Anti-radiation C40 concrete used for prefabricated part and preparation method of anti-radiation C40 concrete

A prefabricated component and concrete technology, which is applied in the field of construction concrete, can solve the problems of high cost of anti-cracking performance and poor shielding effect of large-volume concrete, and achieve the effects of reducing waste of raw materials and energy, improving product quality, and preventing shrinkage cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

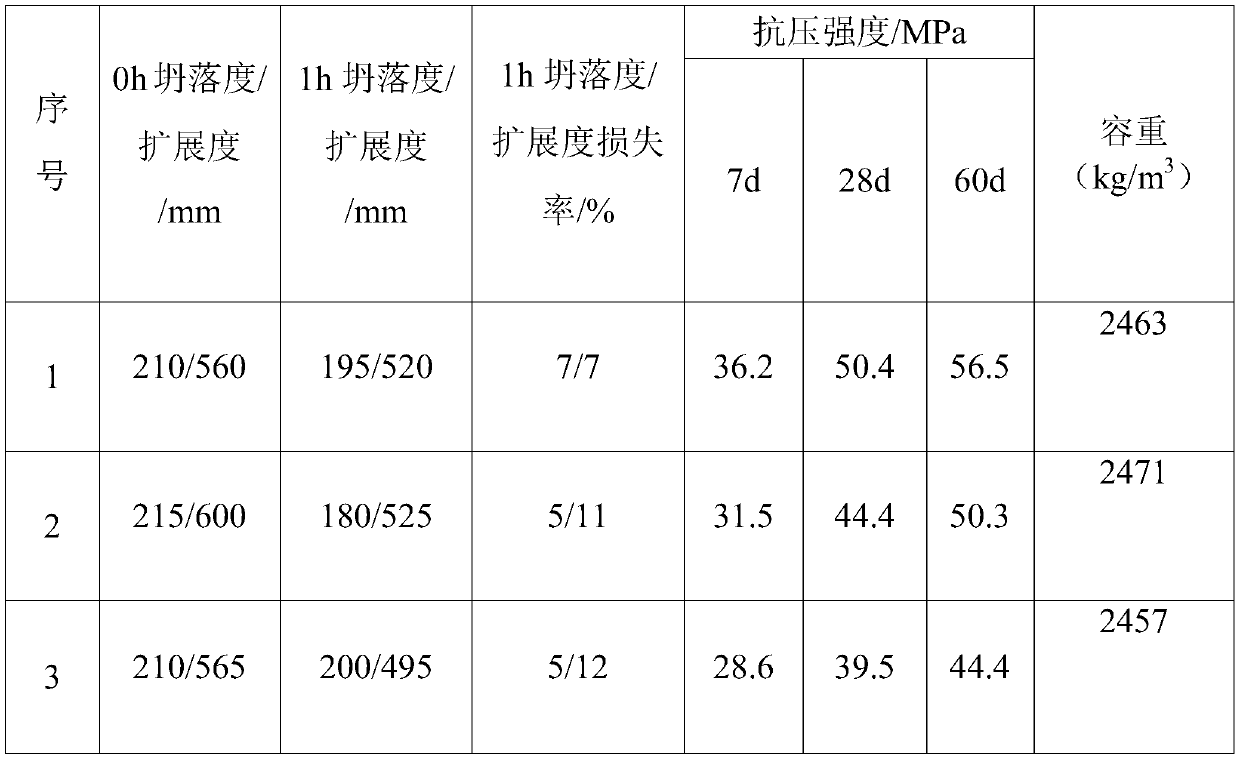

Embodiment 1

[0028] A kind of anti-radiation C40 concrete for prefabricated components, the concrete is made by mixing cement, fly ash, river sand, gravel, admixture, expansion agent and water, and the dosage of each component is: 280 parts of cement , 120 parts of fly ash, 1170 parts of gravel, 720 parts of river sand, 152 parts of water, 9.5 parts of admixture, and 30 parts of expansion agent.

[0029] The dry density of the concrete is 2350kg / m 3 , the initial slump of concrete is 200mm, and the expansion is greater than 550mm.

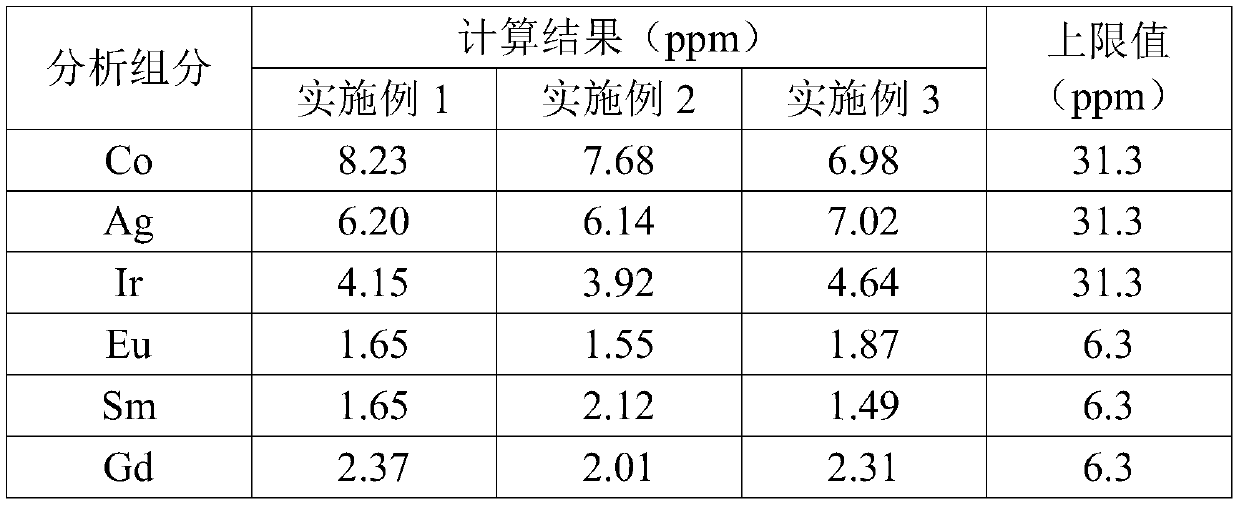

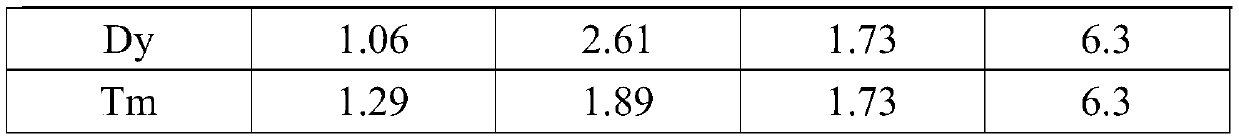

[0030] All contain Co, Ag, Ir, Eu, Sm, Gd, Dy and Tm in the described cement and fly ash, the content of Co, Ag, Ir in the described cement and fly ash is 50ppm, the described The contents of Eu, Sm, Gd, Dy and Tm in the cement and fly ash are all 10ppm.

[0031] The fineness modulus of the river sand is 2.3-2.7.

[0032] The crushed stones are basalt crushed stones with a particle size of 25mm.

[0033] The admixture is retarded polycarboxylate superplasti...

Embodiment 2

[0043] A kind of anti-radiation C40 concrete for prefabricated components. The concrete is made by mixing cement, fly ash, river sand, gravel, admixture, expansion agent and water. According to parts by weight, the dosage of each component is: 245 parts of cement , 165 parts of fly ash, 1170 parts of gravel, 720 parts of river sand, 152 parts of water, 8.5 parts of admixture, and 30 parts of expansion agent.

[0044] The dry density of the concrete is 2350kg / m 3 , the initial slump of concrete is 200mm, and the expansion is greater than 550mm.

[0045] All contain Co, Ag, Ir, Eu, Sm, Gd, Dy and Tm in the described cement and fly ash, the content of Co, Ag, Ir in the described cement and fly ash is 50ppm, the described The contents of Eu, Sm, Gd, Dy and Tm in the cement and fly ash are all 10ppm.

[0046] The fineness modulus of the river sand is 2.3-2.7.

[0047] The crushed stones are basalt crushed stones with a particle size of 25mm.

[0048] The admixture is retarded pol...

Embodiment 3

[0058] A kind of anti-radiation C40 concrete for prefabricated components. The concrete is made by mixing cement, fly ash, river sand, gravel, admixture, expansion agent and water. According to parts by weight, the dosage of each component is: 205 parts of cement , 205 parts of fly ash, 1170 parts of gravel, 720 parts of river sand, 152 parts of water, 7.4 parts of admixture, and 30 parts of expansion agent.

[0059] The dry density of the concrete is 2350kg / m 3 , the initial slump of concrete is 200mm, and the expansion is greater than 550mm.

[0060] All contain Co, Ag, Ir, Eu, Sm, Gd, Dy and Tm in the described cement and fly ash, the content of Co, Ag, Ir in the described cement and fly ash is 50ppm, the described The contents of Eu, Sm, Gd, Dy and Tm in the cement and fly ash are all 10ppm.

[0061] The fineness modulus of the river sand is 2.3-2.7.

[0062] The crushed stones are basalt crushed stones with a particle size of 25mm.

[0063] The admixture is retarded p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com