High-ductility high-strength rare earth aluminum alloy material and preparation method thereof

An aluminum alloy material and ductility technology, applied in the field of metal alloys, can solve problems such as general tensile strength and elongation performance, high requirements for deformed aluminum alloys, and strict requirements for alloy performance, and achieve high industrial value, high strength and Excellent plasticity and molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This example discloses a high ductility and high strength rare earth aluminum alloy material and its preparation method. The rare earth aluminum alloy material introduces Ti, Sr, Ce and La rare earth elements into Al-Cu, effectively improving the aluminum alloy Excellent casting performance, reduce the solidification interval and dendrite spacing of the alloy, and have higher strength and plasticity. The rare earth aluminum alloy material does not require high-purity Al ingots and expensive alloys such as Zr, V, Y, etc., and has low requirements on the ratio control of certain components, low production costs, and high industrialization value.

[0036] The rare earth aluminum alloy material of this embodiment is calculated according to mass percentage, and includes the following components: 2.4% Si, 4.6% Cu, 0.70% Mn, 0.30% Re, 0.20% Ti, 0.01% Sr and 91.63% Al, and the balance is impurities; in the Re, the mass ratio of Ce to La is 14:11.

[0037] The rare earth alumin...

Embodiment 2

[0052] This embodiment provides a rare earth aluminum alloy material, which includes the following components according to the mass percentage: 3.1% Si, 4.1% Cu, 0.6% Mn, 0.15% Re, 0.13% Ti, 0.04% Sr and 91.68% Al, and the balance is impurities; wherein, in the Re, the mass ratio of Ce to La is 1:1.

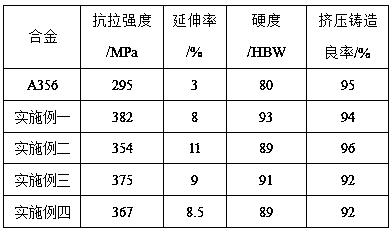

[0053] The preparation raw materials, equipment and preparation method of the rare earth aluminum alloy material are the same as the first embodiment, but the addition amount of each raw material is prepared according to the formula of this embodiment. As shown in Table 1, the tensile strength of this rare earth aluminum alloy material is 354MPa, the elongation is 11%, and the hardness is 89HBW, which has the advantages of high strength and good plasticity.

Embodiment 3

[0055] This embodiment provides a rare earth aluminum alloy material, which includes the following components according to the mass percentage: 3.5% Si, 4.8% Cu, 0.9% Mn, 0.4% Re, 0.15% Ti, 0.02% Sr and 90.03% Al, and the balance is impurities; in the Re, the mass ratio of Ce to La is 7:5.

[0056] The preparation raw materials, equipment and preparation method of the rare earth aluminum alloy material are the same as the first embodiment, but the addition amount of each raw material is prepared according to the formula of this embodiment. As described in Table 1, the tensile strength of this rare earth aluminum alloy material is 375MPa, the elongation is 9%, and the hardness is 91HBW, which has the advantages of high strength and good plasticity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com