Tungsten-polymer composite material and preparation method thereof

A high molecular polymer and composite material technology, which is applied in the field of tungsten-high molecular polymer composite material and its preparation, can solve the problems of poor physical and mechanical properties of composite materials, low loading capacity of composite materials, poor fluidity and compactness, etc. Achieve good radiation shielding performance, good physical and mechanical properties, high loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

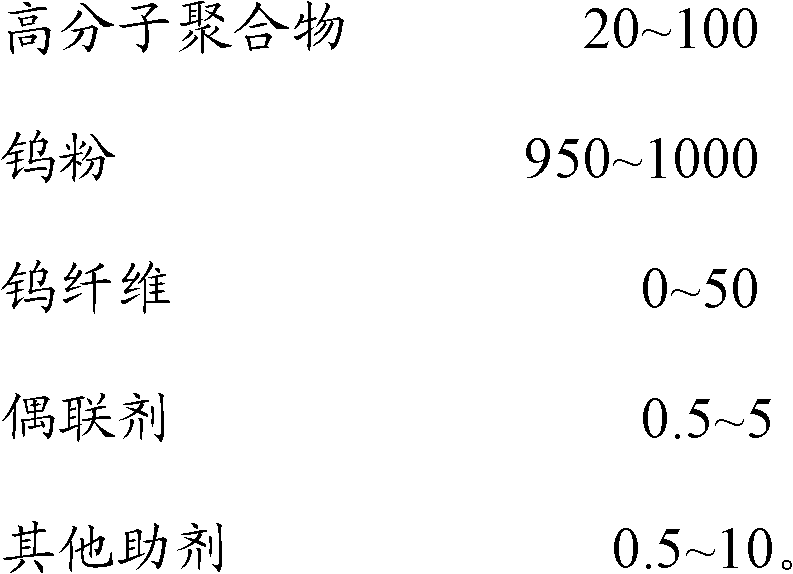

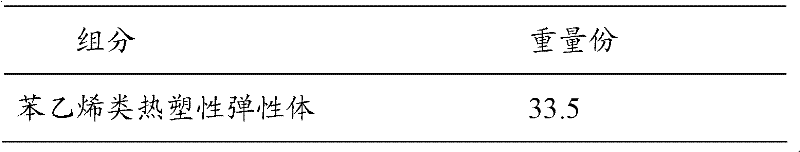

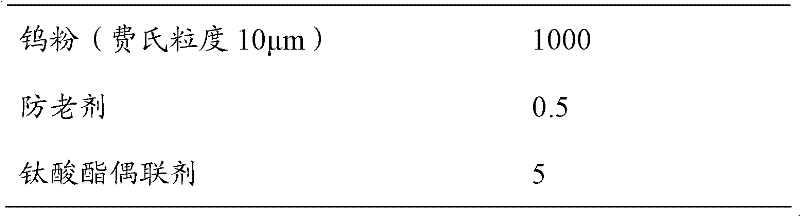

[0029] The formula of high-density tungsten-polymer ray shielding composite material is:

[0030]

[0031]

[0032] The preparation method of above-mentioned tungsten-polymer composite material, its steps are:

[0033] (1) Weigh the tungsten powder according to the above parts by weight, and carry out jet crushing of the tungsten powder, the feed pressure is 0.9MPa, and the crushing pressure is 1.1MPa.

[0034] (2) Stir the jet-milled tungsten powder continuously in the doping pot, and spray the titanate coupling agent diluted with ethanol for surface modification;

[0035] (3) Weigh other materials according to the above parts by weight, first add the styrene thermoplastic elastomer to the kneader, then put in 500 parts by weight of the above tungsten powder, knead for an appropriate time, add the remaining tungsten powder and anti-aging agent, knead Knead evenly and make feed, and above-mentioned kneading temperature is 140 ℃.

[0036] (4) Forming: After granulating ...

Embodiment 2

[0039] The formula of high-density tungsten-polymer ray shielding composite material is:

[0040]

[0041]

[0042] The preparation method of above-mentioned tungsten-polymer composite material, its steps are:

[0043] (1) Weigh the tungsten powder according to the above parts by weight, and carry out jet crushing of the tungsten powder, the feed pressure is 0.8MPa, and the crushing pressure is 1.0MPa.

[0044] (2) The tungsten powder pulverized by airflow is constantly stirred in the doping pot, and the silane coupling agent diluted with ethanol is sprayed for surface modification;

[0045] (3) Weigh other materials according to the above weight parts, first add EPDM rubber into the kneader, then put in 500 parts by weight of the above tungsten powder, knead at 120 °C for an appropriate time, and knead all the remaining materials except the vulcanizing agent The materials are added in sequence, mixed evenly and discharged, and finally the vulcanizing agent is added on ...

Embodiment 3

[0049] The formula of high-density tungsten-polymer ray shielding composite material is:

[0050]

[0051]

[0052] The preparation method of above-mentioned tungsten-polymer composite material, its steps are:

[0053] (1) Weigh the tungsten powder according to the above parts by weight, and carry out jet crushing of the tungsten powder, the feed pressure is 0.9MPa, and the crushing pressure is 1.0MPa.

[0054] (2) Stir the jet-milled tungsten powder and tungsten fiber in the doping pot continuously, and spray the rare earth coupling agent diluted with ethanol for surface modification;

[0055](3) Weigh other materials according to the above parts by weight, first add natural rubber into the kneader, then add styrene-butadiene rubber and 500 parts by weight of the mixture of the above-mentioned tungsten powder and tungsten fiber, and knead at 80 ° C for a suitable time. All the remaining materials except the vulcanizing agent are added in sequence, and the materials are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com