Combined polyether for flame-retardant bulk rigid polyurethane foams and application method of combined polyether

A technology of rigid foam and combined polyether, which is applied in the field of combined polyether, can solve problems such as rotten bottom, foam cracks, cavities, etc., and achieve the effect of wide source of raw materials, low thermal conductivity, and reduced thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

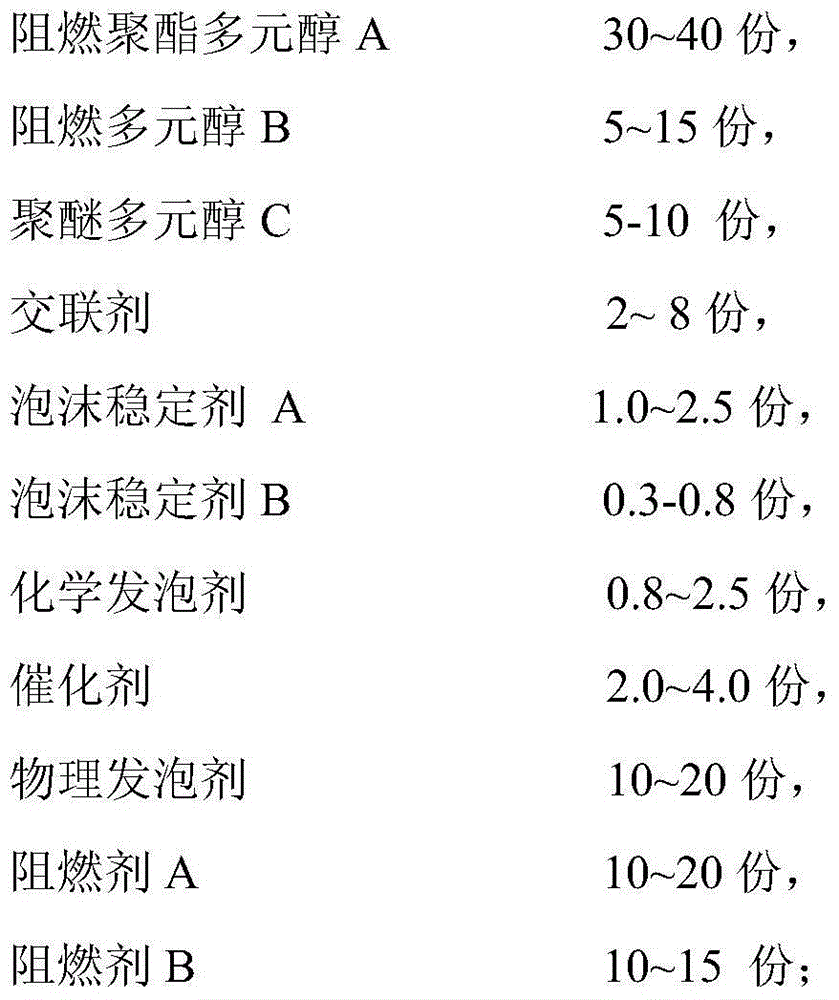

Method used

Image

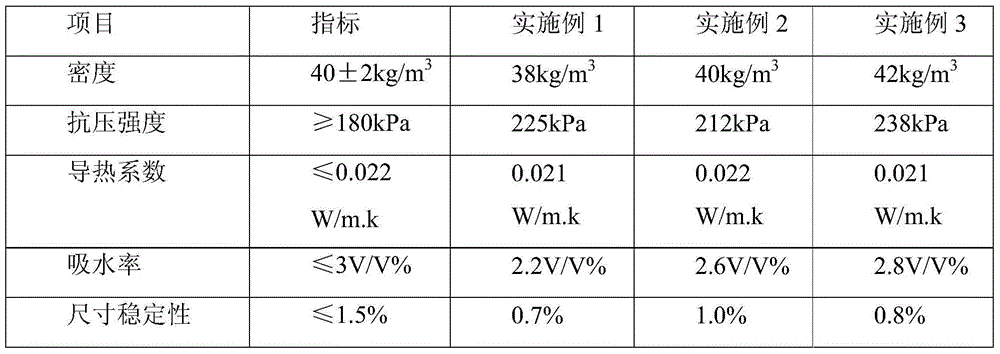

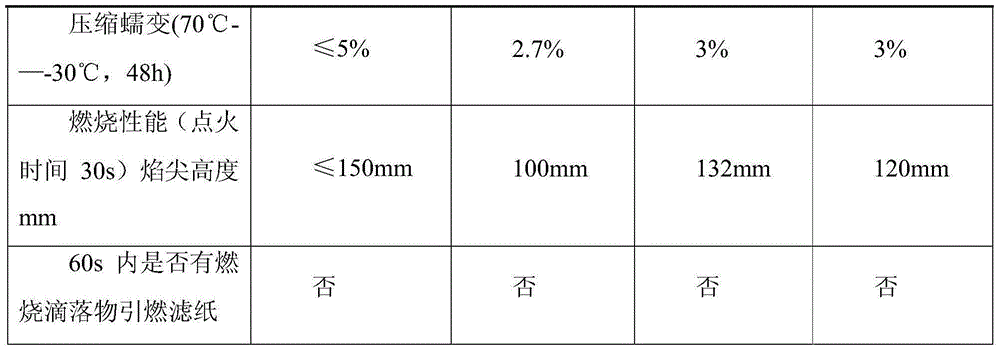

Examples

Embodiment 1

[0037] (1) Preparation of component A, 100kg: Weigh flame-retardant polyester polyol CF-6255 (functionality 2, molecular weight 440, commercially available product of Jiangsu Fusheng New Material Co., Ltd.), 30kg, flame-retardant polyol FR- 2026 (functionality 2.3, molecular weight 640, commercially available product of Wanhua Chemical Group Co., Ltd.), 15kg, polyether polyol SA460 (functionality 6, molecular weight 730, commercially available product of Shandong Bluestar Dongda Chemical Co., Ltd.), 5.3kg, crosslinking agent 403 (functionality 3, molecular weight 220, commercially available product of Shandong Bluestar Dongda Chemical Co., Ltd.), 8kg, foam stabilizer: B8545 (commercially available product of Evonik Degussa Specialty Chemical Co., Ltd.) . Potassium mixture, weighing 1.4kg, 1.5kg and 1.1kg respectively, physical blowing agent 1,1-dichloro-1-fluoroethane, 10.1kg, flame retardant A tris(2-chloropropyl) phosphoric acid Ester, 10kg, flame retardant B triethyl phosp...

Embodiment 2

[0042](1) Prepare component A, 100kg: Weigh flame-retardant polyester polyol 6300 (functionality 2.2, molecular weight is 390, commercially available product of Jiangsu Fusheng New Material Co., Ltd.), 40kg, flame-retardant polyol FR-2026 ( Functionality 2.7, molecular weight 640, commercially available product of Wanhua Chemical Group Co., Ltd.), 5kg, polyether polyol 6207 (functionality 6, molecular weight 730, commercially available product of Hebei Yadong Chemical Group Co., Ltd.), 5kg, cross-linked Agent MN450 (functionality 3, molecular weight 370, commercially available product of Shandong Bluestar Dongda Chemical Co., Ltd.), 2kg, foam stabilizer: B8525 (commercially available product of Evonik Degussa Specialty Chemical Co., Ltd.), 2.0kg, ten Sodium dialkylbenzenesulfonate, 0.3kg, deionized water, 3.5kg, catalyst selection N,N dimethylcyclohexylamine, N,N dimethylbenzylamine and 1,3,5-tri(dimethylamino Propyl) the mixture of hexahydrotriazine, the weight is respectivel...

Embodiment 3

[0047] (1) Prepare component A, 100kg: Weigh flame-retardant polyester polyol 6255 (functionality 2.1, molecular weight is 440, commercially available product of Jiangsu Fusheng New Material Co., Ltd.), 35kg, flame-retardant polyol FR-1830 ( Functionality 2.5, molecular weight 620, commercially available product of Wanhua Chemical Group Co., Ltd.), 10kg, polyether polyol SA460 (functionality 6, molecular weight 730, commercially available product of Shandong Bluestar Dongda Chemical Co., Ltd.) 7kg, delivery Joint agent MN450 (functionality 3, molecular weight 370, commercially available product of Shandong Bluestar Dongda Chemical Co., Ltd.), 3kg, foam stabilizer: L-6950 (commercially available product of Momentive Silicone Material (Shanghai) Co., Ltd.), 1.0kg, polysorbate, 0.5kg, water, 1.3kg, catalyst potassium acetate, 2.0kg, physical blowing agent 1,1-dichloro-1-fluoroethane, 20kg, flame retardant A three (2- Chloropropyl) phosphate, 10.2kg, flame retardant B triethyl pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com