Ethylene propylene diene monomer flexible base neutron shielding material and preparation method thereof

A technology of rubber flexible base and shielding material, applied in the field of radiation protection, can solve the problems of high raw material price, low mechanical strength, limited use range, etc., to ensure life safety, avoid environmental pollution, and good neutron shielding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

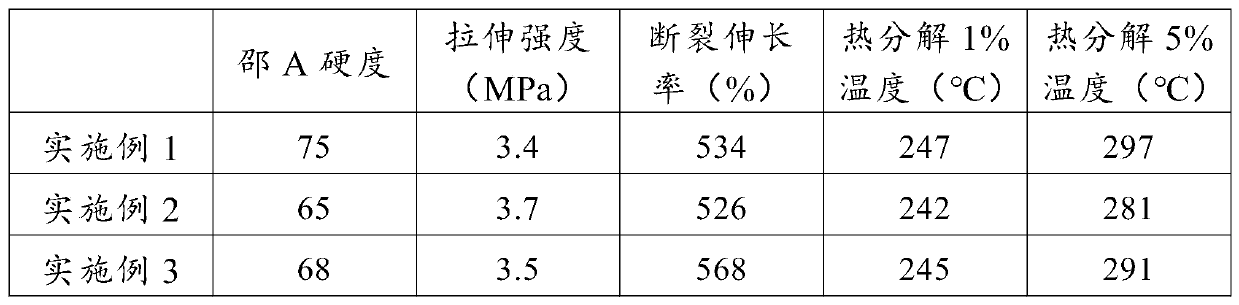

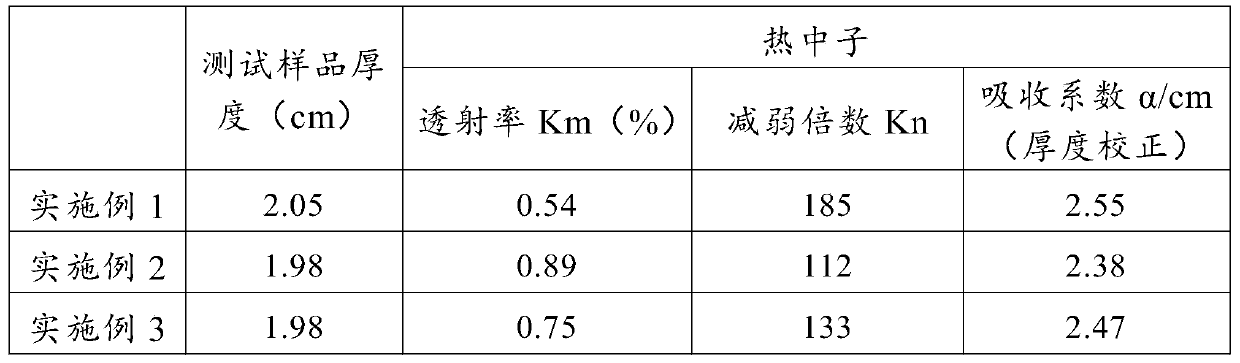

Embodiment 1

[0029] Example 1: Preparation of EPDM flexible-based neutron shielding material (1)

[0030] The preparation raw material of EPDM flexible base neutron shielding material is as follows (parts by weight): 100 parts of EPDM rubber, 225 parts of boron carbide, 2 parts of sulfur, 5 parts of zinc oxide, dicumyl peroxide (DCP ) 2 parts, paraffin wax 7 parts, composite accelerator EM233 1 part, antioxidant RD 0.5 part, antioxidant 4010 0.5 part, N330 15 parts, N234 15 parts, process oil 2 parts.

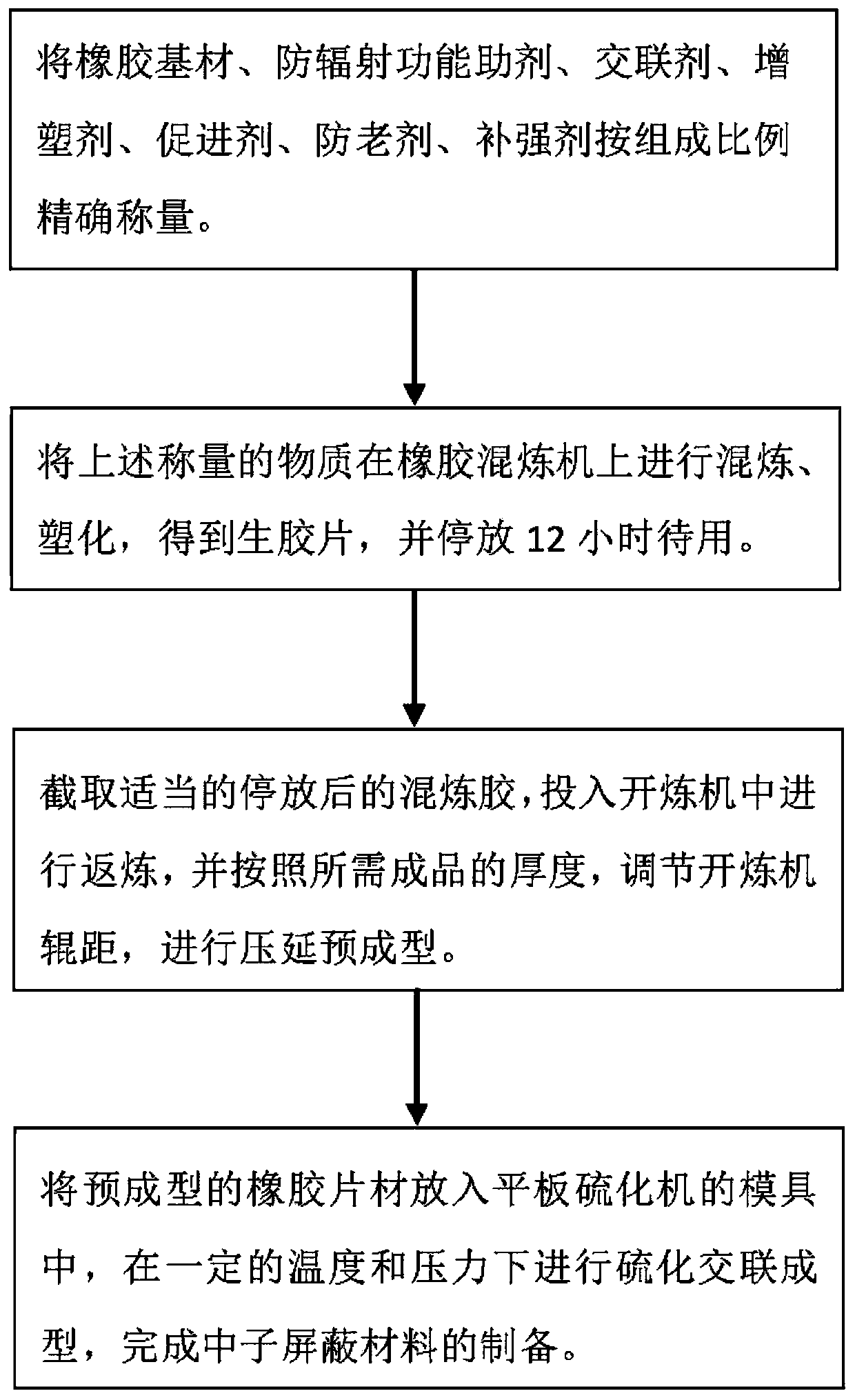

[0031] The preparation method step of EPDM flexible base neutron shielding material is as follows (flow process see figure 1 ).

[0032] 1. EPDM raw rubber plastic training

[0033] Adjust the roller distance according to the amount of raw rubber, put the raw rubber into the rubber roller for cutting and cutting, and completely break the raw rubber; adjust the roller distance, put the broken raw rubber into the rubber roller for thinning and plasticizing, and then put the raw rubber into ...

Embodiment 2

[0040] Example 2: Preparation of EPDM Flexible Base Neutron Shielding Material (2)

[0041]The preparation raw material of EPDM flexible base neutron shielding material is as follows (parts by weight): 100 parts of EPDM rubber, 200 parts of boron nitride, 2 parts of sulfur, 5 parts of zinc oxide, dicumyl peroxide ( DCP) 2 parts, paraffin wax 7 parts, composite accelerator EM2331 parts, antioxidant RD 0.5 parts, antioxidant 40100.5 parts, N33015 parts, N23415 parts, process oil 2 parts.

[0042] The preparation method of the EPDM flexible-based neutron shielding material is the same as that in Example 1.

Embodiment 3

[0043] Example 3: Preparation of EPDM Flexible Base Neutron Shielding Material (3)

[0044] The preparation raw material of EPDM flexible base neutron shielding material is as follows (parts by weight): 100 parts of EPDM rubber, 150 parts of borax, 2 parts of sulfur, 5 parts of zinc oxide, dicumyl peroxide (DCP) 2 parts, 7 parts of paraffin, 1 part of composite accelerator EM2333, 0.5 parts of anti-aging agent RD, 0.5 parts of anti-aging agent, 15 parts of N33015 parts, 15 parts of N2341, 2 parts of process oil.

[0045] The preparation method of the EPDM flexible-based neutron shielding material is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com