Open circuit cement combined and semi-final grinding automatic control method and system based on C#

A technology of loop control and DCS system, applied in general control system, control/regulation system, adaptive control, etc., can solve problems such as short service life of equipment and low cement production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

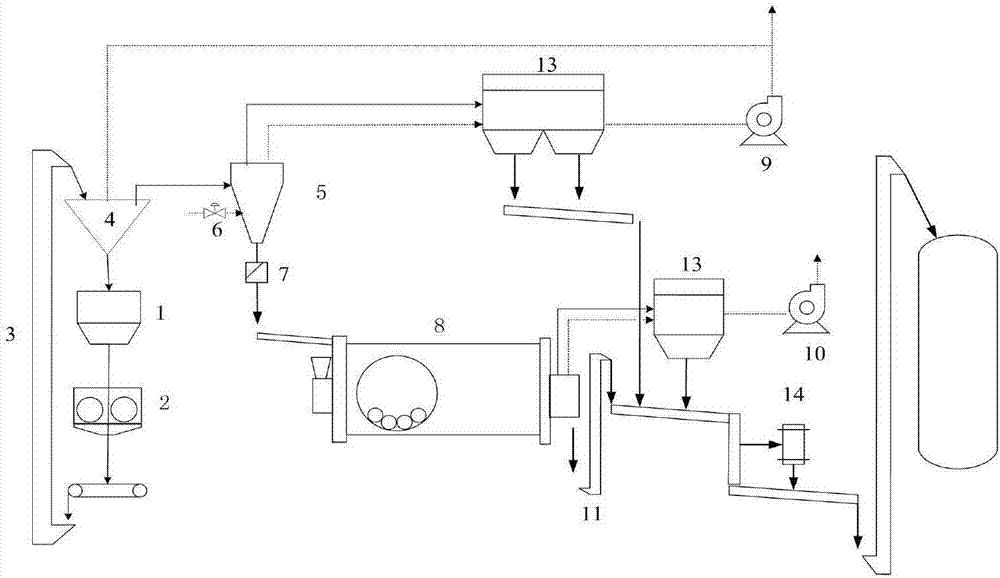

[0071] The current cement production process is as follows: figure 1 As shown, firstly, the materials are buffered in the steady flow bin 1 according to a certain ratio and then flow into the roller press 2. After the rolling, the materials are classified and dispersed by the V-shaped powder separator 4, and the unqualified materials are sent to the roller press 3 again by the elevator 3. To the roller press 2, qualified materials are selected into the powder machine 5. Under the action of the cold air valve 6, the superfine powder enters the dust collector 13 by means of the main exhaust fan 9; After the material is ground in the ball mill 8, the fine powder is fed into the dust collector 13 by the tail fan 10; the coarse powder is mixed with the fine powder through the discharge elevator 11, the chute 12 and other equipment, and is analyzed by the online particle size 14 before storage. Become a cement product.

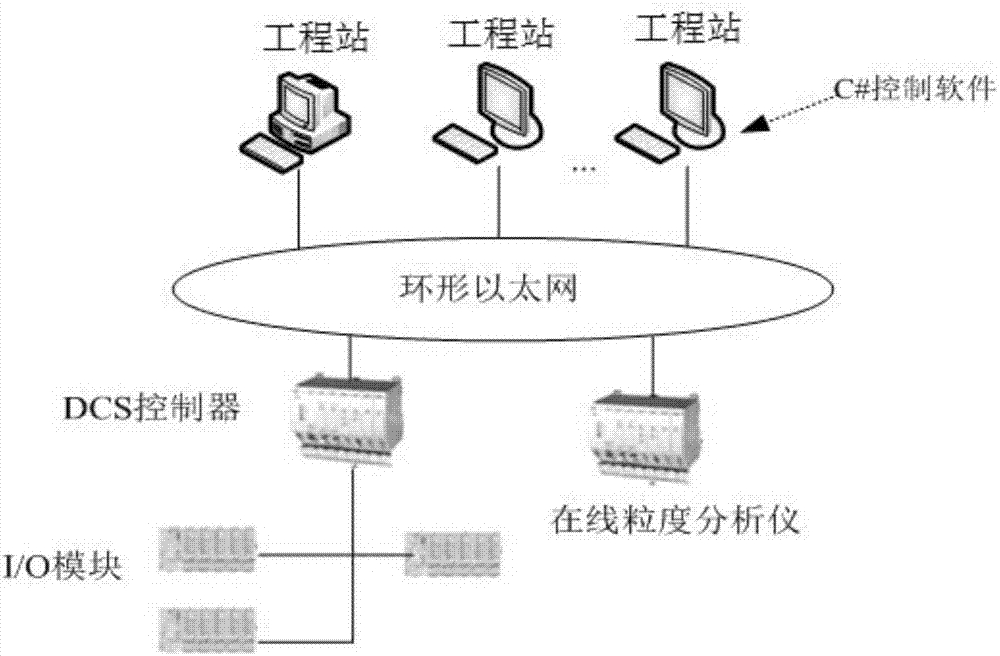

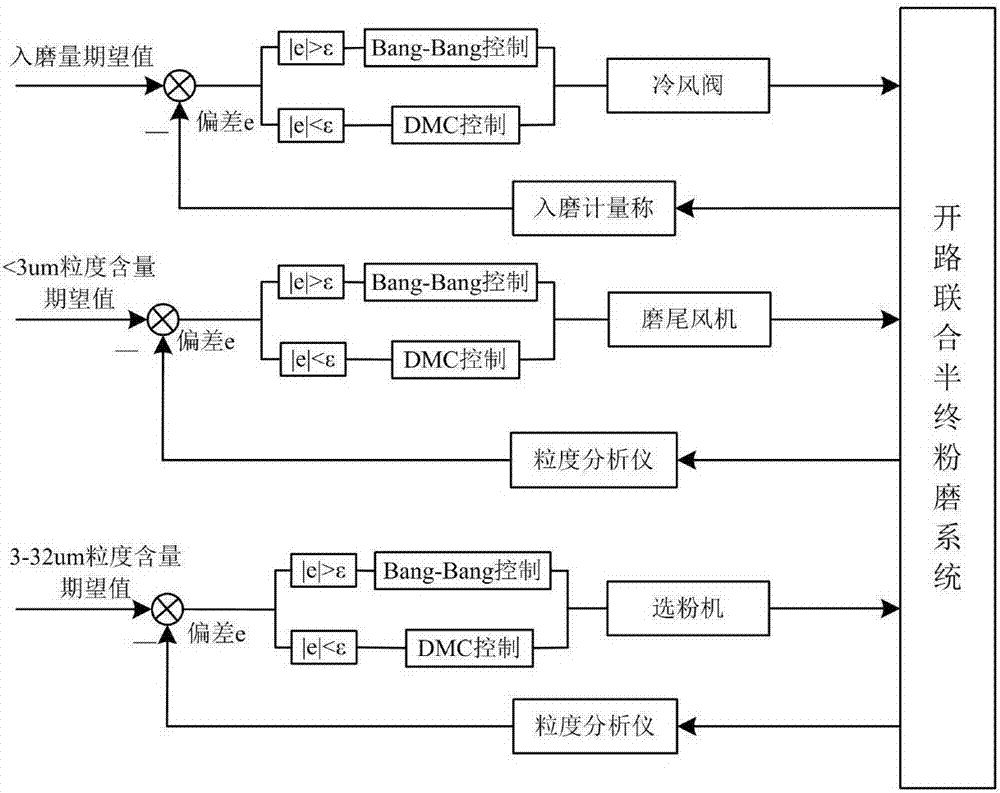

[0072] like figure 2 As shown, in order to solve the probl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com