Radiation-proof concrete and preparation method thereof

A concrete and anti-radiation technology, applied in the field of concrete, can solve the problems of land occupation, environmental pollution, resource waste, etc., and achieve the effects of saving material costs, good radiation protection performance, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

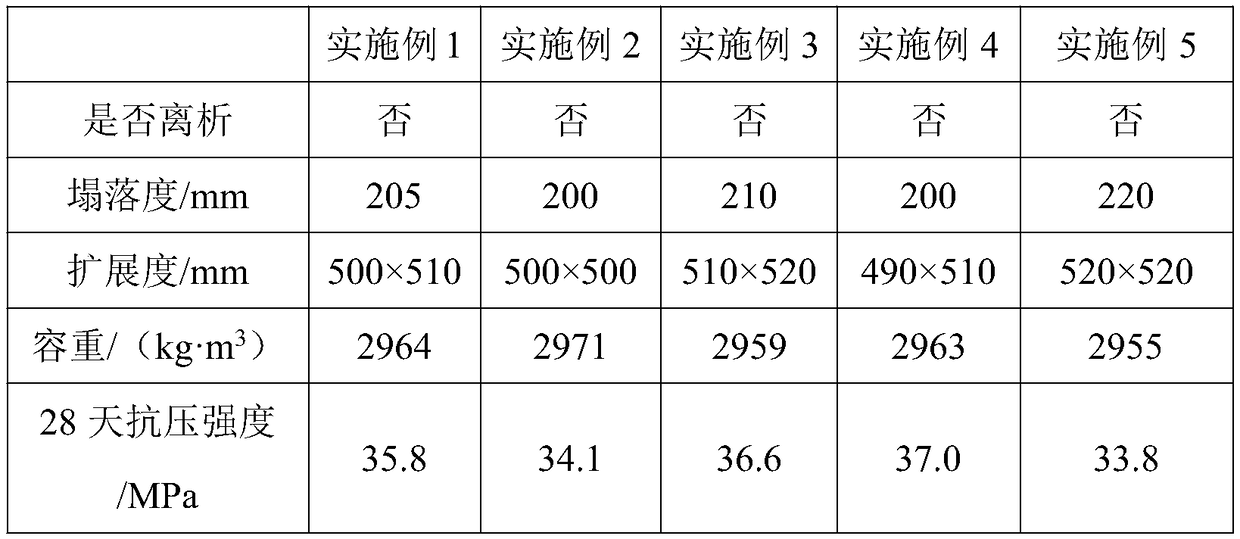

Examples

Embodiment 1

[0036] A kind of anti-radiation concrete, which is composed of the following materials: 325 parts of cement, 1000 parts of fine aggregate, 1300 parts of coarse aggregate, 70 parts of fiber, 18 parts of neutron absorber, 0.5 part of water reducing agent, and 155 parts of water. Count of copies.

[0037] Among them, the cement is selected from barium aluminate cement, provided by Zhengzhou Kanghui Refractories Co., Ltd., and its performance test results are as follows: the specific surface area is 366m 2 kg -1 , initial setting time 106min, final setting time 127min, 1-day compressive strength 76.3MPa, 3-day compressive strength 80.1MPa, Al 2 o 3 The content is 55.46%, the BaO content is 37.45%, the CaO content is 7.32%, and other properties meet the requirements.

[0038] Among them, the fine aggregate is selected from the water-quenched copper slag after mechanical treatment, and the mechanical treatment method is as follows: first, the water-quenched copper slag is crushed...

Embodiment 2

[0048] A kind of anti-radiation concrete, which is composed of the following materials: 310 parts of cement, 1000 parts of fine aggregate, 1300 parts of coarse aggregate, 70 parts of fiber, 18 parts of neutron absorber, 0.5 part of water reducing agent, and 153 parts of water. Count of copies.

[0049] Among them, the cement is selected from barium aluminate cement, provided by Zhengzhou Kanghui Refractories Co., Ltd., and its performance test results are as follows: the specific surface area is 366m 2 kg -1 , initial setting time 106min, final setting time 127min, 1-day compressive strength 76.3MPa, 3-day compressive strength 80.1MPa, Al 2 o 3 The content is 55.46%, the BaO content is 37.45%, the CaO content is 7.32%, and other properties meet the requirements.

[0050] Among them, the fine aggregate is selected from the water-quenched copper slag after mechanical treatment, and the mechanical treatment method is as follows: first, the water-quenched copper slag is crushed...

Embodiment 3

[0060]A radiation-proof concrete, consisting of the following materials: 340 parts of cement, 1000 parts of fine aggregate, 1300 parts of coarse aggregate, 70 parts of fiber, 18 parts of neutron absorber, 0.5 part of water reducing agent, and 157 parts of water. Count of copies.

[0061] Among them, the cement is selected from barium aluminate cement, provided by Zhengzhou Kanghui Refractories Co., Ltd., and its performance test results are as follows: the specific surface area is 366m 2 kg -1 , initial setting time 106min, final setting time 127min, 1-day compressive strength 76.3MPa, 3-day compressive strength 80.1MPa, Al 2 o 3 The content is 55.46%, the BaO content is 37.45%, the CaO content is 7.32%, and other properties meet the requirements.

[0062] Among them, the fine aggregate is selected from the water-quenched copper slag after mechanical treatment, and the mechanical treatment method is as follows: first, the water-quenched copper slag is crushed in a cement te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| curing time | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com