Microinterface preparation device and method for butanol and octanol

A preparation device and interface technology, applied in the field of propylene hydroxylation reaction preparation, can solve the problems of waste of raw materials, unconsidered, small phase boundary area, etc., to increase the mass transfer area of the phase boundary, reduce mass transfer resistance, and reduce liquid film effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

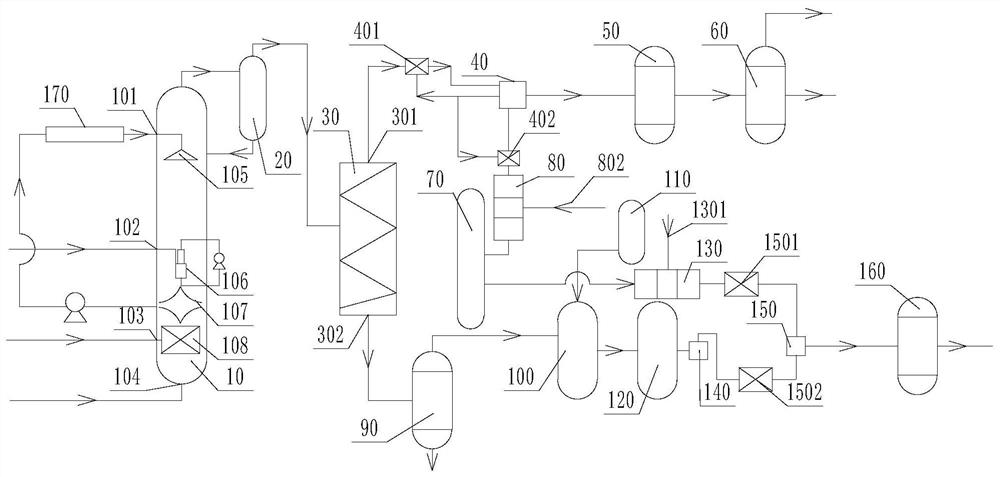

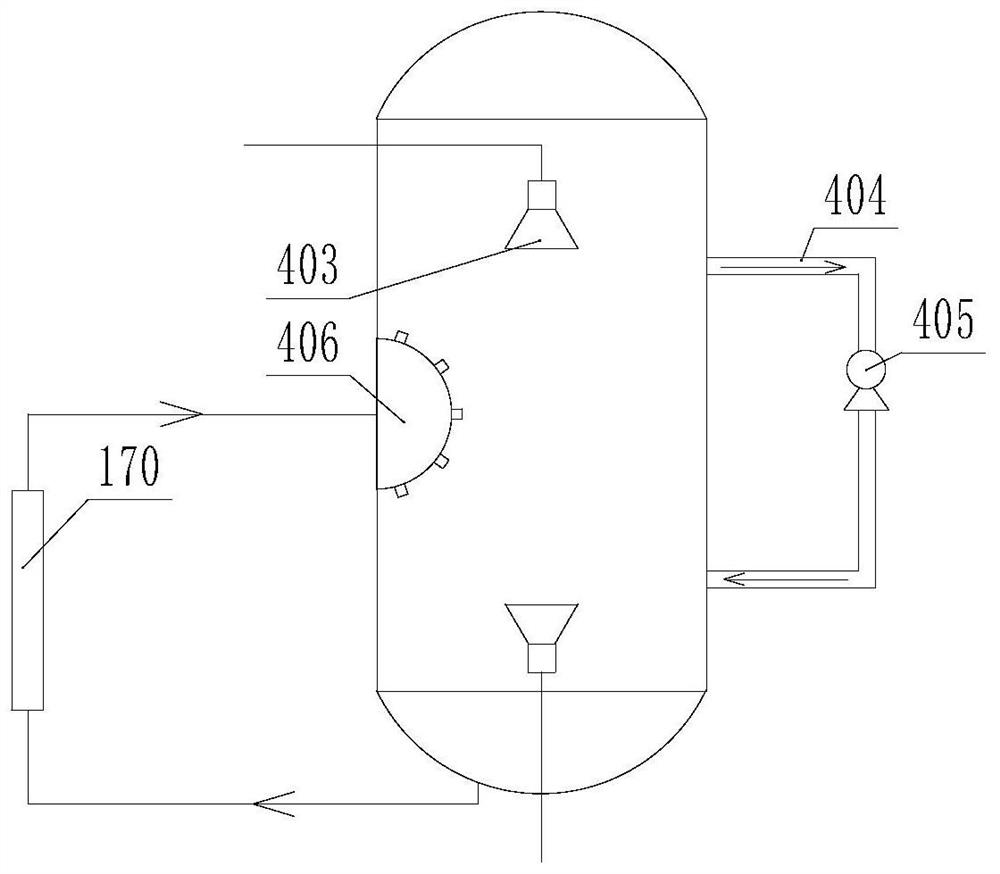

[0099] Such as Figure 1-5 As shown, the present embodiment provides a micro-surface preparation device of butctol, including: carbonyl synthesis tower 10, isomer separator 30, and first hydrogenation reactor 40; carbonyl synthesis tower 10 and isomer separation Connected; the carbonyl synthesis tower 10 is provided with a degree of derivator 20 between the isomer separator 30, and the product of the carbonyl synthesis column 10 is subjected to the mixture of the isomer separator 30 after the mixture 20 is subjected to the mixture.

[0100] Wherein, a solvent inlet 104 is provided at the bottom of the carbonyl synthesis tower 10. The catalyst inlet 101, the propylene inlet 102, and the synthetic gas inlet 103 are sequentially provided on the side wall of the carbonyl synthesis tower 10, and the carbonyl synthesis tower 10 is sequentially provided with a shower 105, a liquid-type micron bubble generator 106 and pneumatic. Micron bubble generator 108; the shower 105 is coupled to the...

Embodiment 2

[0119] The preparation apparatus of the present embodiment is consistent with the first embodiment, and the reaction temperature in the carbonyl synthesis tower 10 is provided only in the present embodiment, and the reaction pressure is provided to 1.1 MPa; the reaction temperature in the condensed reactor 100 is set to 70 At ° C, the reaction pressure is provided to 0.25 MPa; the reaction temperature in the first hydrogenation reactor 40 is provided to 70 ° C, the reaction pressure is provided to 0.70 MPa; the reaction temperature in the second hydrogenation reactor 150 is provided to 70 ° C, and the reaction pressure is set to 0.70MPa.

[0120] After detection, after using the above apparatus and process, the propylene conversion is 99.0%, butontal conversion of 98.0%, and the synthesis efficiency of the process is 4.2%.

Embodiment 3

[0122] The preparation apparatus of the present embodiment consistent with the first embodiment, and the difference is only that the reaction temperature in the carbonyl synthesis column 10 in the present embodiment is provided to 95 ° C, and the reaction pressure is provided to 1.3 MPa; the reaction temperature in the condensed reactor 100 is set to 75 At ° C, the reaction pressure is provided to 0.28 MPa; the reaction temperature in the second hydrogenation reactor 150 is provided to 78 ° C, and the reaction pressure is provided to 0.80 MPa; the reaction temperature in the first hydrogenation reactor 40 is set to 78 ° C, and the reaction pressure is set to 0.80MPa.

[0123] After detection, after the above apparatus and process, the propylene conversion was 99.3%, butontal conversion of 98.5%, and the synthesis efficiency of the process was increased by 4.8%.

[0124] In summary, the microstructure of the micro-surface preparation device of the butter alcohol of the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com