Cast type material separation method and device and separation bin

A separation device and separation method technology, which is applied in the direction of solid separation, chemical instruments and methods, and separation of solids from solids with airflow, can solve problems such as low production efficiency, and achieve improved production efficiency, reduced noise, and reduced power required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

[0031] Specific embodiment 2 of the projectile material separation device of the present invention, the difference between this embodiment and the above-mentioned embodiment is only that the throwing wheel includes a body and at least two throwing wheels welded on the body and extending radially along the throwing wheel. plate, the throwing surface is set on the throwing plate.

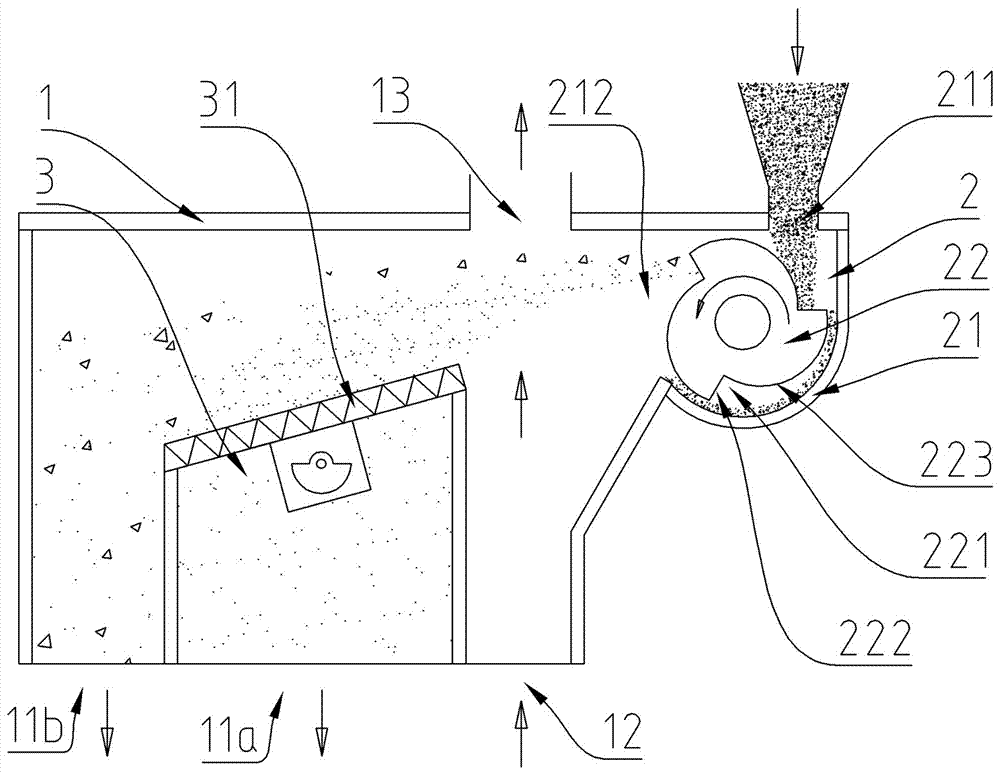

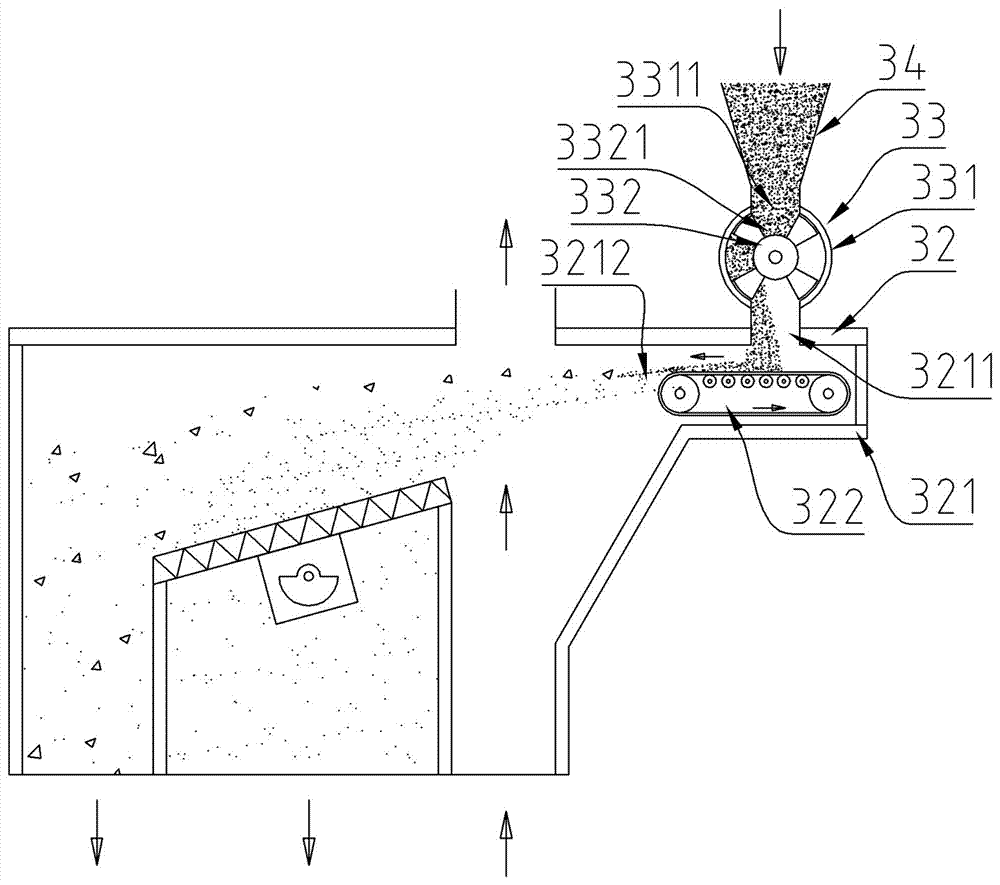

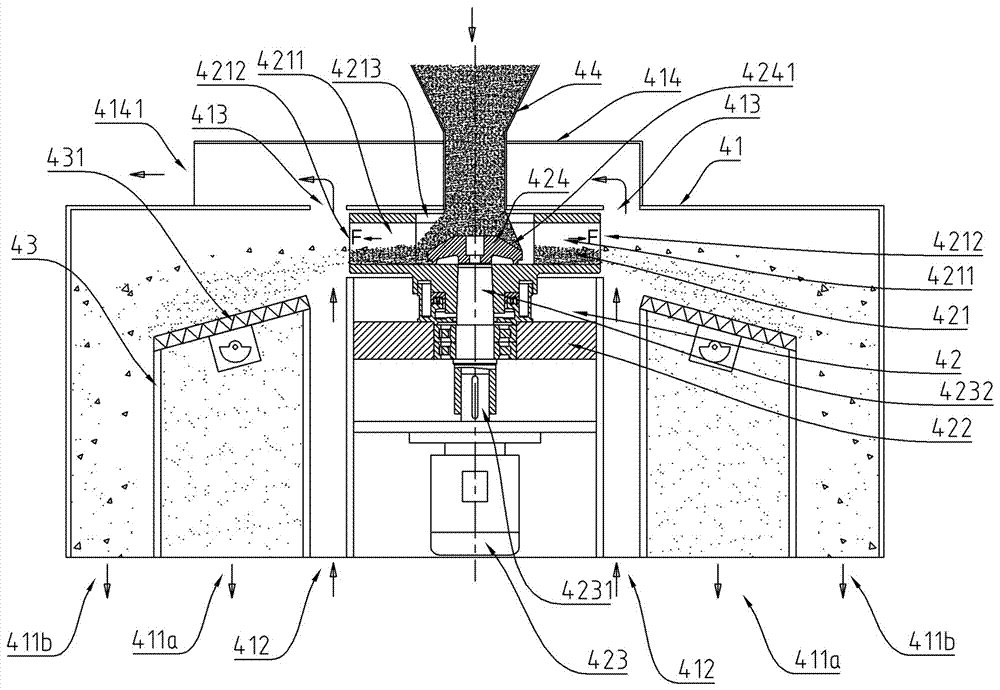

[0032] The specific embodiment 3 of the projectile material separation device of the present invention, the difference between this embodiment and the specific embodiment 1 of the above-mentioned projectile material separation device is only: figure 2 As shown, the projecting device 32 in the present embodiment is an intermittent projecting device, and the intermittent projecting device includes a projecting part and a feeding part, and the projecting part includes a high-speed belt conveyor 322 arranged in the projecting bin 321, and the The feed port 3211 is above the high-speed belt conveyor 322, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com