Method and device for preparing cumene hydroperoxide through cumene oxygenation

A technology of cumene hydroperoxide and diisopropylbenzene hydroperoxide, which is applied in the chemical industry, can solve the problems of large fluctuations in reaction temperature, low production efficiency, and large investment in equipment, so as to maintain the reaction temperature and fast reaction rate , High heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

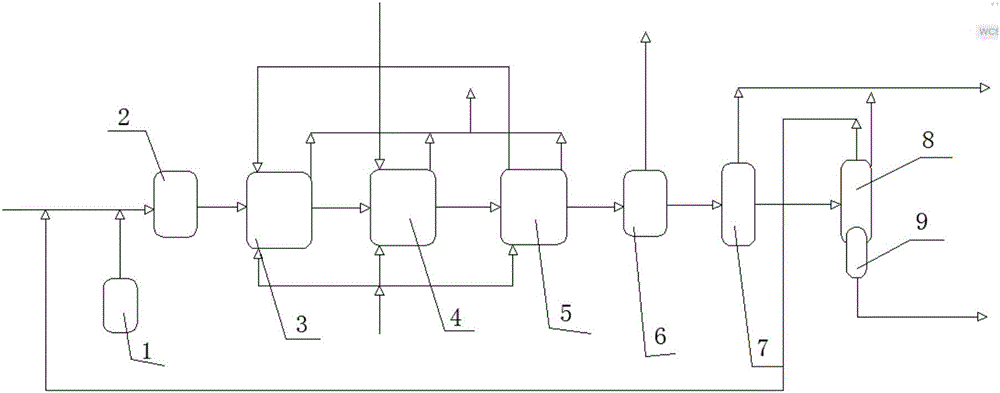

Method used

Image

Examples

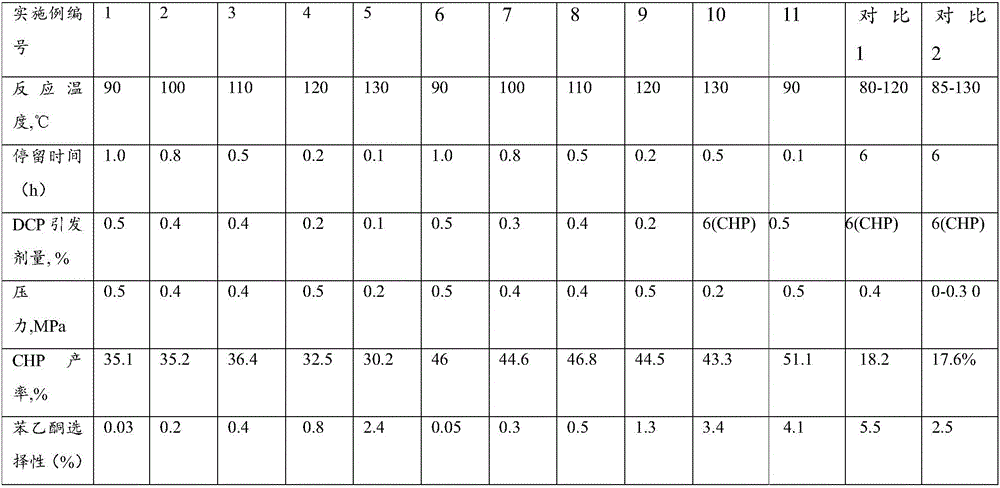

Embodiment 1

[0061] Cumene oxidation produces cumene hydroperoxide (CHP) method, and step is as follows:

[0062] A microreactor system assembled by two microreactors in series is adopted, the heat exchange system of the microreactor system is turned on, the temperature of the microreactor is controlled to be 90°C ± 2, and the reaction pressure is 0.5MPa; After the cumene solution of 0.5% diisopropylbenzene hydroperoxide (DCP) is mixed, pass in the first microreactor, the amount that passes into oxygen simultaneously is 40% of required oxygen total amount, and the total amount of oxygen Amount enters 2 times of the cumene mole number in the reactor compared with the same period, and the residence time of the control reactant is 1.0h; The second microreactor is connected in series at the first microreactor outlet, and there is a Oxygen enters the mouth to supplement the oxygen needed for the reaction. The amount of supplemented oxygen is 60% of the total oxygen required to promote the react...

Embodiment 2

[0064] Operation method is the same as embodiment 1, and the concentration of changing dicumylbenzene hydroperoxide (DCP) cumene solution is 0.4%, and the reaction temperature of adjustment microreactor is 100 ℃ ± 2, and reaction pressure 0.4MPa; Control reaction stops The time is 0.8h; the product after the reaction is separated, and the target reaction product and unreacted reactant are obtained respectively.

Embodiment 3

[0066] Operation method is the same as embodiment 1, and the concentration of changing dicumylbenzene hydroperoxide (DCP) cumene solution is 0.4%, and the reaction temperature of adjustment microreactor is 110 ℃ ± 2, and reaction pressure 0.4MPa; The time is 0.5 h; the product after the reaction is separated, and the target reaction product and unreacted reactant are obtained respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com