Aircraft three-dimensional surface flow distribution wind tunnel measurement method

A three-dimensional surface, flow distribution technology, applied in the direction of measuring devices, testing of machine/structural components, instruments, etc., can solve problems such as low production efficiency, and achieve the effect of solving low production efficiency, improving test efficiency and shortening test cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

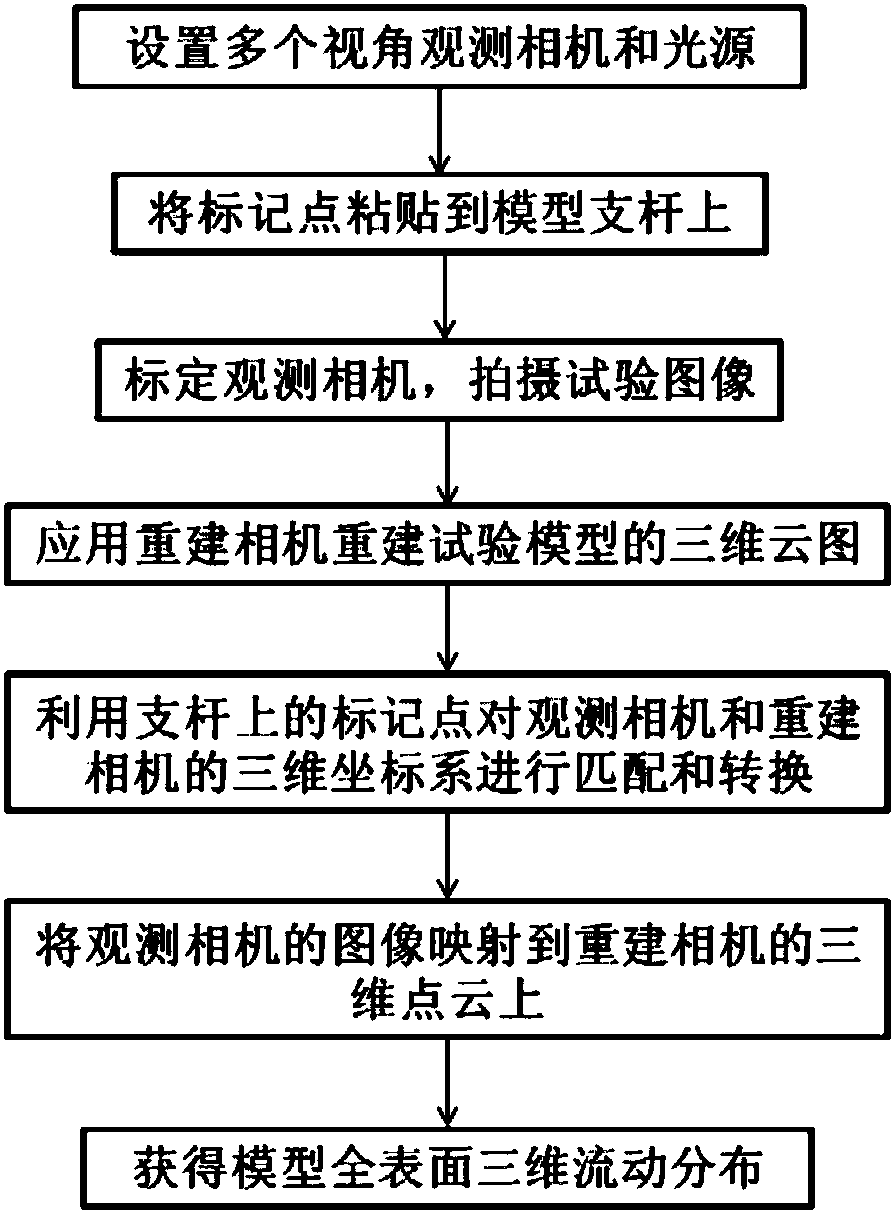

[0034] Such as figure 1 Shown, a kind of aircraft three-dimensional surface flow distribution measurement method that the present invention proposes, the steps are as follows:

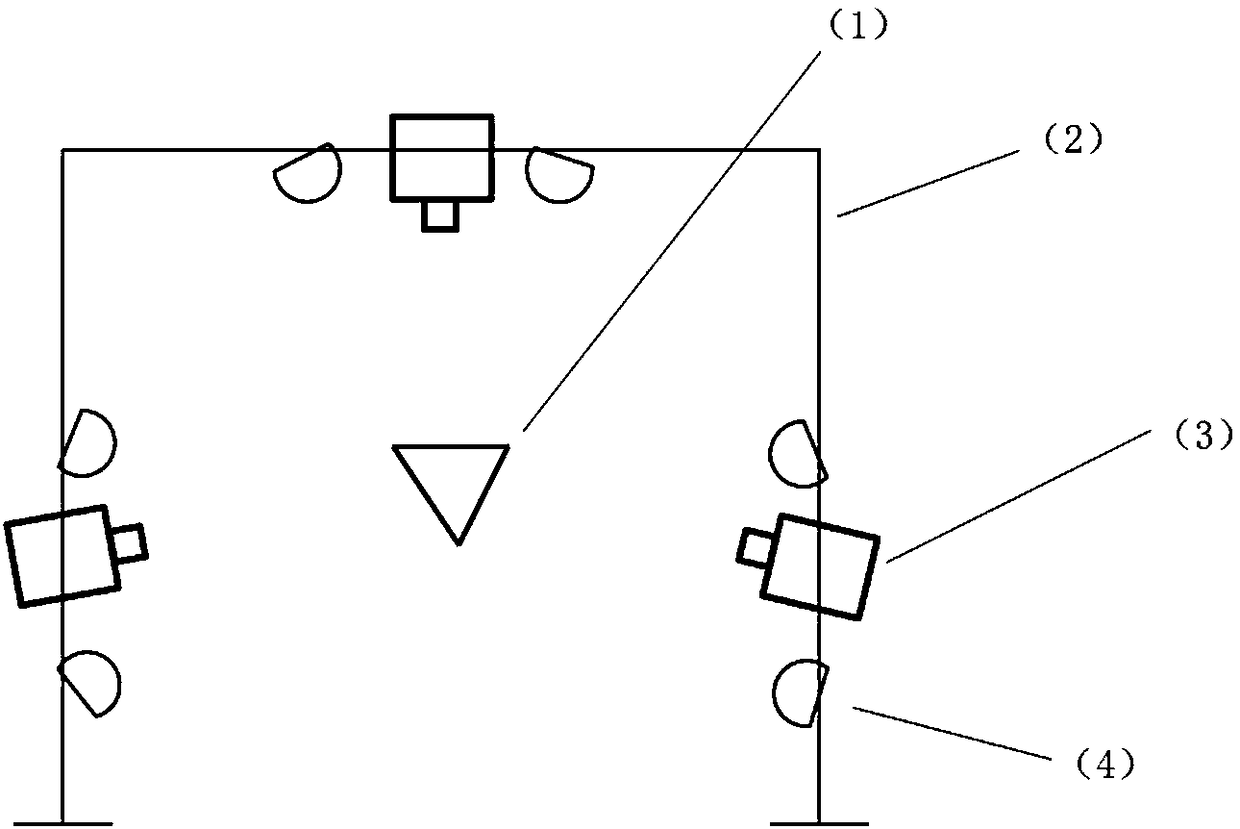

[0035] (1) Spray sensitive coatings on the wind tunnel test model, and set up multiple observation cameras. The observation cameras are set outside the observation window of the wind tunnel or inside the wind tunnel. Used to observe the upper surface, lower surface and side of the model, and arrange the light source to excite the sensitive coating next to the observation camera; such as figure 2 As shown, 1 is the wind tunnel test model, 2 is the visual platform, 3 is the camera, and 4 is the light source.

[0036] The sensitive coating refers to a special material whose optical properties are sensitive to certain physical parameters, such as a temperature-sensitive paint coating. When its temperature changes, its light intensity excited by ultraviolet light will change accordingly . Using this pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com