Wet oxidation enhanced micro-interface system

A wet oxidation and interface technology, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of short oxygen residence time, high equipment requirements, and reduced reaction efficiency, etc., to increase the phase boundary Mass transfer area, shorten reaction time, improve reaction mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

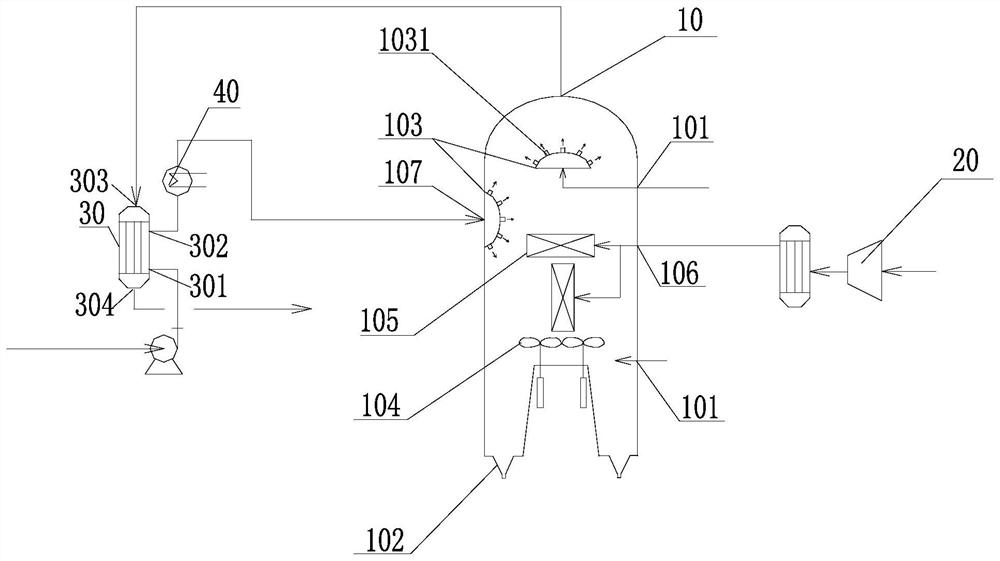

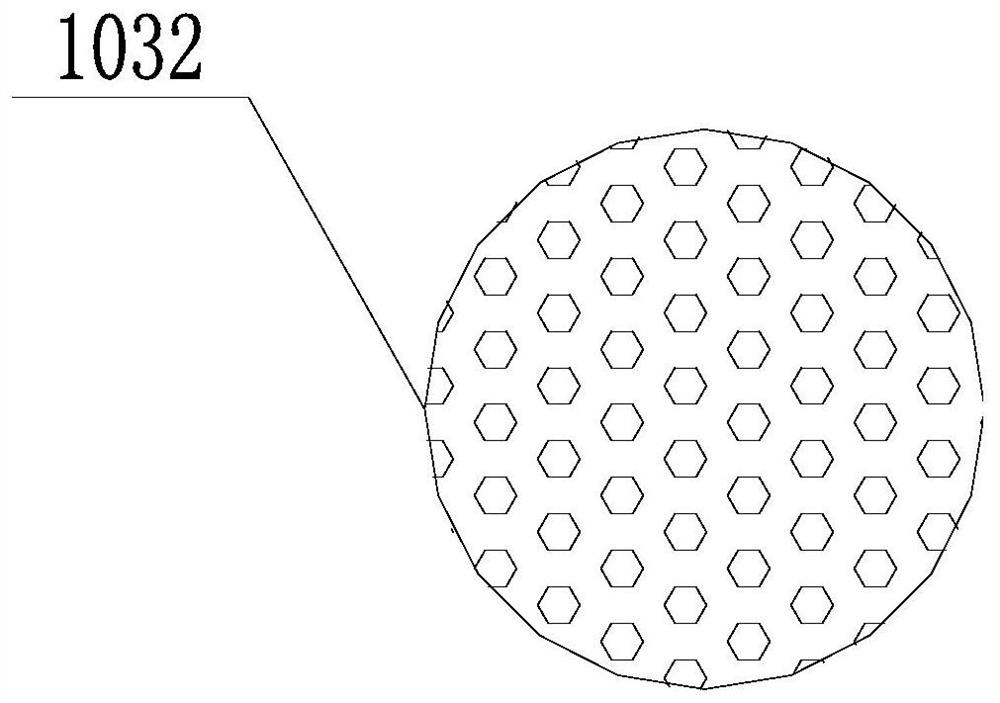

[0047] refer to figure 1 As shown, it is a wet oxidation enhanced micro-interface system according to an embodiment of the present invention, which mainly includes a waste water heat exchanger 30, a waste water heater 40, and an oxidation reactor 10; the waste water heat exchanger 30 is provided with a material inlet 301 and a material outlet 302 , heat source inlet 303 and heat source outlet 304; the oxidized water coming out of the oxidation reactor 10 enters the waste water heat exchanger 30 from the heat source inlet 303, and the material outlet 302 is connected to the waste water heater 40; oxidation reaction The device 10 is provided with a liquid injector 103 and a micro interface generator 105, the liquid injector 103 is respectively arranged on the side wall and the upper part of the oxidation reactor 10, and the micro interface generator 105 is just arranged on the front of the liquid injector 103 at the upper part. Below, the side wall of the oxidation reactor 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com