Anti-crack and anti-impact ultra-high performance radiation protection concrete and preparation method thereof

An ultra-high-performance concrete technology, applied in clay products, ceramic products, and other household appliances, can solve the problems of high cementitious material consumption, affecting mechanical properties, and limiting applications, so as to improve impact toughness and radiation shielding performance Good, enhance the effect of radiation protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Based on the same inventive concept, the present application also provides a method for preparing the above-mentioned crack-resistant and impact-resistant ultra-high-performance radiation-proof concrete, comprising the following steps:

[0040] S1. Combine cement, mineral admixture, nano-TiO 2 , calcium carbonate whiskers, bulking agent and heavy metal sludge regenerated aggregates are added into the concrete mixer and stirred evenly, and then water, water reducing agent and superabsorbent resin are added; Carry out moulding, vibrating and forming to obtain a concrete mixture;

[0041] S2. Cover the surface of the concrete mixture with an impermeable film, and then put it into a curing room for curing to obtain ultra-high performance radiation-proof concrete with crack resistance and impact resistance.

Embodiment 1~3

[0044] The present embodiment provides a method for preparing a heavy metal sludge regeneration aggregate comprising the following steps:

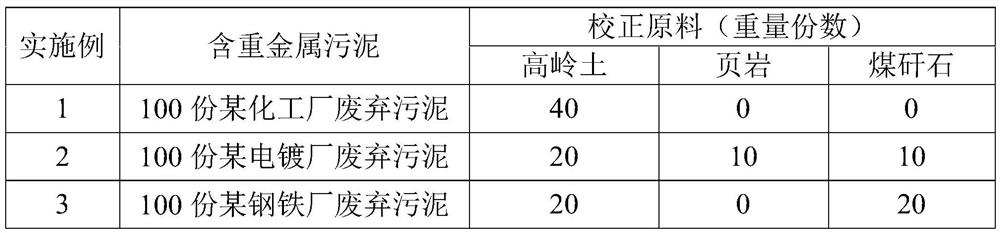

[0045] S1, the heavy metal sludge is mixed with the calibration raw material according to the proportion in Table 1 to obtain a mixture, and the Cr in the mixture is made by matching each component. 2 O 3 The mass content of ZnO is 13%, the mass content of ZnO is 8%, the mass content of alumina is 26%, and the mass content of silicon oxide is 18%;

[0046] S2, mixing the mixture evenly, grinding, and then granulating to obtain particles with a particle size of ≤4.75 mm and a moisture content of 20 to 25%;

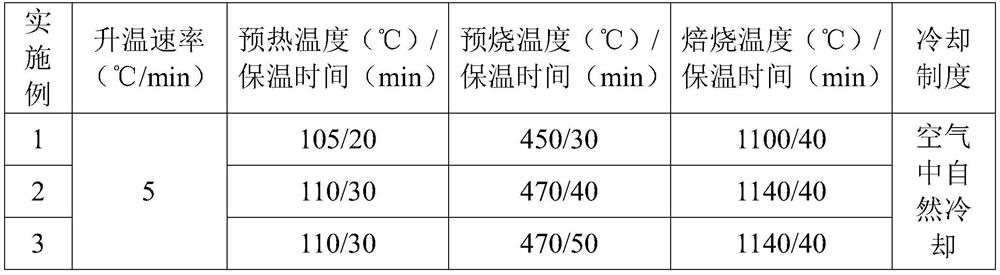

[0047] S3, the granules obtained by granulation are roasted according to the roasting system in table 2 in a high-temperature furnace to obtain heavy metal sludge regeneration aggregates.

[0048] Table 1 - Raw Material Composition of Heavy Metal Sludge Recycled Aggregate

[0049]

Embodiment 4~9

[0058] The embodiment of the present application provides a crack-resistant and impact-resistant ultra-high-performance radiation-proof concrete, including the raw materials in the proportions in Table 4;

[0059] Among them, the cement used is Huaxin P.O 52.5 ordinary Portland cement;

[0060] The silica fume used is produced by Shanghai Tiankai Silica Fume Material Co., Ltd., in which SiO 2 The mass content is 95%, the specific surface area is 17500m 2 / kg, 28d activity index 105%;

[0061] The fly ash microbeads used are produced by Tianjin Zhucheng New Material Technology Co., Ltd. and have a specific surface area of 1300 m. 2 / kg, activity coefficient 105%, water demand ratio 88%, apparent density 2520kg / m 3 ;

[0062] Nano TiO used 2 Produced by Xingtai Xindun Alloy Co., Ltd. with a specific surface area of 35m 2 / g;

[0063] The heavy metal sludge regeneration aggregate used is the heavy metal sludge regeneration aggregate prepared in Example 3;

[0064] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com