Multi-coiled panel veneer simultaneous feeding and automatic quick converting equipment and quick converting method thereof

A technology of rapid conversion and coiling, applied in the field of mechanical processing, can solve the problems of low production efficiency, achieve the effects of improving production efficiency, increasing speed and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

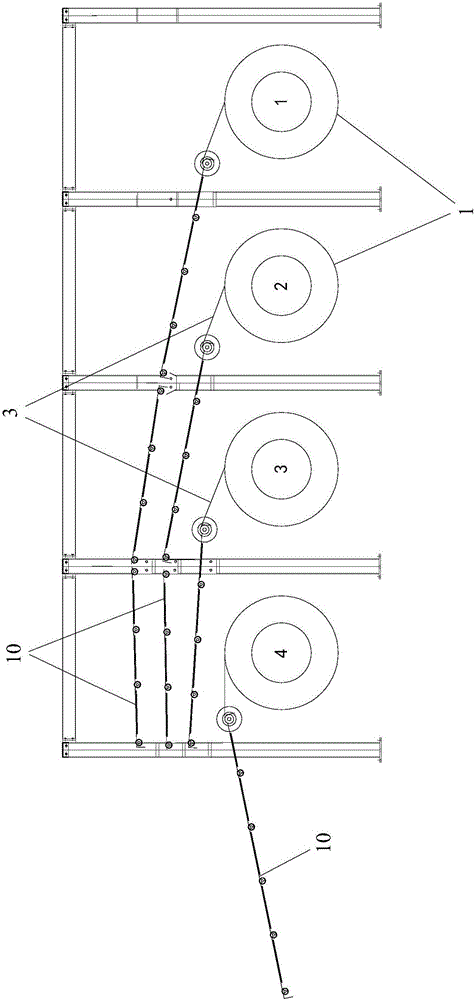

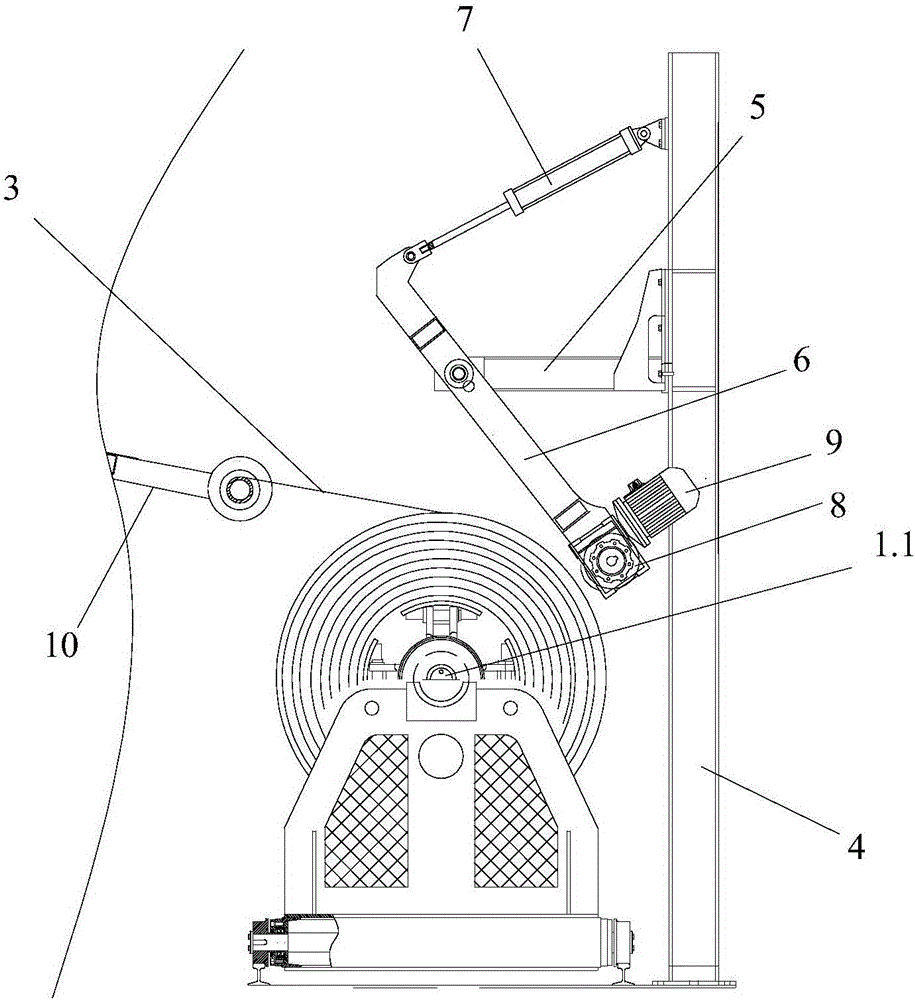

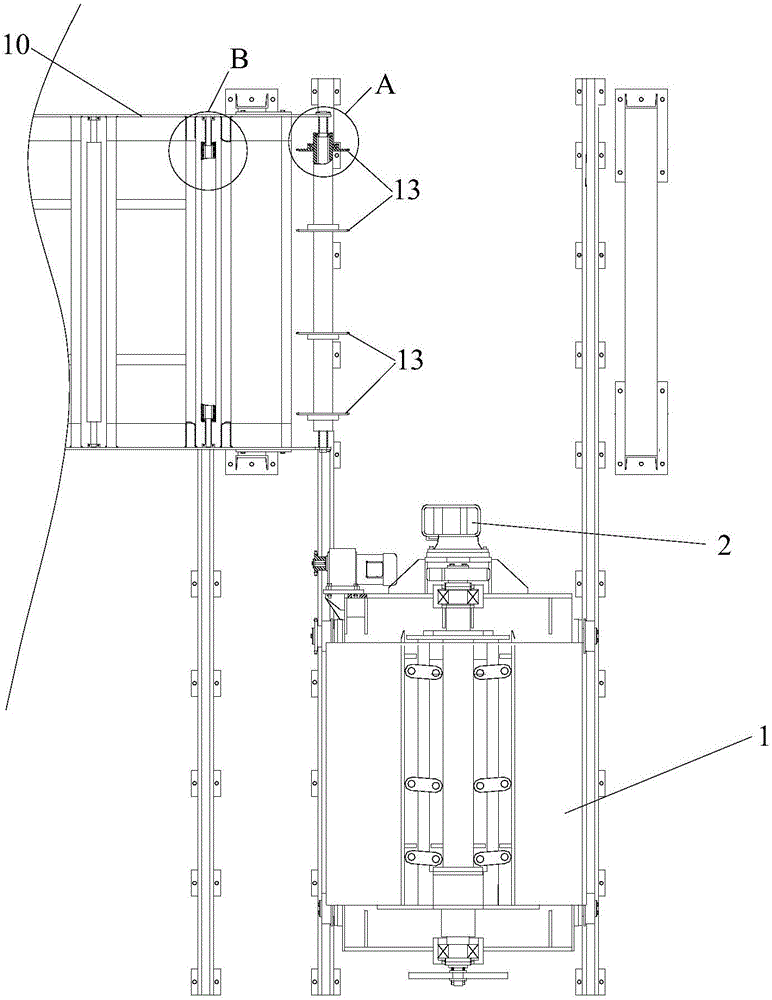

[0040] Such as Figures 1 to 8 As shown, the multi-volume sheet material feeding and automatic fast switching equipment of the present invention includes four metal coil sheet material feeding units and a metal coil sheet material conversion mechanism; wherein, each metal coil sheet material feeding unit includes a An uncoiler 1 for leveling the metal coil (the uncoiler is an integrated machine of the uncoiler and the feeding trolley), a driving device 2, a coiling device and a transmission platform for pushing the metal coil 3 . Among them, the driving device 2 is connected with the supporting shaft 1.1 of the uncoiler 1, and the coil pressing device is rotatably arranged on one side of the uncoiler 1, so as to push the metal coil sheet 3 placed on the uncoiler 1, and transfer the platform Set on the other side of the uncoiler 1.

[0041] And the metal coil sheet material conversion mechanism comprises lifting table 19, connection frame 20 and transmission datum plane 21, wh...

Embodiment 2

[0056] The only difference between this embodiment and the first embodiment is that two, three or more than four metal coil sheet feeding units can be set according to the production requirements, so as to simultaneously uncoil metal coil sheets of different specifications Feeding not only saves a lot of manpower and time, but also greatly improves production efficiency and reduces production costs.

[0057] At the same time, the metal coil sheet conversion mechanism also sets the connecting frame according to the number of metal coil sheet feeding units, and sets two, three or four or more transmission lines on the connecting frame correspondingly, and drives the connection through the lifting platform The lifting frame can connect one of the multiple transmission lines with the transmission reference plane, so as to realize the selective and rapid conversion of the loaded metal coils and sheets of different specifications, which not only saves a lot of manpower and time, but ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com