Polyacrylic acid metal salt/boron oxide material as well as preparation method and application thereof

A polyacrylic acid, boron oxide technology, applied in the field of polymer materials, can solve the problems of harsh preparation conditions, difficult to uniformly disperse functional particles, single radiation shielding performance of materials, etc., and achieves simple preparation methods, lightweight materials, and simple preparation processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

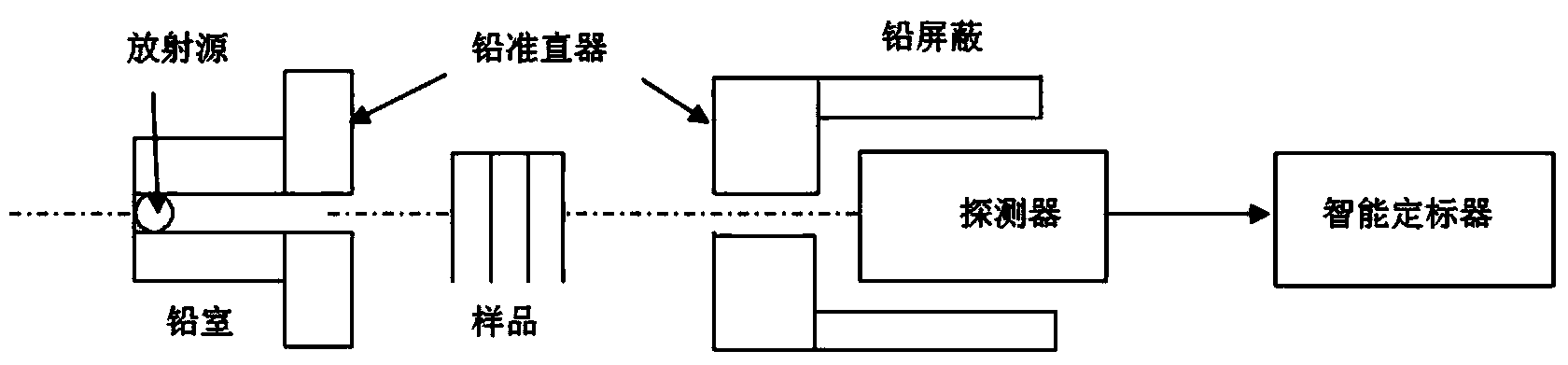

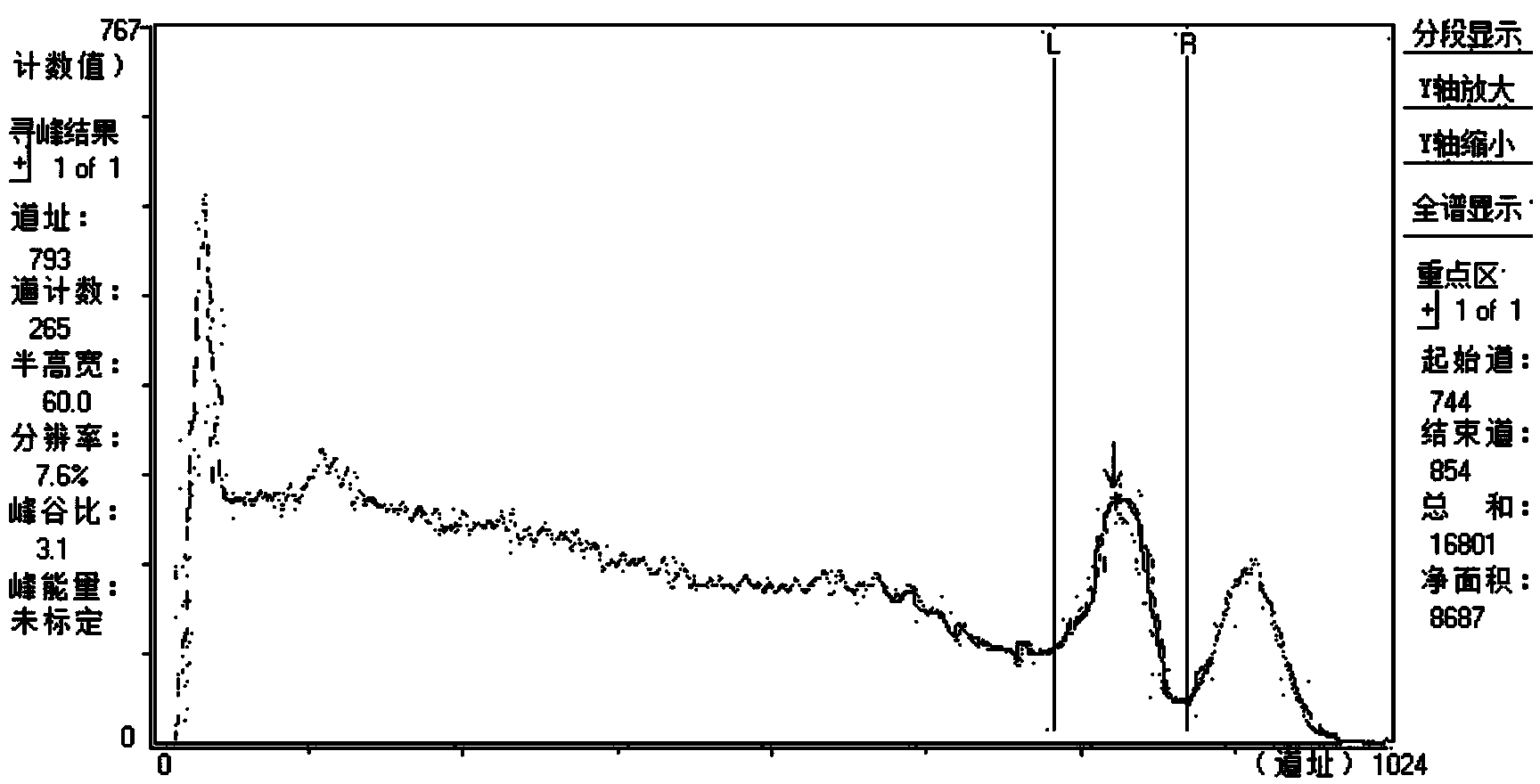

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: prepare lead acrylate, its preparation steps are:

[0043] Add 20mL of absolute ethanol and 6.2mL of acrylic acid into a 50mL three-neck flask, stir at 65°C, then add 8.93g of lead oxide in batches (the molar ratio of HAA to PbO is 2:1, with a slight excess of HAA), raise the temperature to 75°C, and heat to reflux Until the yellow lead oxide is completely dissolved, filter while it is hot, and the filtrate is cooled and crystallized. The obtained solid was filtered with suction and dried at 80° C. to a constant weight to obtain a white lead acrylate solid with a yield of 12.84 g and a yield of 92%.

Embodiment 2

[0044] Embodiment 2: prepare gadolinium acrylate, its preparation steps are:

[0045] Use a graduated cylinder to measure 24 mL of concentrated HCl into a 250 mL beaker, add 50 mL of deionized water to dilute for use. Weigh 14gGd 2 o 3 , heated the beaker containing hydrochloric acid to about 50°C while stirring, and weighed Gd 2 o 3 Slowly add to the beaker in batches, stir until the solution is colorless and transparent, turn off the heating, and filter the solution to remove insoluble impurities. Aqueous ammonia was then slowly added, and a large amount of precipitation gradually appeared, and the pH was adjusted to 8. Suction filtration (centrifugation) of the product, washing and suction filtration (centrifugation), repeat this 2-3 times until there is no ammonia smell, and dry the precipitate at 110°C to constant weight to obtain block Gd(OH) 3 . The mass of the obtained product was 15.35 g, and the yield was 96%.

[0046] Gd(AA) 3 The synthesis according to the ...

Embodiment 3

[0047] Embodiment 3: prepare the polyacrylic acid metal salt / boron oxide composite material (sample 1) that contains lead acrylate 15%, gadolinium acrylate 15%, acrylic acid 25%, boron oxide 30% (sample 1), and its preparation steps are:

[0048] Weigh 30g of lead acrylate, 30g of gadolinium acrylate, and 60g of boron oxide in a beaker, add 50g of acrylic acid and 22mL of deionized water, stir to dissolve completely, add 8g of benzoin dimethyl ether and mix well. Pour the mixed solution into a polytetrafluoroethylene mold with a length, width, and height of 10cm×10cm×2cm, and then irradiate the mold with 200-400nm ultraviolet light for 150 minutes to obtain a layered polymer material. The obtained layered material was placed in a mold with a length, width, and height of 10cm×10cm×5cm, and molded at 100°C and a pressure of 10MPa to obtain a lead acrylate: gadolinium acrylate: boron oxide mass ratio of 1:1:2. Polyacrylic acid metal salt / boron oxide composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com