Composite fiber fabric and preparation method thereof

A technology of composite fibers and composite fabrics, which is applied in textiles, fabrics, textiles and papermaking, etc., can solve the problems of insufficient functions and achieve the effects of smooth cloth surface, good radiation shielding effect, and improved tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

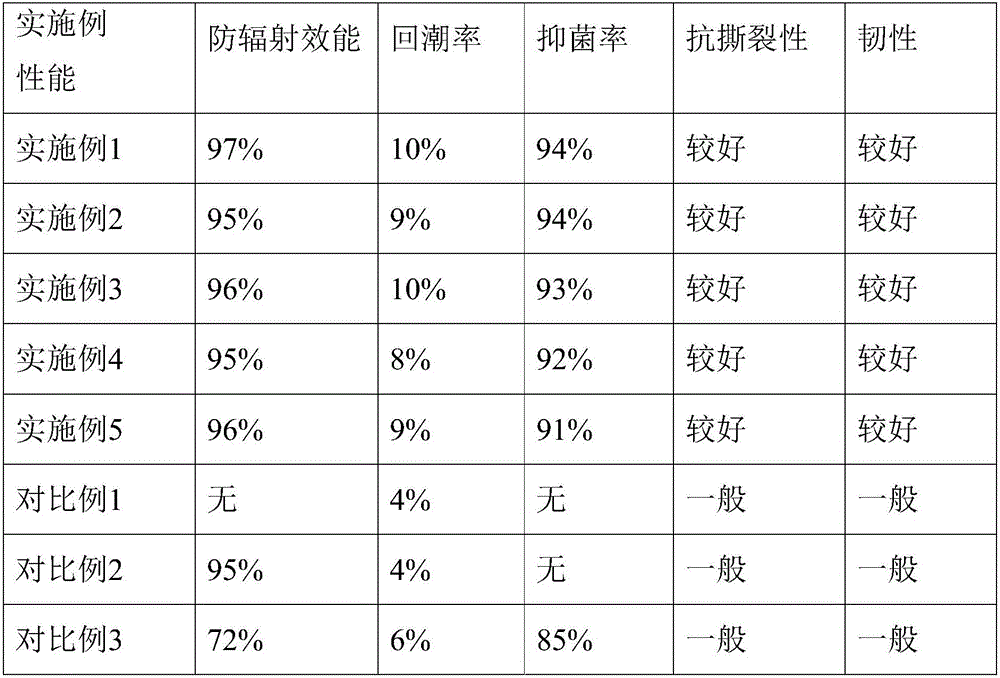

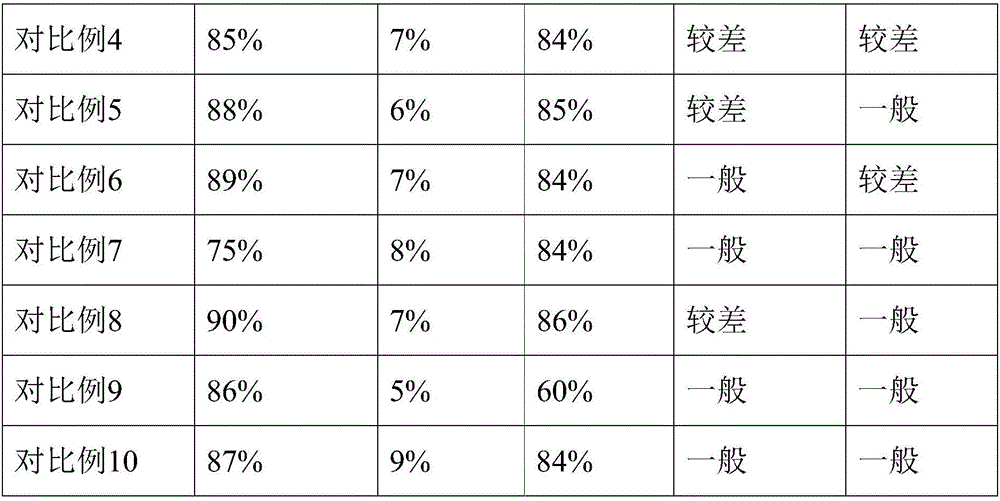

Examples

Embodiment 1

[0019] Spinning: cotton fiber goes through cleaning, carding, combing, multi-pass blending processes, and then goes through roving, spinning, and winding processes. In the multi-pass blending process, stainless steel fiber and carbon fiber are gradually mixed into blended yarn. Among them, the content of stainless steel fiber, carbon fiber and cotton fiber is 15%, 3% and 82% respectively;

[0020] Spinning: cotton fiber goes through cleaning, carding, combing, multi-pass blending processes, and then goes through roving, spinning, and winding processes. In the multi-pass blending process, stainless steel fiber and ramie fiber are gradually mixed into blended yarn. , the content of stainless steel fiber, ramie fiber and cotton fiber are 12%, 6% and 82% respectively; antistatic agent and anti-slip agent are added to ramie fiber before blending;

[0021] Weaving: The warp is made of the blended yarn of stainless steel fiber, carbon fiber and cotton fiber, and the weft is made of t...

Embodiment 2

[0024] In this embodiment, the content of stainless steel fiber, carbon fiber and cotton fiber in the warp yarn are 16%, 4% and 80% respectively; the content of stainless steel fiber, ramie fiber and cotton fiber in the weft yarn are 10%, 7% and 83% respectively; other The process is as described in Example 1, and will not be repeated here.

Embodiment 3

[0026] In this embodiment, the contents of stainless steel fiber, carbon fiber and cotton fiber in the warp yarn are 12%, 4% and 84% respectively; the content of stainless steel fiber, ramie fiber and cotton fiber in the weft yarn are 14%, 6% and 80% respectively; other The process is as described in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com