Patents

Literature

87results about How to "Improved Radiation Shielding Performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

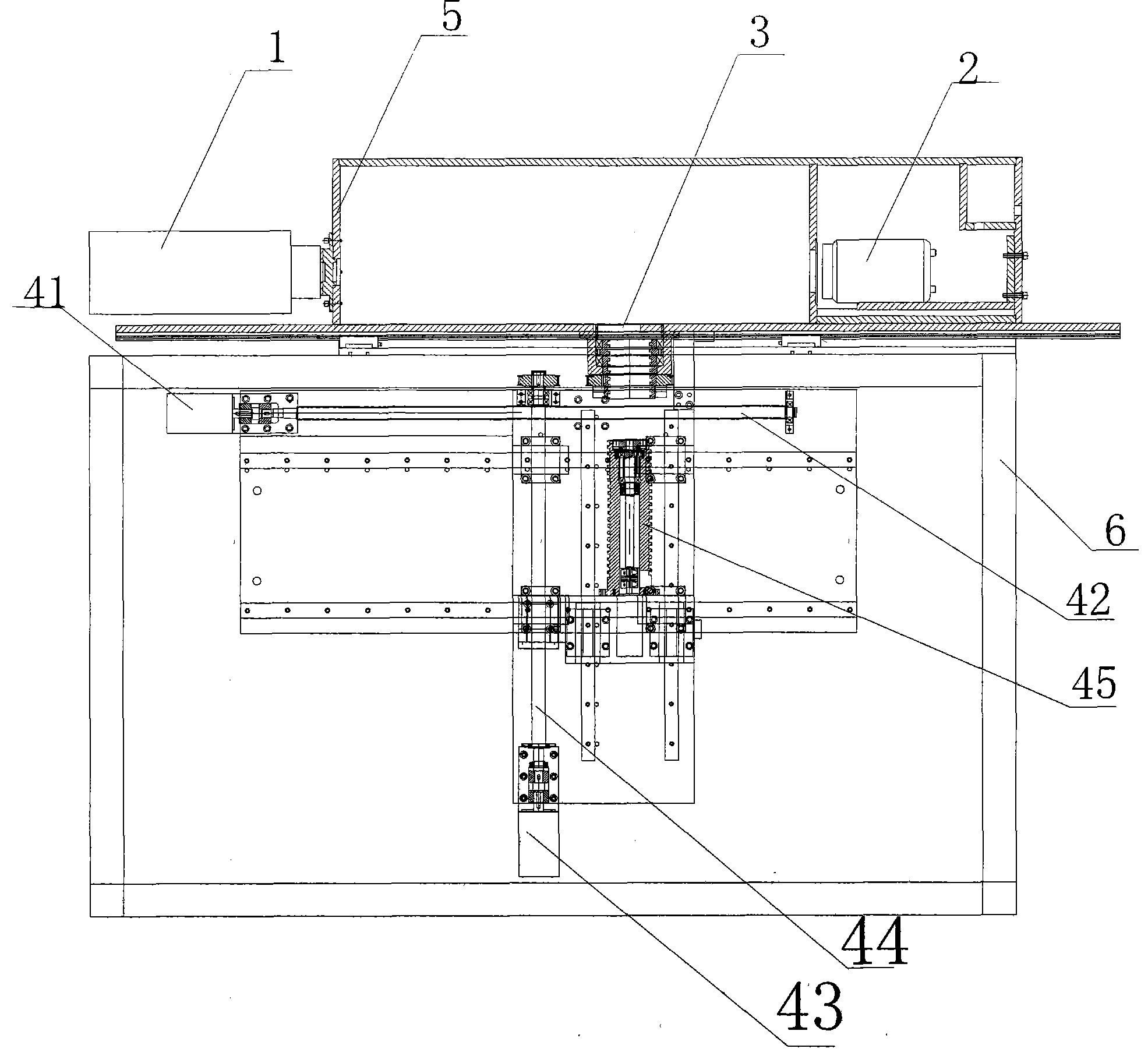

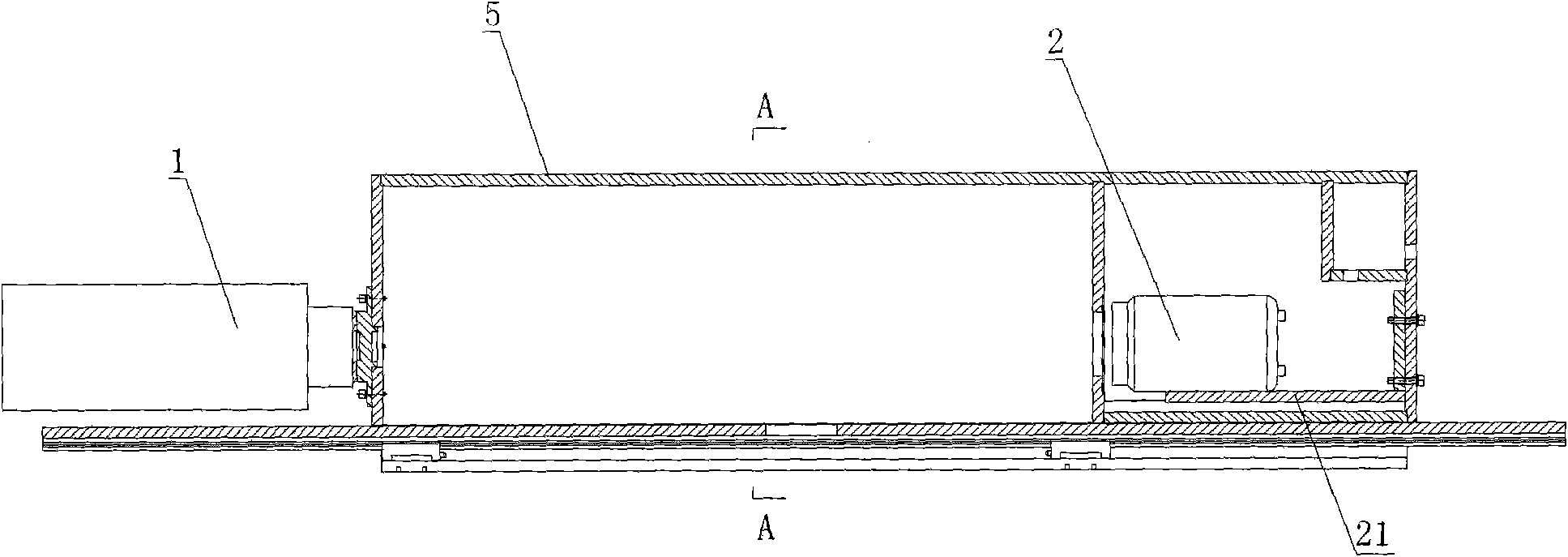

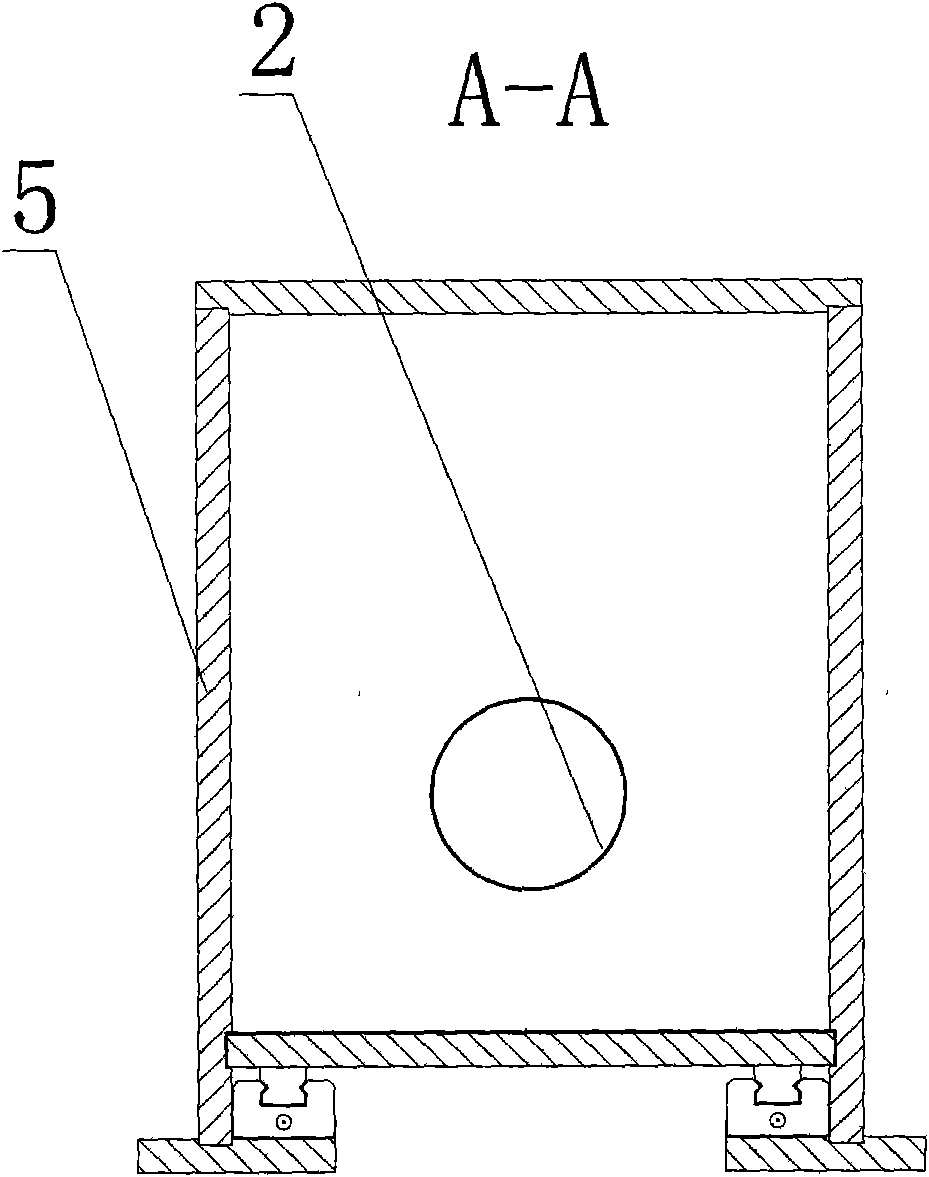

Microscopy CT imaging device with three-free degree motion control and correcting method thereof

InactiveCN101813642AEasy to disassembleSmooth motionComputerised tomographsTomographyPhysicsWire source

The invention provides a microscopy CT imaging device with three-free degree motion control and a correcting method thereof. The microscopy CT imaging device comprises an X-ray source (1) and an X-ray source detector (2), wherein a material-carrying table (3) is arranged between the X-ray source (1) and the X-ray source detector (2). The device is characterized in that the material-carrying table is externally provided with a driving device for driving the material-carrying table to move along the horizontal direction, the vertical direction and the rotation direction. The device solves the problems of serious shake, large error and low precision when the common microscopy CT mechanical device moves; leads the three-free degree direction motion to be more stable, the speed to be more even, and the precision degree to be higher; has better radiation shield effect; solves the problem of the heat dissipation of the X-ray source and the X-ray source detector; solves the problem that the X-ray source, the X-ray source detector and a material-rotating center are positioned at one line; and lays good foundations for the subsequent image acquisition and image reconstruction.

Owner:苏州和君科技发展有限公司 +1

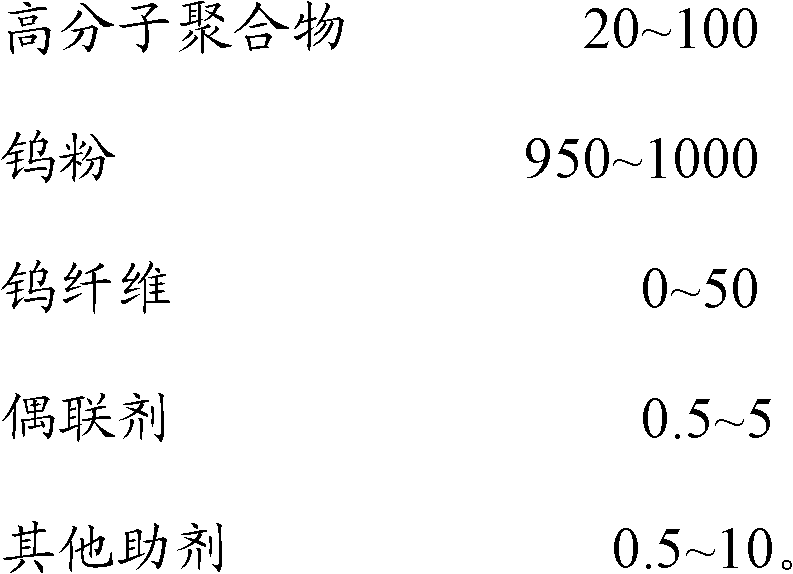

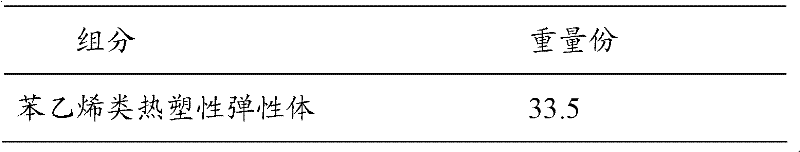

Tungsten-polymer composite material and preparation method thereof

InactiveCN102585330AImproved Radiation Shielding PerformanceHigh mechanical strengthWeather resistanceSurface modification

The invention discloses a tungsten-polymer composite material and a preparation method thereof. The tungsten-polymer composite material comprises the following components in percentage by weight: 20-100% of polymers, 950-1000% of tungsten powder, 0-50% of tungsten fibers, 0.5-5% of coupling agent and 0.5-10% of other auxiliaries, wherein the tungsten powder is prepared through airflow pulverization and surface modification. The tungsten powder disclosed by the invention is good in compaction and flowability and high in loading capacity. The composite material disclosed by the invention is good in physical and mechanical properties, and excellent in weathering resistance, chemical resistance and organic solvent resistance, not only can be applied to the field of ray shielding, but also can be applied to the fields of vibration isolation, weight counterbalance, heat conduction, weapons and ammunitions and the like.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

High-performance radiation-shielding concrete material

InactiveCN101767968ASave raw materialsHigh content of water of crystallizationNuclear reactorGamma ray

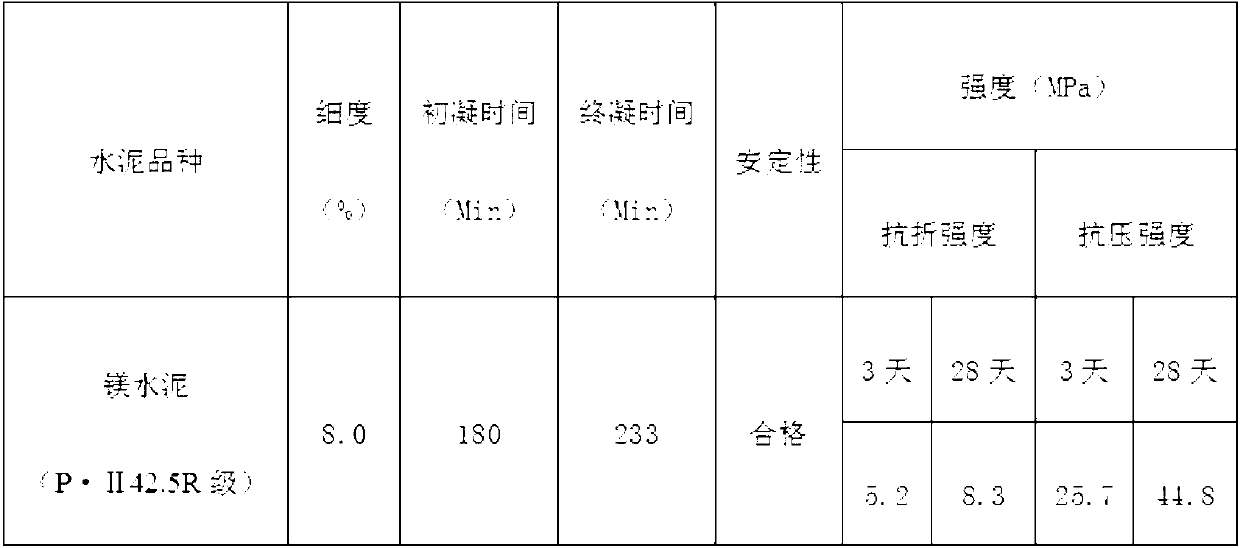

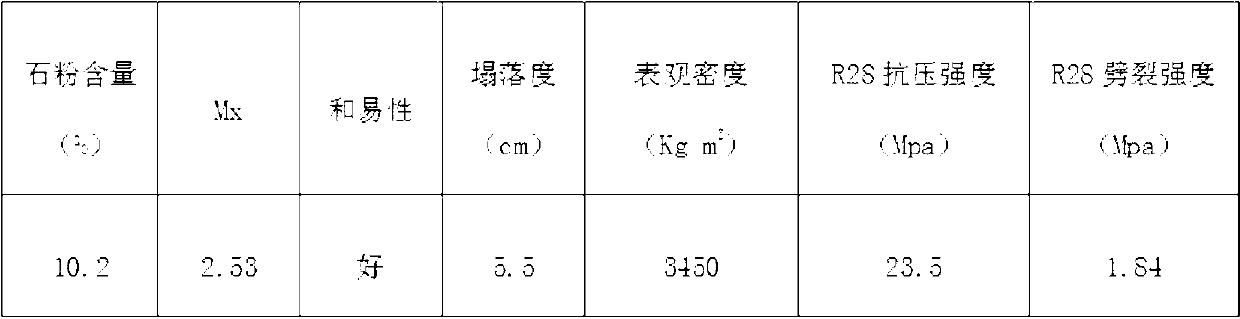

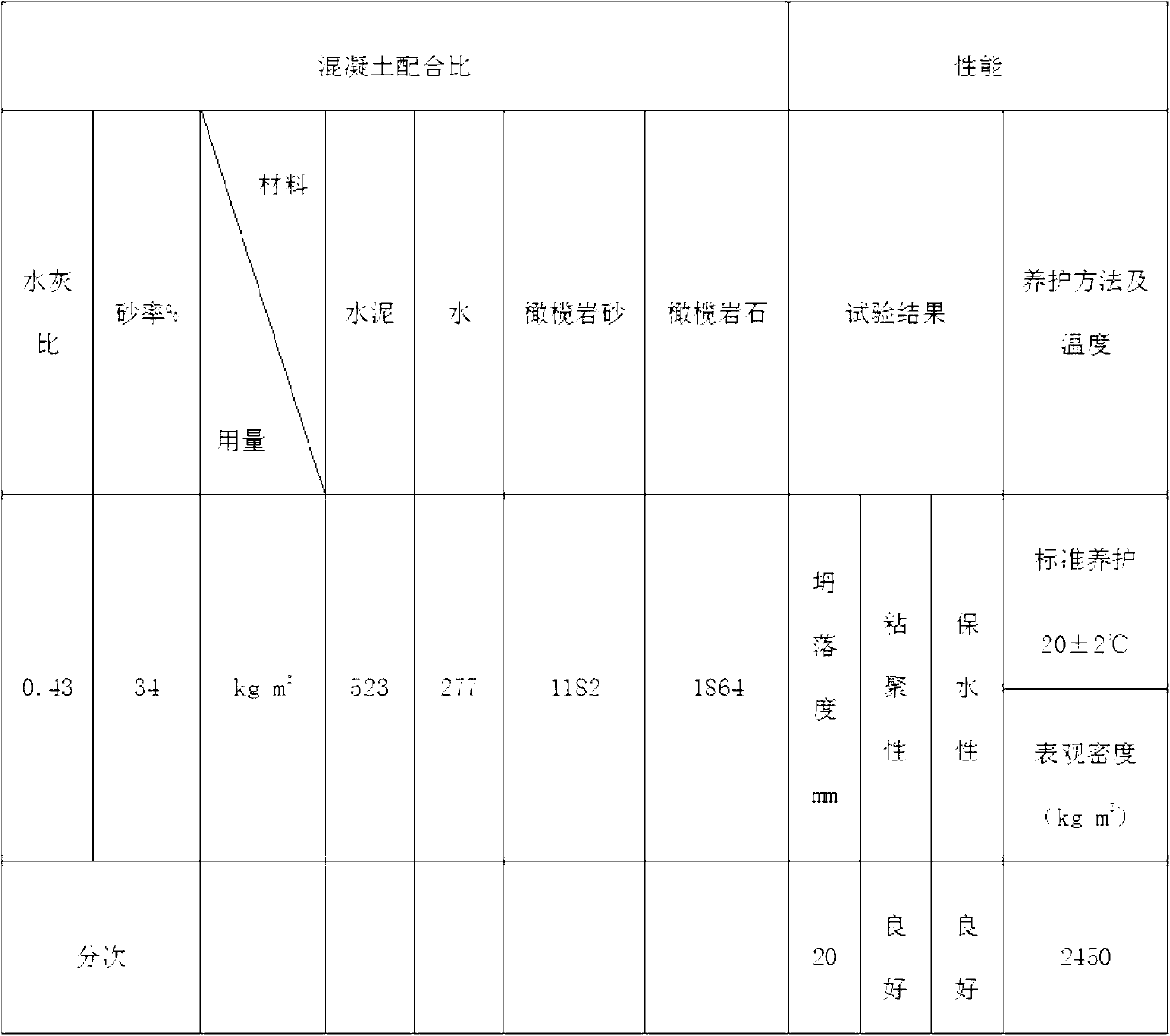

The invention relates to a high-performance radiation-shielding concrete material which belongs to the technical field of building materials. The high-performance radiation-shielding concrete material is characterized by being prepared by mixing silicate cement, rock aggregate enriched in crystal water, water, and the like. The radiation-shielding concrete adopts rocks enriched in crystal water as coarse and fine aggregates of the concrete, wherein the crystal water content range is 6-14 percent, therefore, the radiation-shielding concrete has higher crystal water content (the water content is 13.7 percent by weight) and better neutron shielding capacity. By changing the density of the radiation-shielding concrete, shielding concrete for shielding neutron rays, shielding concrete for shielding Gamma rays and shield concrete for shielding the neutron rays and the Gamma rays simultaneously can be prepared. The invention has the effects and advantages that: the problems of overlarge cement consumption of the common concrete and poor durability of the high-performance concrete are solved. The radiation-shielding concrete is suitable for manufacturing inner and outer shells of a nuclear reactor and solidification process of nuclear wastes.

Owner:DALIAN UNIV OF TECH

Neutron-resistant radiation shield plate and preparation method thereof

InactiveCN103724760AGood radiation shielding effectExtensive engineering applicationPolyolefinLow speed

The invention discloses a neutron-resistant radiation shield plate and a preparation method thereof. The neutron-resistant radiation shield plate comprises the following components in parts by weight: 55-94 parts of polyolefins resin, 4-43 parts of boron carbide powder, 0.5-1.5 parts of a coupling agent, 0.5-1 part of an anti-oxidant and 0.5-2 parts of lubricant. The preparation method of the neutron-resistant radiation shield plate comprises the following steps: 1) batching a composite material, wherein components are added into a high-speed batching stirrer, firstly mixture at a low speed is performed for 30 s, and then mixture at a high speed is performed for 120-180 s; 2) fundamentally pelletizing the composite material, wherein a premixed material is added into a double-screw extruder, and is subjected to smelting, extrusion, cooling, grain cutting and packing to obtain a composite material for the neutron-resistant radiation shield plate; 3) forming the plate, wherein the pelletized composite material is dried, is smelted and extruded by a single-screw extruding machine, is shaped by three-roll pressing, is stretched, drawn and cooled, and then is cut to obtain the neutron-resistant radiation shield plate.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

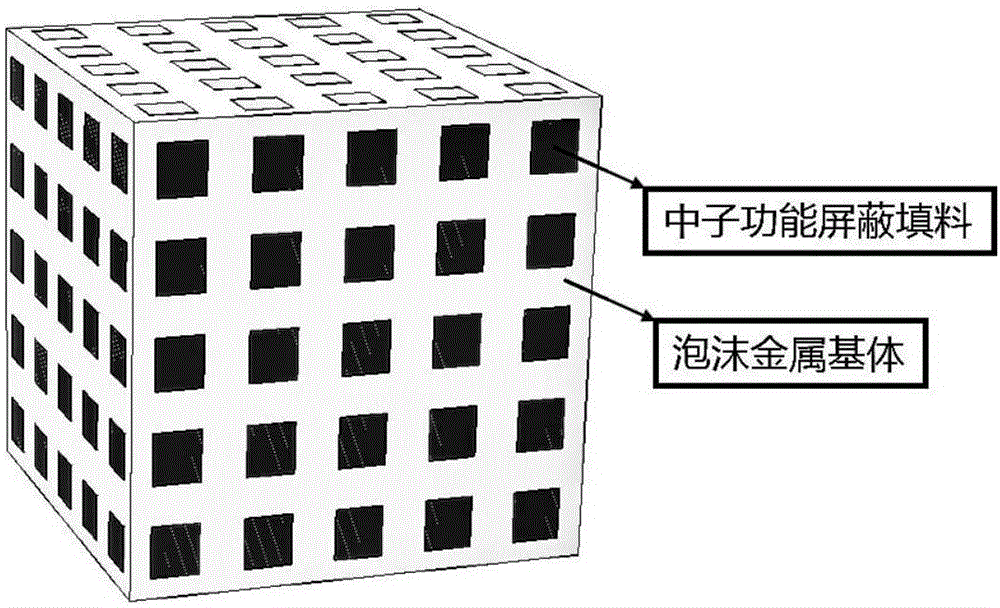

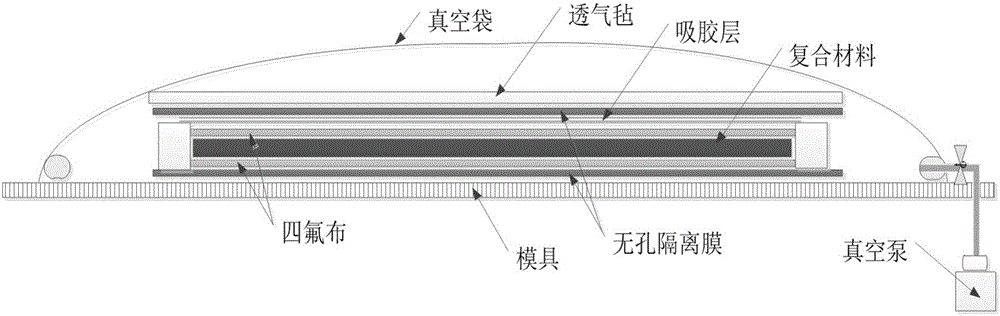

Super-hybrid composite laminate for neutron shield and preparation method of super-hybrid composite laminate

ActiveCN107955332AStrong binding strengthImprove shielding effectSynthetic resin layered productsLaminationInterlaminar shearComposite laminates

The invention provides a super-hybrid composite laminate for neutron shield. The super-hybrid composite laminate comprises a metal plate and a fiber enhanced resin-based composite layer which are alternately laminated, wherein the fiber enhanced resin-based composite layer is prepared from basalt fiber, epoxy resin, modified boron carbide, a curing agent, a moderator and a neutron absorber. The provided fiber enhanced resin-based composite layer has excellent shielding performance and mechanical performance, has the density of 2.36-2.42 g / cm<3>, the tensile strength of 1,120-1,160 MPa, the tensile modulus of 82-85 GPa and the interlaminar shear strength of 78-85 MPa, has the <252>CF neutron source shielding factor Kf (15 mm) of 2.65-3.02 and the neutron shield rate Ath10 (10mm) of 99.88%-99.89%. The invention further provides a preparation method of the composite laminate. The preparation method is simple and convenient to operate and easy to implement.

Owner:BEIHANG UNIV +1

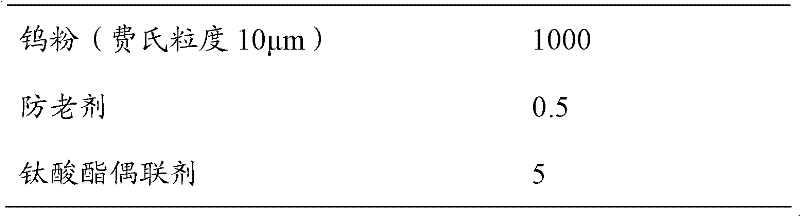

Neutron shield composite material taking foam metal as matrix and preparation method thereof

InactiveCN106280501AHigh neutron shielding performanceImproved Radiation Shielding PerformanceLithium hydridePolypropylene

The invention discloses a neutron shield composite material taking foam metal as a matrix and a preparation method thereof. The material comprises a foam metal matrix and a neutron shield functional filler, wherein the neutron shield functional filler comprises a neutron absorption functional filler and a neutron moderation functional filler; the neutron moderation functional filler is one or a mixture of several materials in resins such as polyethylene, polypropylene, polystyrene and the like or paraffin and water; the neutron absorption functional filler is one or a mixture of several materials in borax, boric acid, boron carbide, lithium hydride and the like; the foam metal is foam of metals such as perforated lead, aluminum, iron, copper, nickel and the like. According to the invention, the preparation method comprises the following steps of: sequentially performing high polymer heating and melting on raw materials, mixing organic fillers with inorganic fillers, pretreating the foam metal, filling the perforated foam metal with fillers, cooling, curing, and finally obtaining the product.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Ionizing-radiation-preventive composite material and preparation method thereof

The invention discloses an ionizing-radiation-preventive composite material and a preparation method thereof. In the ionizing-radiation-preventive composite material, basalt fiber is high in content of heavy-nucleus elements like iron and manganese, and the heavy-nucleus elements improve absorbing and scattering effect on high-energy ionizing radiation of the basalt fiber, so that compared with other reinforced fiber, the basalt fiber has better ray shielding performance; due to special atomic energy level, rare earth oxide has strong photoelectric absorbing effect on rays of 10-80 keV, and weak absorbing area that the heavy-nucleus elements have within the range can be filled up, so that shielding performance of the basalt fiber composite material on wide-energy-range rays is improved remarkably. The rare earth oxide, a resin matrix and the basalt fiber mutually cooperate and mutually act, so that the ionizing-radiation-preventive composite material has good radiation-preventive performance and mechanical performance.

Owner:BEIHANG UNIV

Anti-ionizing radiation fiber-reinforced resin matrix composite and preparation method thereof

In the invention, basalt fiber has relatively high content of heavy-nucleus elements such as iron and manganese, and the heavy-nucleus elements enhance the adsorbing and scattering effects of the basalt fiber on high-energy ionizing radiation; and compared with other reinforcing fiber, the basalt fiber has better ray shielding performance. The elements including tungsten and lead realize perfect weakening and shielding effects on the ionizing radiation with relatively high energy; and by adding the heavy metals tungsten and lead and other compound fillers, the energy of high-energy ray can be effectively reduced so that the high-energy ray is converted into low-energy radiation and further absorbed by the basalt fiber. In the invention, the heavy metals and compounds thereof, the resin matrix and the basalt fiber cooperate with each other and interact, and the obtained anti-ionizing radiation composite obtains good anti-radiation property and mechanical property.

Owner:BEIHANG UNIV

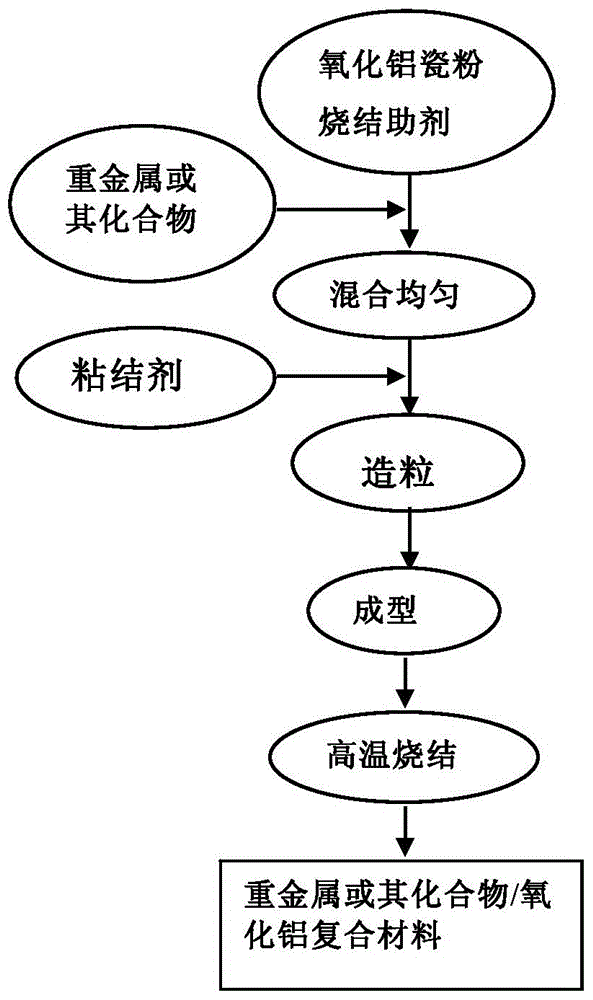

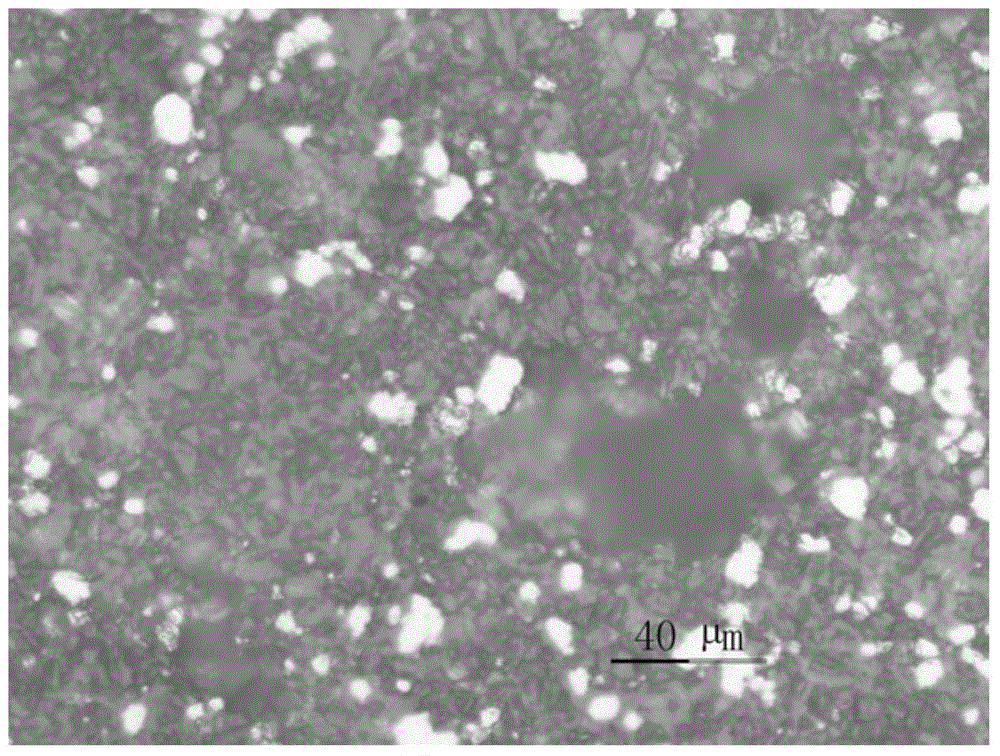

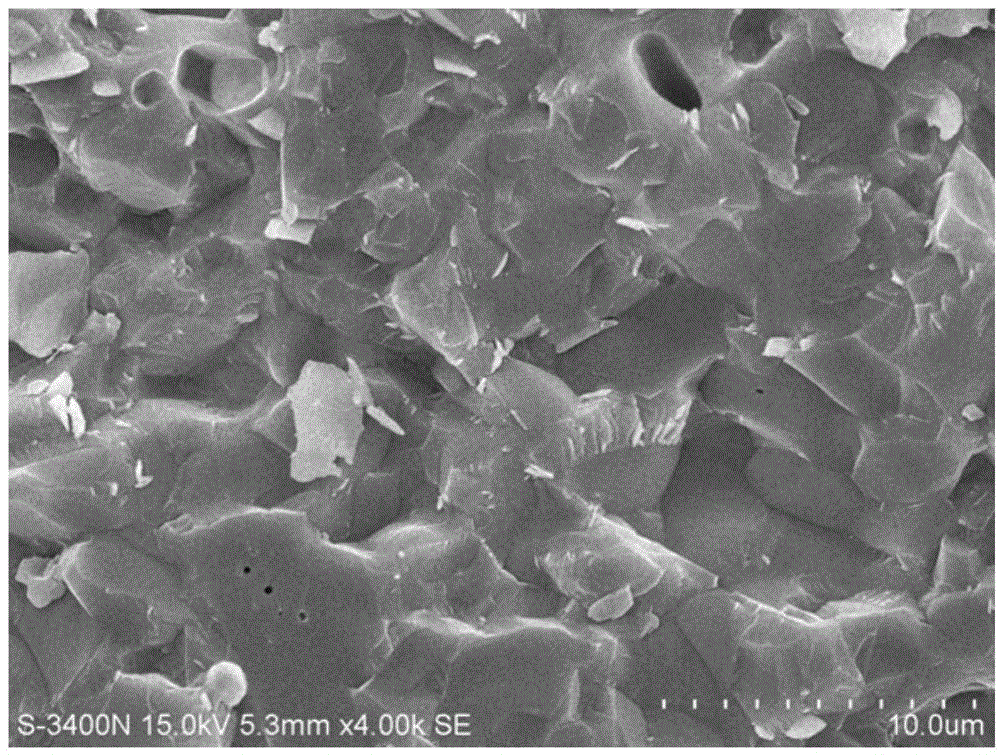

Radiation shielding electronic packaging material and preparation method for same

ActiveCN104658624AReduce porositySmall coefficient of thermal expansionSemiconductor/solid-state device detailsSolid-state devicesOrganic solventHeavy metal compound

The invention discloses a radiation shielding electronic packaging material, which comprises a sintered body of a composition, wherein the composition comprises heavy metal or heavy metal compound powder serving as a radiation shielding functional component, alumina ceramic powder serving as a substrate component, a sintering aid and an adhesive. The radiation shielding electronic packaging material is prepared by the following steps: uniformly mixing the heavy metal or heavy metal compound powder, the alumina ceramic powder and the sintering aid by taking an organic solvent as a dispersion medium; mixing the adhesive into the mixture after the mixture is dried, and performing granulation to obtain composite granules; performing dry-pressing molding and high-temperature sintering. The obtained material has high ray shielding performance, particularly high X and gamma ray radiation shielding performance.

Owner:EAST CHINA UNIV OF SCI & TECH

High-performance radiation-shielding concrete

InactiveCN103000242ASave raw materialsHigh content of water of crystallizationShieldingRadiation shieldMaterials science

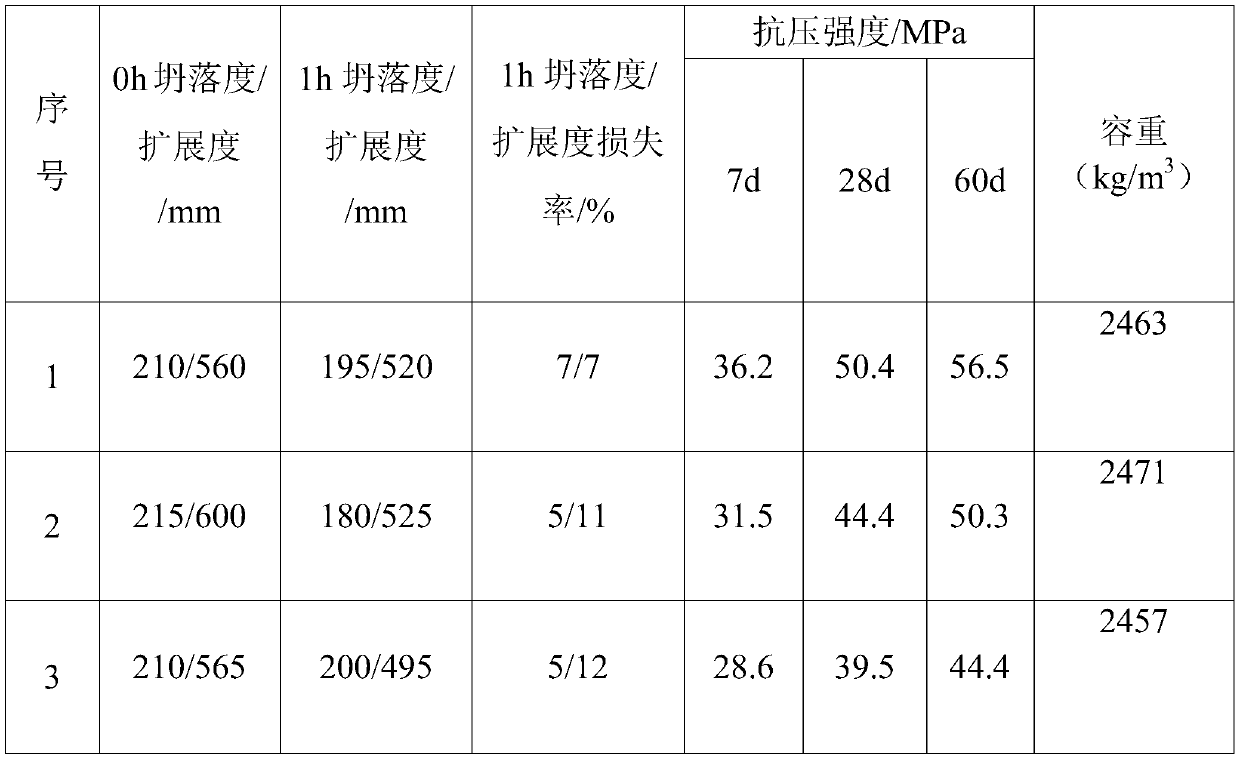

The invention relates to a high-performance nuclear radiation-shielding concrete material which is mixed by concrete, aggregate, water and the like. The radiation-shielding concrete takes the crystal water-enriched olivinite as the aggregate, so that the material is higher in crystal water content (the moisture content is 6-14%), thereby being better in neutron shielding capability. The shielding concrete for shielding the neutron ray, the shielding concrete for shielding the gamma ray, and the shielding concrete for shielding the neutron ray and the gamma ray can be prepared by changing the density of the radiation-shielding concrete. The high-performance radiation-shielding concrete contains a mass of light nucleus substances, so that the material has good characteristic in the aspect of the neutron shielding characteristic. Aiming at the problem that the current common concrete package material is heavy in weight, small in volume, and inconvenient for long-distance transportation, the concrete package material is prepared due to the characteristic that the material is enriched in the crystal water, so that the aims of weight reducing and volume enlarging can be achieved.

Owner:DALIAN UNIV OF TECH

Anti-radiation C40 concrete used for prefabricated part and preparation method of anti-radiation C40 concrete

The invention discloses anti-radiation C40 concrete used for a prefabricated part. The concrete is prepared by mixing the following ingredients in parts by weight: 200-300 parts of cement, 120-210 parts of coal ash, 700-750 parts of river sand, 1,100-1,200 parts of gravels, 7-10 parts of an additive, 20-40 parts of an expanding agent and 140-160 parts of water. Compared with the prior art, the anti-radiation C40 concrete has the following advantages: 1, basalt is taken as an aggregate, and the performance density of the concrete is ensured to be 2,350kg / m<3> through optimization of a match ratio, so that the anti-radiation C40 concrete has the performance of shielding proton rays and neutron rays, and the strength of the concrete reaches the C40 grade; 2, the quantity of induced radioactivity of a concrete shield wall is controlled by strictly controlling the content of harmful elements in raw materials of the concrete; 3, by mixing a large amount of admixtures, solid wastes are utilized, the cost is lowered, and the hydration heat and pre-cracking of the concrete can be greatly reduced; 4, by adding the high-performance expanding agent, the shrinkage of the concrete is compensated, the cracking caused by shrinkage is prevented, and the radiation shield effect is intensified.

Owner:安徽海龙建筑工业有限公司

Polyether-ether-ketone composite material containing gadolinium oxide and preparation method of composite material

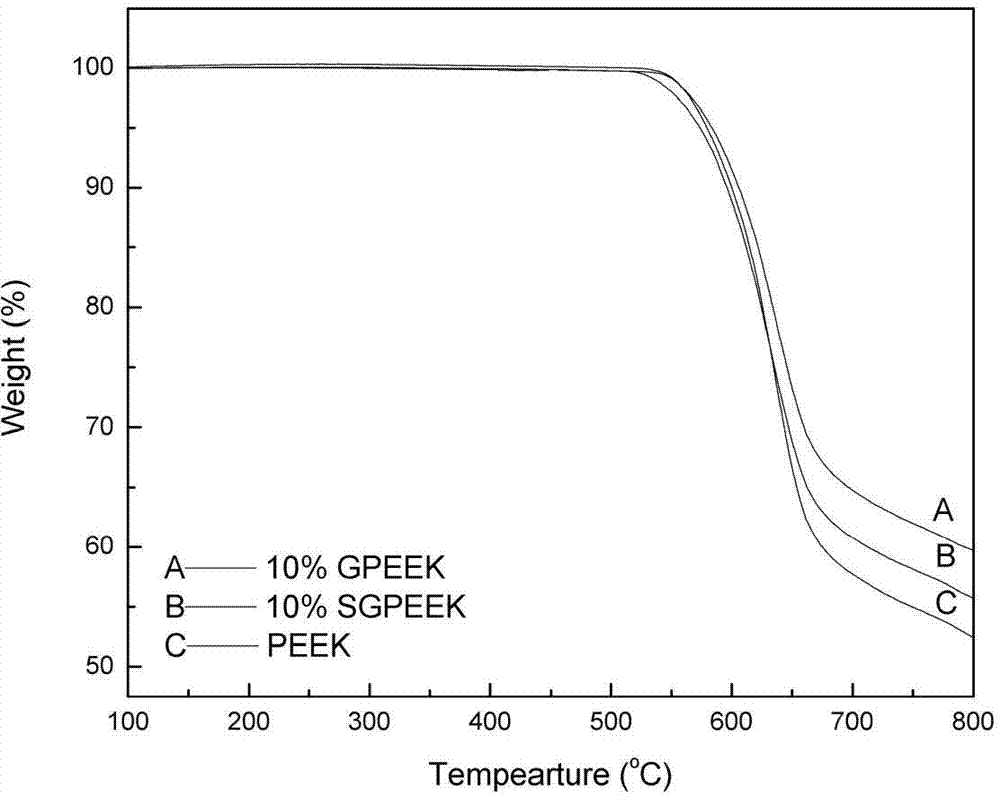

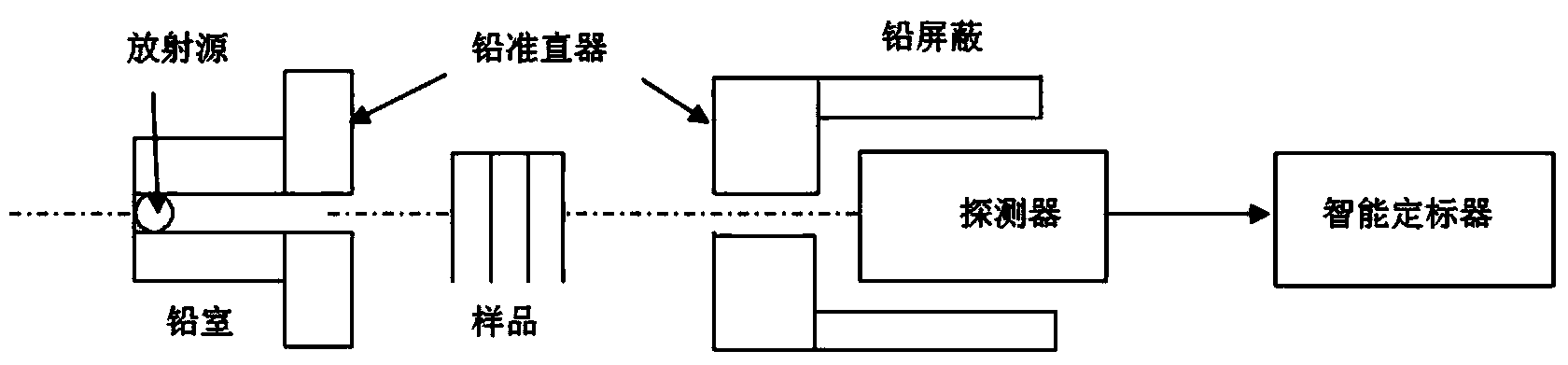

The invention relates to a polyether-ether-ketone composite material containing gadolinium oxide and a preparation method of the composite material, which belong to the technical field of special engineering plastics. The polyether-ether-ketone composite material comprises the following raw materials in parts by weight: 5-35 parts (X) of the gadolinium oxide, 0-0.08X of sulfonated polyether-ether-ketone and the balance of polyether-ether-ketone. The preparation method of the composite material comprises the following steps of: modified treatment of the gadolinium oxide and melt blending of the raw materials, wherein the modified gadolinium oxide and the polyether-ether-ketone are mixed together, and a double-screw extruding machine is used for carrying out the melting blending on the mixture to obtain the composite material. In order to improve interaction between two phases of the polyether-ether-ketone and the gadolinium oxide in the composite material, the sulfonated polyether-ether-ketone is firstly added into the gadolinium oxide to modify the gadolinium oxide, and then the melt blending is carried out on the mixture, so that the gadolinium oxide can be dispersed well in the polyether-ether-ketone matrix. The composite material has higher strength and modulus, excellent heat stability and a favorable X-ray shielding property.

Owner:JILIN UNIV

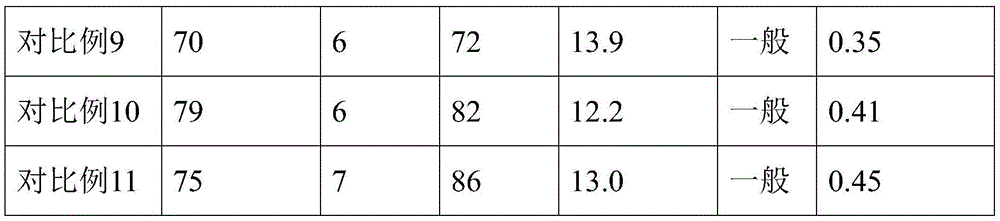

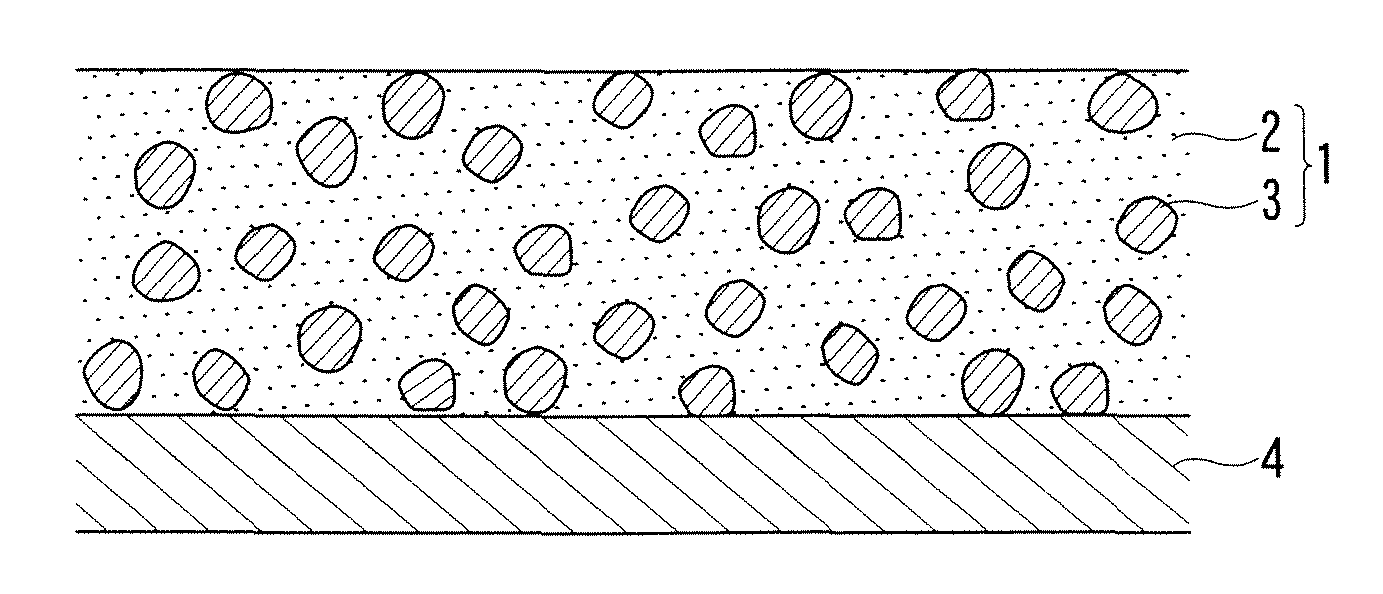

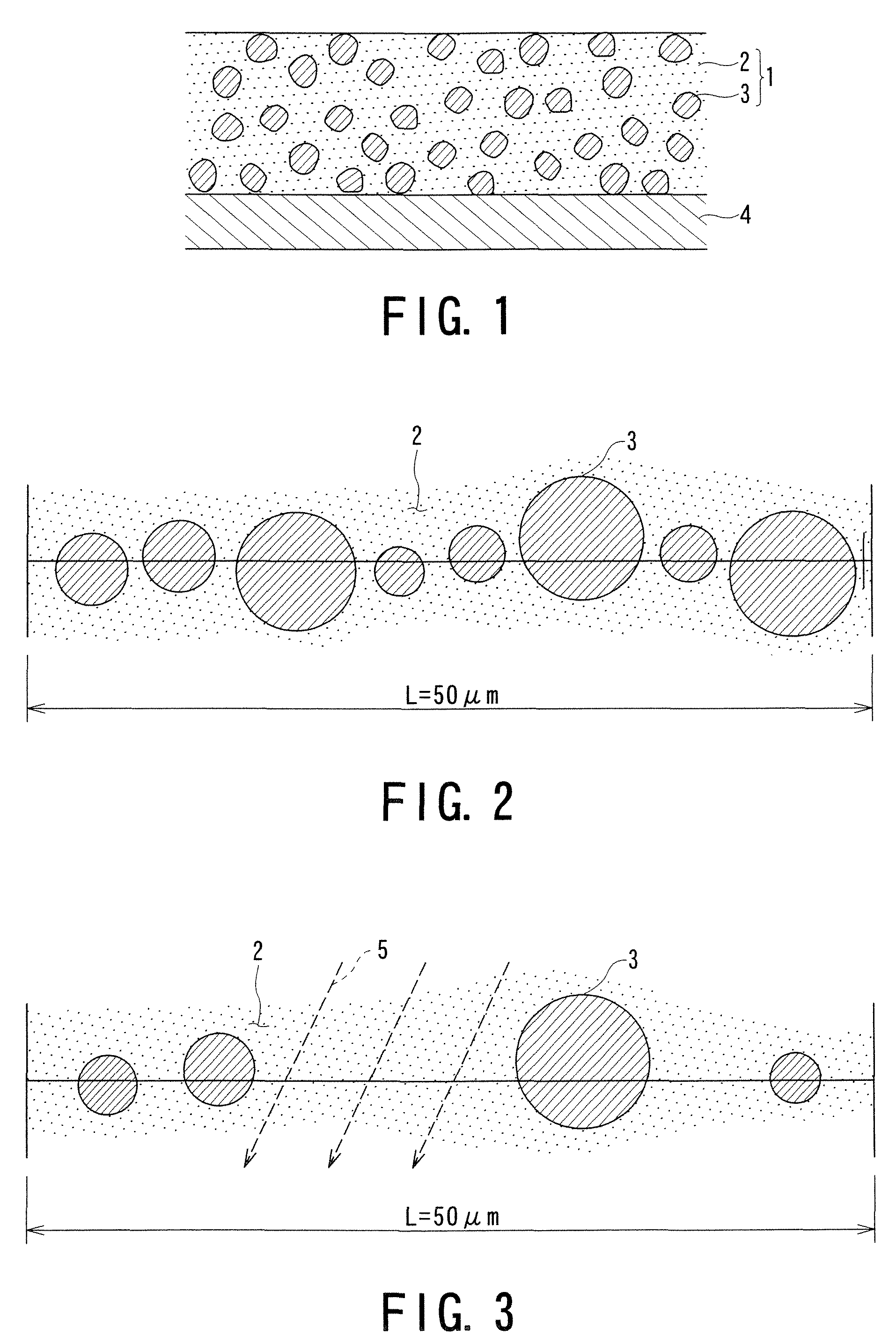

Master batch containing heat radiation shielding component, and heat radiation shielding transparent laminate for which the master batch has been used

ActiveUS20060009559A1High heat radiation shielding performanceSuperior visible-light transmission powerSynthetic resin layered productsRadiation-absorbing paintsThermal radiationRadiation shield

In a master batch containing a heat radiation shielding component, which is used to produce heat radiation shielding transparent resin forms, the master batch has as chief components a thermoplastic resin and a hexaboride represented by XB6, wherein X is at least one selected from La, Ce, Pr, Nd, Gd, Tb, Dy, Ho, Y, Sm, Eu, Er, Tm, Yb, Lu, Sr and Ca. The hexaboride, which is a heat radiation shielding component, is contained in an amount of from 0.01 part by weight or more to less than 20 parts by weight based on 100 parts by weight of said thermoplastic resin. The use of this master batch enables simple production of heat radiation shielding transparent resin forms having a high visible-light transmission power and a high heat radiation shielding performance, without relying on any high-cost physical film formation methods.

Owner:SUMITOMO METAL MINING CO LTD

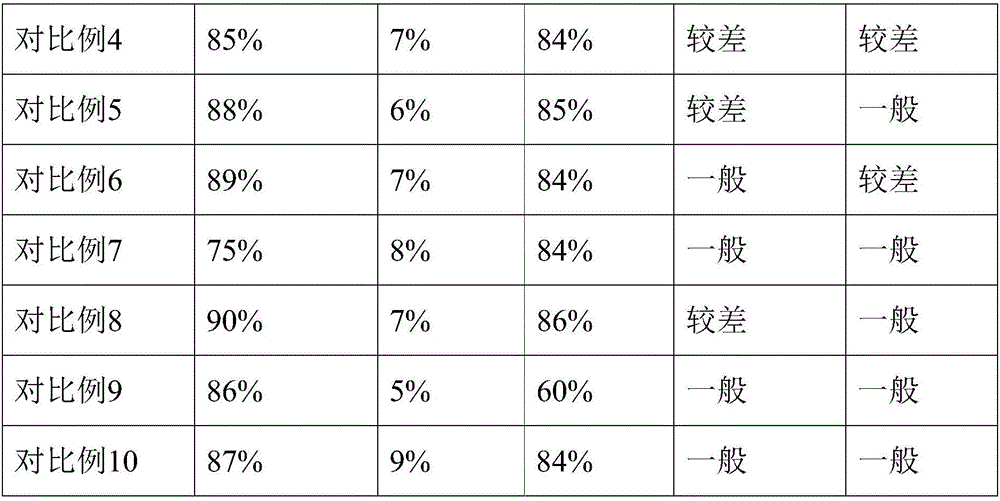

Production process of anti-radiation blended yarn

The invention discloses a production process of anti-radiation blended yarn. The production process includes blending, by mass percentage, 60-65% of hemp fibers and 35-40% of stainless steel fibers sequentially through opening picking, cotton carding, drawing, roving and spinning. The hemp fiber and stainless steel fiber blended yarn produced by the process has the advantages that advantages of the two fibers are combined, the yarn is smooth in touch, the stainless steel fibers are evenly blended in the yarn, and the yarn has environmental protection property and functionality, such as bacteria resistance, dampness absorption and fast dry and biodegradability, of hemp fibers, and good radiation shielding effect.

Owner:KUNSHAN WANFENG GARMENT

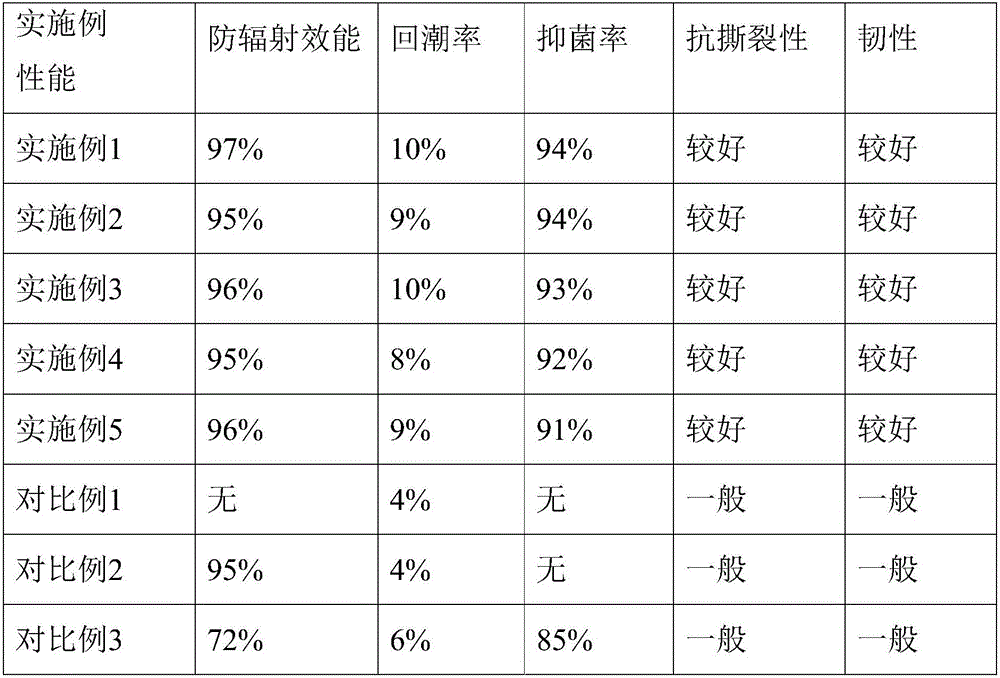

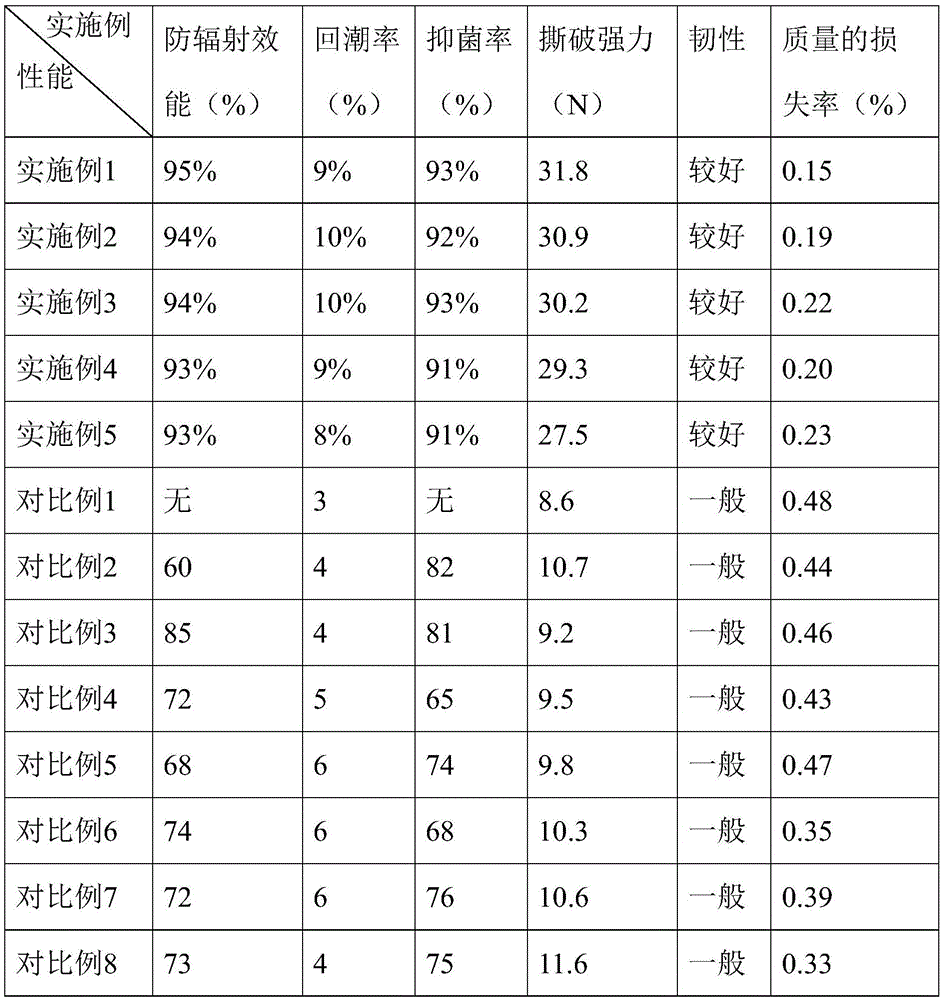

Composite fiber fabric and preparation method thereof

InactiveCN105671734AImprove performanceImprove tear resistanceWoven fabricsCarbon fibersTear resistance

The invention relates to a composite fiber fabric and a preparation method thereof and belongs to the technical field of spinning engineering. Warp yarn of the composite fiber is blended yarn of stainless steel fibers, carbon fibers and cotton fibers, and weft yarn is blended yarn of stainless ramie and cotton fibers. In the blended yarn of the warp yarn, the content of the stainless steel fibers is 10-18%, the content of the carbon fibers is 2-5% and the content of the cotton fibers is 77-88%. In the blended yarn of the weft yarn, the content of the stainless steel fibers is 8-15%, the content of the ramie is 5-8% and the content of the cotton fibers is 77-87%. The fabric has the environmental protection performance and functionality in the aspects of bacteria resistance and bacteriostasis, moisture absorption, fast drying, biodegradation and the like of the ramie, has the strength of the carbon fibers so that the tear resistance of the fabric can be improved, and also has a good anti-radiation shielding effect of the stainless steel fibers, a cloth cover is level, soft and smooth, the anti-radiation effect is larger than or equal to 95%, and the moisture regain is 8-10%; the fiber bacteriostasis rate is larger than or equal to 90%.

Owner:宁波弘邦信息咨询有限公司

Polyacrylic acid metal salt/boron oxide material as well as preparation method and application thereof

The invention discloses a polyacrylic acid metal salt / boron oxide material as well as a preparation method and application thereof. The material is obtained by mixing lead acrylate, gadolinium acrylate, acrylic acid, deionized water, boron oxide and benzoin dimethyl ether serving as a photoinitiator, preparing by virtue of an ultraviolet light-induced crosslinking method at room temperature and then molding by virtue of a mold-pressing method. The composite material disclosed by the invention can be used for radiation shielding and thus gamma ray irradiation can be effectively shielded and thermal neutrons can be absorbed. Since the ultraviolet light-induced crosslinking is directly carried out by virtue of in-situ polymerization and multi-network cross-compounding of ionic and covalent bonds is performed, the prepared material is dense and lightweight, is simple in process and low in cost and has good radiation shielding effect.

Owner:SOUTHEAST UNIV

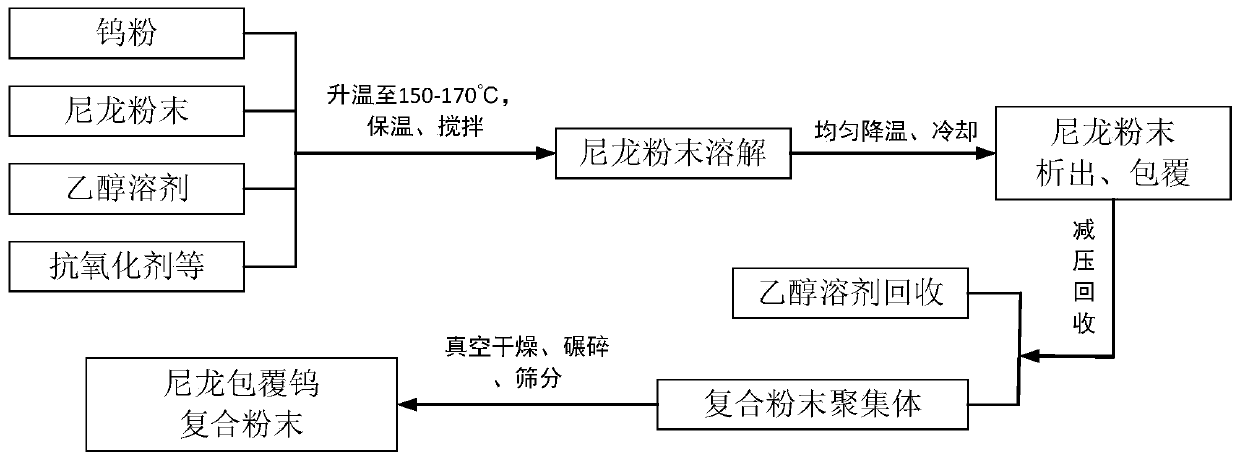

Nylon-coated metal tungsten radiation-shielding composite material and preparation method thereof

The invention discloses a nylon-coated metal tungsten radiation-shielding composite material and a preparation method thereof. The preparation method comprises the steps: mixing nylon, tungsten powder, an ethanol solvent and other substances in a reaction kettle, performing heating until complete dissolution of the nylon, then controlling temperature lowering precisely so as to precipitate the nylon and coat the precipitated nylon on the surface of tungsten powder particles, opening the reaction kettle, performing filtration, collecting the ethanol solvent so as to obtain nylon-coated tungsten composite powder aggregate, and performing drying, stirring, dispersion, powder flow guiding and other post-treatment so as to obtain the nylon-coated tungsten composite powder which is suitable for selective laser sintering forming. The nylon powder is nylon powder specific for 3D printing, has reliable performance and stable selective laser sintering forming. The nylon-coated metal tungsten radiation-shielding composite material has excellent performance, good fluidity and a good nylon coating effect, requirements of forming in an SLS process are met fully, and molding of a structural member with excellent radiation shielding performance, no toxicity, environmental protection and good mechanical properties can be achieved through a selective laser sintering process.

Owner:SOUTH CHINA UNIV OF TECH

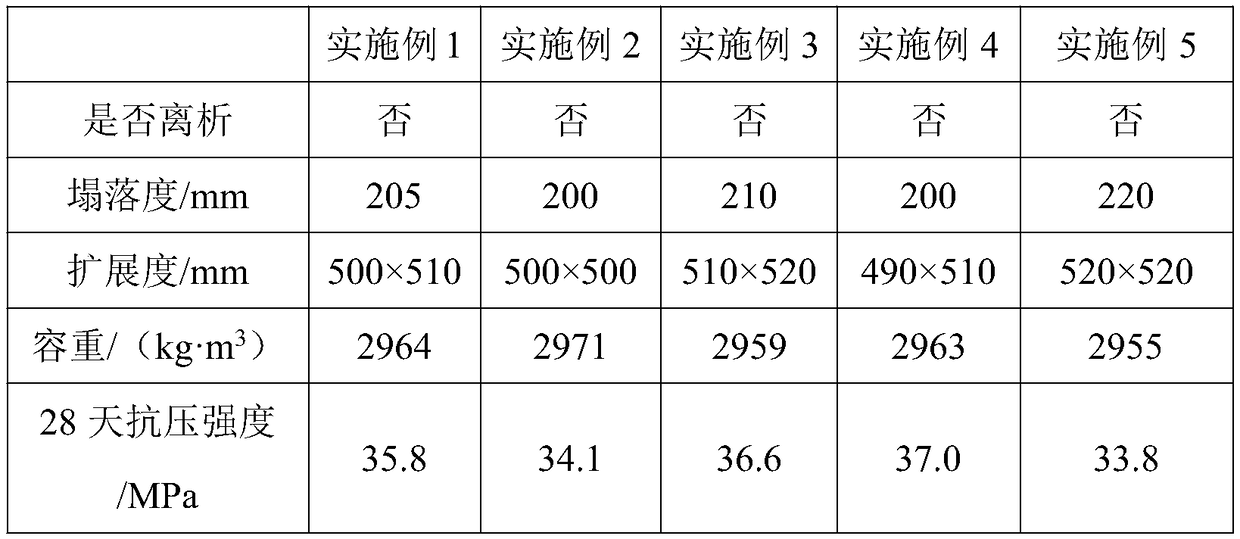

Radiation-proof concrete and preparation method thereof

The invention belongs to the field of concrete, and particularly discloses radiation-proof concrete and a preparation method thereof. The concrete is prepared from the following materials in parts byweight: 300-350 parts of cement, 900-1,200 parts of fine aggregate, 1,200-1,500 parts of coarse aggregate, 60-80 parts of fibers, 10-20 parts of a neutron absorber, 0.4-0.6 part of a water reducing agent, and 145-165 parts of water. The radiation-proof concrete prepared by the method is in compliance with a strength requirement of concrete C30 without a segregation phenomenon, good in slump degreeand extended degree, wherein a volume weight ranges between 2,900 and 2,950 kg*m<3>, and is in compliance with a volume weight requirement to the radiation-proof concrete. In addition, the radiation-proof concrete has the characteristics of excellent working performance, good radiation-proof performance, low cost, fire resistance, crack resistance and the like, and is beneficial to solve problemsof traditional radiation-proof concrete that segregation is easy, homogeneity is poor, workability is not good and the like, and an application problem in the environment with fire-proof and anti-crack requirements.

Owner:成都宏基建材股份有限公司

Blended yarn multifunctional fabric and making method thereof

The invention relates to a blended yarn multifunctional fabric and a making method thereof, and belongs to the technical field of spinning engineering. Warp of the fabric is blended yarn spun by adopting spandex silk as a yarn core and wrapping the yarn core by stainless steel fibers, copper fibers and carbon fibers. Weft of the fabric is blended yarn spun by adopting spandex silk as a yarn core and wrapping the yarn core by stainless steel fibers, natural bamboo fibers and ramie. The content of the stainless steel fibers in the warp ranges from 5% to 10%, the content of the copper fibers in the warp ranges from 2% to 5%, the content of the carbon fibers in the warp ranges from 2% to 5%, and the content of the spandex silk in the warp ranges from 80% to 91%. The content of the stainless steel fibers in the weft ranges from 3% to 10%, the content of the natural bamboo fibers in the weft ranges from 3% to 8%, the content of the ramie in the weft ranges from 3% to 8%, and the content of the spandex silk in the weft ranges from 74% to 91%. The fabric has the environmental protection property and functionality on the aspects of bacteria resistance and bacteriostasis, moisture absorption and quick drying, biodegradation and the like, and has good strength, elasticity, tear resistance and tenacity, and a good radiation protection and shielding effect is further achieved. The cloth face is flat, soft and smooth, the radiation protection efficiency reaches 92% or above, the moisture regain ranges from 8% to 10%, and the fiber bacteriostasis rate is larger than or equal to 91%.

Owner:NINGBO MH IND CO LTD

Radiation shielding sheet

ActiveUS7923708B2Increase elasticityHigh strengthRadiation/particle handlingElectrode and associated part arrangementsCeriumLanthanum

A radiation shielding sheet formed by filling a shielding material into an organic polymer material. The shielding material is an oxide powder containing at least one element selected from the group consisting of lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), samarium (Sm), europium (Eu) and gadolinium (Gd). The oxide powder has an average grain size of 1 to 20 μm, and a volumetric ratio of the shielding material filled in the radiation shielding sheet is 40 to 80 vol. %.

Owner:KK TOSHIBA +1

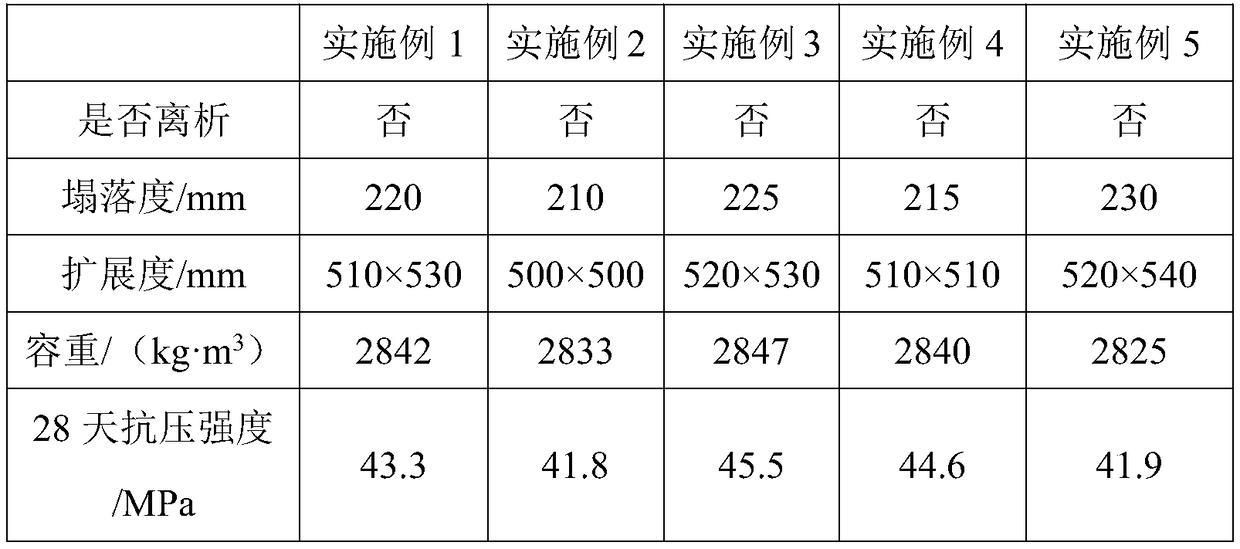

Low thermal micro-expansive cement based radiation shielding concrete and preparation method thereof

InactiveCN109320159AReduce the chance of segregationImprove homogeneityUltimate tensile strengthLarge size

The invention belongs to the field of concrete and particularly discloses low thermal micro-expansive cement based radiation shielding concrete and a preparation method thereof. The low thermal micro-expansive cement based radiation shielding concrete is prepared from the following materials in parts by weight: 280-320 parts of cement, 900-1200 parts of fine aggregates, 1200-1500 parts of coarse aggregates, 10-20 parts of a neutron absorber, 0.4-0.6 part of a water reducer and 140-160 parts of water. The concrete accords with the strength requirements for C30 concrete without the segregation phenomenon, is good in slump and divergence, has the bulk density ranging from 2800 kg.m<3> to 2900 kg.m<3>, has the 28d restrained expansion rate ranging from 0.004 percent to 0.007 percent under thewater cultivation condition, has the characteristics of excellent working performance, good radiation shielding performance, low cost and the like at the same time, solves the problems of easiness insegregation, poor homogeneity, poor construction performance and the like of the traditional radiation shielding concrete, is further beneficial to meeting the requirements for the special performanceincluding non shrinkage, micro expansion, low hydration heat and the like of the radiation shielding concrete and is very suitable for large-size radiation shielding concrete engineering.

Owner:成都宏基建材股份有限公司

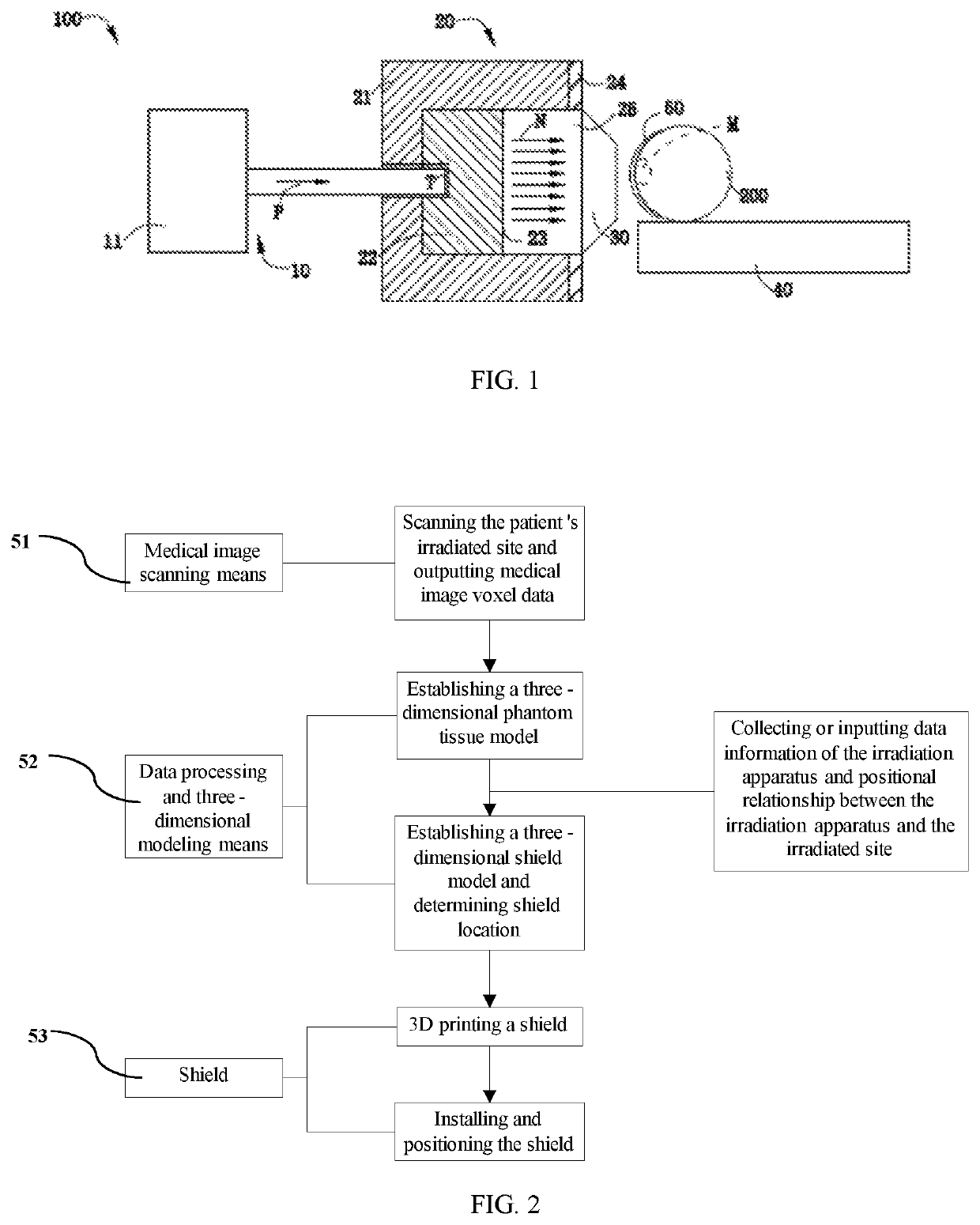

Medical image-based radiation shielding device and method thereof

ActiveUS10994154B2More targetedImprove accuracyAdditive manufacturing apparatusRadiation safety meansVoxelComputer printing

A medical image-based radiation shielding device and method thereof, which may form a targeted and highly accurate radiation shielding according to individual differences in patients, such as tumor location and size, thereby reduce or avoid radiation from a irradiation apparatus to normal tissues of patients. The shielding device includes a medical image scanning means for scanning an irradiated site of an irradiated subject and outputting medical image voxel data, a data processing and three-dimensional modeling means for establishing a three-dimensional phantom tissue model according to the medical image voxel data and establishing a three-dimensional shield model according to the three-dimensional phantom tissue model; a shield located between the irradiation apparatus and the irradiated site, wherein the shield is formed by printing the three-dimensional shield model data input to a 3D printer.

Owner:NEUBORON MEDTECH

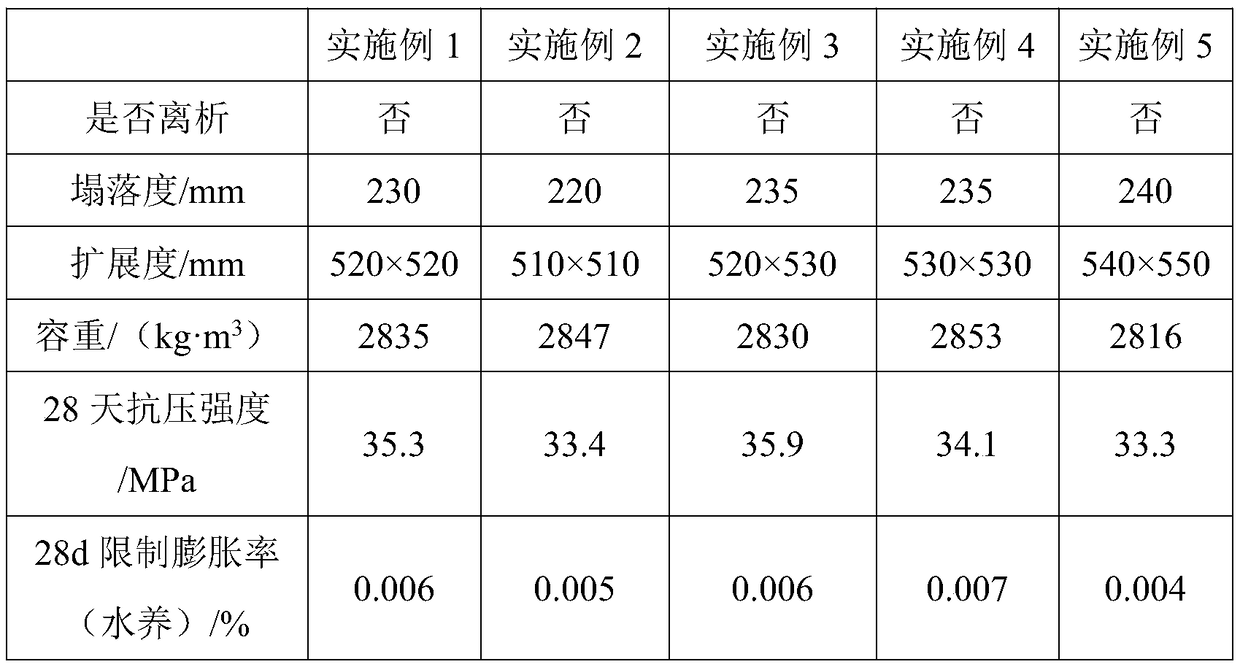

C40 ordinary Portland cement base radiation shield concrete and preparation method thereof

InactiveCN109133803AReduce the chance of segregationImprove homogeneityWork performancePortland cement

The invention belongs to the field of concrete and in particular discloses C40 ordinary Portland cement base radiation shield concrete and a preparation method thereof. The concrete consists of the following raw materials in parts by weight: 330-370 parts of cement, 800-1000 parts of fine aggregate, 1200-1500 parts of crude aggregate, 10-20 parts of a neutron absorber, 0.5-0.7 part of a water reduction agent and 150-170 parts of water. The C40 ordinary Portland cement base radiation shield concrete disclosed by the invention meets C40 concrete strength requirements, is free of separation phenomenon, is high in collapsbillity and expansion degree, has a volume weight within 2800-2850 kg.m<3>, meets requirements of radiation shield concrete on volume weights, and meanwhile has the characteristics of being excellent in working performance, high in radiation shield property, low in cost, and the like, and problems that conventional radiation shield concrete is liable to separate, low in homogeneity, low in construction performance, and the like, can be solved.

Owner:成都宏基建材股份有限公司

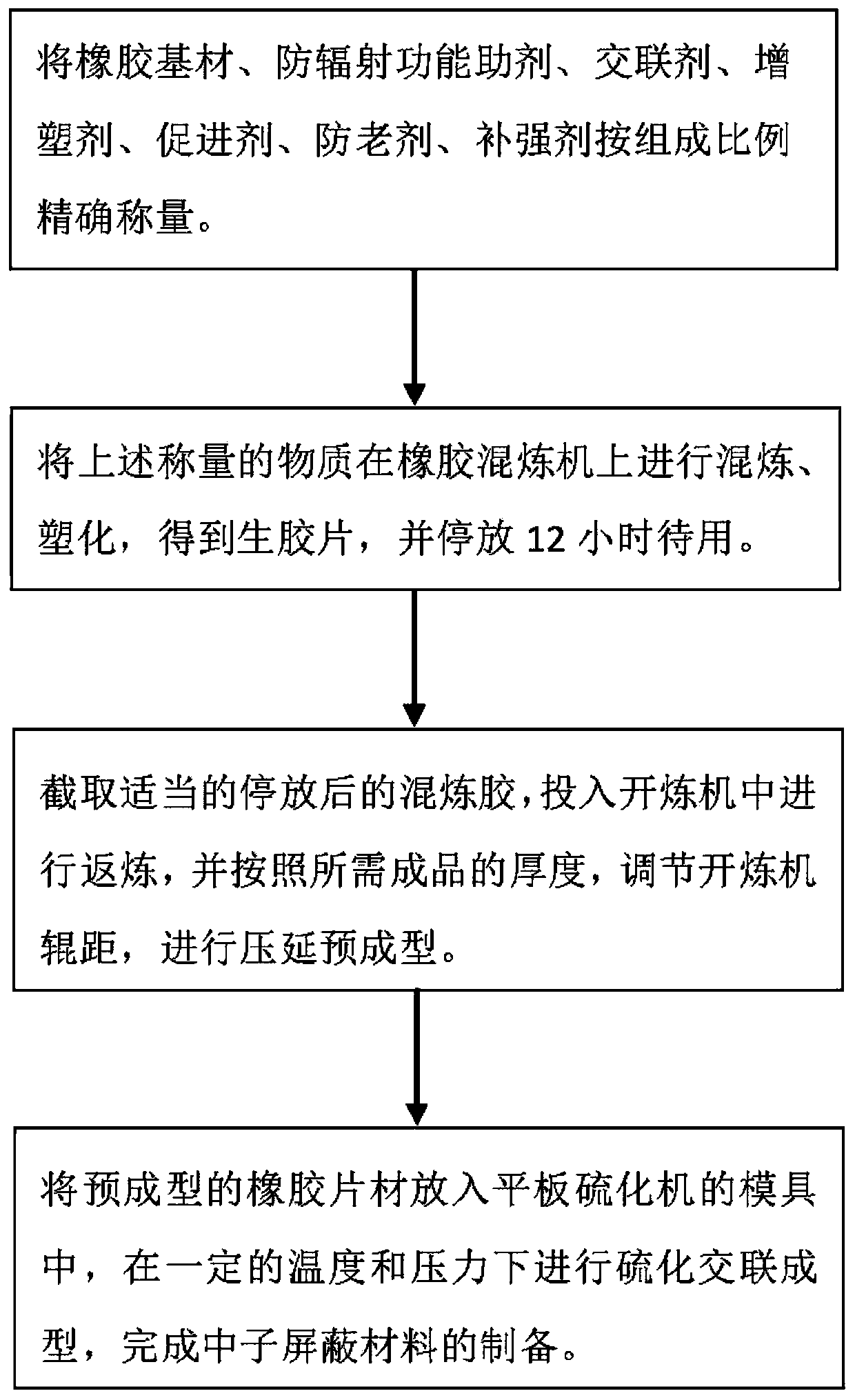

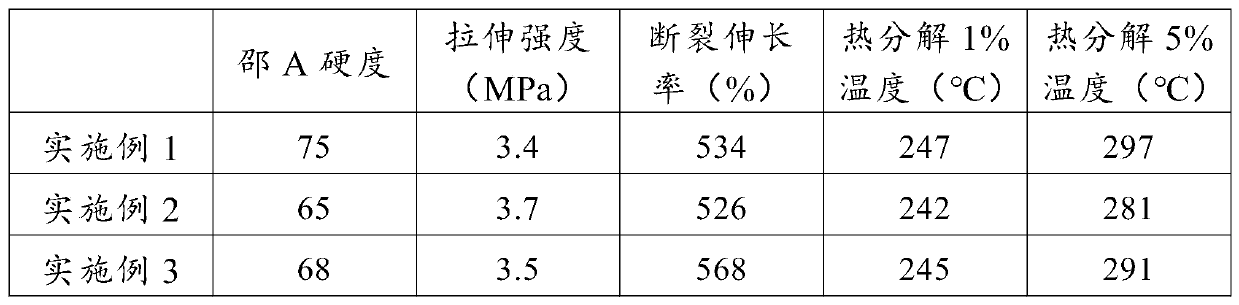

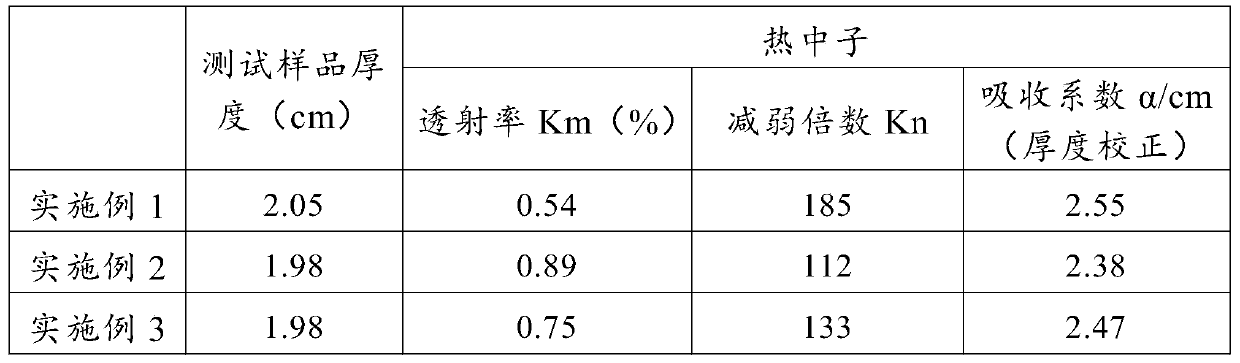

Ethylene propylene diene monomer flexible base neutron shielding material and preparation method thereof

InactiveCN110240757AGood physical and mechanical propertiesCost-effectiveShieldingRadiation protectionPlasticizer

The invention belongs to the technical field of radiation protection and relates to an ethylene propylene diene monomer flexible base neutron shielding material and a preparation method thereof. The raw materials for preparing the neutron shielding material comprise the following components in parts by weight: 50-100 parts of ethylene propylene diene monomer, 30-150 parts of a radiation-proof functional auxiliary agent, 5-14 parts of a crosslinking agent, 3-7 parts of a plasticizer, 0.4-1 part of an accelerator, 0.5-1 part of an antioxidant and 10-70 parts of a reinforcing agent. The ethylene propylene diene monomer flexible base neutron shielding material has good physical and mechanical properties, ozone and thermal oxygen aging resistance and shielding effect, and has high cost performance.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

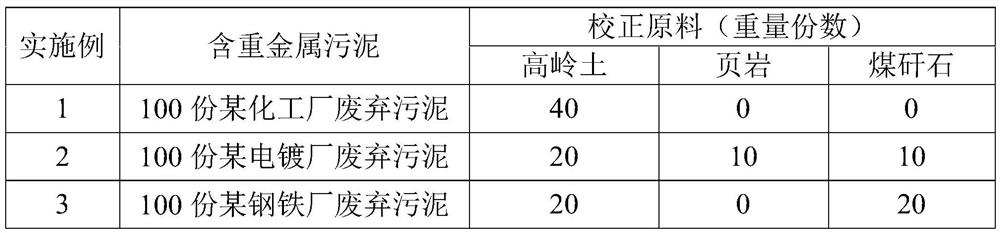

Anti-crack and anti-impact ultra-high performance radiation protection concrete and preparation method thereof

ActiveCN114573299AImprove compactnessImprove radiation protection performanceSolid waste managementCeramic materials productionFiberCrazing

The invention provides anti-crack and anti-impact ultra-high-performance radiation-proof concrete and a preparation method thereof. The radiation-proof concrete comprises cement, a mineral admixture, nano TiO2, calcium carbonate whiskers, an expanding agent, heavy metal sludge regenerated aggregate, a water reducing agent and super absorbent resin. According to the ultra-high-performance radiation-proof concrete disclosed by the invention, the nano TiO2, the calcium carbonate whiskers and the hybrid fibers are doped to toughen a concrete material from different scales and are disorderly distributed in the concrete, and the nano TiO2, the calcium carbonate whiskers and the hybrid fibers have ultra-high tensile strength, are complementary in size range and can bridge cracks with different scales in the concrete; impact energy is absorbed when the concrete is subjected to an impact load, so that the impact toughness of the anti-radiation ultra-high performance concrete is effectively improved. The filling effect of the micro-nano scale material TiO2 and calcium carbonate whiskers can improve the compactness of the ultra-high performance concrete, and the TiO2 material itself has a strong ray shielding effect, so that the radiation protection performance of the ultra-high performance concrete can be enhanced.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE +1

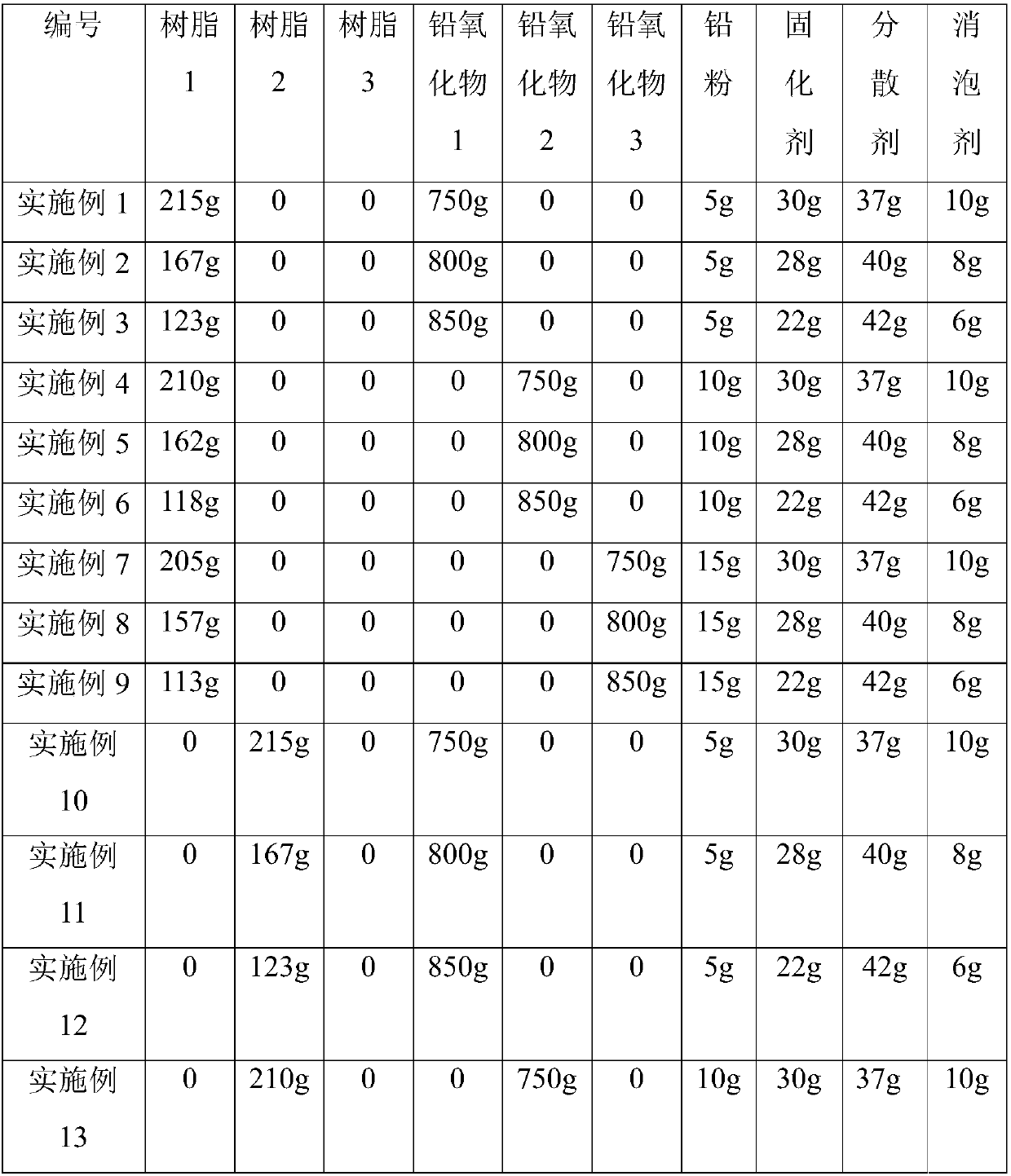

Ray shielding and high-voltage insulating resin composition, as well as preparation method and application of composition

InactiveCN107556703AReduce porosityOvercome the defect of poor high voltage insulationEpoxyPolymer science

The invention discloses a ray shielding and high-voltage insulating resin composition, as well as a preparation method and application of the composition. The epoxy resin composition contains lead metal oxide powder having a grain size distributed in ranges of being more than 16 microns, between 10 and 16 microns and less than 10 microns, and lead metal powder having a grain size distributed in ranges of being between 0.5-1.0 micron, between 5-15 micron and between 1.0-5 microns, each kind of powder can form a uniformly distributed structure in the resin, the aggregation phenomenon caused by uneven distribution and uneven grain size can be avoided, pores inside resin can be finally reduced, and the resin material having higher density can be obtained. The composite material has remarkableimprovement in the aspects of insulating strength, ray shielding effect and the like, and has wide application prospect in the fields of X ray source, ray shielding, high-voltage insulating devices and the like.

Owner:合肥显宏安瑞电子科技有限公司

Opaque multi-layer container

ActiveCN103317779AHigh light shielding abilityEffective combination shieldingSynthetic resin layered productsDomestic containersPolyethylene terephthalate glycolPolyethylene terephthalate

The invention discloses an opaque multi-layer container with light shielding, of the type produced by blowing a preform or by injection-blowing, preferably intended to contain photosensitive substances, which includes at least two layers of thermoplastic material with opacifying materials dispersed in the layers of the thermoplastic material, said thermoplastic material being polyethylene terephthalate (PET) in all of the layers and including, in at least one of the layers, aluminium metal (Al) and a light absorbent as opacifying material dispersed in the thermoplastic matrix. The invention that is presented provides the main advantage of being able to achieve practically total protection at any wavelength of the light spectrum, with much lower filler levels than those conventionally used to date.

Owner:阿拉贡卡塔拉矿业股份有限公司

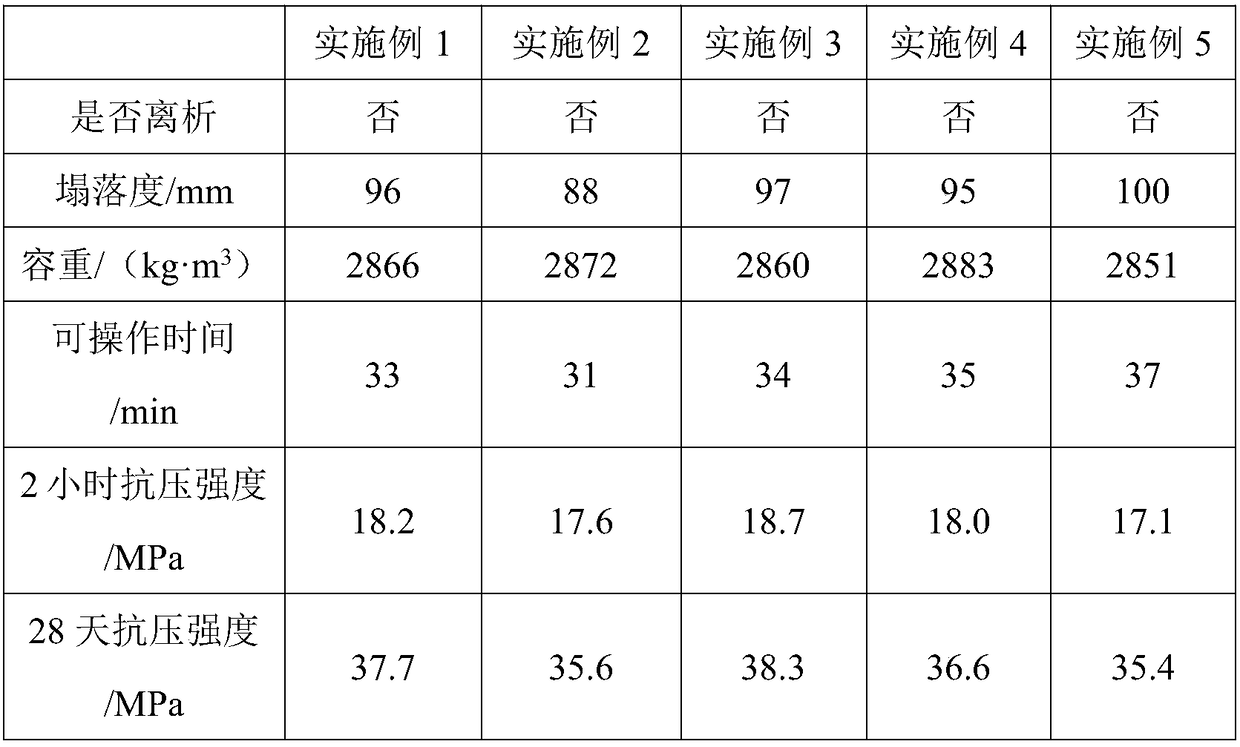

Quick-setting and quick-hardening calcium fluoraluminate cement-based radiation-prevention concrete and preparation method thereof

InactiveCN109320172AFast setting and hardening timeReduce the chance of segregationCompressive strengthUltimate tensile strength

The invention belongs to the field of concrete and in particular discloses quick-setting and quick-hardening calcium fluoraluminate cement-based radiation-prevention concrete and a preparation methodthereof. The concrete is prepared from the following raw materials in parts by weight: 280 to 320 parts of cement, 900 to 1200 parts of fine aggregate, 1200 to 1500 parts of coarse aggregate, 10 to 20parts of a neutron absorbent, 0.4 to 0.6 part of a water reducing agent, 0.1 to 0.3 part of a set retarder and 145 to 165 parts of water. The invention provides the quick-setting and quick-hardeningcalcium fluoraluminate cement-based radiation-prevention concrete; the concrete meets the strength requirements of C30 concrete; the compressive strength within 2h reaches about 18MPa and the operabletime is greater than 30min; no segregation phenomenon occurs and the slump is relatively good; the volume weight is in a range of 2850 to 2900kg.m<3> and meets the requirements of radiation-prevention concrete on the volume weight.

Owner:成都宏基建材股份有限公司

Subway steel structure closed protective door and preparation method thereof

InactiveCN107060606ALight weight and high strengthImproved Radiation Shielding PerformanceLamination ancillary operationsRadiation protectionCompression moldingFiber

The invention discloses a subway steel structure closed protective door. The subway steel structure closed protective door comprises a door frame and a door body. The door frame is made from a glass steel material. The door body is manufactured by means of the method that the middle of two layers of glass steel materials is composited with a lead boron polyethylene plate. Each glass steel material is composed of 72-85% of glass steel fibers, 18-25% of neutron shielding fibers and 10-12% of X and Gamma ray shielding fibers. Compared with the prior art, the subway door is low in self weight and high in strength, the door body is manufactured by means of the method that the middle of the two layers of glass steel materials is composited with the lead boron polyethylene plate, so that the subway door has a good radiation shielding effect; and the door frame and the door body adopt an SMC sheet stock compression molding forming preparation technology and a laminating technology, so that no crack and bubble exists in the glass steel materials and the lead boron polyethylene plate, and the mechanical property accordant with requirements can be achieved.

Owner:ANHUI ZHONGNAN AIR DEFENCE WORKS PROTECTIVE EQUIP

Radiation-Shielding Glass and Method of Manufacturing the Same

ActiveUS20090242809A1Appropriate transparencySufficient visibilityGlass drawing apparatusGlass forming apparatusGamma rayLength wave

Provided is a radiation-shielding glass, including a glass composition in % by mass of 10 to 35% SiO2, 55 to 80% PbO, 0 to 10% B2O3, 0 to 10% Al2O3, 0 to 10% SrO, 0 to 10% BaO, 0 to 10% Na2O, and 0 to 10% K2O, in which the radiation-shielding glass has a total light transmission at a wavelength of 400 nm at a thickness of 10 mm of 50% or higher. Also provided is a radiation-shielding glass which has the similar glass composition and can be used for a gamma-ray shielding glass for a PET examination.

Owner:NIPPON ELECTRIC GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com