A kind of method for preparing silica with high specific surface area by tubular continuous flow method

A high specific surface area, silica technology, applied in the direction of silica, silicon oxide, etc., can solve the problems of silica specific surface area that is difficult to break through, low production efficiency, safety hazards, etc., to achieve uniform concentration of reactants, The effect of sufficient contact and elimination of mass transfer problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

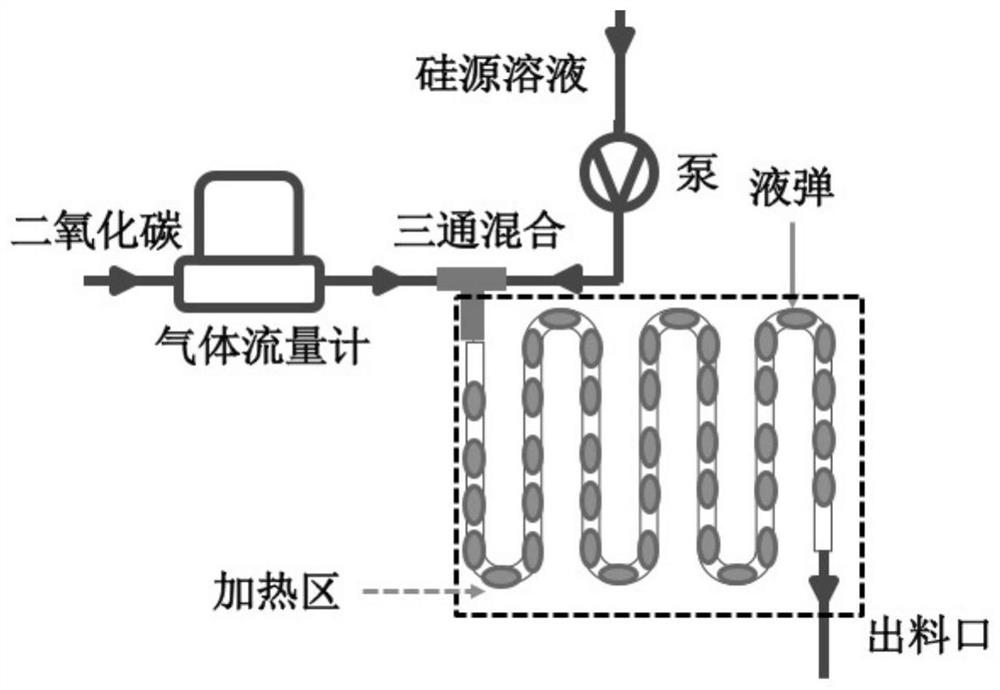

[0034] A method for preparing silicon dioxide with a high specific surface area by a tubular continuous flow method, comprising the following steps:

[0035] (1) Prepare ammonium salt solutions and silicon source aqueous solutions of different concentrations, add the silicon source solution into the ammonium salt solution, wherein the silicon concentration in the silicon source solution is 0.2mol / L, and the concentration of the salt solution is 2.0mol / L;

[0036] (2) Regulate reaction system temperature, reaction temperature is at 40 ℃;

[0037](3) regulate the flow rate of carbon dioxide gas and silicon source solution, the flow rate of carbon dioxide gas and silicon source solution is controlled at 20ml / min, 2ml / min respectively, carbon dioxide gas and silicon source liquid are passed through the tee of continuous flow reactor simultaneously, thereby Produce alternating segment flow of gas and liquid, and the liquid part separated by carbon dioxide bubbles is called a liquid...

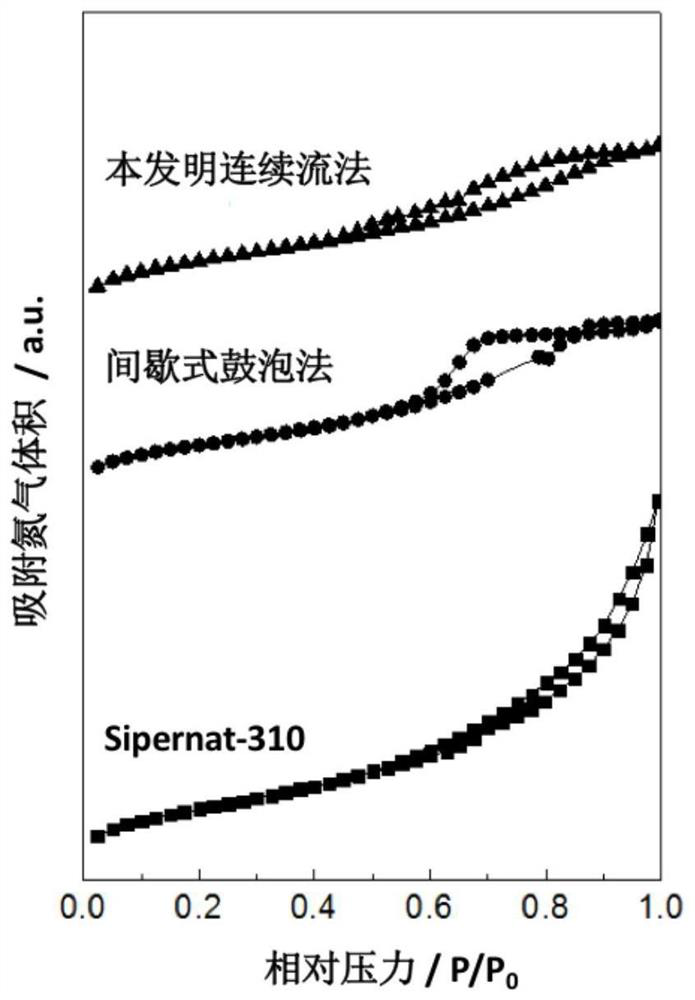

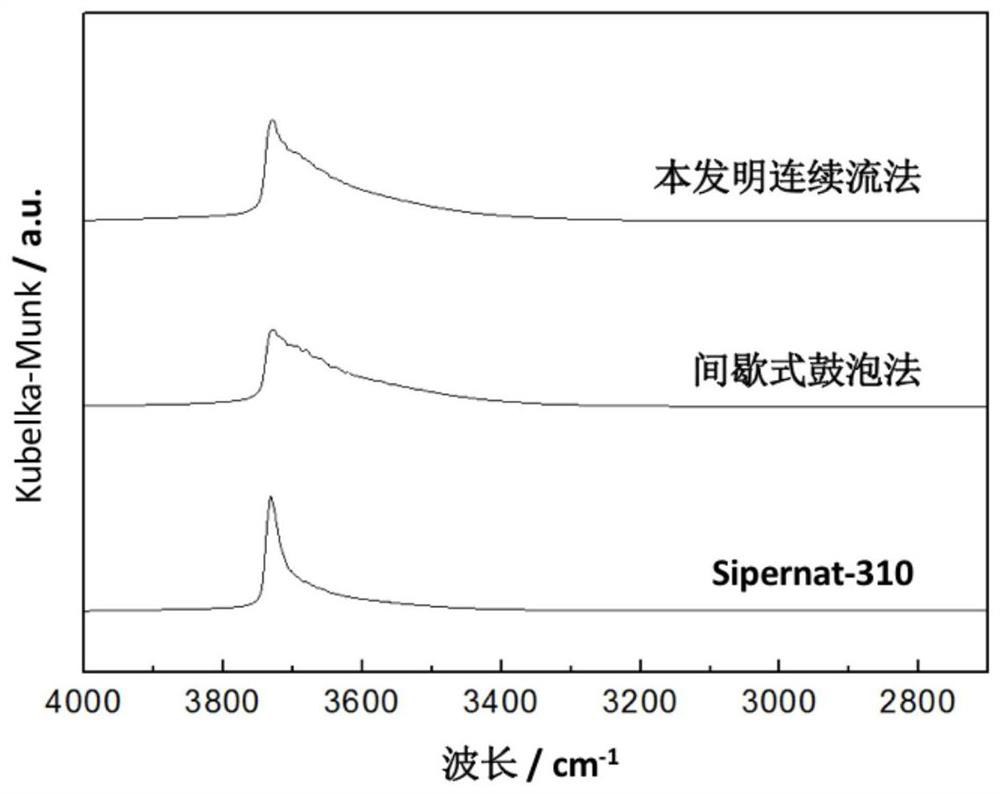

Embodiment 2

[0041] As a comparison, silica was prepared using the traditional intermittent bubbling method, the specific method is as follows:

[0042] 1. Mix the silicon source solution with the salt solution, the concentration is the same as in Example 1.

[0043] 2. Pass carbon dioxide gas into the above-mentioned solution, and keep stirring, the temperature and the flow rate of carbon dioxide are the same as in Example 1.

[0044] 3. The aftertreatment method is the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com