Compound for wet etching silicon dioxide

A technology of silicon dioxide and wet etching, which is applied in the direction of surface etching compositions, chemical instruments and methods, electrical components, etc., can solve problems such as pollution particles, process temperature, transportation and storage problems, and use difficulties, and achieve reduction Effect of processing time, shortening processing time, and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

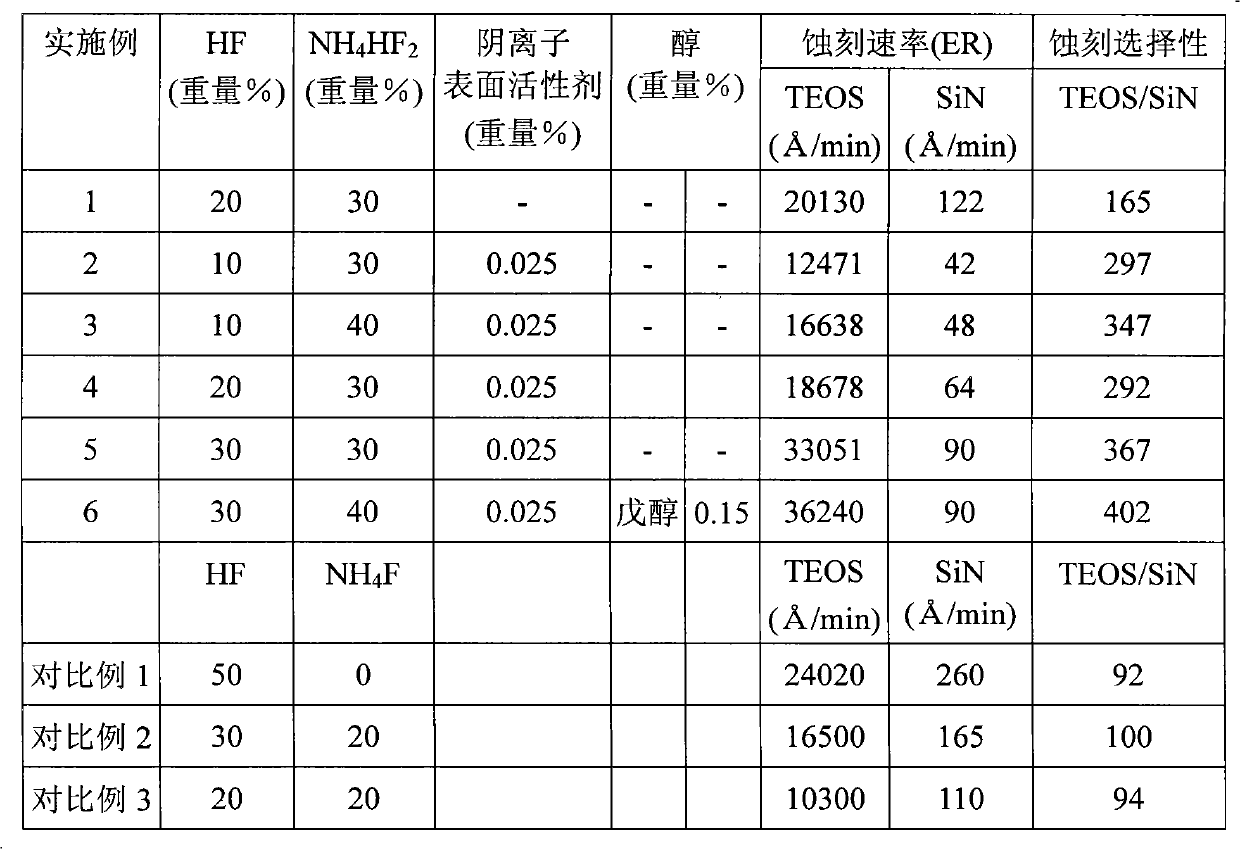

[0028] An etchant containing the ingredients shown in Table 1 below and water was prepared. In Table 1, polyoxyethylene (C1-C20) alkylammonium sulfate was used as an anionic surfactant.

[0029]According to the etching process, when both the silicon dioxide wafer and the silicon nitride film are placed in a single type wet etching device, the etchant is introduced on the silicon dioxide for 10 seconds and on the silicon nitride film for 1 minute, Wherein the flow rate is 2 L / min, and the wafer is rotated at a rate of 200 rpm at the same time. Then rinse with deionized water and N 2 Spin dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com