Ray shielding and high-voltage insulating resin composition, as well as preparation method and application of composition

A resin composition and high-voltage insulation technology, which is applied in the field of radiation shielding and high-voltage insulation resin materials, can solve problems such as insufficient effective lead equivalent, poor shielding performance, and poor insulation, and achieve improved radiation shielding performance and radiation shielding effect Improve and overcome the effect of poor high voltage insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-27

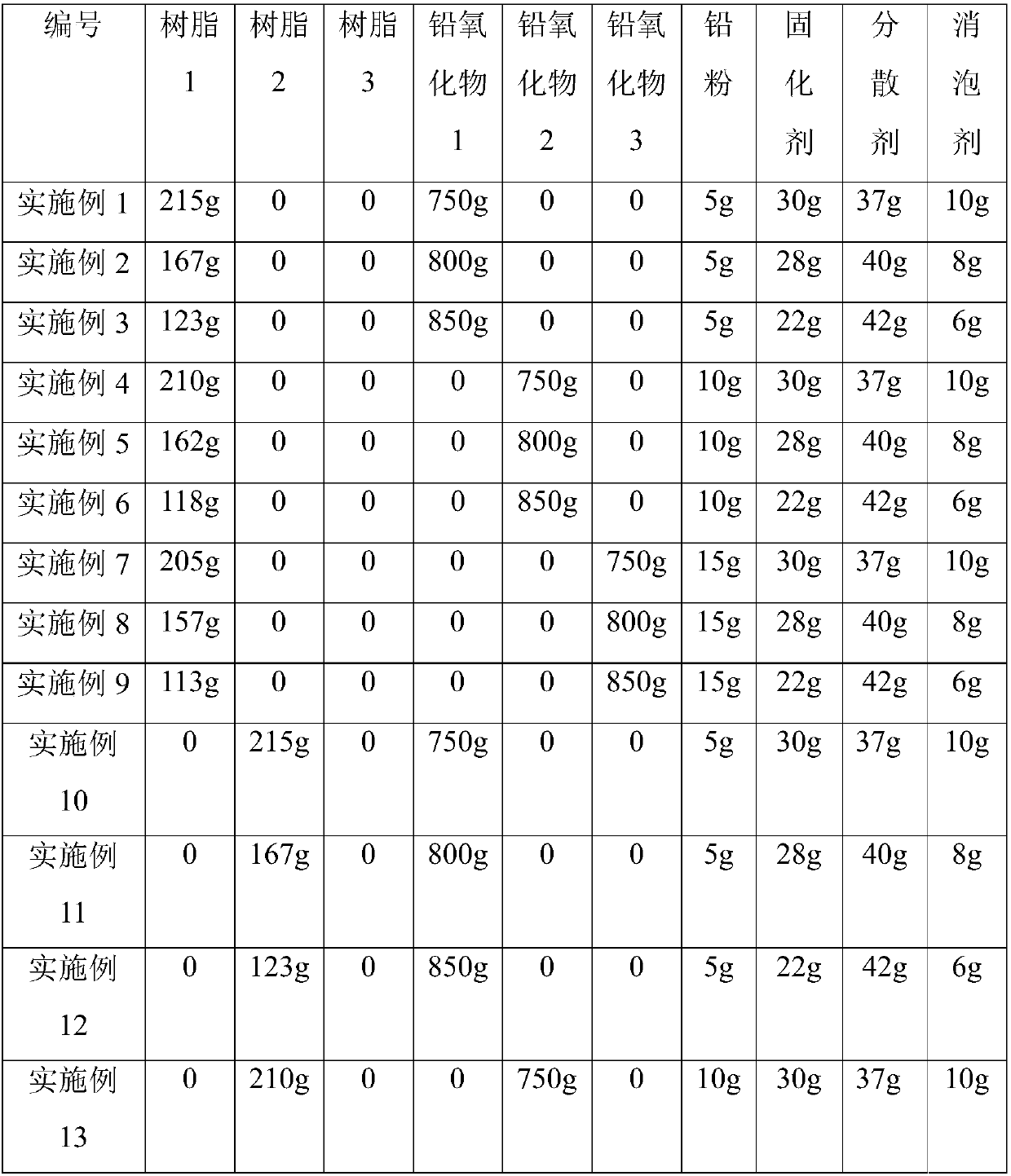

[0045] The resin compositions of Examples 1-27 were prepared according to the formulation amounts of each component in Table 2 according to the following steps:

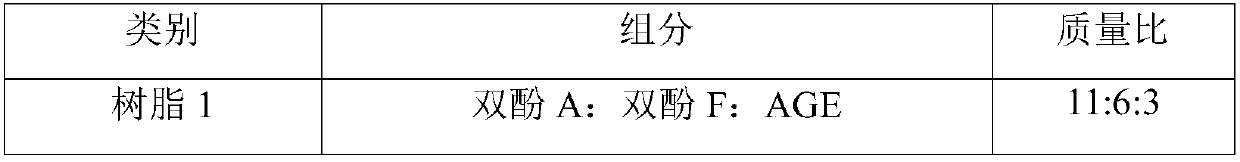

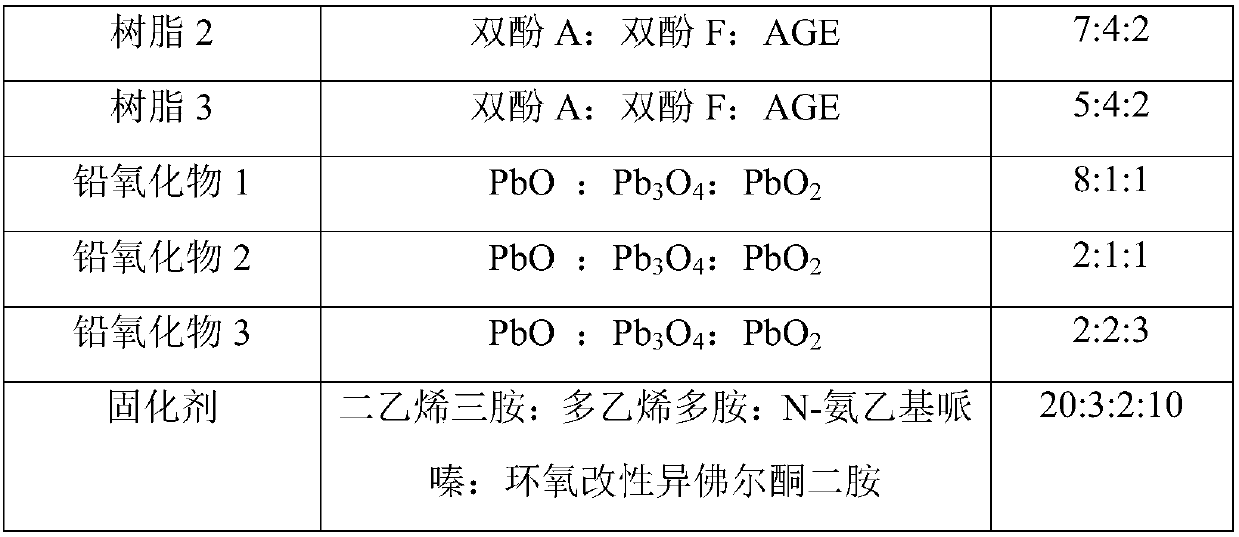

[0046] Step 1. Prepare resin premix according to Table 1;

[0047] Step 2. Weigh the dispersant in proportion and add it to the resin premix obtained in Step 1, stir and mix evenly;

[0048] Step 3. Determine the particle size of the lead metal oxide with a particle size analyzer. Weigh the ratio according to Table 1 to obtain the lead oxide premix, then add this premix to the components obtained in step 3, and disperse while Add to uniform dispersion at high speed;

[0049] Step 4. Determine the particle size of the lead metal powder with a particle size analyzer, and weigh and proportion the resulting lead metal powder into the components obtained in step 3, and disperse while adding, until the high-speed dispersion is uniform;

[0050] Step 5. Weigh the organosilicon defoamer in proportion and add it to the components obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com