mixed rare earth containing Ce and La. According to the high-ductility high-strength rare earth aluminum alloy material, the rare earth element is introduced into an aluminum alloy, so that the fluidity of the aluminum alloy is improved,and the initiation of shrinkage porosity, shrinkage and crack is reduced. On the other hand, the invention provides a preparation method of the high-ductility high-strength rare earth aluminum alloymaterial. An indirect squeeze casting process is adopted, industrial scale production is realized, and the rare earth aluminum alloy material has great development potential in the fields of automobile light weight, intelligent robots, aerospace and the like.

Owner:KA FUNG IND TECH HUIZHOU CO LTD

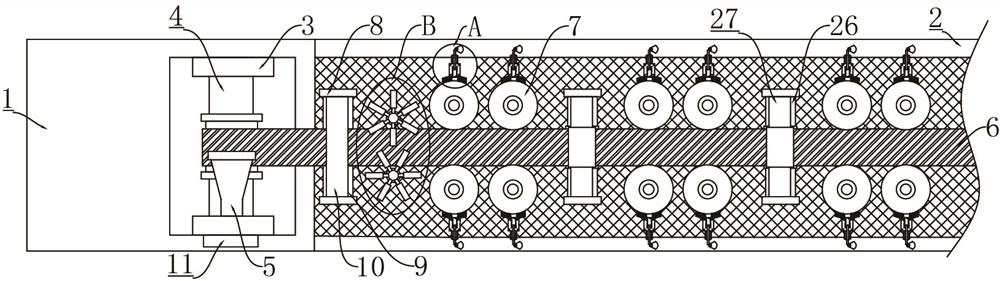

Glue spraying, pattern adding and quick cooling device of artificial turf

InactiveCN109304283AImprove cooling effectIncrease contact areaPretreated surfacesCoatingsArtificial turfEngineering

The invention relates to the technical field of artificial turf production equipment, in particular to a glue spraying, pattern adding and quick cooling device of an artificial turf. The glue spraying, pattern adding and quick cooling device comprises the design of a quick cooling and pattern pressing device; after being subjected to glue spraying of a T-shaped mold head, bottom cloth is attachedto a quick cooling roller under the action of a press roller, and patterns are ground at the bottom of a back glue layer through a pattern groove; during gluing, part of glue flows into the patterns,the contact area of the glue and the back glue layer is increased, the connecting strength is improved, and the problems that the contact area of the glue and the back glue layer is limited, the connecting strength is low, the phenomenon of edge warping frequently happens, and both attractiveness and use are influenced are solved; heat conduction oil is pumped into a circulating pump in the quickcooling roller for cooling, and after glue spraying of the back glue layer, forced cooling is carried out through the quick cooling roller, and finally natural cooling and airing are achieved; and through adding of forced cooling of the quick cooling roller, the production efficiency is greatly increased, and the problems that during traditional back glue layer processing, no glue spraying and cooling device is arranged, only natural cooling and airing are adopted, and the production and work efficiency is low are solved.

Owner:韩晓雷

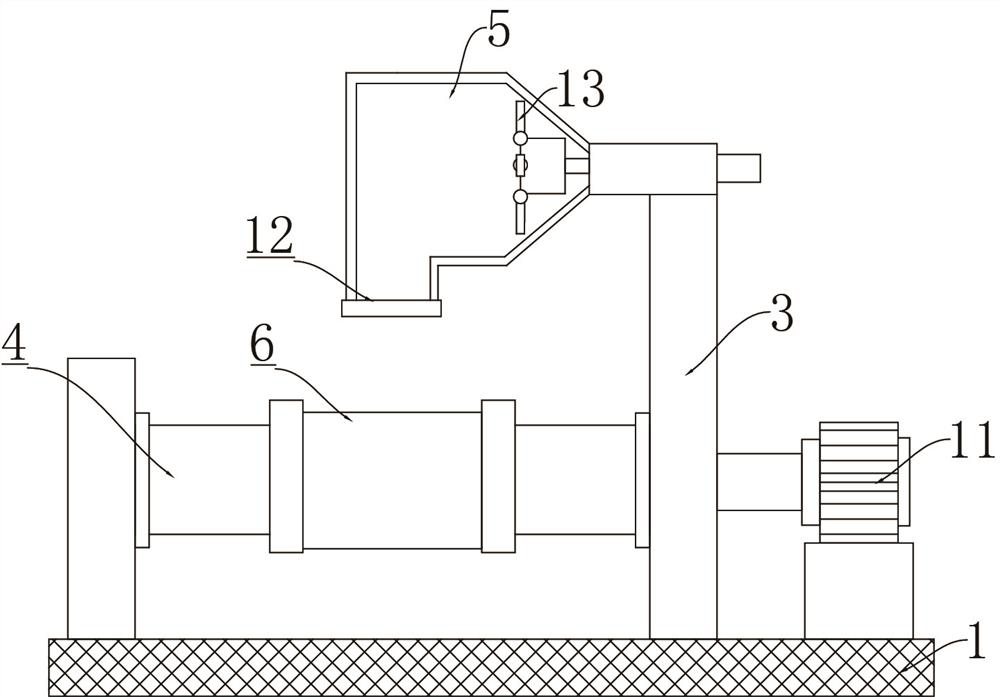

Rolling mill for copper pipe production

ActiveCN112427460AAdd in timeImprove functionalityRollsWork cleaning devicesOil canMaterials science

The invention discloses a rolling mill for copper pipe production. The rolling mill for copper pipe production comprises a base, two first supporting blocks are fixedly connected to the base, a rolling roller is rotationally connected between the two first supporting blocks, two limiting cavities are fixedly connected to the top of the base, and multiple second supporting blocks are fixedly connected to the base. An upper pressing roller and a lower pressing roller are rotationally connected between two of the second supporting blocks, an upper roller and a lower roller are rotationally connected between the other two corresponding second supporting blocks, the rolling roller is sleeved with a copper sheet in a rolling mode, and the end, away from the rolling roller, of the copper sheet islocated between the upper pressing roller and the lower pressing roller. According to the rolling mill for copper pipe production, by arranging a smearing mechanism, lubricating oil can be added intoa touch roller in time in the process that the copper sheet is used for machining a copper pipe by the touch roller, and the problem that the production effect is low due to the fact that the lubricating oil is not added into the touch roller in time when a traditional rolling mill produces the copper pipe is solved.

Owner:ZHEJIANG CHUANBOZHE METAL DECOUATION MATERIAL CO LTD

Electronic product production line and voltage withstand test system thereof

InactiveCN105510788AReduced pressure resistanceSteps to reduce electronicsElectrical testingProduction lineAlternate current

The invention provides an electronic product production line and a voltage withstand test system thereof. The voltage withstand test system comprises a voltage withstand tester and further comprises a positioning and clamping device and a controller. The positioning and clamping device comprises a first driving component and a clamping plate fixedly connected with the first driving component. The controller is connected with the first driving component and used for controlling the first driving component to move the clamping plate. Two test probes of the voltage withstand tester are fixedly installed on the two clamping sides of the clamping plate. After the clamping plate clamps an electronic product, one test probe makes contact with an alternating current input line of the electronic product, and the other test probe makes contact with a metal shell of the electronic product. Thus, the step of manually connecting the voltage withstand tester and the electronic product in production is omitted, and production efficiency is improved.

Owner:ZHUHAI GOTECH INTELLIGENT TECH

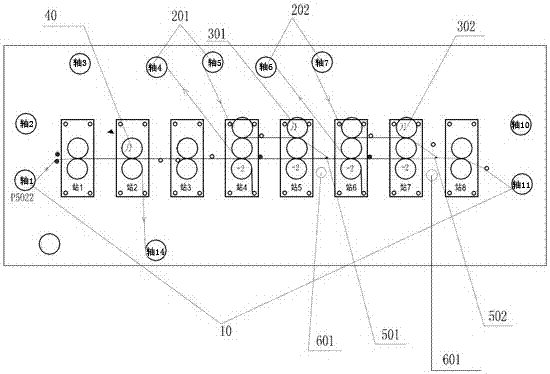

Circular knife laminating machine

ActiveCN106863988ASolve the problem of low production efficiencyAvoid misalignmentLamination ancillary operationsLaminationControl theory

The invention discloses a circular knife laminating machine comprising a controller, a material transmission shaft component, at least two groups of lamination object transmission shaft components and at least two second circular knifes used for cutting at least two lamination objects, wherein a first circular knife used for engraving a model hole in the material is arranged on the material transmission direction of the material transmission shaft component, at least two scraping knives are sequentially distributed behind the first circular knife, the at least two scraping knives are in one to one correspondence with the at least two second circular knifes, each lamination object is transmitted bypassing the second circular knifes and the scraping knives in sequence, an infrared sensing device is arranged at a position aligned with the lower side of each scraping knife, the infrared sensing device is used for detecting and locating the model hole in the martial, each group of lamination object transmission shaft components is further connected with a corresponding servo motor, the infrared sensing device is connected with the controller, and the controller is connected with the servo motor so as to guarantee the quality of the finished products and improve the production efficiency.

Owner:深圳市领滔科技有限公司

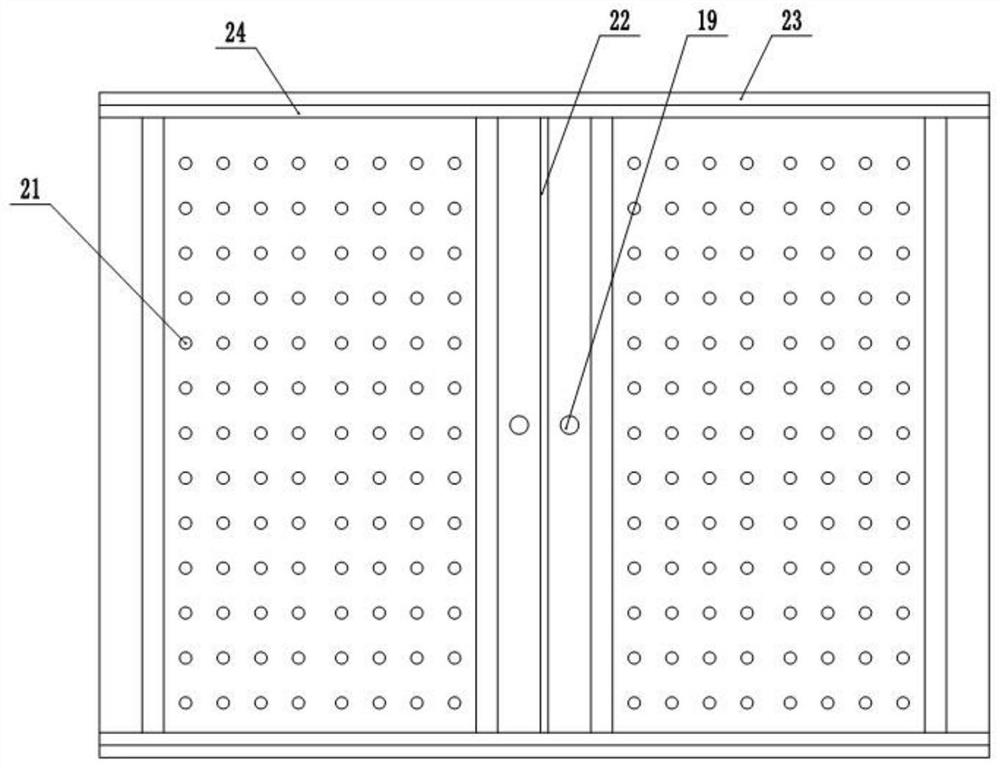

Multifunctional automatic assembling machine for inlaying ceramic chips

PendingCN114340176AQuick correctionSolve the problem of low production efficiencyPrinted circuit detailsPrinted circuit manufactureStructural engineeringAssembly machine

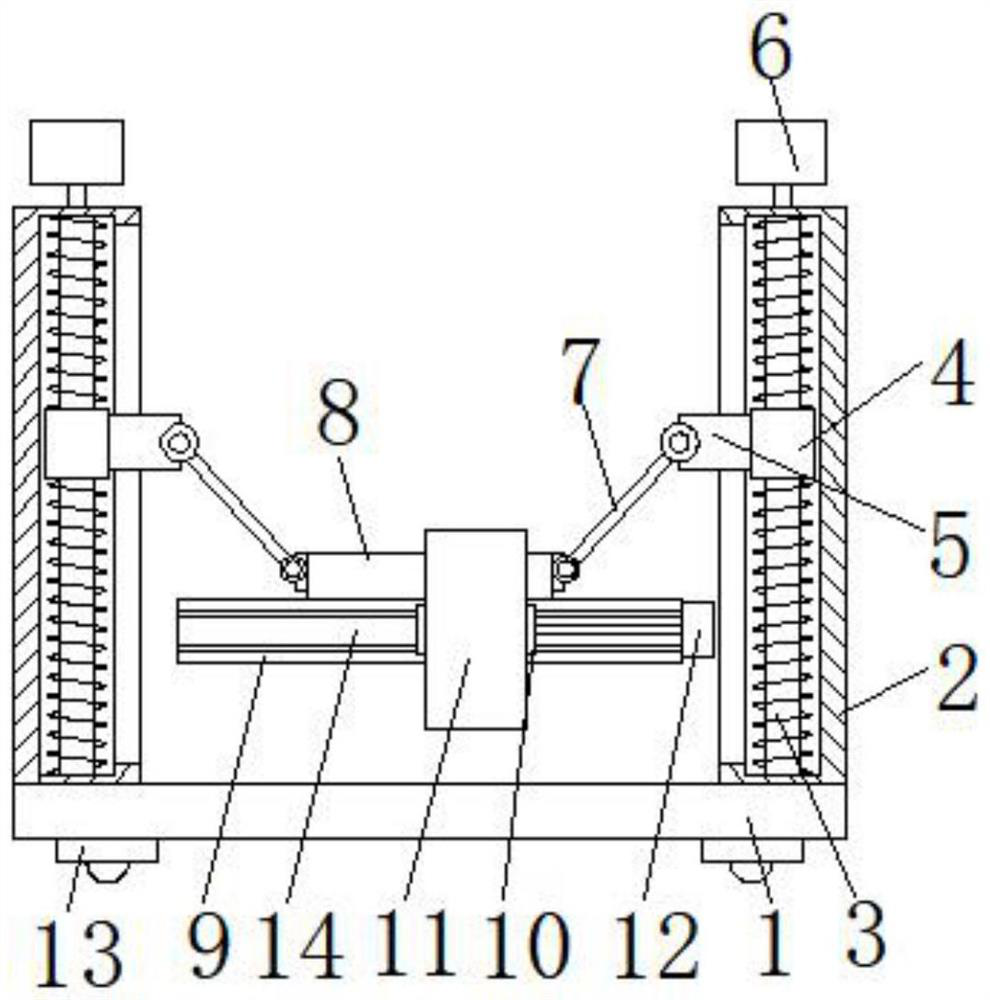

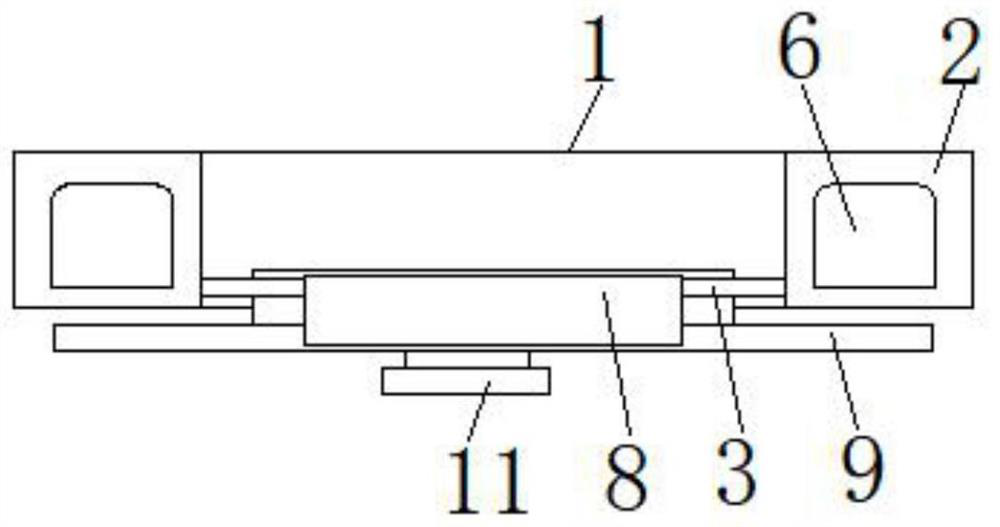

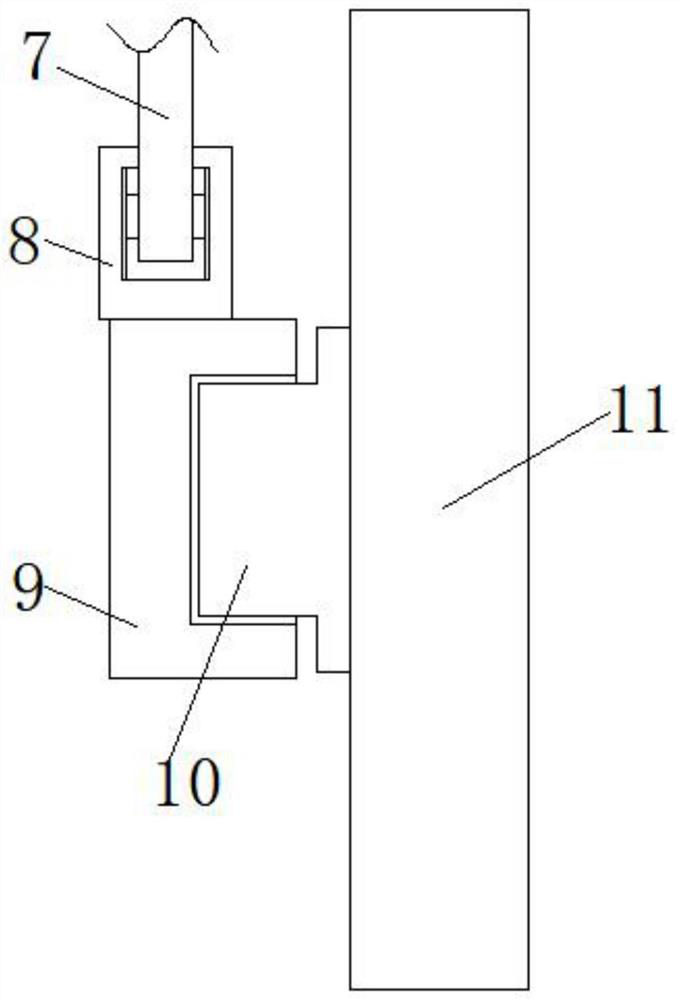

The invention relates to the technical field of ceramic wafer inlaying, in particular to a multifunctional automatic assembling machine for inlaying ceramic wafers, which comprises a base, vertical columns are respectively arranged on two sides of the top surface of the base along the edges, liftable connecting blocks are respectively connected in the columns in a lead screw transmission mode, and connecting rods are hinged to the connecting blocks. And the opposite ends of the connecting rods located on the two sides are hinged to the two sides of the same mounting support, a transverse plate is arranged at the bottom of the mounting support, a mounting plate is slidably connected to the transverse plate through a sliding table mechanism, and an inlaid ceramic wafer to be assembled is attached to the mounting plate. According to the assembling machine, the position of the ceramic wafer can be rapidly corrected according to the actual PCB assembling requirement, the ceramic wafer can be accurately positioned and installed at the designated position, the automatic adjusting process is achieved, the assembling machine is simple and reliable, and the working efficiency can be improved easily.

Owner:厦门鑫晶垡陶瓷制品有限公司

Quick-frozen ball production equipment

InactiveCN113324356ASolve the problem of low production efficiencyContinuous and efficient productionLighting and heating apparatusIce productionSpherical recessIndustrial engineering

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

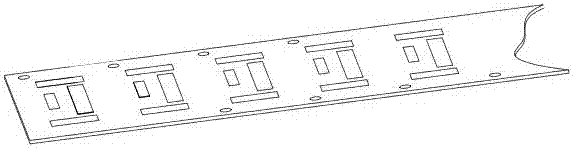

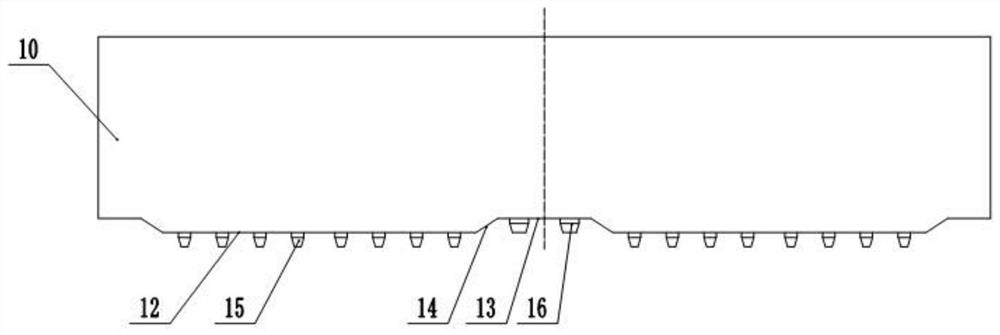

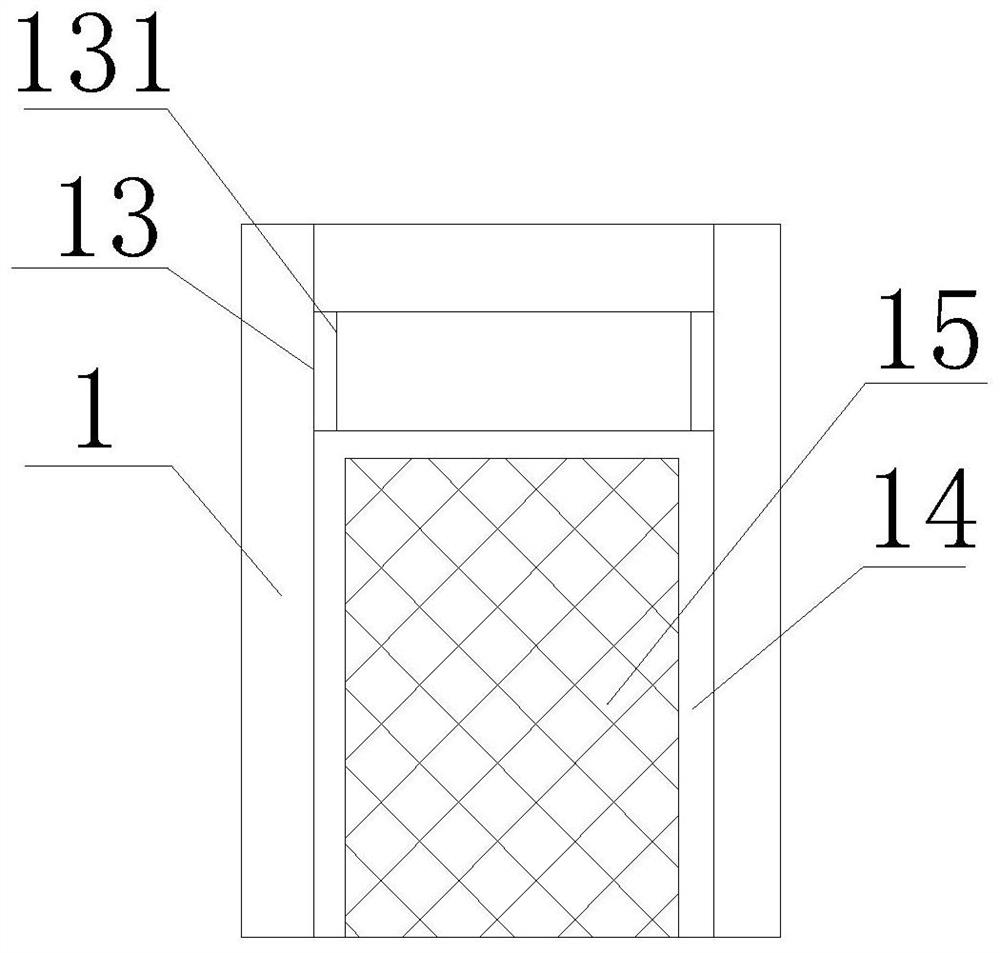

Distribution box door plate bevel edge process

ActiveCN111604414AQuality improvementEven by forceShaping toolsPerforating toolsPunch pressStructural engineering

The invention relates to the technical field of distribution box preparation, and particularly discloses a distribution box door plate bevel edge process. A special bevel edge mold is adopted and comprises an upper mold head and a lower mold base, convex mold faces are symmetrically arranged at the bottom of the upper mold head and comprise convex edges and side edges, bevel edges are formed between the convex edges and the side edges, a plurality of hole forming punches are evenly distributed on the convex edges, lock hole punches are arranged on the side edges, a concave mold groove is formed in the lower mold base, and a first containing cavity and a second containing cavity are formed in the bottom of the concave mold groove. The process comprises the specific steps that the upper moldhead is fixed to hydraulic equipment, and the lower mold base is fixed to a punch press; two door plates to be punched are placed on the lower mold base and are symmetrically placed relative to the center line of the upper mold head; and the upper mold head is driven to move downwards, and meanwhile punching of the two door plates are completed. By the adoption of the process, the door plate production efficiency is improved, and the service life of the mold is prolonged.

Owner:重庆博顺电气有限公司

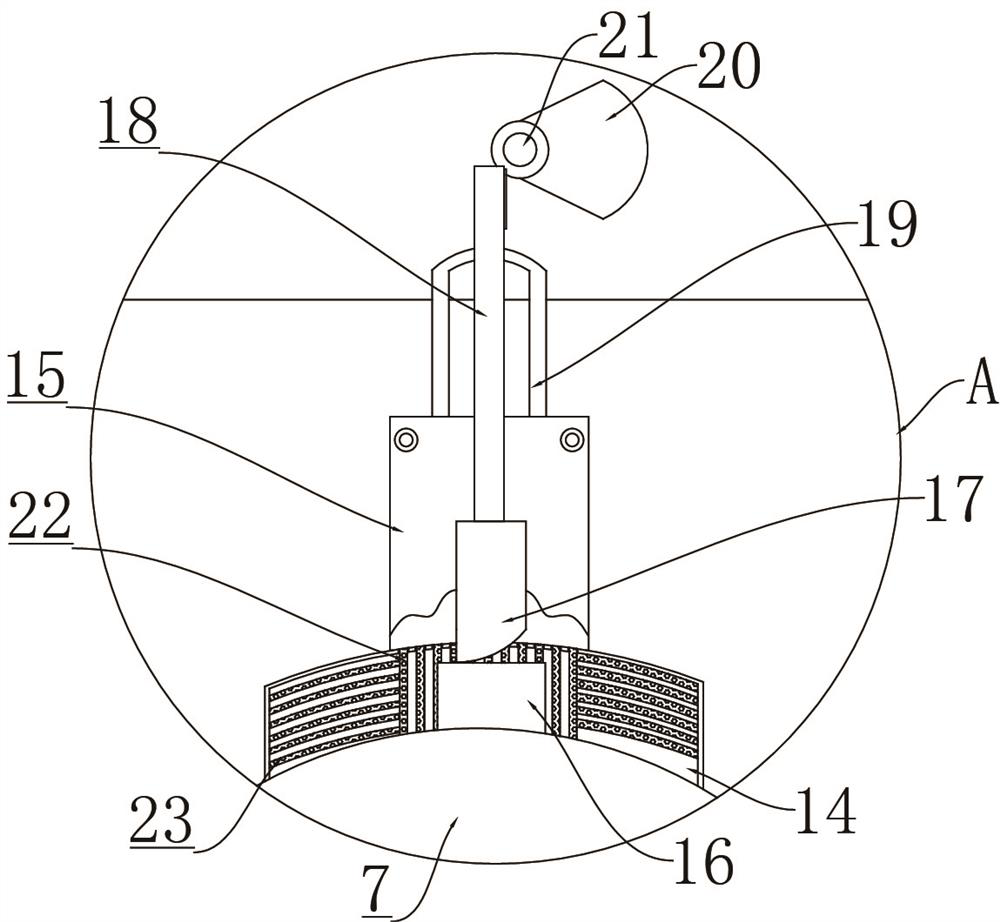

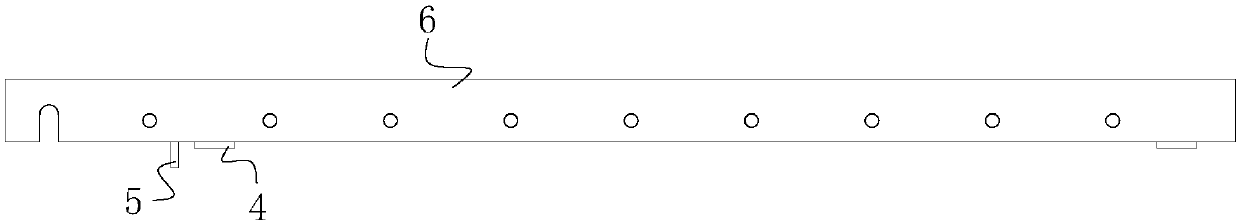

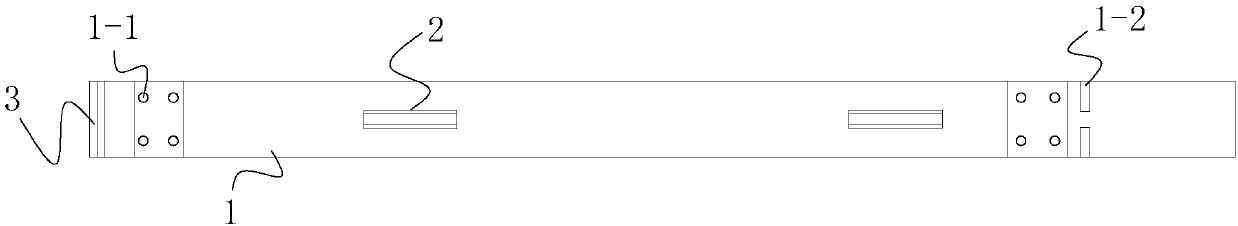

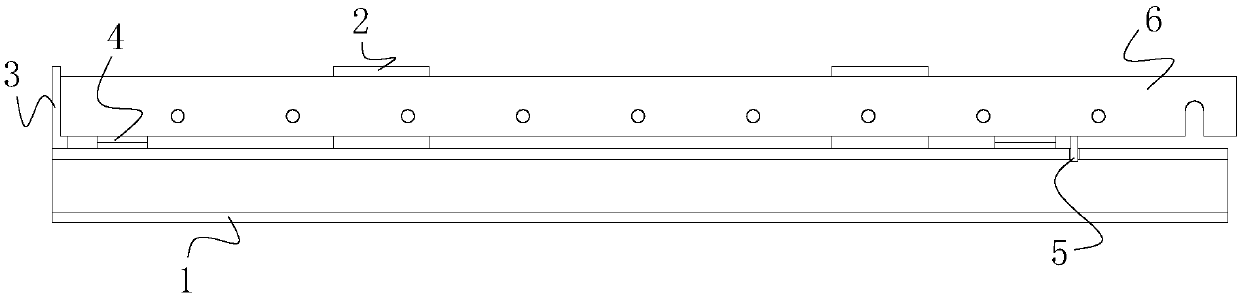

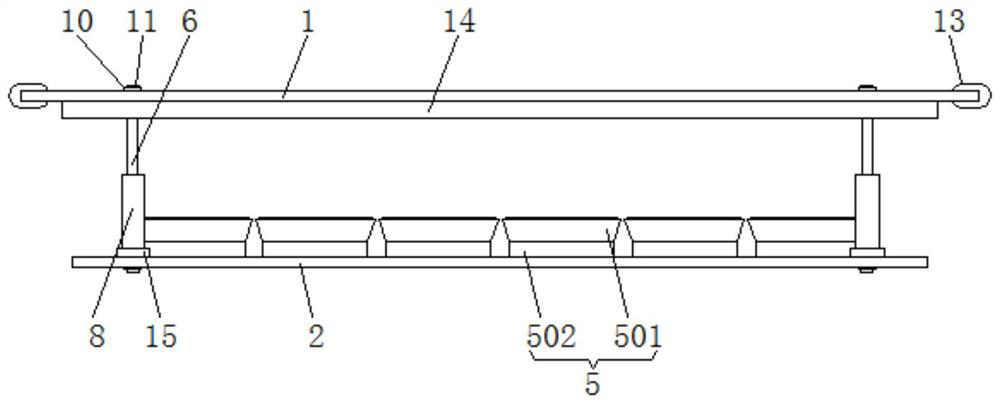

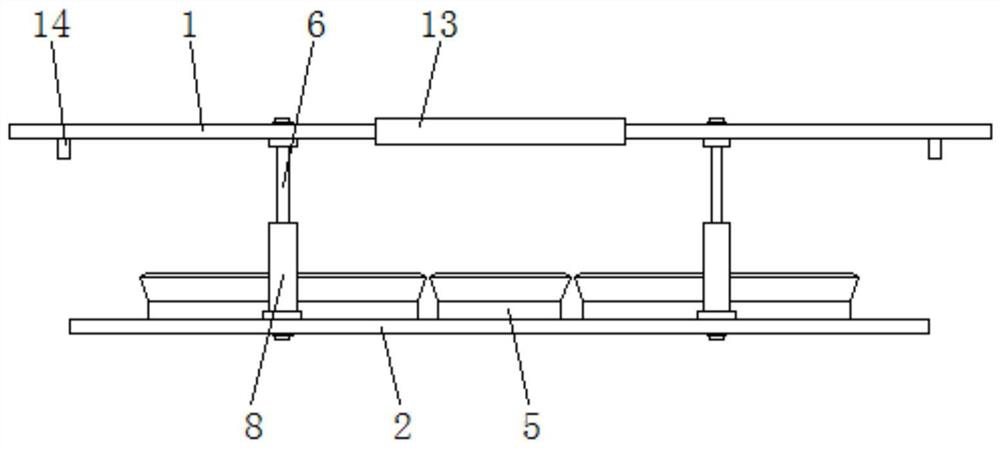

Assembly welding fixture for airport transportation roller bed connecting beam

InactiveCN107775238AQuality improvementSolve the problem of low production efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention relates to a butt welding tool for connecting beams of airport transport rollers, which is characterized in that it includes a base, a transverse positioning plate and a longitudinal positioning plate; the longitudinal positioning plate is fixed on the base, and the transverse positioning plate is fixed on the base On the seat, the longitudinal positioning plate has a longitudinal positioning plane, the transverse positioning plate has a transverse positioning plane, the longitudinal positioning plane is perpendicular to the transverse positioning plane, the base is provided with a positioning hole, and the base is provided with a positioning slot. The welding position and accuracy of the connecting beam, the bottom support plate and the motor connecting plate can be precisely positioned by using the tooling of the present invention, which solves the problem that it is difficult to ensure the position requirements and the production efficiency is low only by manual marking and alignment, and finally realizes the airport High-quality, efficient production of transport rollers.

Owner:TIANJIN SERI MACHINERY EQUIP

Kitchen knife blade preparation process

ActiveCN103317302BSolve the problem of low production efficiencyFurnace typesHeat treatment furnacesKnife bladesMachining process

Owner:如东县东广物流有限公司

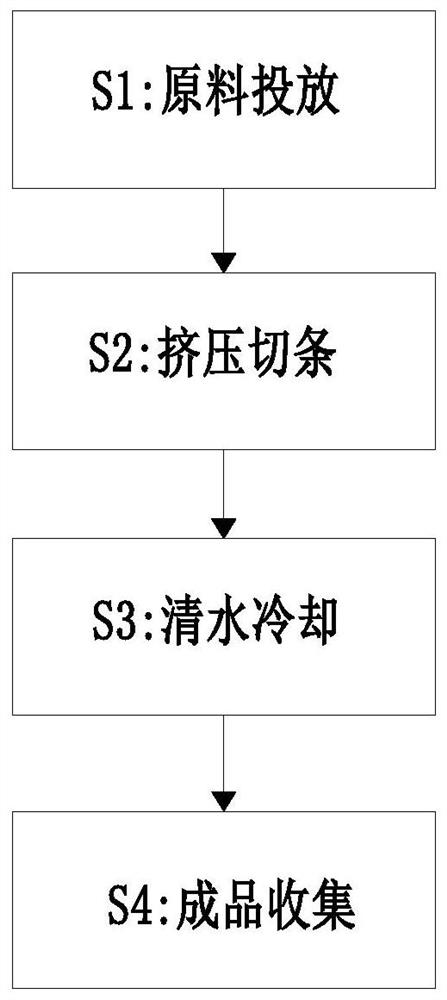

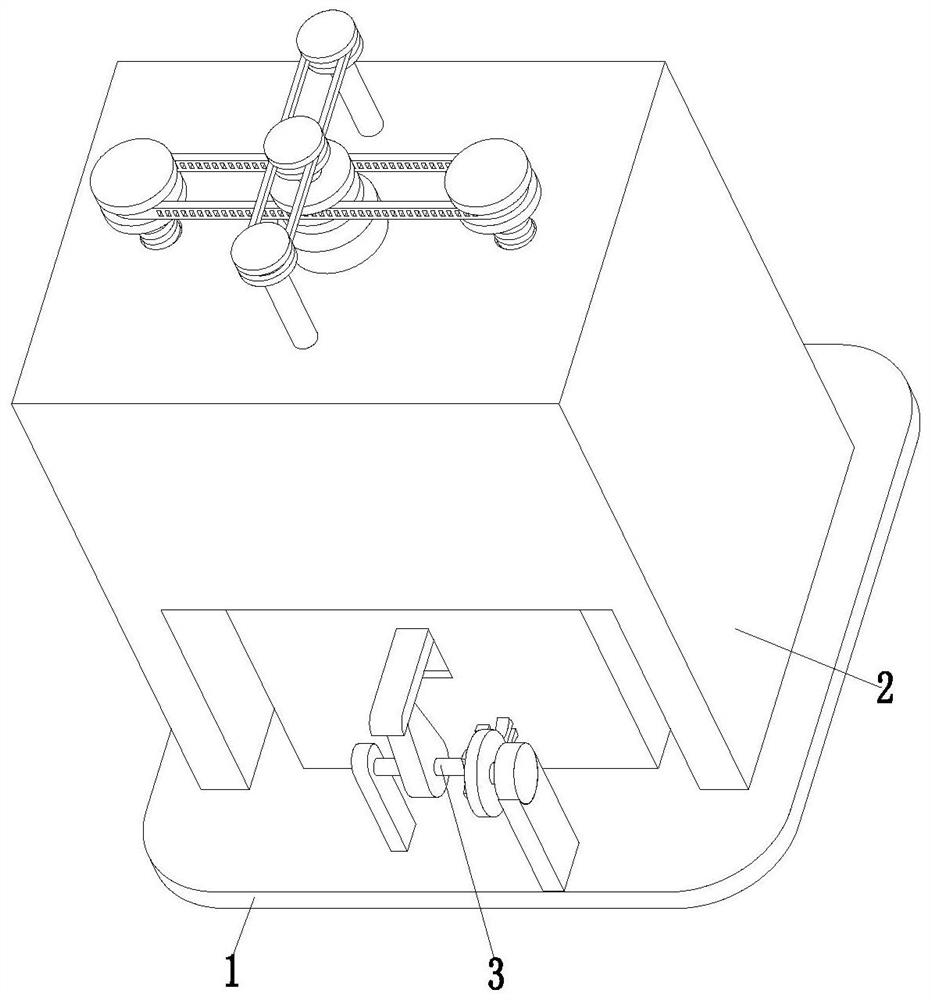

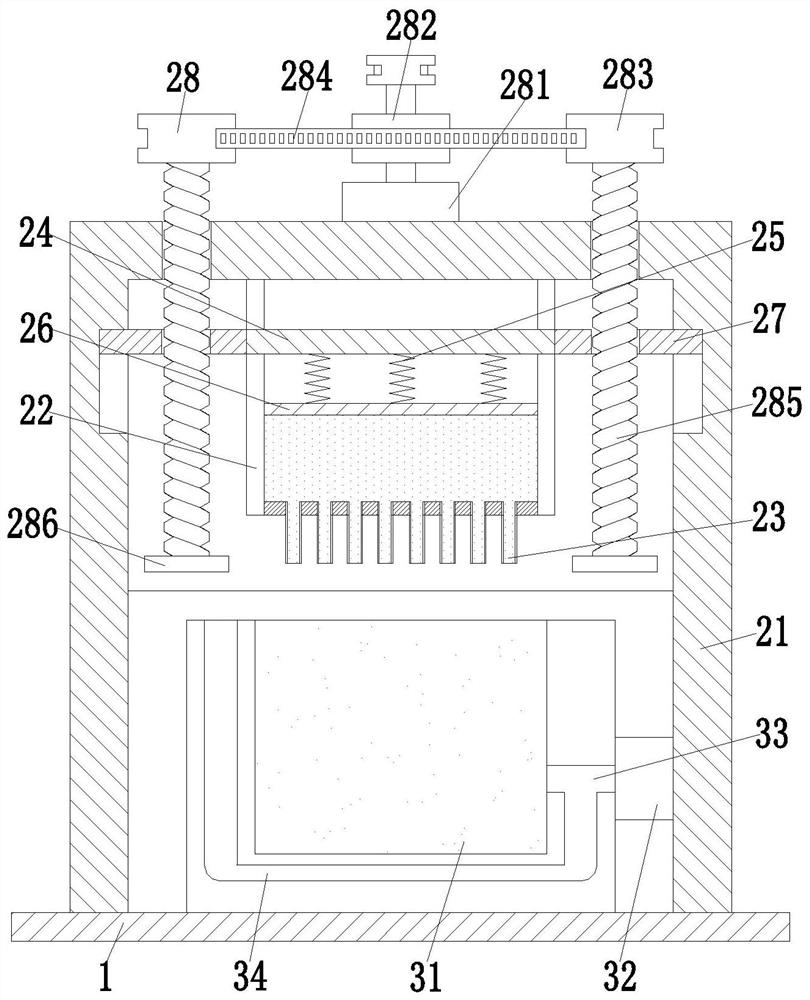

Buna-N rubber product producing and machining method

InactiveCN113021827ASolve the problem of low production efficiencyImprove cooling effectMetal working apparatusProcess engineeringMaterials science

The invention relates to a Buna-N rubber product producing and machining method. A Buna-N rubber product producing and machining device is used in the method, and comprises a bottom plate, an extruding and slitting mechanism and a cooling and shaping mechanism. The method can solve the problems that an existing Buna-N rubber product producing and machining device cannot stably extrude a rubber raw material in a molten state from a molding pipe, it cannot be guaranteed that the rubber strip extruding action and the rubber strip cutting action are conducted at the same time, the cutting lengths of rubber strips are different, and the rubber strip producing and manufacturing efficiency is low; and the method can also solve the problems that due to the fact that the existing Buna-N rubber product producing and machining device cannot rapidly cool the cut rubber strips in time, the rubber strips are stacked together and are pressed and deformed, cooling water cannot be circulated in time, and consequently, the cooling effect on the rubber strips is poor.

Owner:邹乐云

Material head punching device

ActiveCN105382883BSolve the problem of low production efficiencyIncrease productivityMetal working apparatusPunchingEngineering

The invention discloses a stub bar punching device. A rack is provided with an upper die seat and a lower die seat. The bottom face of the upper die seat is provided with multiple punching dies annularly arranged. The top face of the lower die seat is provided with workpiece grooves corresponding to the punching dies. The portion, above the upper die seat, of the rack is provided with a punching air cylinder connected with the upper die seat. The portion, below the lower die seat, of the rack is provided with an ejection air cylinder. The ejection air cylinder is connected with ejector rods arranged in the workpiece grooves. By means of the stub bar punching device, the problems that the manner in which a single workpiece is punched multiple times is adopted and production efficiency is very low in the prior art are solved effectively; and multiple workpieces can be separated through one-time punching, production efficiency is high, the uniformity of products is good, and the stub bar punching device has very high practical value.

Owner:宁波拓普电器有限公司

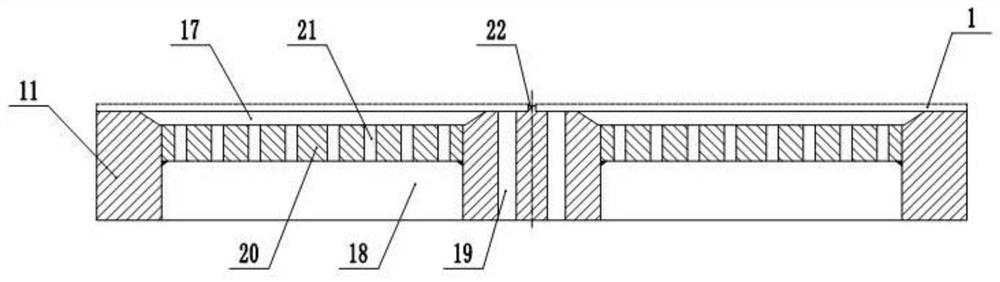

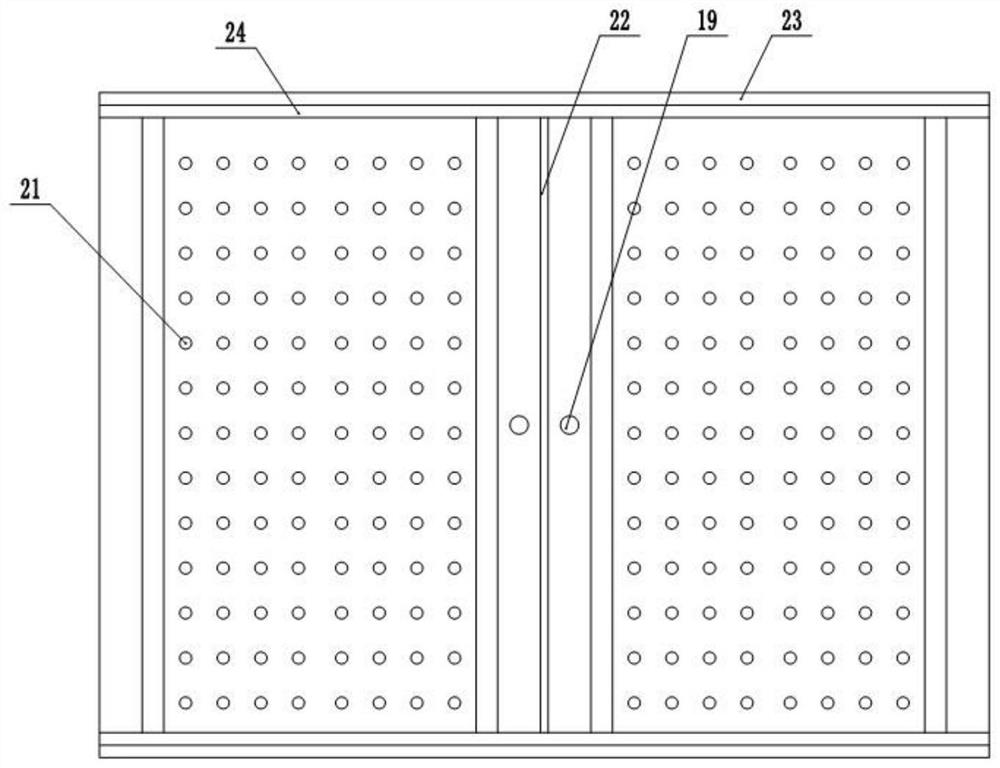

Multifunctional rapid loading and unloading goods shelf tray for cosmetic production

ActiveCN112623398AIncrease productivityQuick loading and unloadingMetal working apparatusIndividual articlesCotton padSemi automation

The invention discloses a multifunctional rapid loading and unloading goods shelf tray for cosmetic production, and relates to the technical field of cosmetics. The multifunctional rapid loading and unloading goods shelf tray for cosmetic production comprises a panel and a bottom plate, wherein the bottom plate is located under the panel; the panel and the bottom plate are parallel to each other; mounting top holes and a plurality of station holes are formed in the upper surface of the panel; the plurality of station holes are distributed in a matrix mode; the mounting top holes are located in the side faces, close to the station holes in the two sides of the panel, of the panel; the number of the mounting top holes is four; positioning cylinders are arranged at the positions, corresponding to the station holes, of the upper surface of the bottom plate; and movable rods are arranged at the positions, corresponding to the mounting top holes, of the lower surface of the panel. According to the multifunctional rapid loading and unloading goods shelf tray for cosmetic production provided by the invention, by arranging the panel, the bottom plate, the station holes, the positioning cylinders, the movable rods, fixed pipes and baffles, the problem that the production efficiency is not high due to the fact that makeup cotton produced by semi-automatic makeup cotton production equipment is connected with leftover materials and needs to be taken down by workers one by one so as to be packaged is solved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Bevel edge technology of distribution box door panel

ActiveCN111604414BEven by forceExtended service lifeShaping toolsPerforating toolsPunchingStructural engineering

Owner:重庆博顺电气有限公司

A hvpe device capable of mass production of gallium nitride

ActiveCN108914202BSolve the problem of not enough to completely cover the substrate sheetSolve the problem of low production efficiencyPolycrystalline material growthFrom chemically reactive gasesSemiconductor materialsHigh volume manufacturing

Owner:北京镓数智能科技有限公司

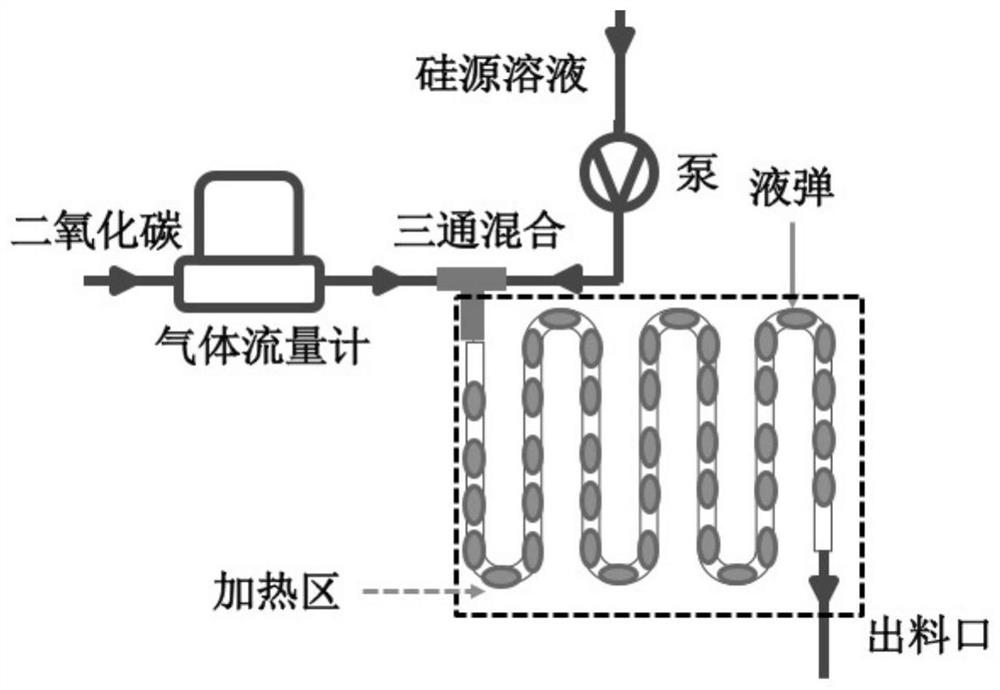

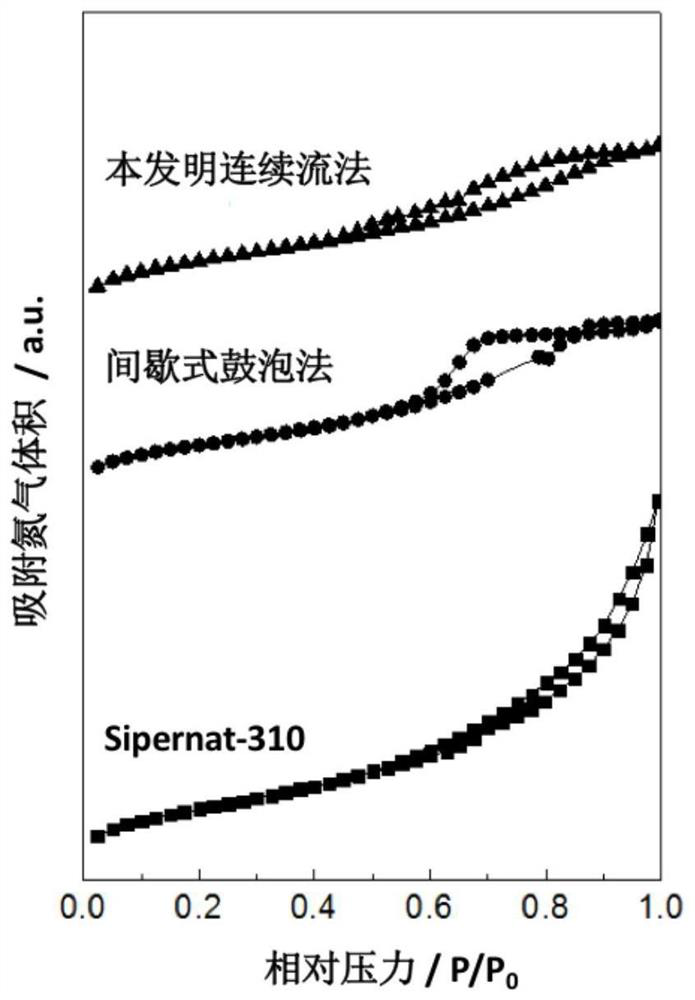

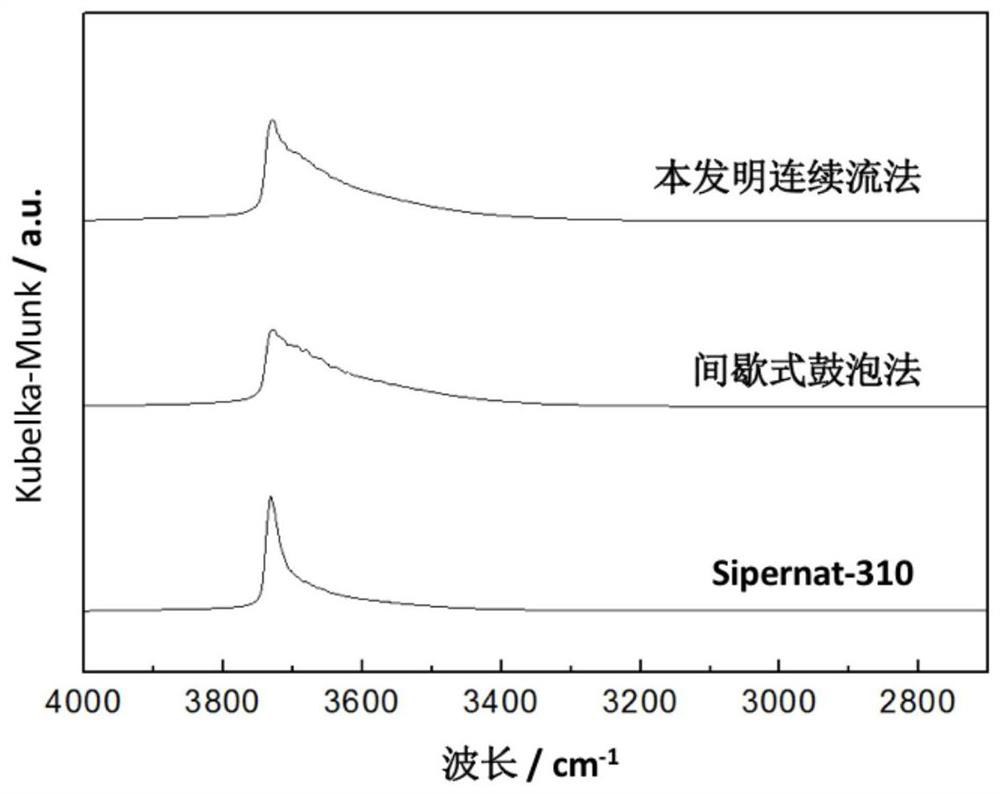

A kind of method for preparing silica with high specific surface area by tubular continuous flow method

The invention discloses a method for preparing silicon dioxide with high specific surface area by using a tubular continuous flow method, and develops a novel precipitation method based on a small tube diameter tubular continuous flow method. The method is used for producing the silicon dioxide with high specific surface area, wherein a raw material for producing white carbon black is sodium silicate, silica sol or a mixed solution of sodium silicate and silica sol, and carbon dioxide gas serving as an acidifying agent goes through a gas-liquid alternating section flow formed by the tubular continuous flow method, so that the problem of mass and heat transfer on micro level is solved fundamentally. Therefore, according to the method disclosed by the invention, silicon dioxide with high specific surface area, small particles and stable product quality can be produced continuously.

Owner:合肥星巢环保科技有限公司

Map element extraction method, device and server

ActiveCN110160502BImage Segmentation AccurateGuaranteed accuracyImage enhancementImage analysisPattern recognitionPoint cloud

The present invention discloses a map element extraction method, device and server. The map element extraction method includes: acquiring a laser point cloud and an image of a target scene, the target scene including at least one element entity corresponding to a map element; performing the registration between the laser point cloud and the image to obtain a depth map of the image; image segmentation is performed on the depth map of the image to obtain a segmented image of the map element in the depth map; according to the The registration relationship between the laser point cloud and the image converts the two-dimensional position of the segmented image in the depth map into the three-dimensional position of the map element in the target scene. The method, device and server for extracting map elements provided by the present invention solve the problem of low production efficiency of high-precision maps in the prior art.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Portable paint filtering device

InactiveCN106474807ALow costSimple structureFiltration circuitsStationary filtering element filtersEngineeringOne pass

The invention relates to a portable paint filtering device which comprises a bottom plate. Two L-shaped support plates are symmetrically installed on the upper end face of the bottom plate, a feed hopper is installed between the upper ends of the two L-shaped support plates which play a role of fixing and supporting the feed hopper, an S-shaped filter pipe is connected to the lower end of the feed hopper, a sundry pipe is connected to the lowest portion of the left end of the S-shaped filter pipe, a screw cap is installed at the lower end of the sundry pipe through a thread, an operator only needs to manually rotate the screw cap to open the sundry pipe, the inner wall of the middle portion of the S-shaped filter pipe is provided with a first filter disc which is uniformly provided with first filter holes, one-pass filtration is conducted on paint through the first filter holes formed in the first filter disc, large impurities are removed, and residual large impurities can be taken out through the sundry pipe. According to the portable paint filtering device, on the premise of the low cost, the automatic and rapid filtering function of the paint can be achieved, the portable paint filtering device has the advantages of being simple in structure, low in cost, high in filtration efficiency and the like, and the production efficiency of the paint is greatly improved.

Owner:ANHUI MEILIN BUILDING MATERIAL

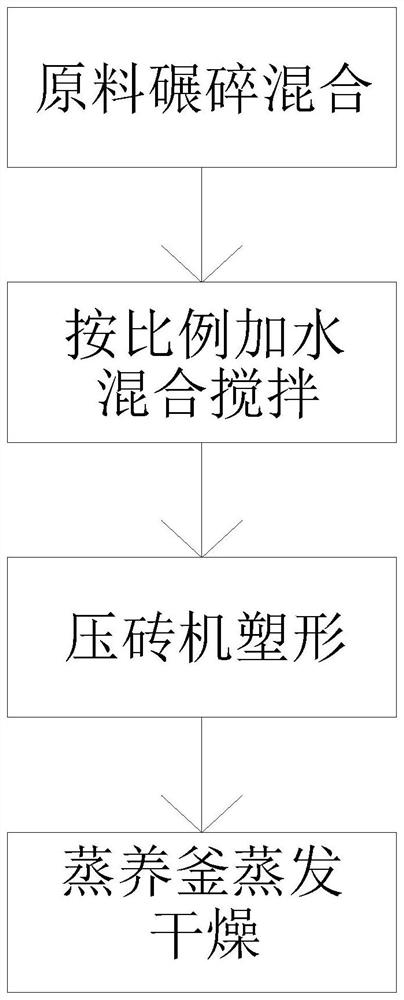

Tailing sintered brick for room body building and processing technology

ActiveCN114455937AEasy to manufactureMeet the need for plasticityMixing operation control apparatusPretreatment controlBrickMining engineering

The invention discloses a tailing sintered brick for room body building and a processing technology, and relates to the technical field of building bricks, the tailing sintered brick comprises a sintered brick, the sintered brick comprises main mineral compositions of clay, shale and fly ash, and the raw materials comprise 30-75% of clay, 15-30% of shale and 30-50% of fly ash. Through the crushing function of the crushing machine device, raw materials are crushed into small blocks, then the small blocks are matched with a material screening net at a discharging opening of the crushing machine for filtering, the crushing machine can conveniently crush qualified raw materials, so that the raw materials are better mixed and stirred, and then the raw materials are put into a stirring valve, so that clay, shale and coal ash are stirred and mixed; after stirring is conducted for a period of time, water is injected into the device, mixed materials become thick slurry, the problems that the raw materials are different in size, so that convenient mixing of the raw materials is affected, and the green brick manufacturing efficiency is reduced are solved, the device can conveniently smash the raw materials, and the device can better conduct mixing and stirring.

Owner:吉林吉辉钼业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com