Anti-radiation functional aggregate prepared from Cr-containing and Zn-containing electroplating sludge

A technology for electroplating sludge and radiation protection, which is applied in the direction of material analysis, application, and household appliances using wave/particle radiation. , avoid loss, avoid the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

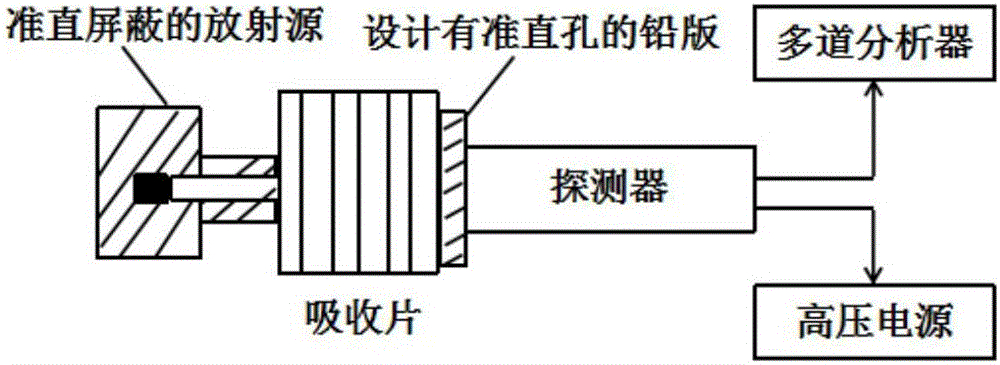

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of described flux comprises the following steps:

[0040] 1) Add 550ml of distilled water into the magnetic stirring heating pot, and heat it to about 95°C, then add 250g of borax, stir well until the borax is completely dissolved, ensure that the temperature of the mixed solution is above 90°C, and filter the solution at the same time to obtain clarification solution; 2) using an acidic burette to step 1) in the clarified solution obtained, add dropwise the dilute sulfuric acid with a mass concentration of 15%, and slowly stir until crystals are separated out; at this time, the addition speed of the sulfuric acid is controlled to ensure that the pH value of the solution is maintained In 4-5, when all the crystals are precipitated, the remaining solution is filtered, and then dried at 65° C. for 1.5 hours to obtain boric acid crystals; 3) the boric acid crystals obtained in step 2) are heated under vacuum conditions (260 Pa) to Calcined at 350°C f...

Embodiment 1~4

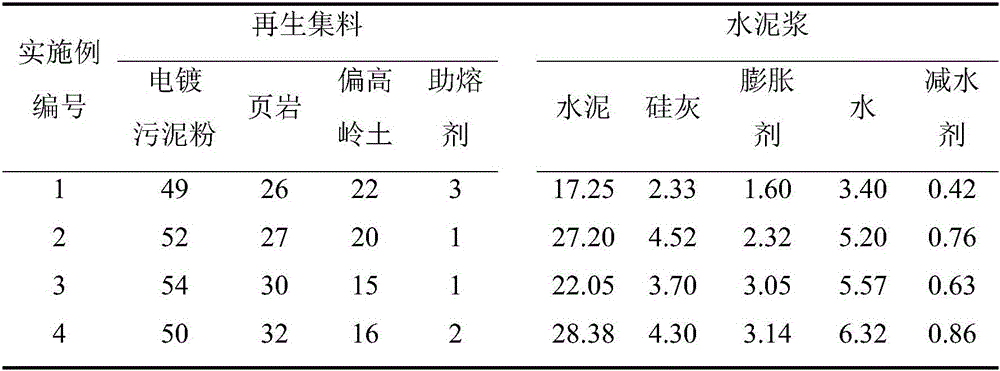

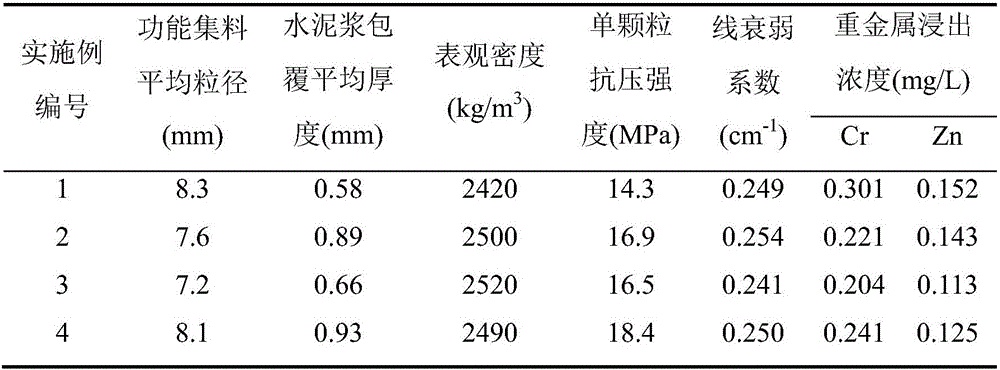

[0042] The anti-radiation functional aggregates prepared by using Cr and Zn-containing electroplating sludge described in Examples 1 to 4 include recycled aggregates and cement slurry shells coated on their surfaces; the recycled aggregates are made of electroplated sludge powder , shale, metakaolin, and flux are sintered; the cement slurry shell is made of cement, silica fume, expansion agent, water, and water-reducing agent as raw materials through mixing and solidification. The specific ratio is shown in Table 1; The preparation method comprises the following steps:

[0043] 1) Weigh the components for aggregate sintering according to the proportions described in Table 1, mix and grind the weighed raw materials, and then granulate, the particle size is 5-10 mm, and the moisture content is controlled to 18%; 2 ) Preheat the granulated pellets at 550°C for 35 minutes, then calcinate at 1060°C for 50 minutes, and finally cool naturally in the air to room temperature to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com