Ultrasonic wastewater treatment device and method

A wastewater treatment and ultrasonic technology, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of low efficiency, increased energy consumption, low effect, etc. The effect of phase boundary mass transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

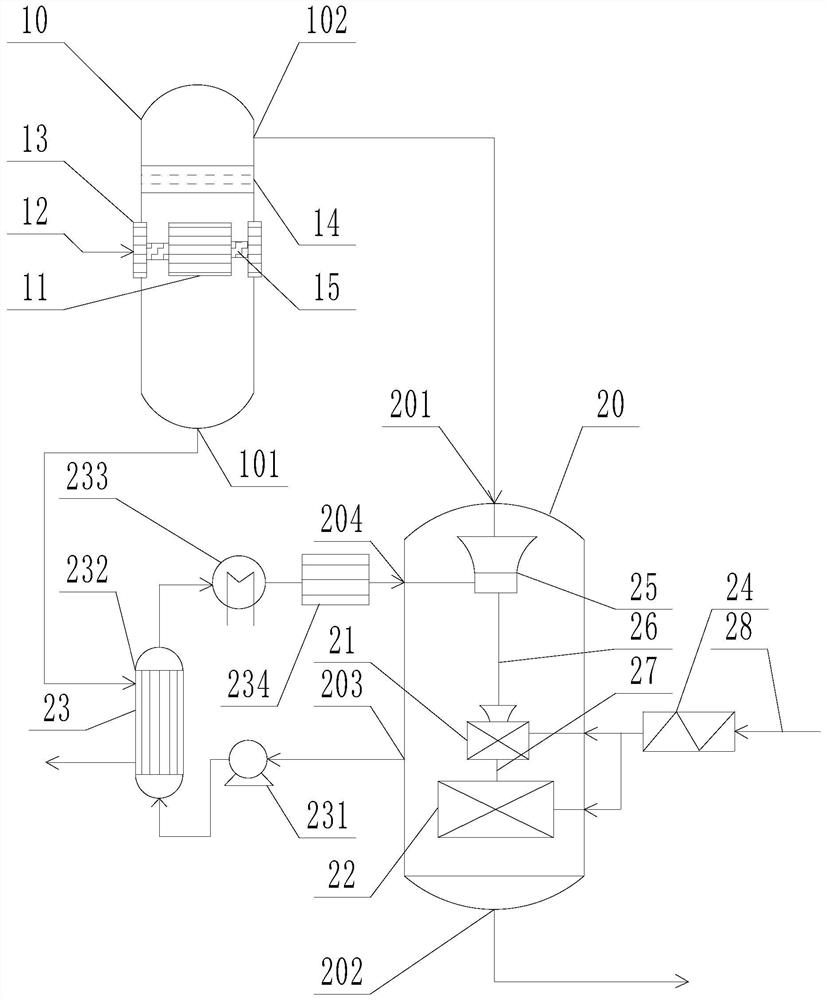

[0049] refer to figure 1 As shown, it is a schematic structural diagram of an ultrasonic wastewater treatment device provided in this embodiment, including a tank body 10 and an oxidation reactor 20 .

[0050] The very center in the tank body 10 is provided with the first sonotrode 11, and now the first sonotrode 11 is a built-in type, and the left and right sides of the first sonotrode 11 are respectively connected with connecting rods 15, and the two connecting rods 15 are connected to each other. The end is also connected with telescopic device 13, and two telescopic devices 13 are respectively arranged on the sidewall of tank body 10, can prevent like this tank body 10 deformation when first ultrasonic generator 11 vibrates, influences safety. A reverse osmosis membrane 14 is arranged above the first ultrasonic generator 11 . The waste water pipeline 12 is connected with the first ultrasonic generator 11 , the top of the tank body 10 is provided with an aqueous phase outl...

Embodiment 2

[0059] Other operation steps are the same as in Embodiment 1, the only difference is that there is no first ultrasonic generator.

Embodiment 3

[0061] Other operating steps are the same as in Example 1, the only difference is that there is no hydraulic micro-interface generator inside the oxidation reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com