Reaction system and process for synthesizing dimethyl carbonate through liquid-phase oxidative carbonylation of methanol

A technology of dimethyl carbonate and oxidative carbonylation, which is applied in the field of the reaction system of methanol liquid-phase oxidative carbonylation to synthesize dimethyl carbonate, can solve the problems of reduced yield of dimethyl carbonate and inability to fully mix, and achieves guaranteed Effects of reaction rate, production cost reduction, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

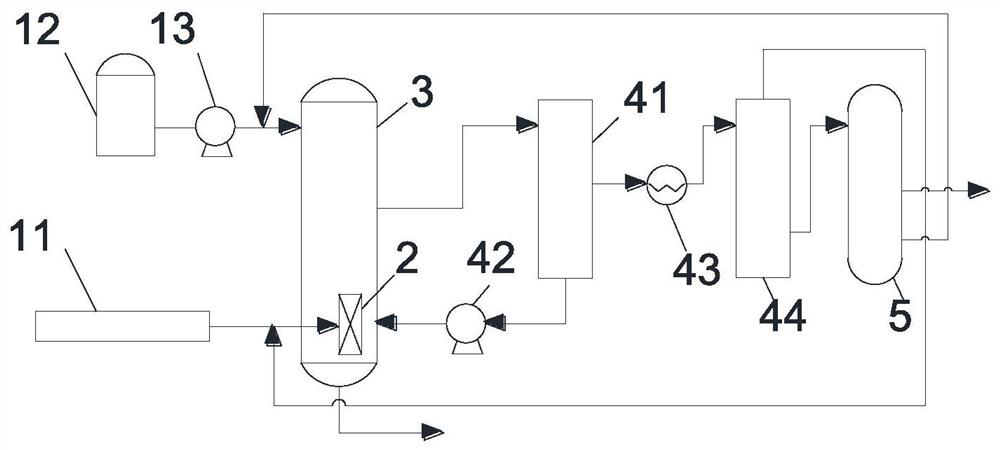

[0054] Fill a sufficient amount of methanol and a corresponding proportion of catalyst into the liquid phase storage tank 12, connect the gas phase feed pipeline 11 to the gas source containing 150L of carbon monoxide and oxygen mixed gas, and the molar ratio of carbon monoxide and oxygen in the gas source 3-50:1, start the system, set the system temperature to 115°C, set the pressure to 0.8MPa, transport methanol and catalyst to the inside of the reactor 3, and at the same time, transport the mixed gas of carbon monoxide and oxygen through the gas phase feed pipeline 11 to the inside of the micro-interface generator 2;

[0055] The micro-interface generator 2 breaks the mixed gas of carbon monoxide and oxygen into micro-bubbles on a micron scale, and releases the micro-bubbles into the inside of the reactor 3, so that the mixed gas of carbon monoxide and oxygen is fully mixed with methanol in the state of micro-bubbles. Contact, and carry out oxidative carbonylation reaction....

Embodiment 2

[0059] Fill a sufficient amount of methanol and a corresponding proportion of catalyst into the liquid phase storage tank 12, connect the gas phase feed pipeline 11 to the gas source containing 150L of carbon monoxide and oxygen mixed gas, and the molar ratio of carbon monoxide and oxygen in the gas source 3-50:1, start the system, set the system temperature to 120°C, set the pressure to 0.9MPa, transport methanol and catalyst to the inside of the reactor 3, and at the same time, transport the mixed gas of carbon monoxide and oxygen through the gas phase feed pipeline 11 to the inside of the micro-interface generator 2;

[0060] The micro-interface generator 2 breaks the mixed gas of carbon monoxide and oxygen into micro-bubbles on a micron scale, and releases the micro-bubbles into the inside of the reactor 3, so that the mixed gas of carbon monoxide and oxygen is fully mixed with methanol in the state of micro-bubbles. Contact, and carry out oxidative carbonylation reaction....

Embodiment 3

[0064] Fill a sufficient amount of methanol and a corresponding proportion of catalyst into the liquid phase storage tank 12, connect the gas phase feed pipeline 11 to the gas source containing 150L of carbon monoxide and oxygen mixed gas, and the molar ratio of carbon monoxide and oxygen in the gas source 3-50:1, start the system, set the system temperature to 125°C, set the pressure to 1MPa, transport methanol and catalyst to the inside of the reactor 3, and at the same time, transport the mixed gas of carbon monoxide and oxygen to the Inside the microinterface generator 2;

[0065]The micro-interface generator 2 breaks the mixed gas of carbon monoxide and oxygen into micro-bubbles on a micron scale, and releases the micro-bubbles into the inside of the reactor 3, so that the mixed gas of carbon monoxide and oxygen is fully mixed with methanol in the state of micro-bubbles. Contact, and carry out oxidative carbonylation reaction.

[0066] The oxidative carbonylation reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com