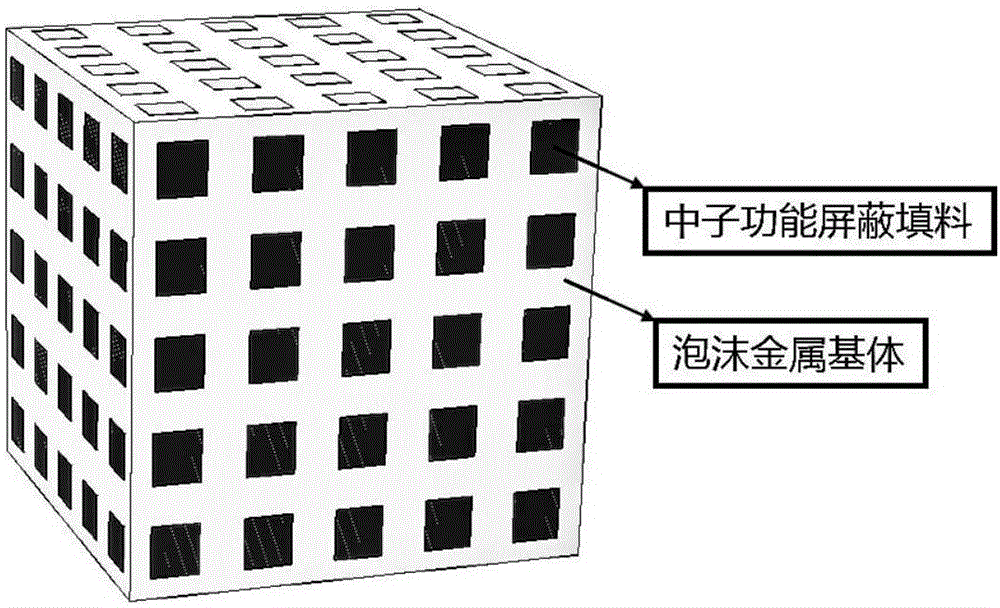

Neutron shield composite material taking foam metal as matrix and preparation method thereof

A foam metal and composite material technology, applied in the field of neutron shielding composite materials and their preparation, can solve the problems of poor mechanical properties and impact resistance, poor secondary gamma ray protection ability, poor heat dissipation, etc. The effect of comprehensive shielding performance, good comprehensive mechanical properties, and high neutron shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] (1) Preparation of filler: Evenly mix one or several fillers with neutron moderating function and divide them into two parts, first take one part and heat it in a container until completely melted, keep stirring during the heating process, and continue stirring after melting For 20 minutes, keep the filler temperature at 15°C above the melting point to keep the melt in a low viscosity state.

[0034] (2) Cut the foam metal into a suitable size, immerse in one or more of hydrochloric acid, ethanol, petroleum ether, and silane coupling agent in turn, and use an ultrasonic generator to add ultrasonic treatment for 30 minutes to remove surface oxides and Oil stains, and form an oleophilic layer on the metal surface, improve the wettability of metal and organic matter, and put it into the pre-prepared mold.

[0035] (3), inject the filler obtained in step (1) into the metal foam prepared in step (2) from two corners of the container simultaneously, so that the filler is imme...

Embodiment 1

[0041] The neutron shielding material of the present invention taking metal foam as matrix:

[0042] The structural parameters of the metal foam substrate of the shielding material are as follows

[0043] Material Hole density Porosity length (cm) width (cm) Thickness (cm) Al 5PPI 97% 40 40 2.09

[0044] The weight of each component of the shielding material functional neutron shielding filler is as follows: paraffin wax 3kg

[0045] The steps of the method for preparing the neutron shielding material with metal foam as the base are as follows:

[0046] (1) Melting of the filler: Put the paraffin in a water bath heating container and heat it to about 78°C. Stir continuously during the heating process to make it evenly heated to ensure that the paraffin is completely melted into a fluid and then continue to stir for 20 minutes to keep warm.

[0047] (2) Pretreatment of foamed metal: cut the foamed metal to 40cm*40cm*2.09cm, put it in 2% hydro...

Embodiment 2

[0054] The neutron shielding material based on metal foam according to the present invention:

[0055] The structural parameters of the metal foam substrate of the shielding material are as follows:

[0056] Material Hole density Porosity length (cm) width (cm) Thickness (cm) Cu 10PPI 99.6% 40 40 1.35

[0057] The weight of each component of the functional neutron shielding filler of the shielding material is as follows: 2kg of low-density polyethylene, 350g of boron carbide, and 20g of methacryloxysilane.

[0058] (1) Melting of the filler: Take 1kg of polyethylene particles and put them into a heating container and heat them to about 135°C. Stir continuously during the heating process. After the polyethylene is completely melted into a fluid, continue to stir for 20 minutes and keep warm for later use.

[0059] (2) Pretreatment of foamed metal: cut the foamed metal to 40cm*40cm*1.35cm, first put it in 2% hydrochloric acid solution and soni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com