Multi-purpose double-roll continuous rheological forming device for liquid metal

A liquid metal, rheological forming technology, applied in the direction of metal rolling, can solve the problems of low cooling strength, difficult forming, small extrusion force, etc., to improve the quality of the edge, save the side sealing device, and easily squeeze The effect of press forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

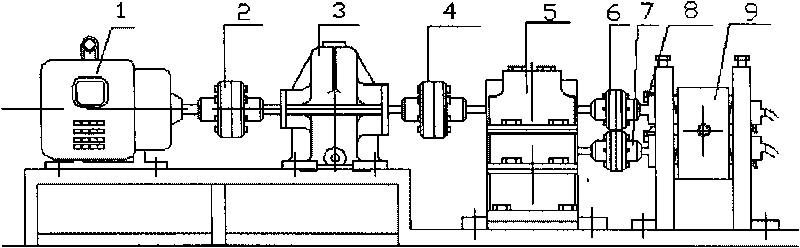

[0035] Such as figure 1 As shown, when the present invention is used for plate production, the motor 1 (DC motor) in this device is connected to one end of the reducer 3 through the half coupling I 2, and the other end of the reducer 3 is connected to the half coupling II 4 , the half-coupling II 4 is connected to one end of the gearbox 5, and the two shafts separated from the other end of the gearbox 5 are respectively connected to the main machine 9 through the half-coupling III6 and half-coupling IV7, and the two working rolls of the main machine 9 A rotational speed sensor 8 is arranged at the shaft head to measure the rotational speed.

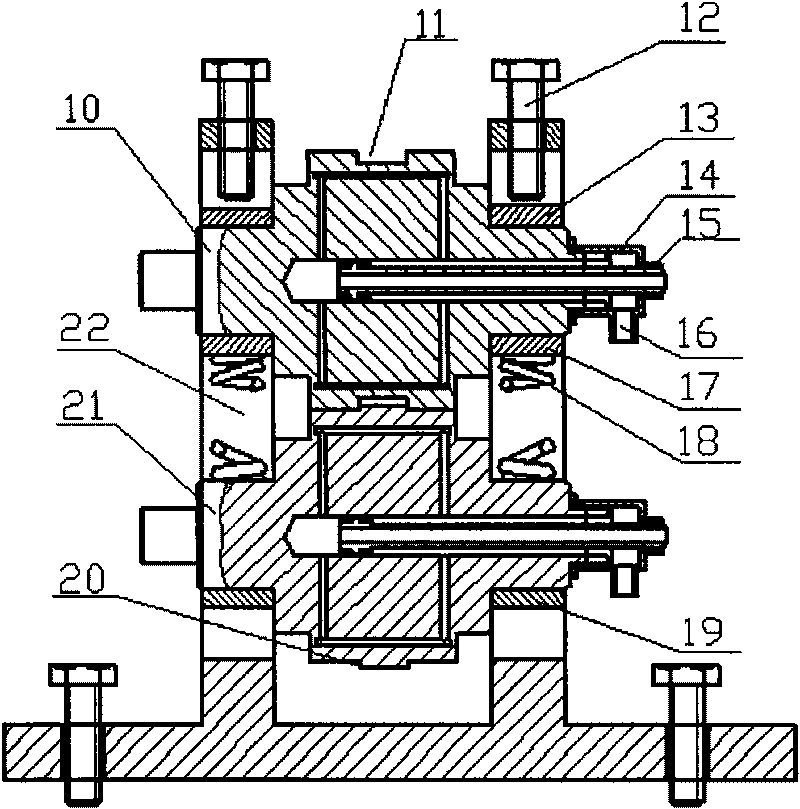

[0036] Depend on figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the main machine 9 is mainly composed of two water-cooled work rolls that cooperate with each other. The lower work roll 21 is placed flat on the lower tile 19 placed on the two vertical plates of the frame 22, and the upper work roll 10 is placed on ...

Embodiment 2

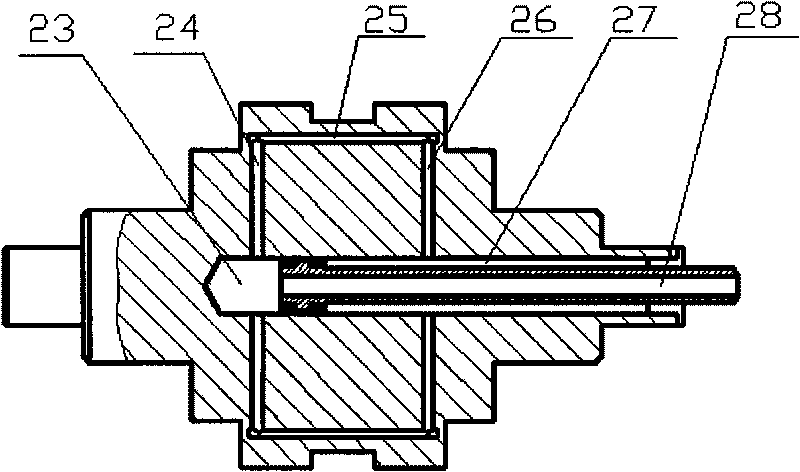

[0042] When the present invention is used in profile production, the basic principle of host work is as follows: Figure 10 As shown, the structure of the main unit of the device along the horizontal section of the roll gap is as follows Figure 11 As shown, the difference from Example 1 is that the discharge end of the main engine is equipped with an extrusion shoe 35, and the extrusion shoe 35 has a mold cavity 40 for assembling the mold, and a mold 52 is installed in the mold cavity. Before the mold 52, there is a structure such as Figure 7 The receiving die 53 shown, the extrusion shoe cooling water hole 36 can cool the extrusion shoe. After the extrusion shoe 35 is close to the work roll under the action of the hydraulic device 54, the upper arc-shaped surface 38 of the extrusion shoe squeezes the shoe boss 37 into the groove of the upper work roll 10, and the receiving die groove 43 and the extrusion The shoe groove 42 is consistent, and the lower roller annular boss 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com