Ammonium sulfite oxidation enhanced micro-interface reaction system and method

An ammonium sulfite and reaction system technology, applied in chemical instruments and methods, mixing methods, separation methods, etc., can solve the problem of increasing the phase boundary mass transfer area of oxygen and ammonium sulfite solution, small phase boundary mass transfer area, sulfuric acid. The problem of low ammonium efficiency, etc., can increase the mass transfer area of the phase boundary, ensure full utilization, and improve the reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

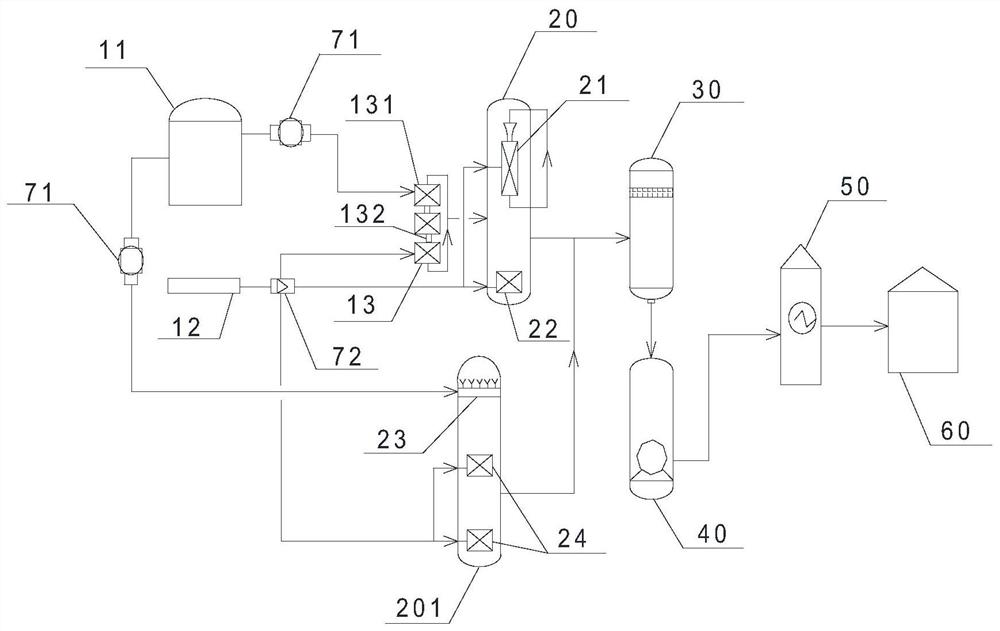

[0050] refer to figure 1As shown, the enhanced micro-interface reaction system for ammonium sulfite oxidation provided by the embodiment of the present invention mainly includes a first oxidation reactor 20, a micro-interface unit 13, an ammonium sulfite storage tank 11, an oxygen intake pipe 12, a second Dioxidation reactor 201 , evaporation crystallizer 30 , filter centrifuge 40 , dryer 50 and ammonium sulfate storage tank 60 . The ammonium sulfite storage tank 11 is connected to the top external micro-interface generator 131 in the micro-interface unit 13, and the oxygen inlet pipeline 12 is connected to the bottom external micro-interface generator 131 in the micro-interface unit 13. The storage tank 11 is connected with the external micro-interface generator 131 above because the ammonium sulfite solution will flow from top to bottom due to gravity, forming a cycle, and the oxygen inlet pipeline 12 is connected to the bottom external micro-interface generator. 131 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com