Tailing sintered brick for room body building and processing technology

A processing technology and sintered brick technology, which is applied in the field of building bricks, can solve problems such as brick shaking, device is easy to generate vibration force, and affects the working efficiency of bricks, so as to achieve a good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] First aspect, such as Figure 1-7 As shown, the present invention provides a kind of tailings sintered bricks for house construction, including sintered bricks, the main mineral composition of sintered bricks is clay, shale and fly ash, and the proportion of raw materials is: clay 30-75% , shale 15-30%, fly ash 30-50%, the SiO2 content in the fly ash is 20-47%, the Al2O3 content is 16-26%, the particle size of the fly ash is ≤0.08mm, and the powder coal The ash contains irregular vitreous bodies.

[0043] In this embodiment, clay, shale and fly ash are crushed, according to the ratio: 30-75%, 15-30% and 30-50%, mixing and stirring, using shale and fly ash The chemical composition of the clay is similar to that of clay, and a certain amount of clay is added to the interior of shale and fly ash to meet the need for plasticity during billet making, making the device better for manufacturing fired bricks.

Embodiment 2

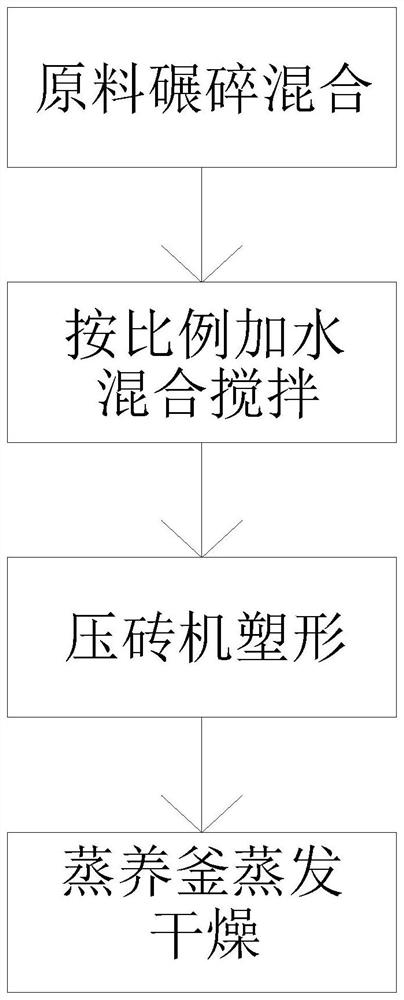

[0045] Second aspect, such as Figure 1-7 As shown, the present invention also provides a processing technology for tailings sintered bricks used in house construction, and the processing technology for tailings sintered bricks used in house construction includes the following steps:

[0046] Step 1: The raw materials are crushed and mixed;

[0047] Step 2: Add water in proportion to mix and stir;

[0048] Step 3: Brick press shaping;

[0049] Step 4: Evaporate and dry in the steam-cured kettle.

[0050] Step 1 also includes: placing the raw materials of clay, shale and fly ash in the crusher for crushing, and then screening them with a sieve, and then placing them in the mixing valve for mixing according to the ratio of the raw materials. Step 2 also includes: injecting 15% of water into the inside of the stirring valve, so that the mixed material is mixed with water, and then stirs and mixes. Step 3 also includes: placing the mixed raw materials on the conveyor belt, and ...

Embodiment 3

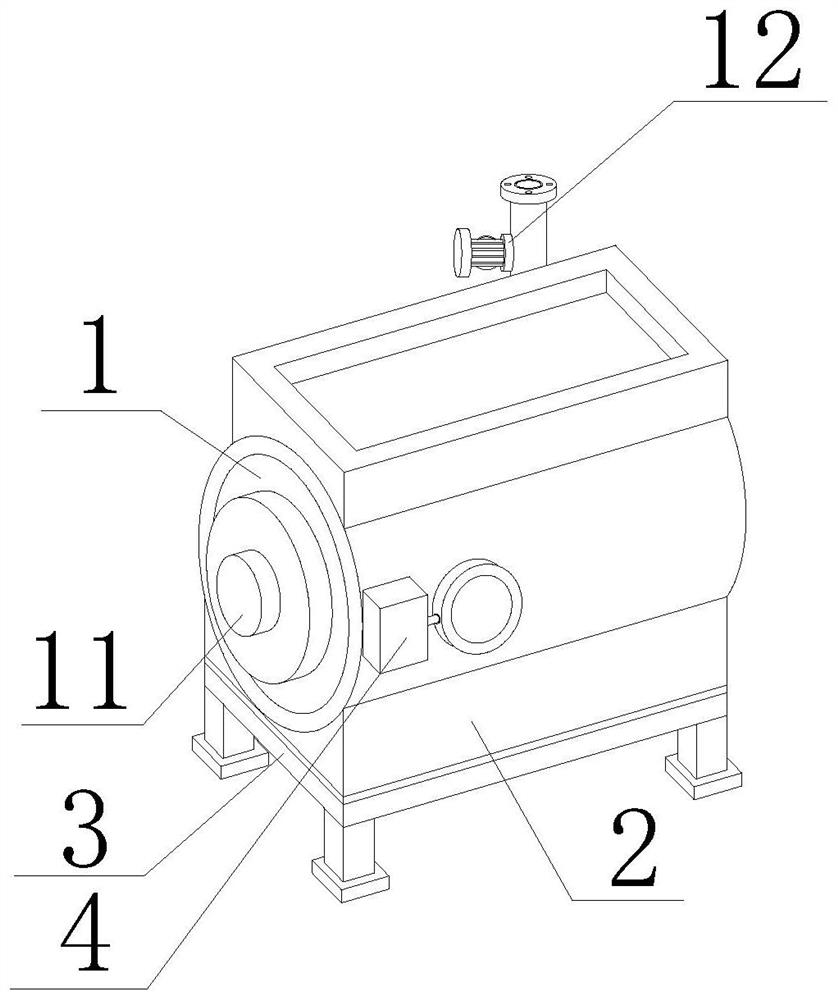

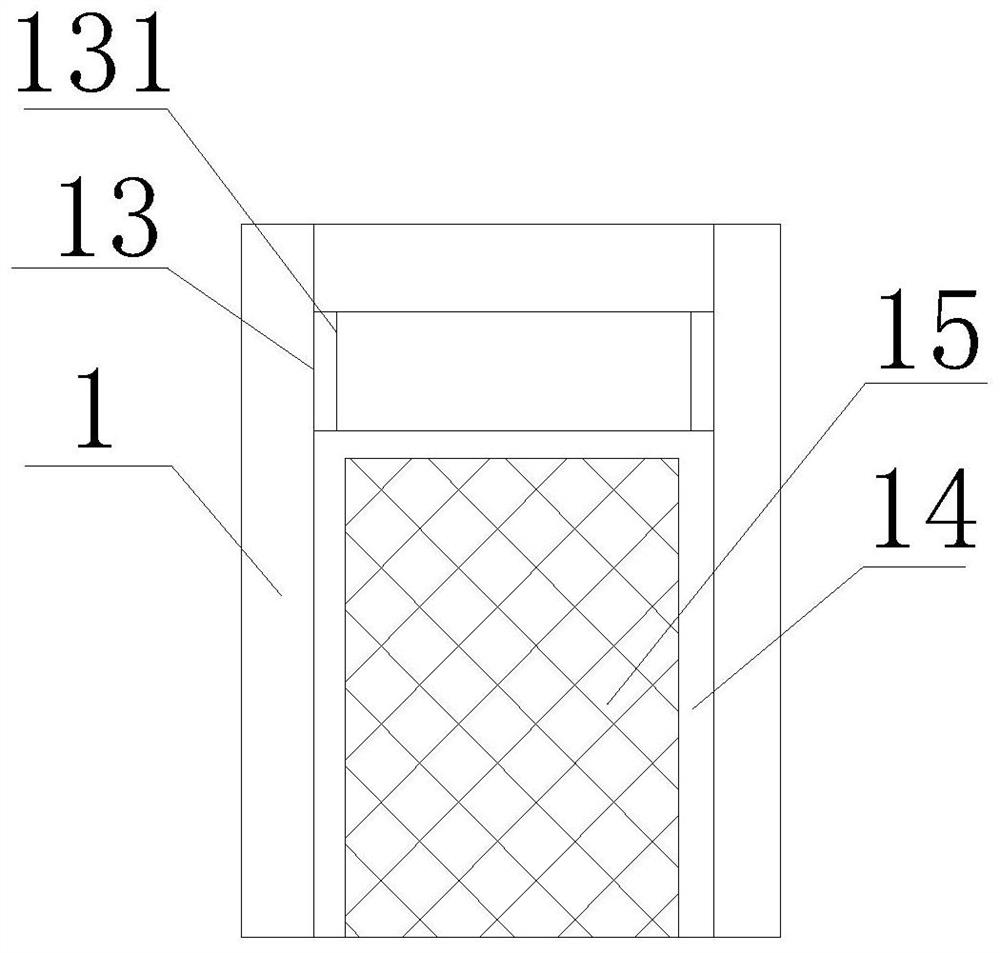

[0053] Such as Figure 1-7 As shown, on the basis of Example 2, the present invention provides a technical solution: preferably, one side of the steam-cured kettle body 1 is provided with a sealing cover 11, and the bottom of the steam-cured kettle body 1 is fixedly installed with an installation base plate 2, The bottom of the installation base plate 2 is fixedly installed with a support frame 3, the surface of the steam-cured kettle body 1 is fixedly installed with a temperature detector 4, the back of the steam-cured kettle body 1 is fixedly installed with a steam valve 12, and the two sides of the steam-cured kettle body 1 inner cavity The side is provided with a chute 13, the inner wall of the chute 13 is provided with a slide rail 131, the inside of the slide rail 131 is movable to install a sliding frame 14, the inside of the slide frame 14 is fixedly equipped with a protective net 15, and the protective net 15 is close to the side of the chute 13. A socket block 141 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com