A kind of composite anode electrode and its preparation method and application

A composite anode and electrode technology, applied in the direction of electrodes, electrode shapes/types, chemical instruments and methods, etc., can solve the problems of non-reusable, easy inactivation, poor stability of free enzyme treatment wastewater, etc., to achieve simple operation and improve efficiency , The effect of improving the efficiency of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] According to the preparation method of a kind of composite anode electrode provided by the present invention, the method comprises the following steps:

[0026] (1) Pretreating the metal substrate in an acidic chemical cleaning solution, the metal substrate being one or more of titanium, zirconium and nickel;

[0027] (2) Dissolving the metal oxide mesoporous material and oxide active component precursor in an alcohol solvent to make a coating liquid, wherein the metal oxide mesoporous material is CeO 2 、Co 3 o 4 , ZrO 2 and SnO 2 One or more of them, the product of the oxide active component precursor after thermal decomposition is the oxide active component;

[0028] (3) spraying or brushing the coating solution prepared in step (2) on the metal substrate and calcining it to prepare a composite anode electrode precursor; and

[0029] (4) Immerse the composite anode electrode precursor prepared in step (3) in a laccase solution to form a composite anode electrode ...

Embodiment 1

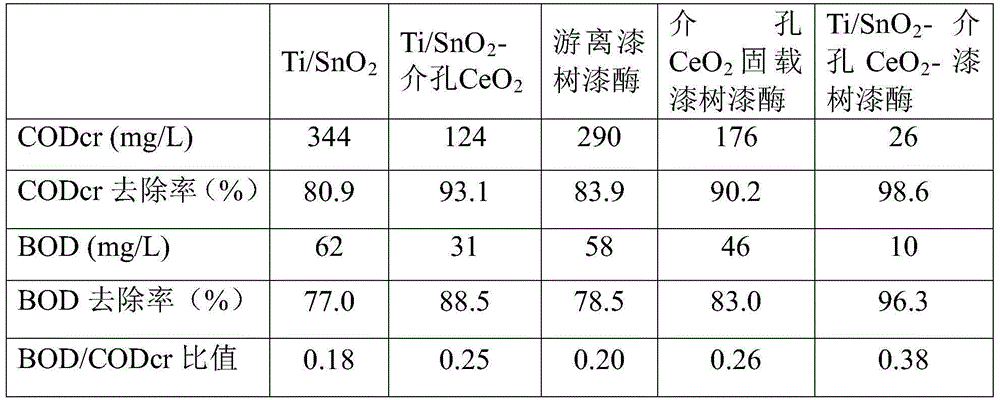

[0060] This embodiment is to illustrate the Ti / SnO prepared by the method of the present invention 2 -Mesoporous CeO 2 - Sumac laccase composite anode electrode

[0061] 1) Metal substrate pretreatment:

[0062] Polish the titanium (porous) surface with sandpaper, then put it into 0.05mol / L oxalic acid solution, boil for 20min, wash with distilled water and set aside.

[0063] 2) Metal oxide mesoporous material CeO 2 Preparation of:

[0064] (a) Disperse 2g of SBA-15 in 20mL of absolute ethanol, stir evenly, add 5mL of mercaptan and 10g of cerium nitrate in turn, stir at room temperature for 24h, evaporate the solvent to obtain -SH modified CeO 2 / SiO 2 composite materials;

[0065] (b) Calcining the composite material at 600°C for 3h;

[0066] (c) Remove the SBA-15 template with 60 mL of 1.0 mol / L HF solution, stir at room temperature for 24 h, centrifuge, wash, and dry to obtain the -SH-modified metal oxide mesoporous material CeO 2 . mesoporous CeO 2 The specific ...

Embodiment 2

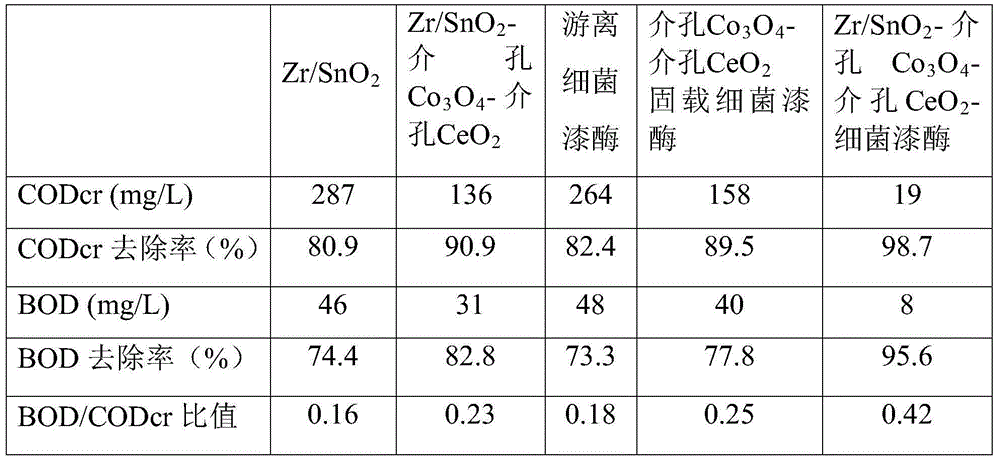

[0073] This embodiment is to illustrate the Zr / SnO prepared by the method of the present invention 2 -Mesoporous Co 3 o 4 -Mesoporous CeO 2 - Bacterial Laccase Composite Anode Electrode

[0074] 1) Metal substrate pretreatment:

[0075] Polish the surface of zirconium (metal mesh) with sandpaper, then put it into 50% (volume) mixed acid solution (phosphoric acid: hydrochloric acid = 2:1), soak for 30min, wash with distilled water and set aside.

[0076] 2) Mesoporous Co 3 o 4 -Mesoporous CeO 2 Preparation of complex:

[0077] (a) Disperse 2g of SBA-15 in 30mL of absolute ethanol and stir well; add 10g of 3-aminopropyltriethoxysilane APTES while stirring. After stirring evenly, add 10g of cobalt nitrate and 10g of cerium nitrate successively, after stirring at room temperature for 24h, evaporate the solvent to obtain -NH 2 Modified Co 3 o 4 -CeO 2 composite materials;

[0078] (b) Calcining the composite material at 600°C for 2h;

[0079] (c) Use 75mL of 1.0mol / L ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com