Anti-ionizing radiation fiber-reinforced resin matrix composite and preparation method thereof

A fiber-reinforced resin and ionizing radiation technology, which is applied in the field of fiber-reinforced resin-based composite materials and its preparation, can solve the problems of high-density lead with low mechanical properties, difficulty in meeting structural material requirements, increasing system weight and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

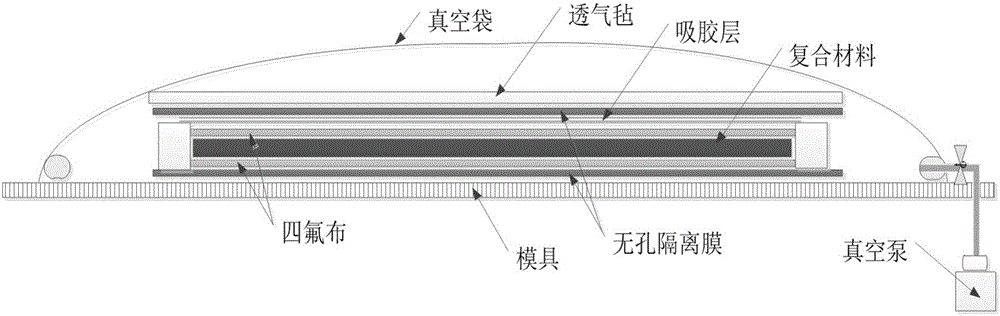

Method used

Image

Examples

preparation example Construction

[0050] The present invention has no special requirements for the preparation method of the resin matrix, and the preparation method of the resin matrix is well known to those skilled in the art. In the present invention, when the curing agent is liquid, the curing agent and epoxy resin can be mixed directly; when the curing agent is solid, the present invention preferably first dissolves the curing agent with acetone, and then Mix the dissolved curing agent with epoxy resin. The present invention has no special requirements on the amount of acetone, as long as the curing agent can be dissolved.

[0051] In the present invention, the ratio of the epoxy resin to the curing agent is preferably 100: (5 to 80), more preferably 100: (5 to 15), most preferably 100: (50 to 80). .

[0052] In the present invention, the mass ratio of the modified heavy metal and its compound to the resin matrix is 1:(5-10), specifically it can be 1:5, 1:6, 1:7, 1:8, 1: 9 and 1:10.

[0053] The present ...

Embodiment 1

[0075] Weigh 58 parts by weight of DDS curing agent according to the preparation of 100 parts by weight of AG80 resin, add 30 parts by weight of acetone to dissolve DDS first, and mix and stir the acetone solution after dissolving DDS with AG80 resin until the solution is uniform and clear to obtain a resin matrix.

[0076] In parts by weight, weigh 16 parts of micron-sized tungsten powder (particle size 1μm), 15 parts of acetone and 5 parts of KH560 coupling agent, dissolve the KH560 coupling agent in acetone, and then add to the tungsten powder In the process, stir uniformly at a temperature of 10°C, and activate at a constant temperature for 10 minutes to prepare surface modified tungsten powder. Mix the surface modified tungsten powder with the resin matrix, and adjust the solution density to 1.09g / cm with a densitometer 3 .

[0077] A wet prepreg machine is used to prepare unidirectional basalt fiber / AG80 resin / modified tungsten powder prepreg. The resin content of the prepreg...

Embodiment 2

[0086] In parts by weight, weigh 100 parts of submicron tungsten carbide powder (average particle size 600nm), 30 parts of ethanol, 3 parts of deionized water and 5 parts of KH550 coupling agent. The KH550 coupling agent is dissolved in a mixed solvent of 30 parts of ethanol and 3 parts of deionized water, and then the tungsten carbide powder is added, stirred evenly at a temperature of 40°C, and activated at a constant temperature for 12 minutes to prepare KH550 surface modified tungsten carbide powder was obtained.

[0087] Weigh 100 parts by weight of AG80 epoxy resin, 58 parts by weight of DDS curing agent, 16 parts by weight of surface-modified tungsten carbide powder, and stir with a planetary stirrer. The stirring temperature is 90°C and the stirring time is 30 minutes. Get AG80 / tungsten carbide powder resin.

[0088] A hot melt prepreg machine is used to pre-impregnate the basalt fiber with AG80 / tungsten carbide powder resin to prepare a basalt fiber / AG80 / tungsten carbide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com