Patents

Literature

71results about How to "Avoidance of damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

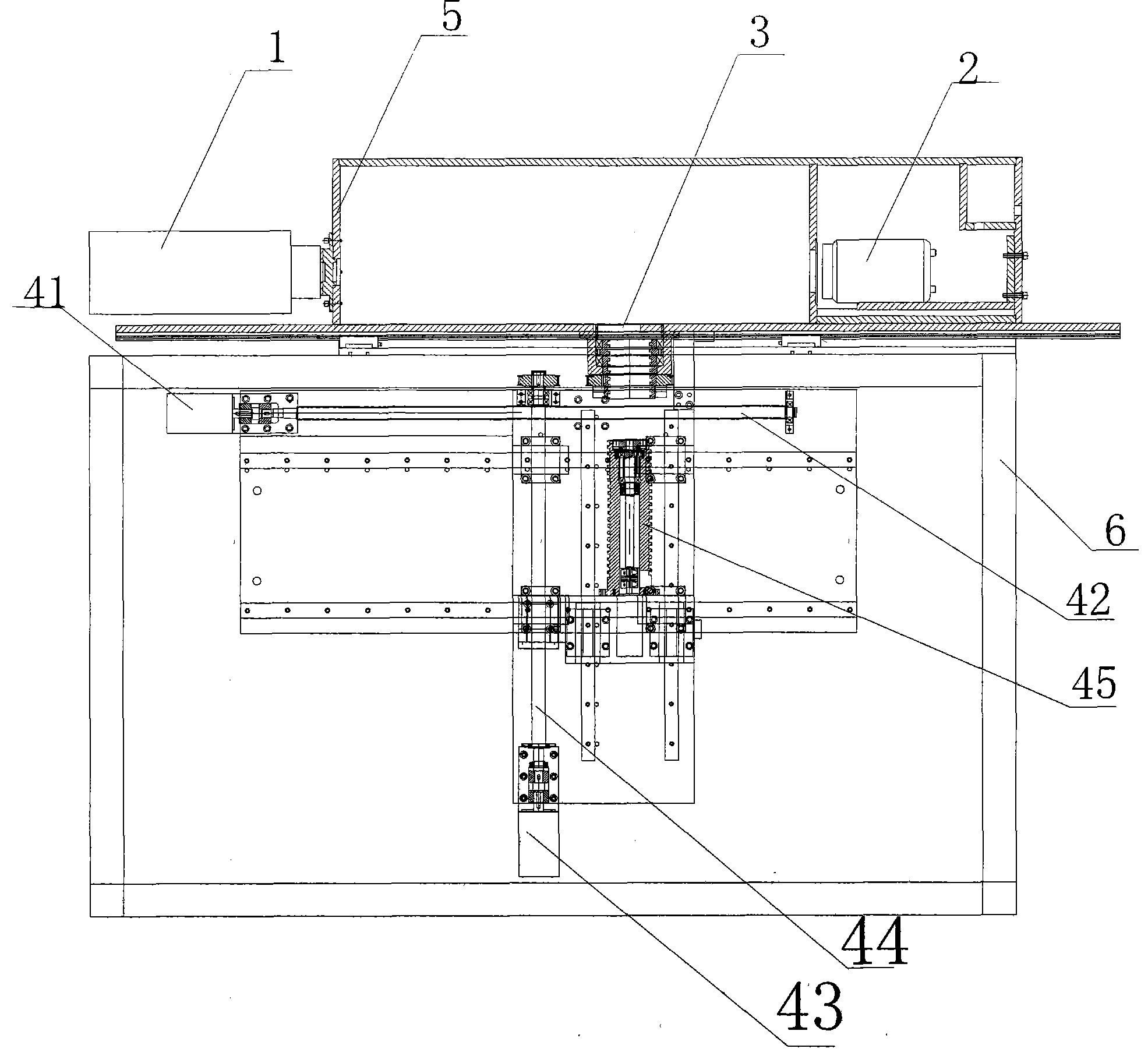

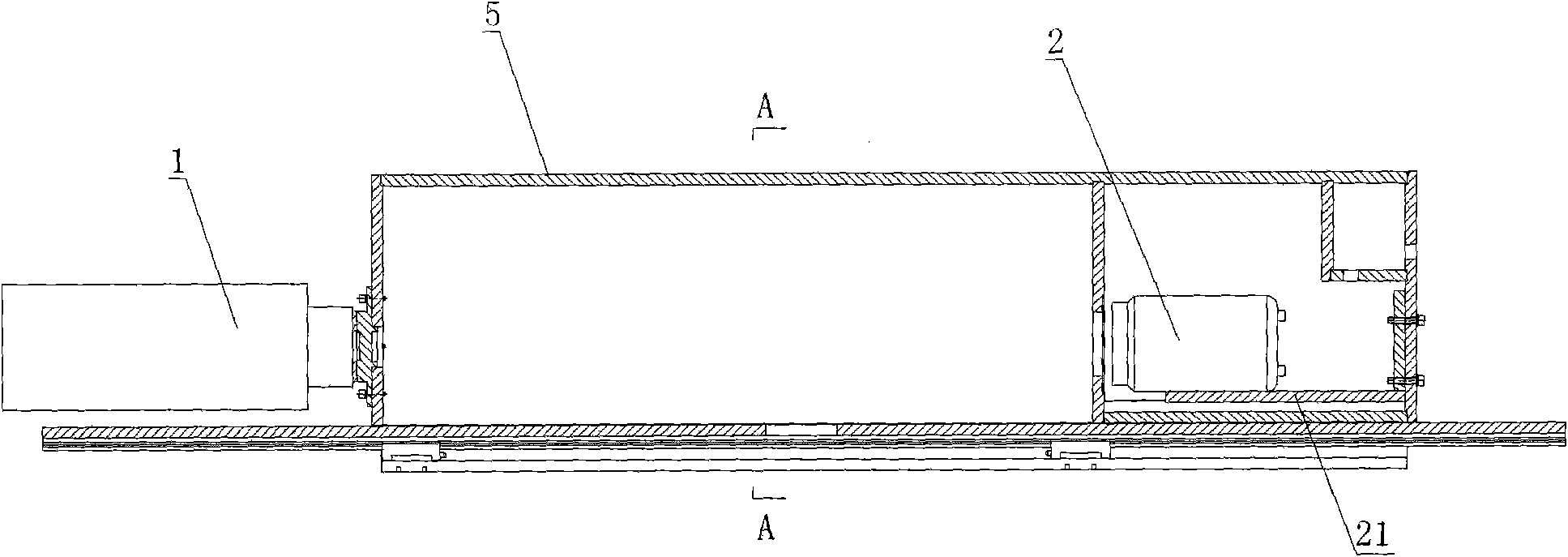

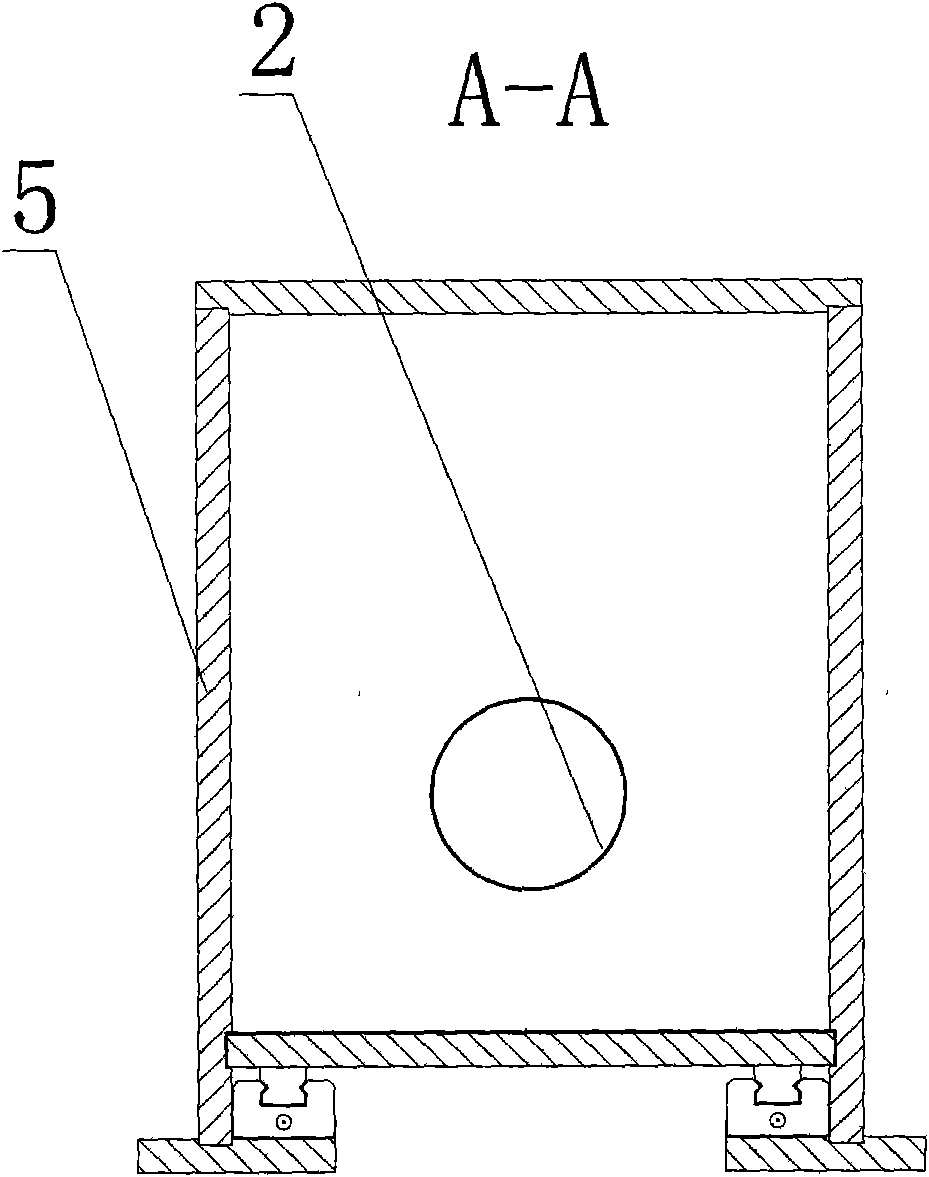

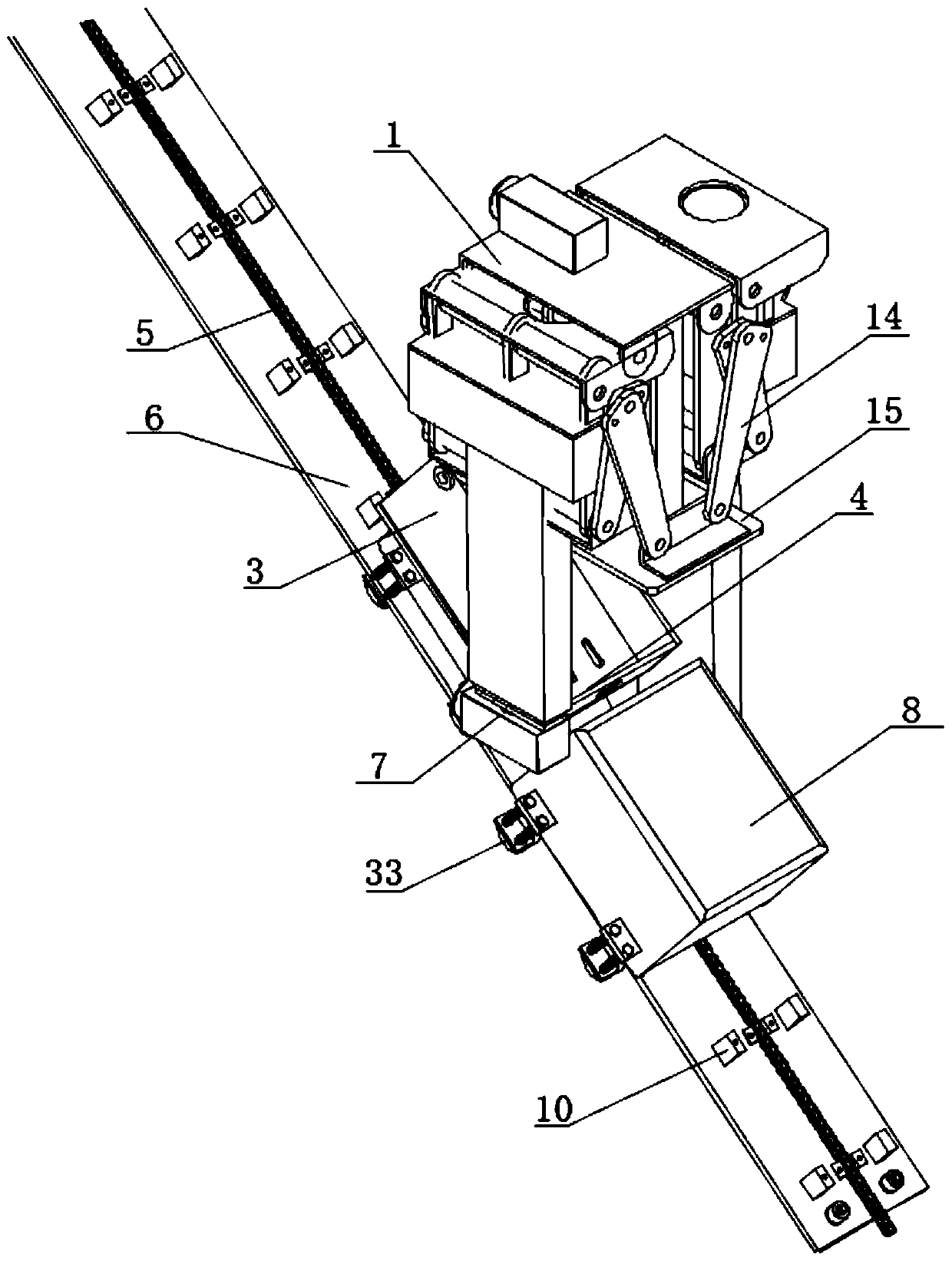

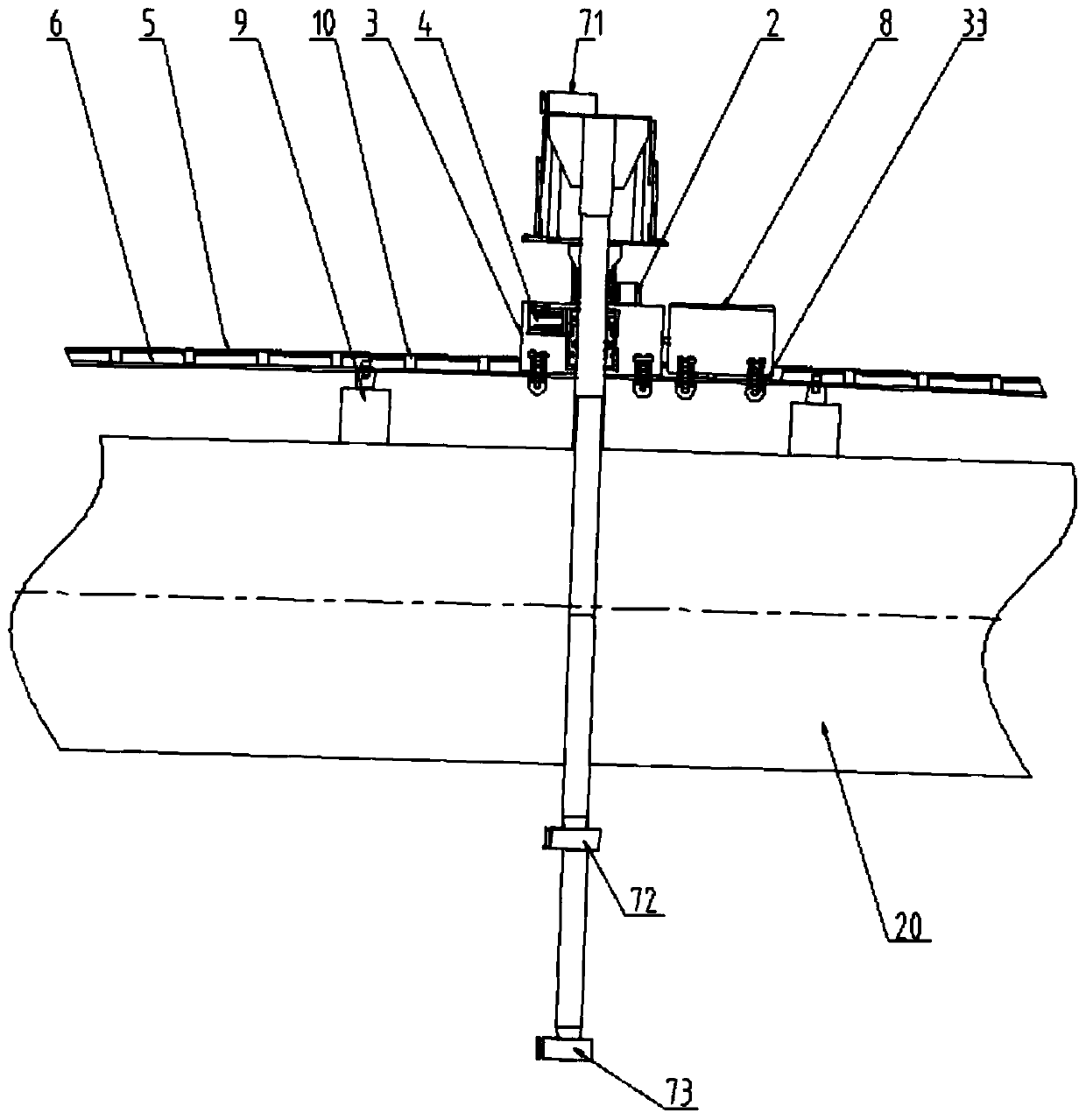

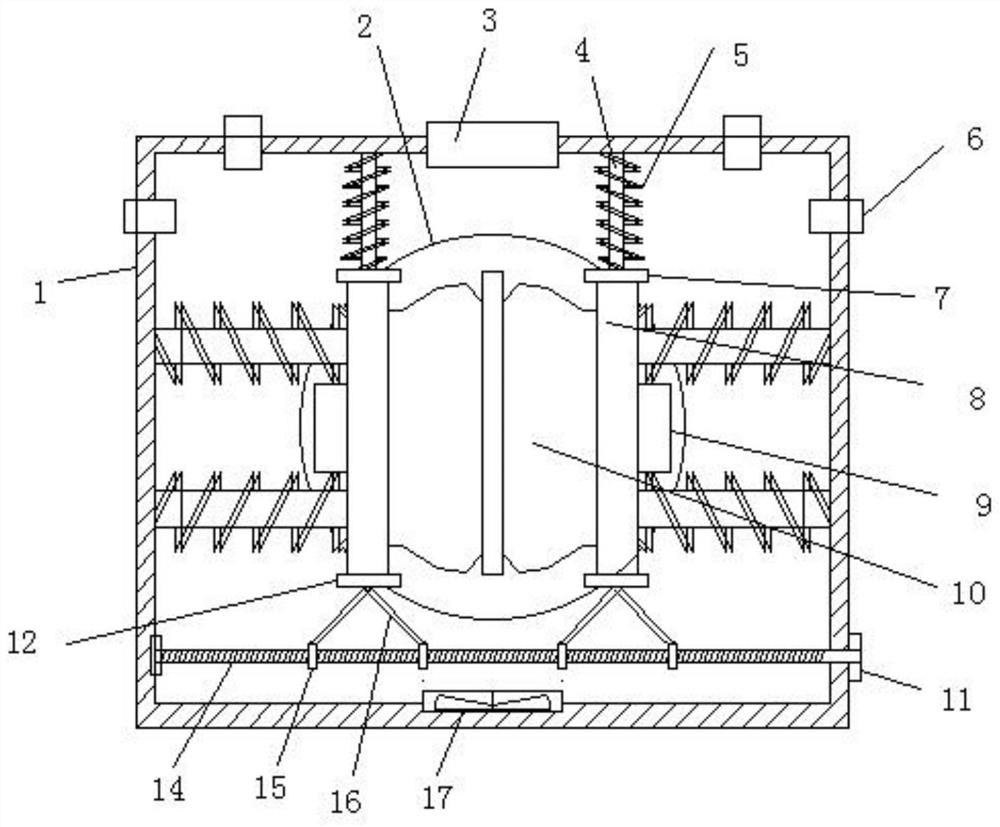

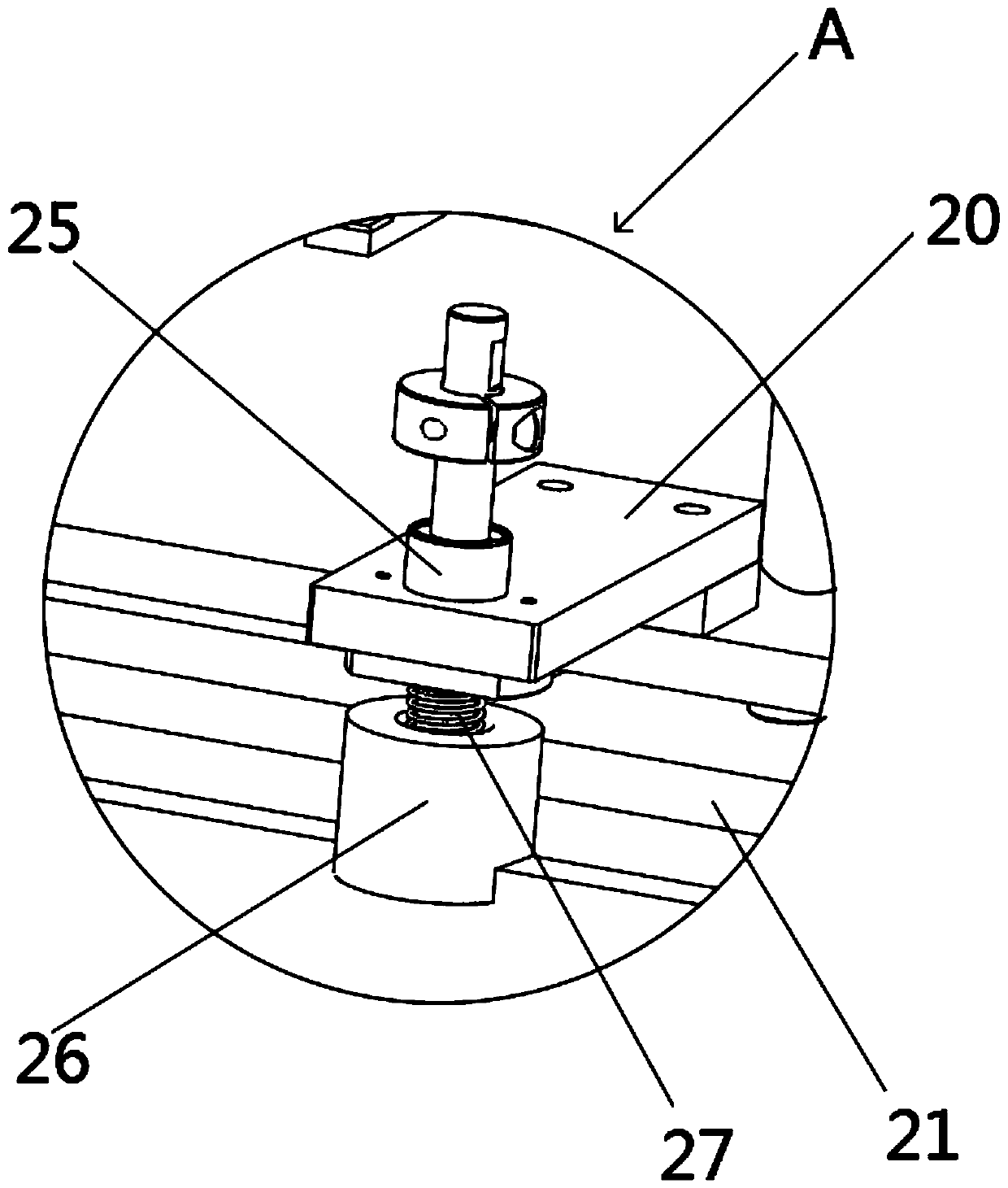

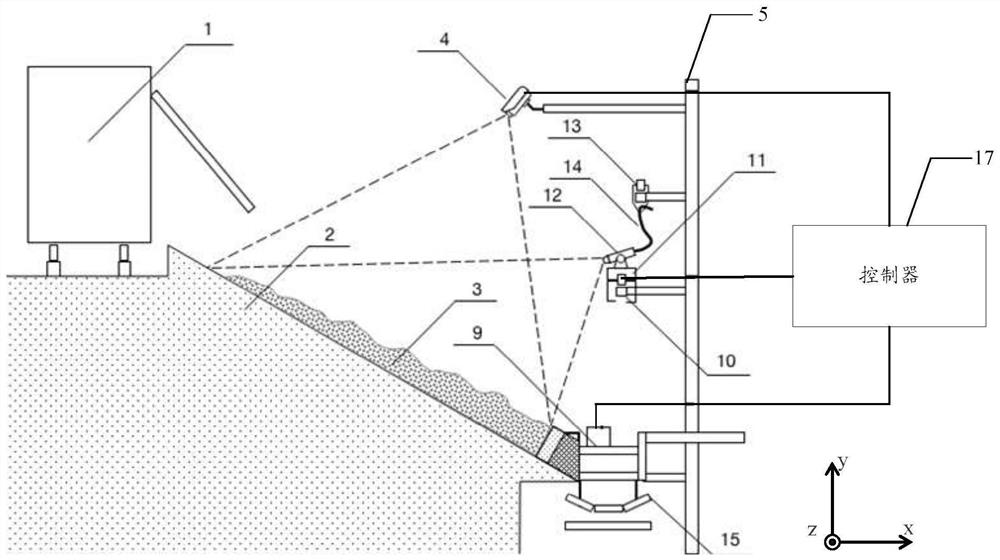

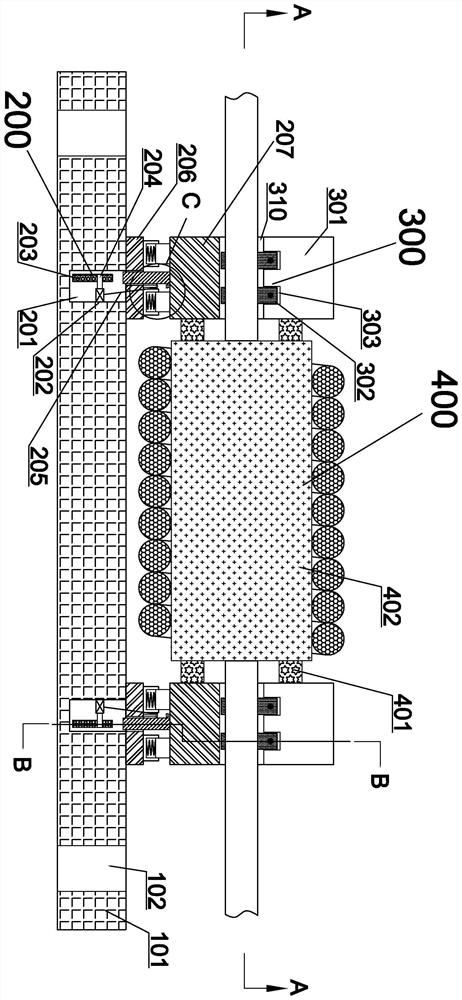

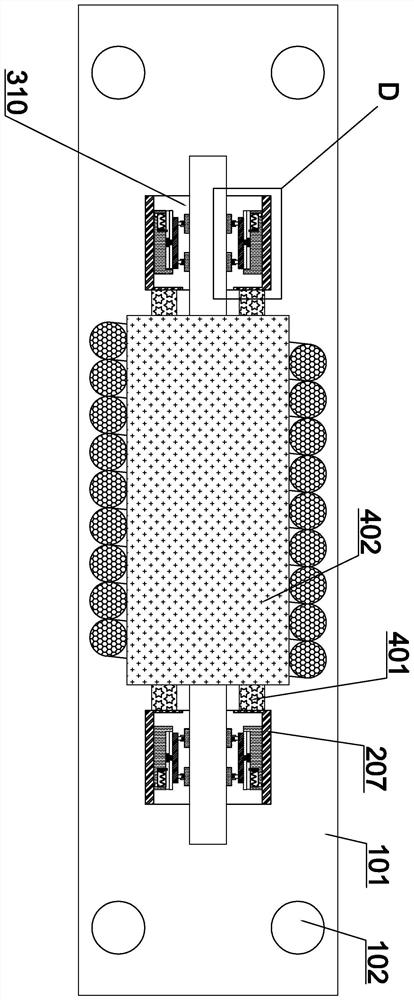

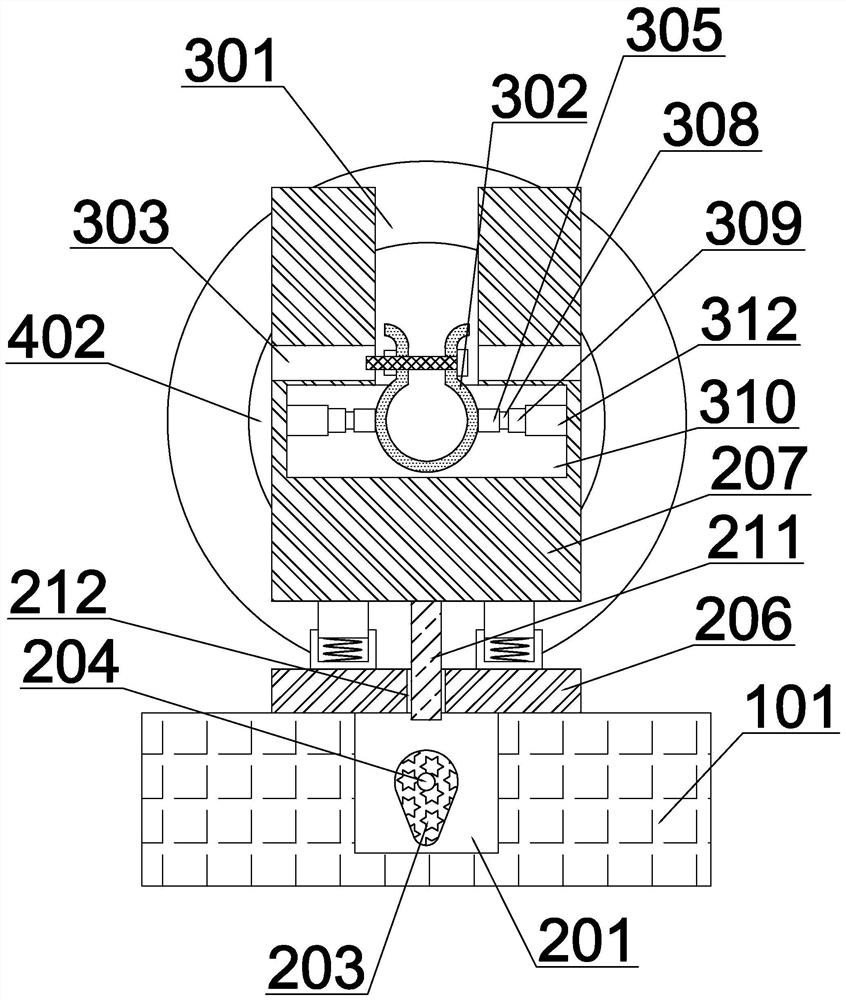

Microscopy CT imaging device with three-free degree motion control and correcting method thereof

InactiveCN101813642AEasy to disassembleSmooth motionComputerised tomographsTomographyPhysicsWire source

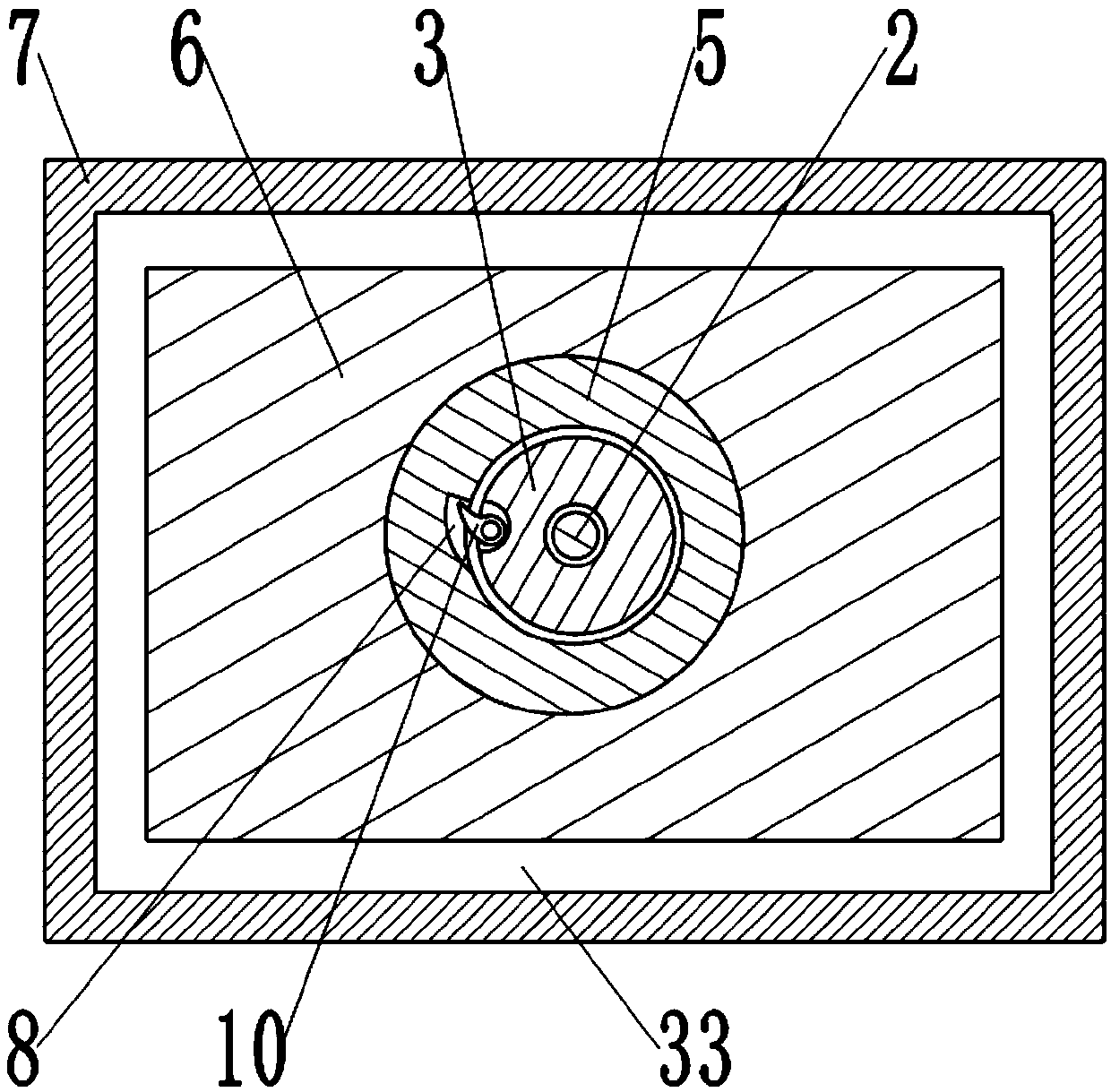

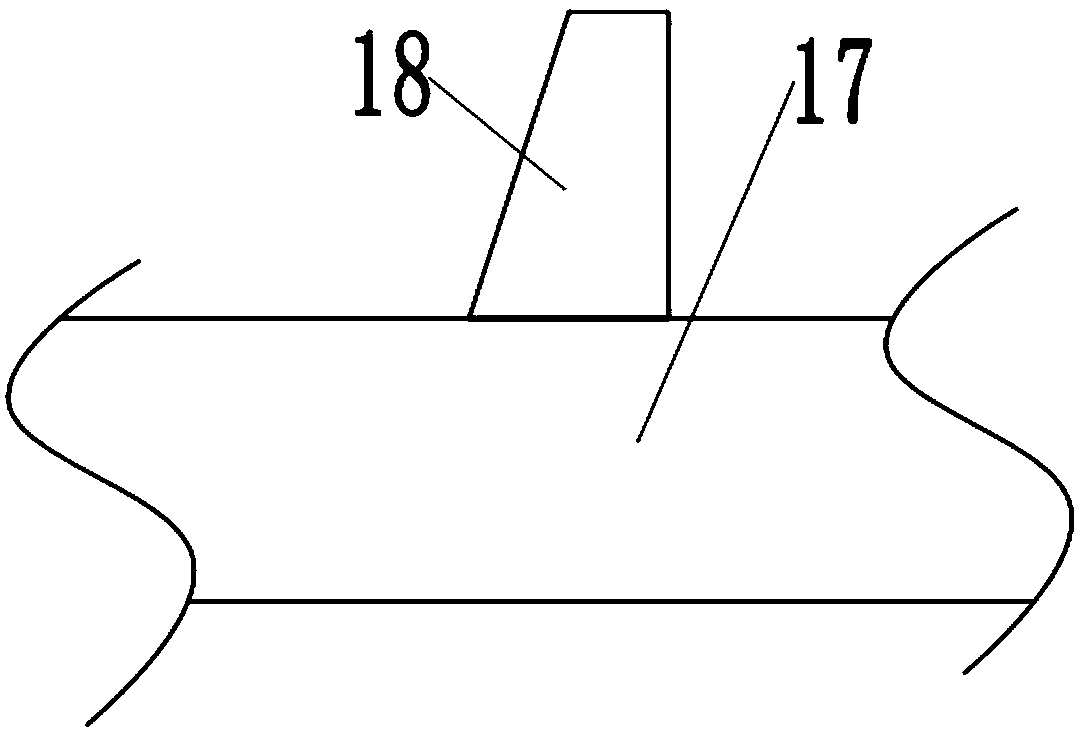

The invention provides a microscopy CT imaging device with three-free degree motion control and a correcting method thereof. The microscopy CT imaging device comprises an X-ray source (1) and an X-ray source detector (2), wherein a material-carrying table (3) is arranged between the X-ray source (1) and the X-ray source detector (2). The device is characterized in that the material-carrying table is externally provided with a driving device for driving the material-carrying table to move along the horizontal direction, the vertical direction and the rotation direction. The device solves the problems of serious shake, large error and low precision when the common microscopy CT mechanical device moves; leads the three-free degree direction motion to be more stable, the speed to be more even, and the precision degree to be higher; has better radiation shield effect; solves the problem of the heat dissipation of the X-ray source and the X-ray source detector; solves the problem that the X-ray source, the X-ray source detector and a material-rotating center are positioned at one line; and lays good foundations for the subsequent image acquisition and image reconstruction.

Owner:苏州和君科技发展有限公司 +1

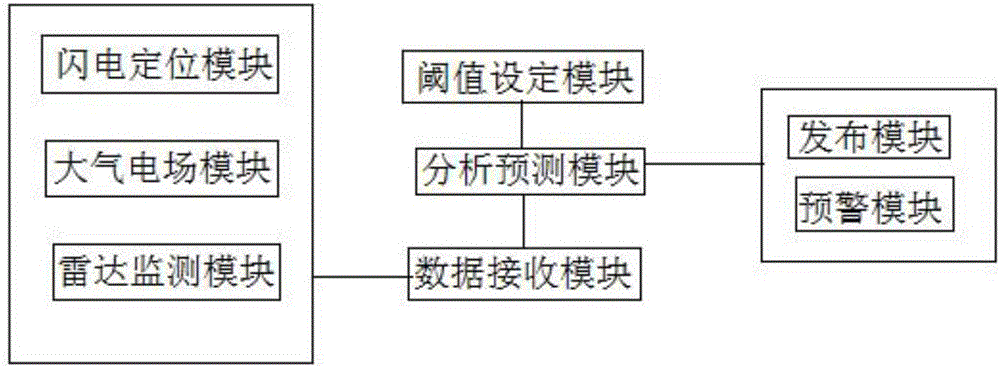

Lightning monitoring and early-warning system

InactiveCN106443212ATimely collection and transmissionAvoidance of damageWeather condition predictionElectrostatic field measurementsEarly warning systemRadar

The invention discloses a lightning monitoring and early-warning system. The lightning monitoring and early-warning system comprises a lightning positioning module, an atmospheric electric field module, a radar monitoring module, a threshold setting module, a data receiving module, an analyzing and predicting module, an issuing module and an early warning module, wherein the lightning positioning module, the atmospheric electric field module and the radar monitoring module take charge of collecting lightning information in a monitored area; the analyzing and predicting module is connected with the data receiving module and the threshold setting module and takes charge of analyzing and processing data of the information received by the data receiving module, predicting a lightning moving direction in combination with lightning positioning information and radar echo information and obtaining the probability grades that the lighting passes through the monitored area; the early warning module is connected with the analyzing and predicting module and takes charge of grading and early warning according to the probability grades that the lighting passes through the monitored area obtained by the analyzing and predicting module. Through the lightning monitoring and early-warning system, the situation of the damage of lightning to people is avoided; the incidence rate of accidents is reduced.

Owner:安徽锦坤电子科技有限公司

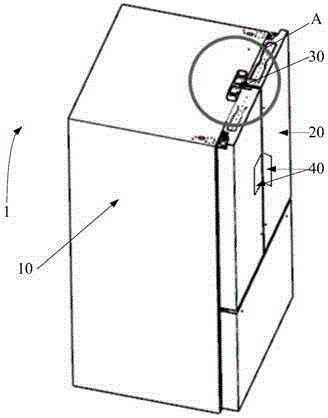

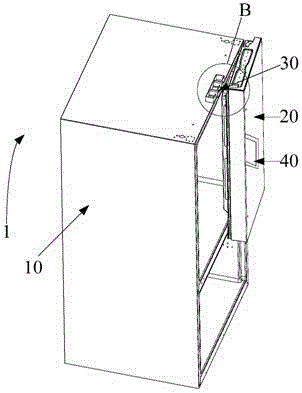

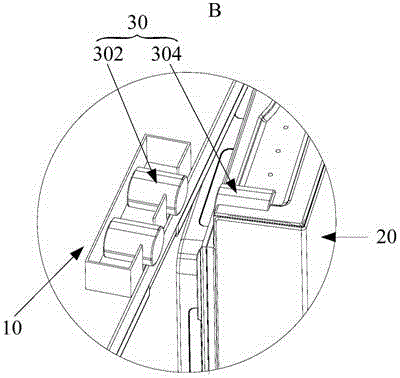

Refrigerating device

InactiveCN106016894AOvercoming magnetismImprove sealingLighting and heating apparatusDomestic refrigeratorsMagnetic tension forceElectrical polarity

Owner:HEFEI HUALING CO LTD +1

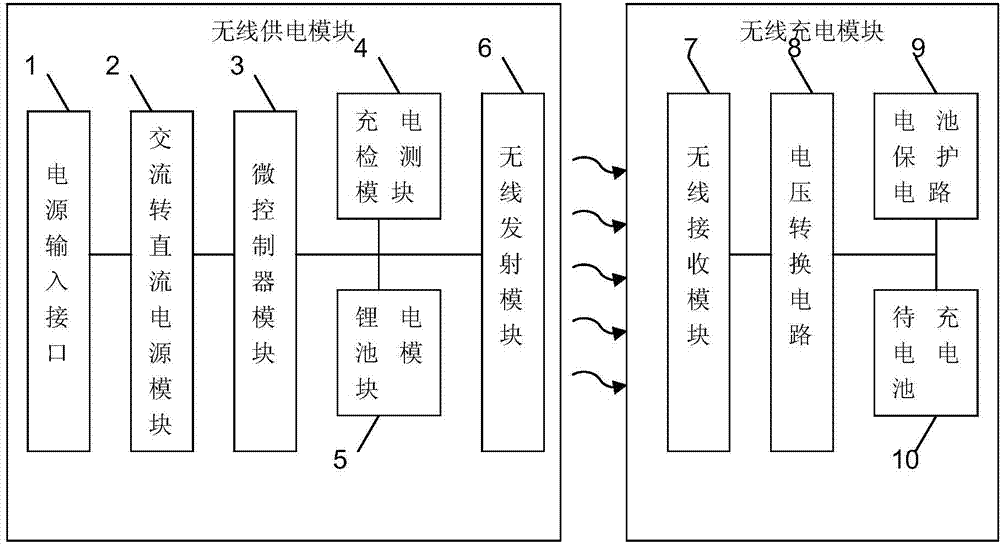

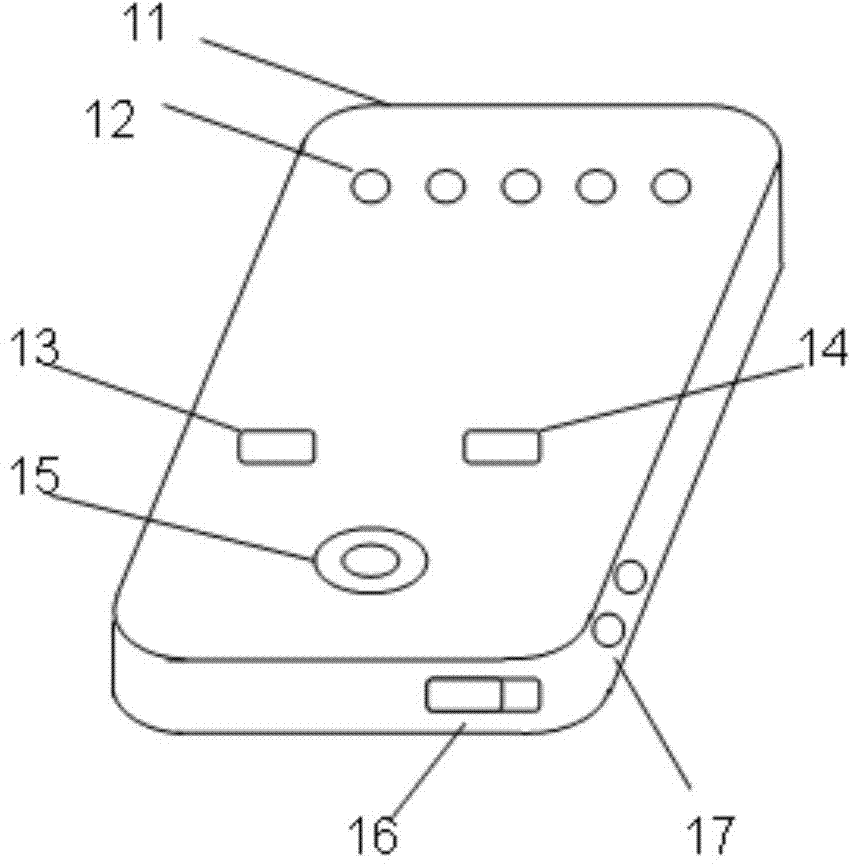

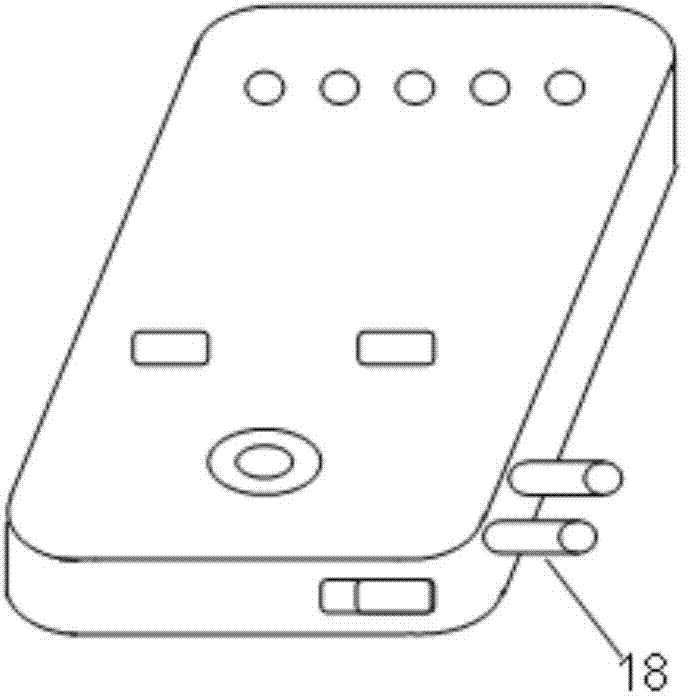

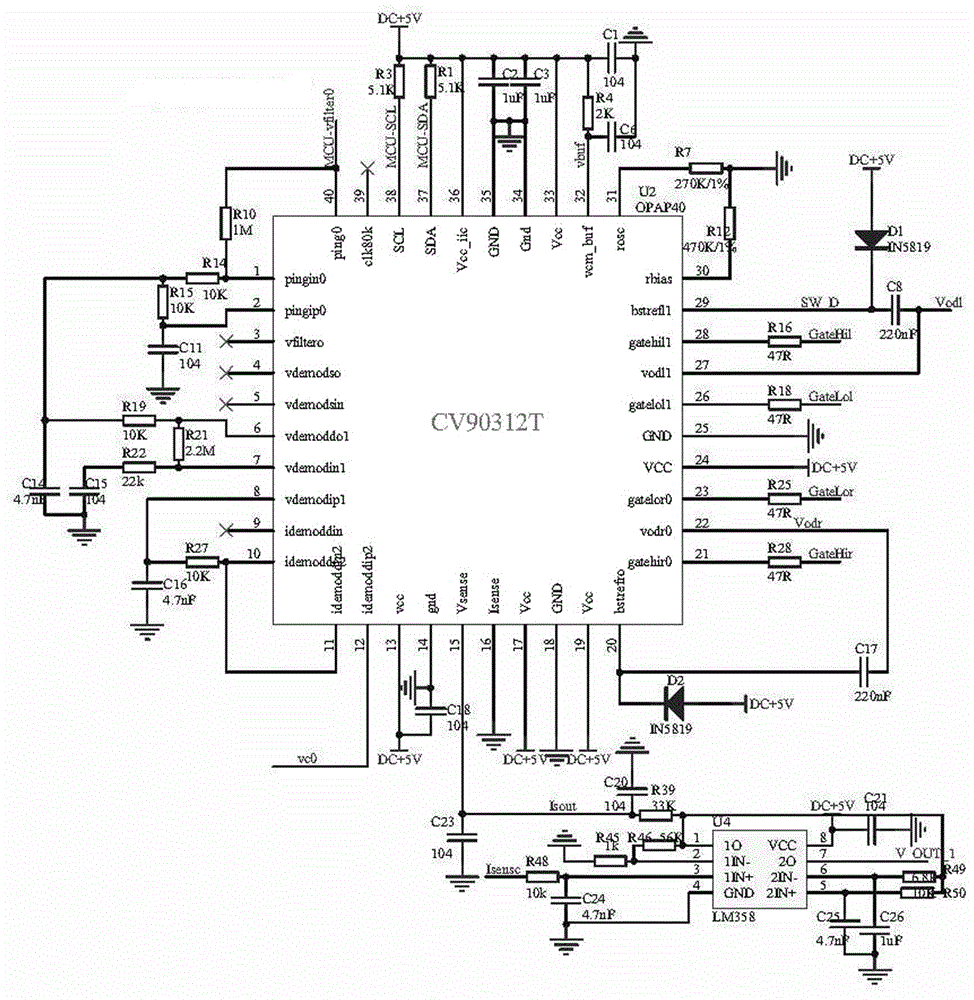

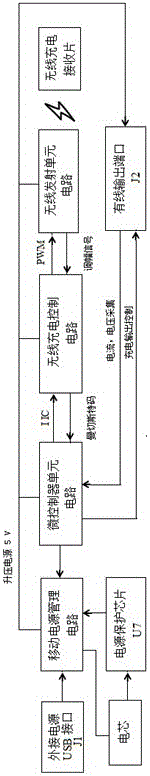

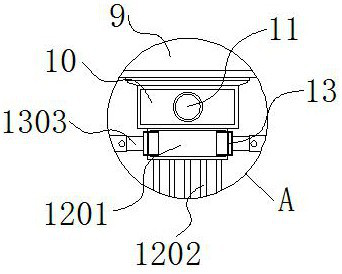

Wearable wireless charger baby

InactiveCN104779657AHigh degree of intelligenceReduce volumeBatteries circuit arrangementsElectromagnetic wave systemElectrical batteryEngineering

The invention discloses a wearable wireless charger baby which comprises a wireless power supply module and a wireless charge module, wherein a charge detection module is adopted to detect whether equipment to be charged is in a charge area of the wearable wireless charger baby or not; if the equipment to be charged is in the charge area of the wearable wireless charger baby, the lithium battery of a wireless transmitting module is adopted to supply power to enable a transmitting coil to generate and output radio frequency according to the result of the charge detection module; an energy conversion circuit in a wireless receiving module is adopted to receive electromagnetic signals transmitted from the wireless transmitting module and to convert the electromagnetic signals into alternative current; a voltage conversion circuit is adopted to receive generated alternative current and convert the alternative current into direct current; a battery protecting circuit is adopted to prevent the situation that a battery is damaged by situations such as over charge, over current and short circuit. Due to the adoption of a telescopic elastic band and double additional elliptical buckles, the wearable wireless charger baby disclosed by the invention can be worn on arms, wrists and legs or suspended above other articles, is convenient to carry over, and further has the advantages of wide wireless charge range, high intelligent degree, small size, simplicity in operation and the like.

Owner:HANGZHOU DIANZI UNIV

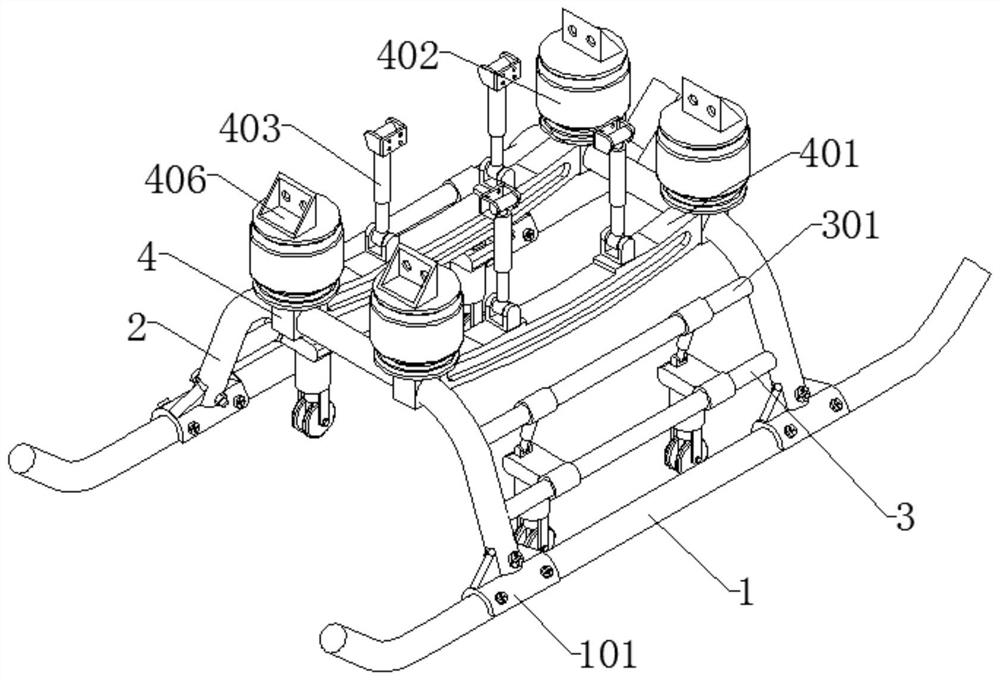

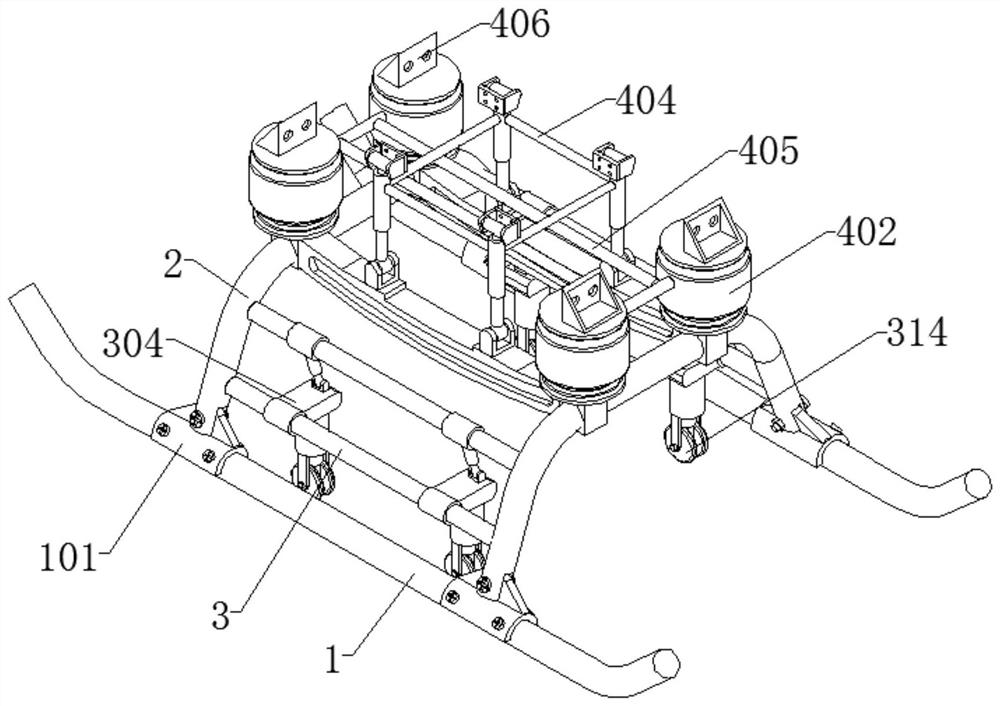

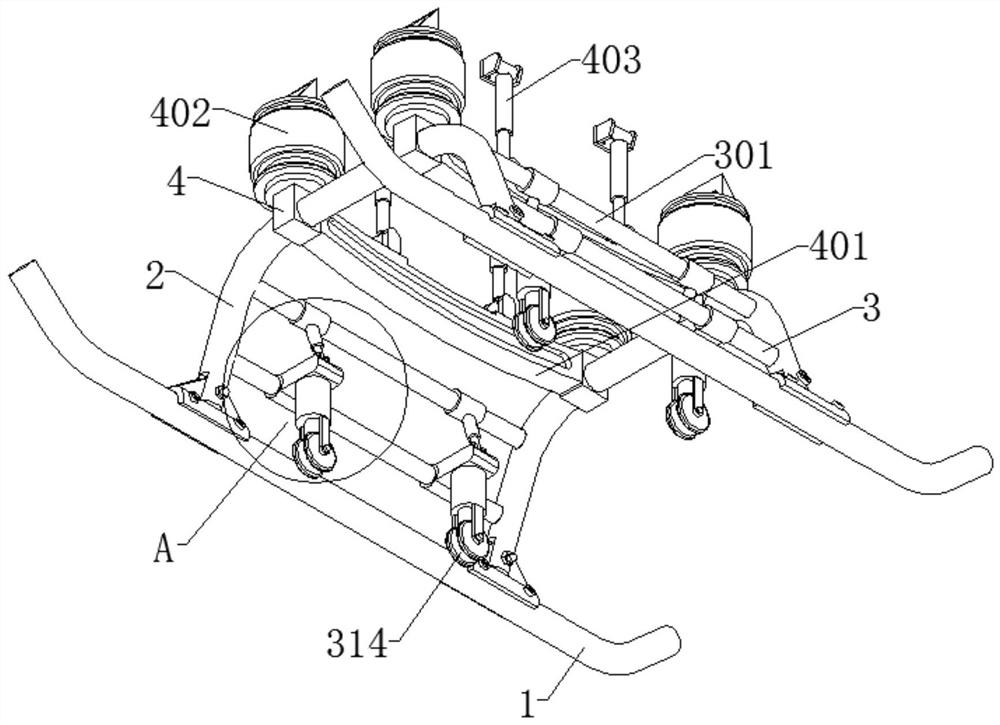

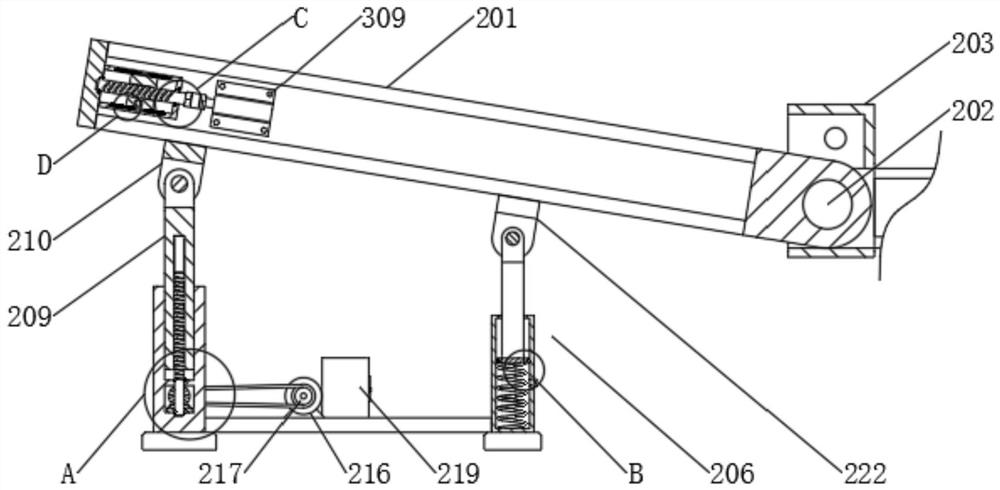

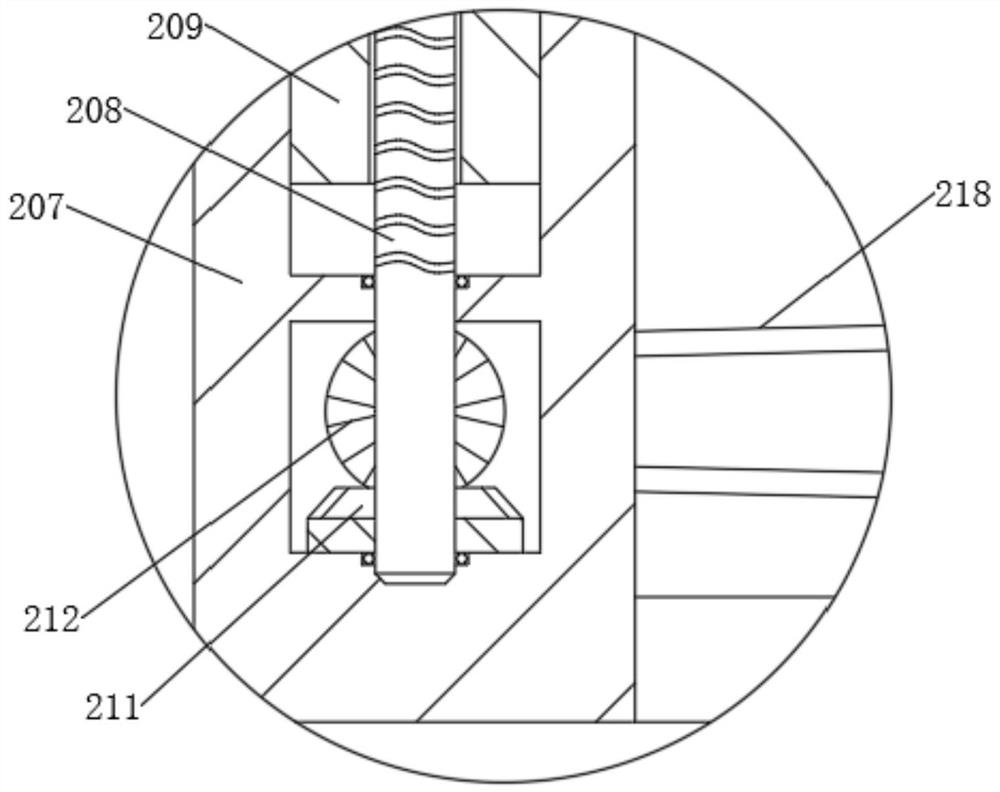

Helicopter undercarriage with protection function

InactiveCN112706914AGood cushioning and shock absorption effectGood cushioning and shock absorptionWheel arrangementsLanding gearShaped beam

The invention discloses a helicopter undercarriage with the protection function; the undercarriage comprises a skid and an arch-shaped beam, the arch-shaped beam is connected to the top wall of the skid, a first supporting rod and a second supporting rod are connected to the inner wall of the arch-shaped beam, and a first supporting plate is rotatably connected to the outer wall of the first supporting rod; a first shock absorber body is connected to the top wall of the first supporting plate, a sleeve is connected to the bottom wall of the first supporting plate, a buffer shock absorption mechanism is arranged in the sleeve, the output end of the buffer shock absorption mechanism penetrates through the sleeve and is connected with a rotating shaft, a machine wheel is connected to the outer wall of the rotating shaft, and a connecting base is connected to the top wall of the arched beam. A supporting beam is connected to the inner wall of the connecting base, and a second buffer damping mechanism is connected to the top wall of the supporting beam; according to the helicopter undercarriage, a good buffering and damping effect can be effectively achieved on the helicopter body during landing, the situation that the helicopter is damaged due to the fact that the helicopter is subjected to high impact force during landing is avoided, and then a good protection effect is effectively achieved on the helicopter body.

Owner:北京中联国成科技有限公司

Corridor elevator control method

ActiveCN104909235AAvoid injuryAvoid the situationElevatorsBuilding liftsReciprocating motionSimulation

The invention discloses a corridor elevator control method. When an elevator meets a barrier during descending, vertical reciprocating motion is performed, whether the barrier below the elevator exists or not is probed by triggering a limiting switch, a track frame can automatically descend to the bottom position on the condition that the barrier disappears, and the track frame is stopped on the condition that the barrier exists for a long time; the barrier is removed through personnel intervention, and the phenomena that the personnel are injured and equipment is damaged due to forcible descending are avoided; when the elevator meets a barrier during ascending, emergency braking is performed, the control right of a traction control button is cut off, a rider is prevented from conducting the ascending operation forcibly, and the phenomena that the personnel are injured and the equipment is damaged due to forcible ascending are avoided.

Owner:浙江道可道楼道电梯有限公司

Ultraviolet sterilization device

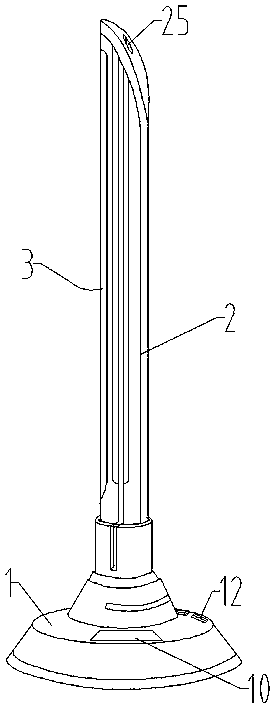

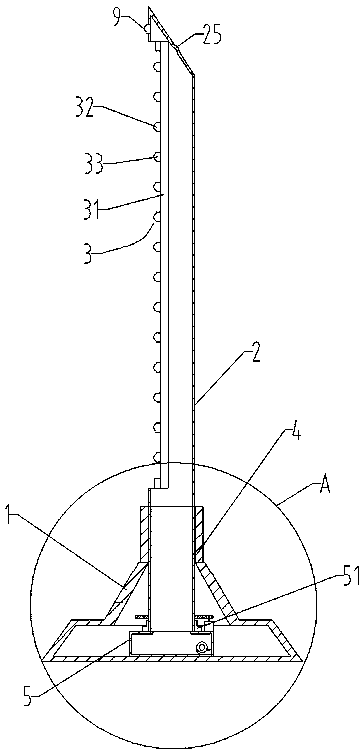

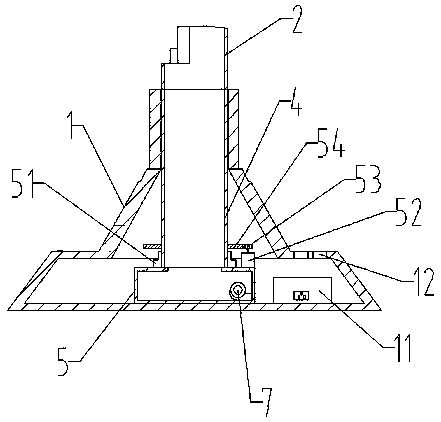

PendingCN111437424ARealize all-round sterilizationWide range of irradiationGas treatmentDispersed particle separationUltraviolet lightsLight beam

An ultraviolet sterilization device comprises a base, a lamp tube body is rotationally arranged above the base, an LED light source used for emitting visible ultraviolet light beams is arranged in thelamp tube body, and a rotation driving mechanism used for driving the lamp tube body to automatically rotate by 360 degrees is arranged in the base; the lamp tube body is provided with a safety control device used for controlling the LED light source to automatically start and stop and preventing visible ultraviolet light beams emitted by the LED light source from irradiating a human body. Visible ultraviolet light beams emitted by the LED light source can inhibit bacteria and sterilize the interior of a room, the interior of the room can be comprehensively scanned and sterilized, the irradiation range is widened, then the sterilization work efficiency is improved, a strong catalytic degradation function can be generated when the ultraviolet light beams irradiate a photocatalyst layer, soas to effectively degrade toxic and harmful gas in air, effectively kill various bacteria and decompose and innocuously treat toxins released by the bacteria or fungi, and meanwhile the device has the functions of removing formaldehyde, deodorizing, resisting pollution, purifying air and the like.

Owner:嵇刚

Arch bridge video inspection vehicle and matching structure of arch bridge video inspection vehicle and track

InactiveCN109837834AImprove securityAvoid working at heightsBridge structural detailsLeveling mechanismUltimate tensile strength

The invention relates to the technical field of bridge inspection, in particular to an arched bridge video inspection vehicle comprising: a main vehicle body provided with a camera mechanism; a walking mechanism that walks along the bridge top of the arched bridge and is used for driving the main vehicle body to move; a leveling mechanism installed between the walking mechanism and the main vehicle body and movably connected with the main vehicle body. In the moving process of the walking mechanism, the main vehicle body is adjusted in real time by the leveling mechanism, so that the main vehicle body is kept vertical. The invention further provides a matching structure of the arched bridge video inspection vehicle and a track. The arched bridge video inspection vehicle provided by the invention can be remotely operated, and is high in safety, high in automation degree, simple to operate, low in labor intensity and wide in application range.

Owner:BEIJING HENGLI TIEKE TECH DEV

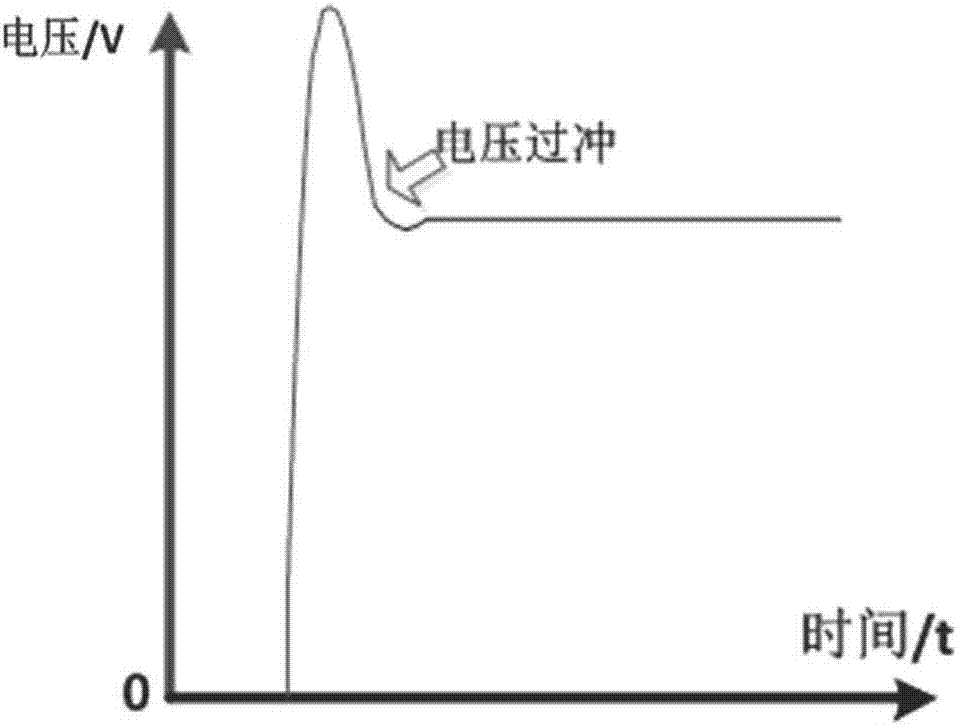

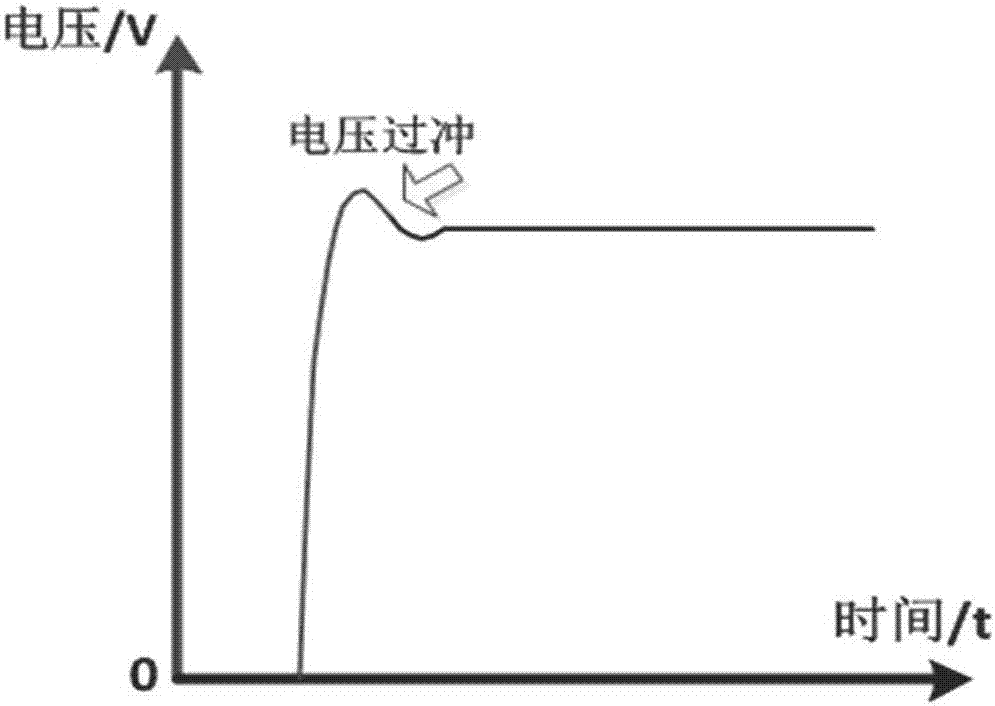

Power protection device and circuit board testing system

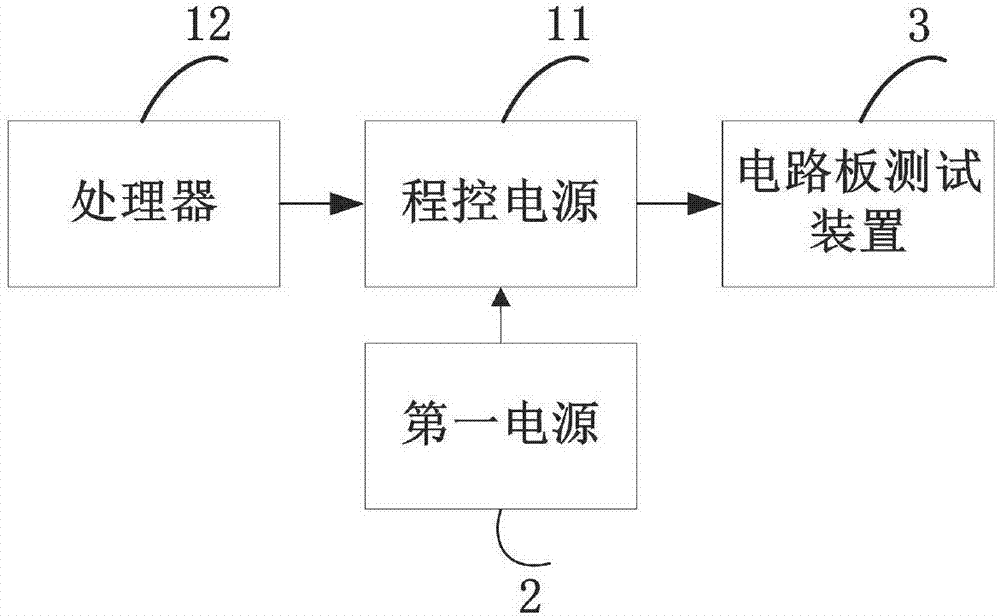

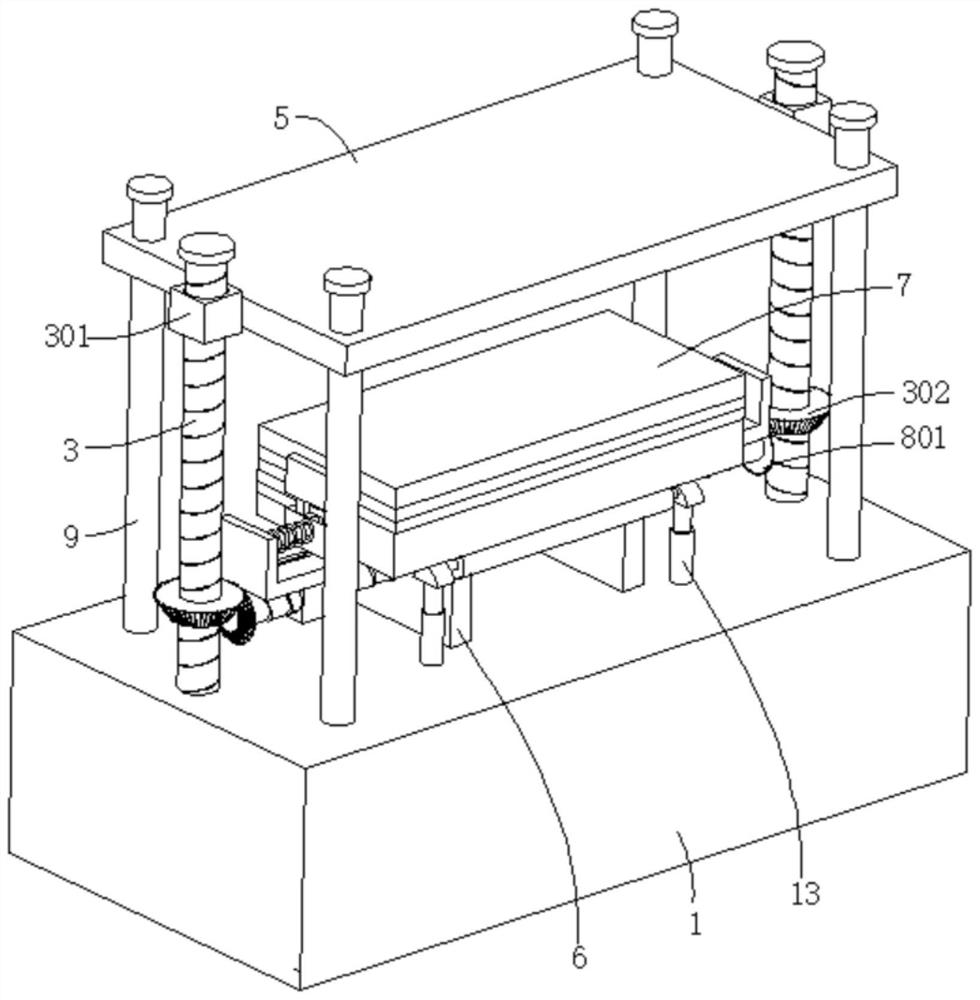

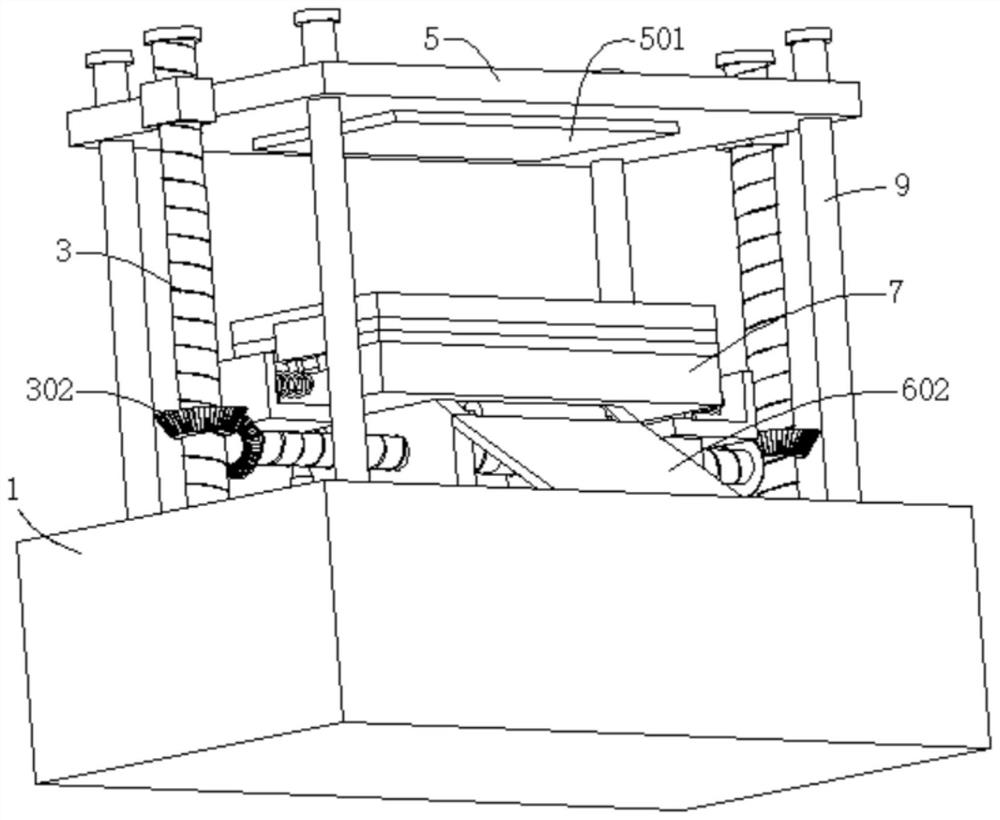

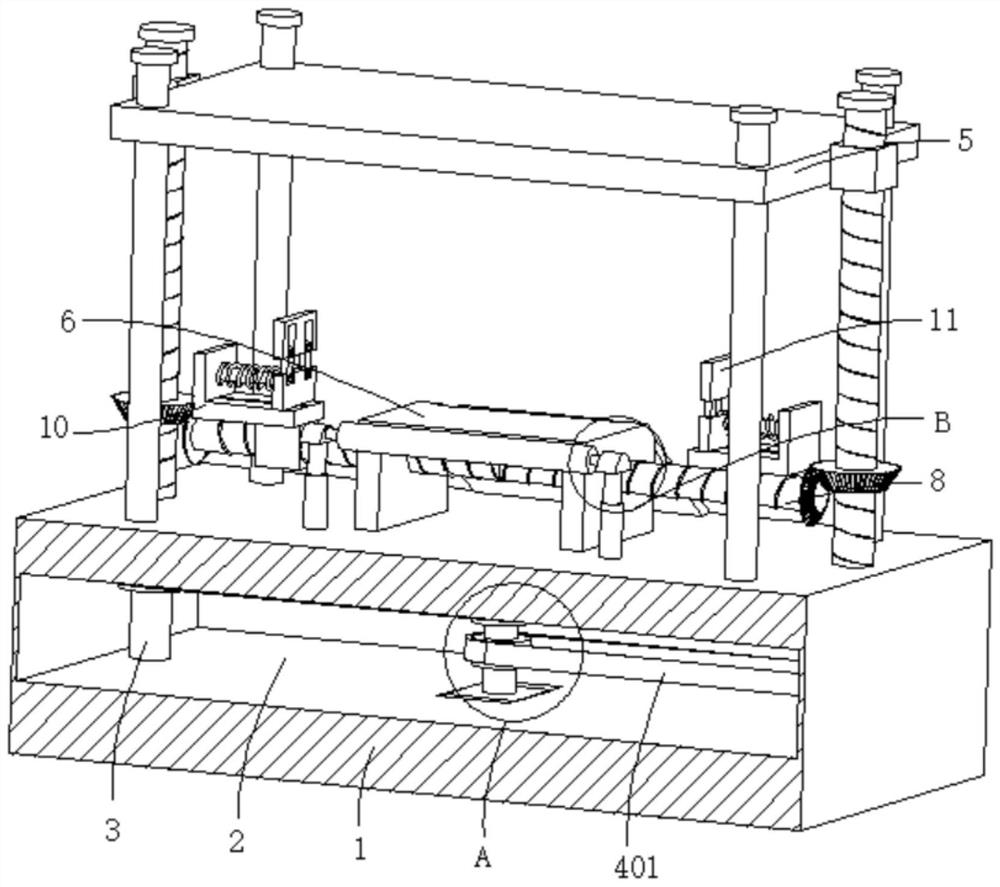

InactiveCN107356858AAvoid damageSolve the problem of voltage overshootElectronic circuit testingVoltage overshootEngineering

Embodiments of the invention relate to the technical field of electronic products, and disclose a power protection device and a circuit board testing system. In the embodiments of the invention, the power protection device includes at least one programmable power supply and a processor; a control end of the programmable power supply is connected with the processor, a voltage input end of the programmable power supply is configured to connect to a first power supply, and a voltage output end of the programmable power supply is configured to connect to a circuit board testing device; and the processor is configured to control the programmable power supply to convert the voltage output by the first power supply into a step voltage and supply power to the circuit board testing device. The embodiments of the invention further provide the circuit board testing system. The embodiments of the invention solve the voltage overshoot problem caused by instantly turning on the power supply, avoid the damage to electronic components on a circuit board, improve the product yield and reduce the loss.

Owner:XIAN YIPU COMM TECH

Pressing device for building insulation board processing

InactiveCN112297450ARealize clamping and fixingPrevent movementFlat articlesElectric machineArchitectural engineering

The invention discloses a pressing device for building insulation board processing, and belongs to the technical field of insulation board processing. The pressing device for building insulation boardprocessing comprises a base, wherein a cavity is formed in the base; a motor is fixedly connected to the inner wall of the cavity; a rotating shaft is connected to the output end of the motor; firstlead screws are rotationally connected to the two sides of the base through first bearings; the two first lead screws are connected with synchronous wheels matched with the outer wall of the rotatingshaft; a synchronous belt is connected between the two synchronous wheels; the outer walls of the two first lead screws are in threaded connection with first sleeves; a pressing plate is connected between the two first sleeves; and a workbench is connected to the outer wall of the top of the base. According to the pressing device, the pressing plate is used for clamping and fixing an insulation board body in the pressing process of the insulation board body, so that the force distribution can be more uniform to a certain extent, the pressing effect is guaranteed, the insulation board body is prevented from moving in the pressing process, the dislocation of multiple layers of boards is prevented, and the probability of defective products is reduced.

Owner:陈波浪

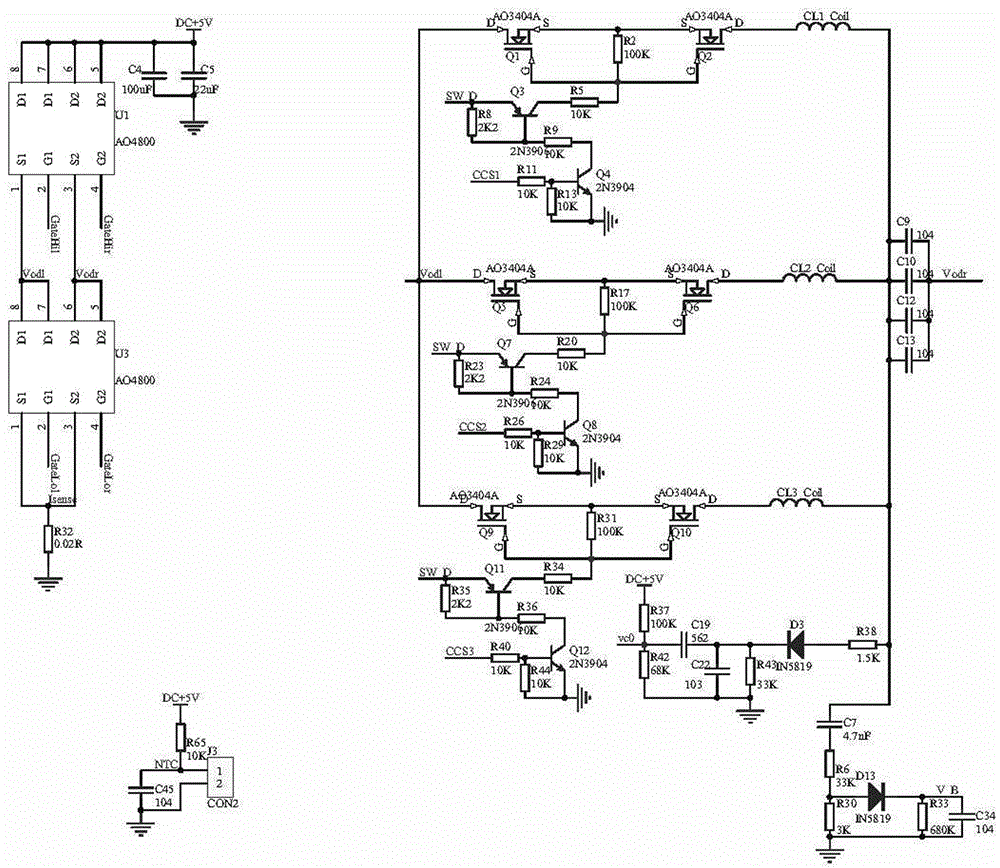

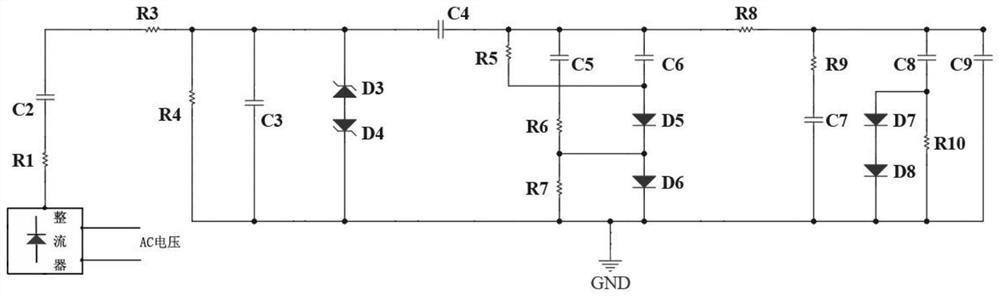

Wireless mobile power pack circuit and charging method

InactiveCN105811511AAvoid heatingImprove experienceBatteries circuit arrangementsElectric powerEngineeringInductor

The invention relates to a wireless mobile power pack circuit and a charging method, and belongs to the mobile device charging. A wireless charging receiving slice is connected with a mobile phone through a mobile phone USB interface. The wireless charging receiving slice is adhered on the shell of a mobile power pack. When an alternating current passes through coils of an inductor CL1, an inductor CL2 and an inductor CL3, magnetic induction lines changing along with time appear around the coils. Induction electromotive force is generated at two ends of the coils by the changing magnetic induction lines. The induction electromotive force is equivalent to a new power supply. When the coil of a receiving device is located in the ranges of magnetic induction lines changing along with the time, the induction electromotive force is produced at two ends of the coils through electromagnetic induction, thus generating a current. The power supply is supplied to the mobile phone through the receiving slice of the mobile phone or by using the wireless charging receiving slice. When the circuit is used, it is unnecessary to plug in and pull out a charging plug repeatedly; and a charger is avoided from being damaged due to frequent plug-in and pull-out. The circuit and the method are safe and convenient in use and have a function of flexible usage of wireless charging and wire changing.

Owner:ZHONGHUAN TELCOM TECH

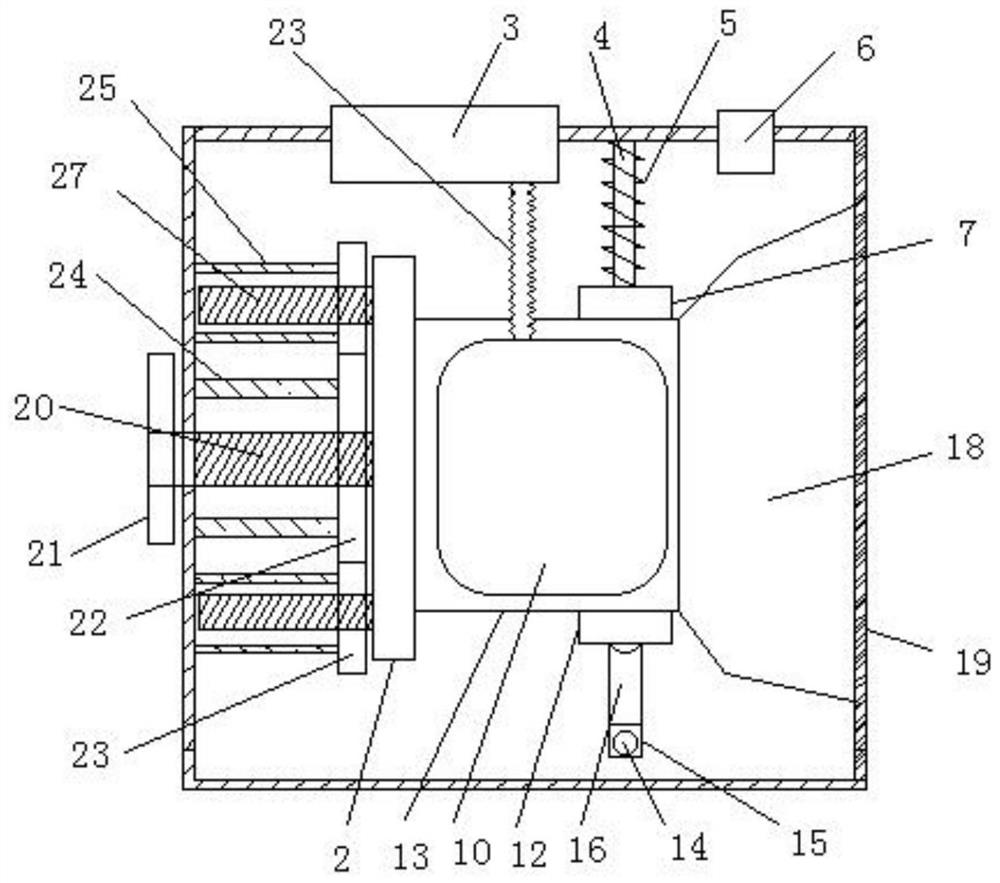

Moving and transporting protection device for semiconductor device

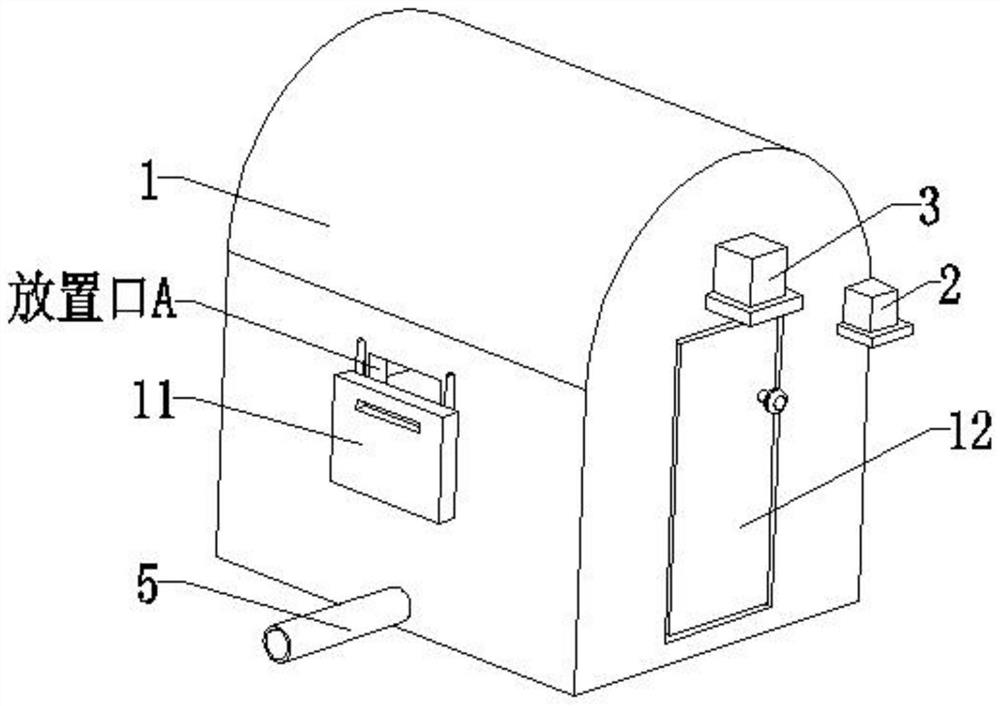

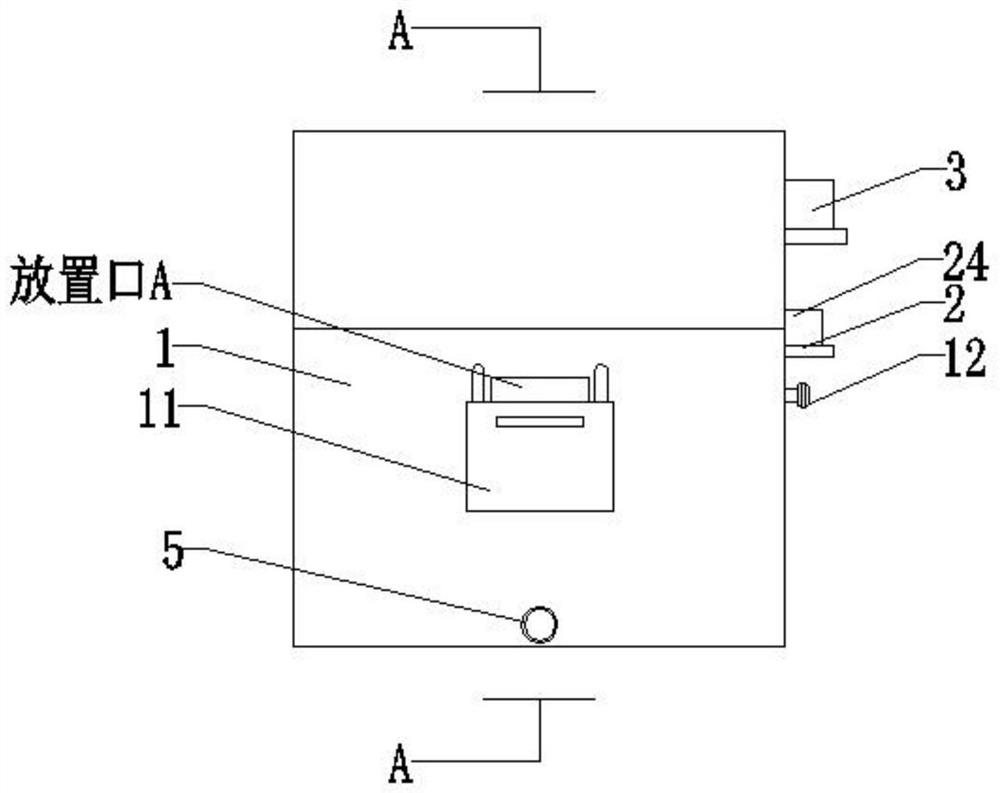

ActiveCN114044251AAvoidance of damageQuality assuranceContainers preventing decayContainers to prevent mechanical damageCircular discDevice material

The invention relates to a semiconductor device moving and transporting protection device which comprises a protection box, a rotating disc is arranged in the protection box, two clamping plates are symmetrically arranged on the rotating disc and slidably connected with a disc, compressed air bags are arranged on the opposite sides of the two clamping plates respectively, and air supply boxes are arranged on the opposite sides of the two clamping plates. The air supply boxes are communicated with the compressed air bags, an air suction pump is arranged at the top of the protection box, and the air suction pump communicates with the air supply boxes through air supply pipes; spring compression parts are arranged on the side wall, close to the clamping plates, of the protection box, the clamping plates are connected with the side wall of the protection box through the spring compression parts, the back face of the rotating disc is connected with the side wall of the protection box through a rotating assembly, the side wall, opposite to the front face of the rotating disc, of the protection box is movably connected with a movable door, a fan is arranged at the bottom of the protection box, and a temperature and humidity sensor is arranged in the protection box.

Owner:SHANGLUO UNIV

LED package transferring equipment convenient to use

InactiveCN109860373AMeet the placement conditionsImprove protectionSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical and Electronics engineeringR package

The invention discloses LED package transferring equipment convenient to use. The LED package transferring equipment comprises a first mounting board and a second mounting board, a plurality of sets of shaft sleeves are mounted on the opposite inner sides of the first mounting board and the second mounting board correspondingly, conveying rods are connected between the shaft sleeves on the inner sides of the first mounting board and the second mounting board, and a transition rod is mounted in the middle between the opposite inner sides of the first mounting board and the second mounting board. Through a first storage plate and a second storage plate, LED packages can be stored conveniently during being transferred, the internal spaces of the first storage plate and the second storage plate can be adjusted flexibly and thus are suitable for storing the different specifications and sizes of the LED packages, the LED packages are collected in a unified mode by a collecting mechanism, thus the LED packages are conveniently subjected to the next step of transferring in the later period, the buffer effect of buffer bottom feet is adopted in the equipment transferring period, thus the LED packages have good stability during being transferred, and damage of equipment shaking to the LED packages is avoided.

Owner:李栩

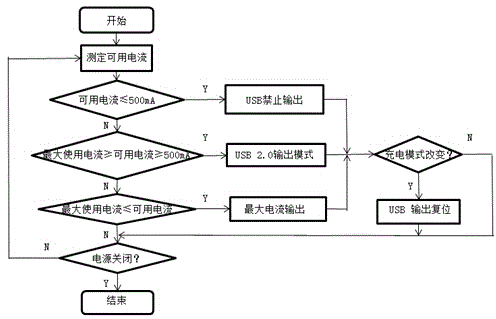

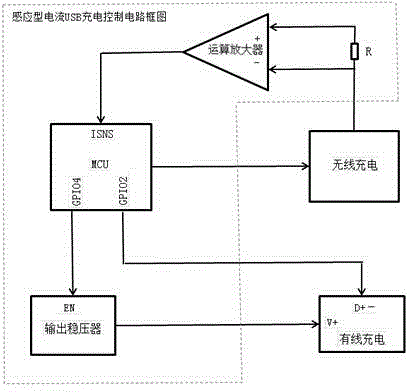

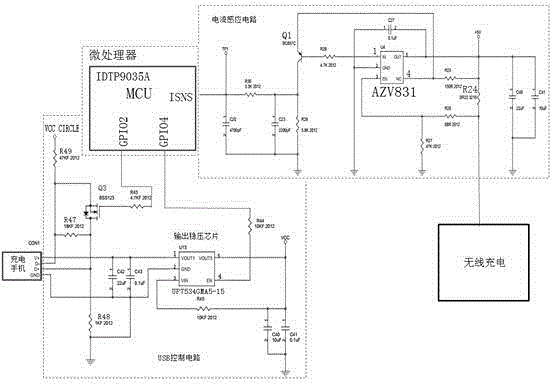

Electromagnetic induction and USB dual-port charging control circuit and control flow

InactiveCN105337333AAvoidance of damageAvoid running out of powerBatteries circuit arrangementsElectromagnetic wave systemCharge controlUSB

The invention provides an electromagnetic induction and USB dual-port charging control circuit and control flow. A limited input power source (Adaptor) is utilized, based on that normal use of basic devices is guaranteed, the power source technology used by a superfluous available current supply appending device is calculated. The flow is characterized by comprising a charging sheet, a wireless charger body and an auxiliary device, the auxiliary device comprises a power source output controller and a USB interface, the charger can realize wireless charging, so the charger can be used without repeatedly plugging and unplugging a charging plug, so the charger is prevented from being damaged by frequent plugging and unplugging.

Owner:ZHONGHUAN TELCOM TECH

Heat dissipation and insect repelling device for 5G communication cabinet

InactiveCN114190051AImprove cooling effectSpeed up the flowCasings/cabinets/drawers detailsAnimal repellantsEngineeringInsect repellants

The invention discloses a heat dissipation and insect repelling device for a 5G communication cabinet, and the device comprises a cabinet body, the upper end of the cabinet body is provided with a mounting box, the mounting box is internally provided with a rectangular cavity, the rectangular cavity is internally vertically provided with a rotating rod, and the two ends of the rotating rod are rotatably connected with the inner bottom and the inner top of the rectangular cavity. The lower end of the rotating rod extends into the cabinet body and is provided with a rotating connector, a fan is installed on the left side of the cabinet body, the air inlet end of the fan is communicated with the interior of the cabinet body through an air inlet pipe, the air outlet end of the fan is communicated with the rotating connector through an air outlet pipe, a vertical cavity is formed in the rotating rod, and the lower end of the vertical cavity is communicated with the upper end of the rotating connector. A plurality of arc-shaped pipes are arranged on the outer wall of the rotating rod in the circumferential direction of the rotating rod. According to the device, gas in the communication cabinet can be actively replaced, heat dissipation in the communication cabinet is accelerated, sound generated by impact is used for driving and reminding a slightly large animal, meanwhile, insect repellant can be evenly sprayed, and insects and the like are prevented from entering the communication cabinet.

Owner:陈伟财

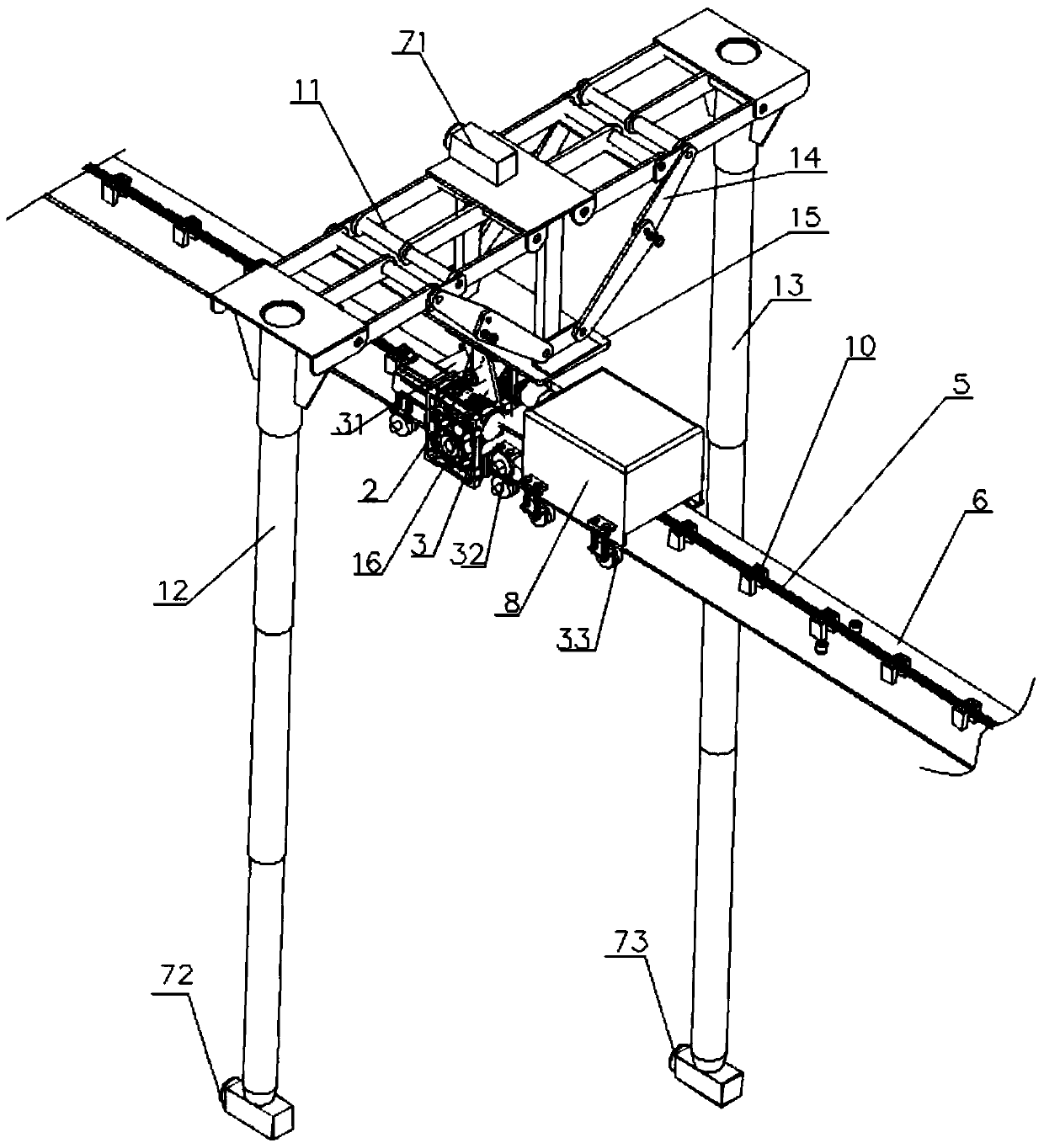

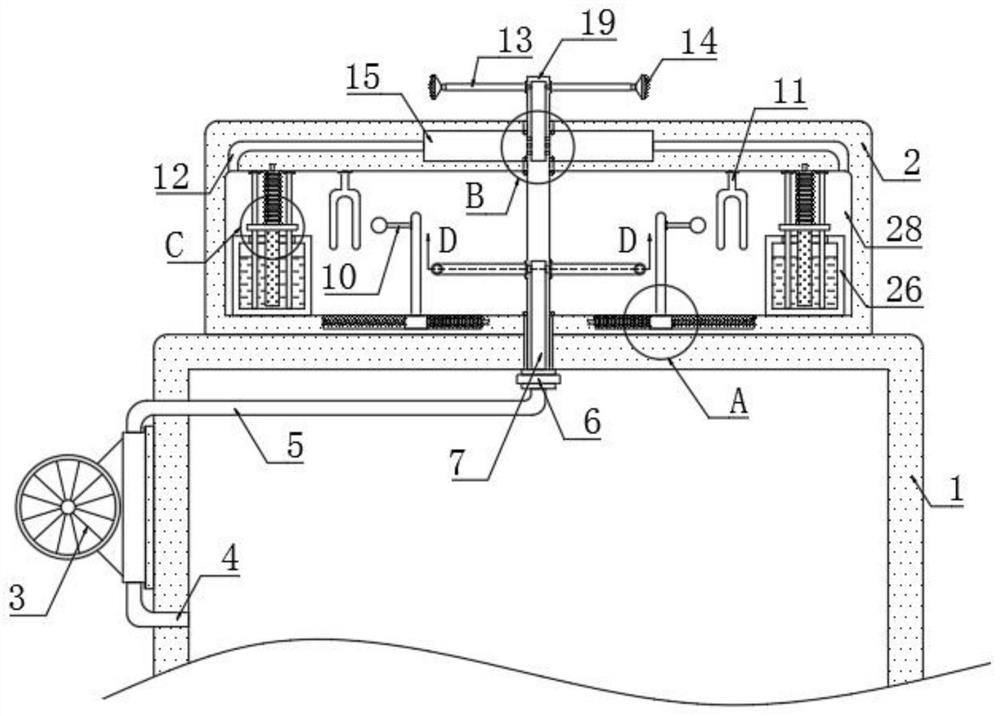

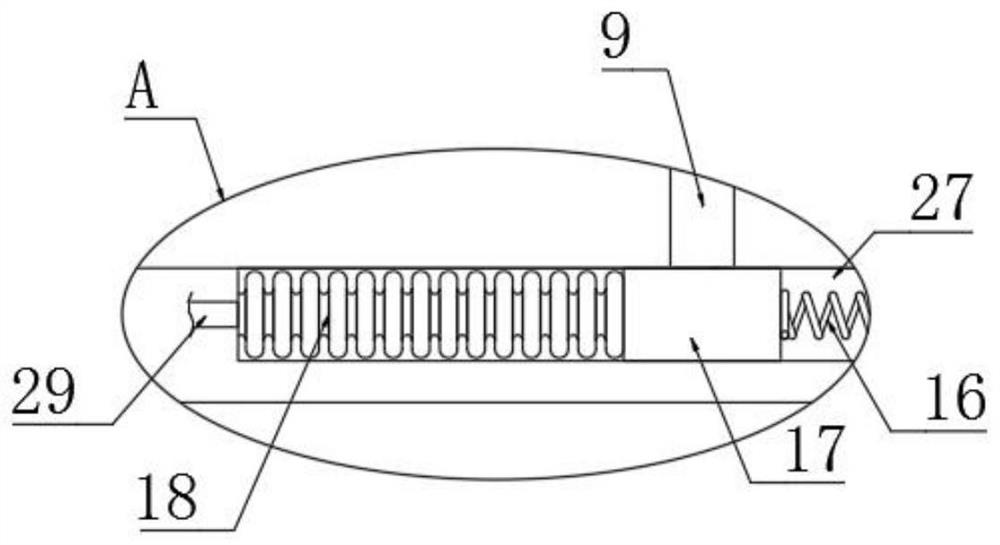

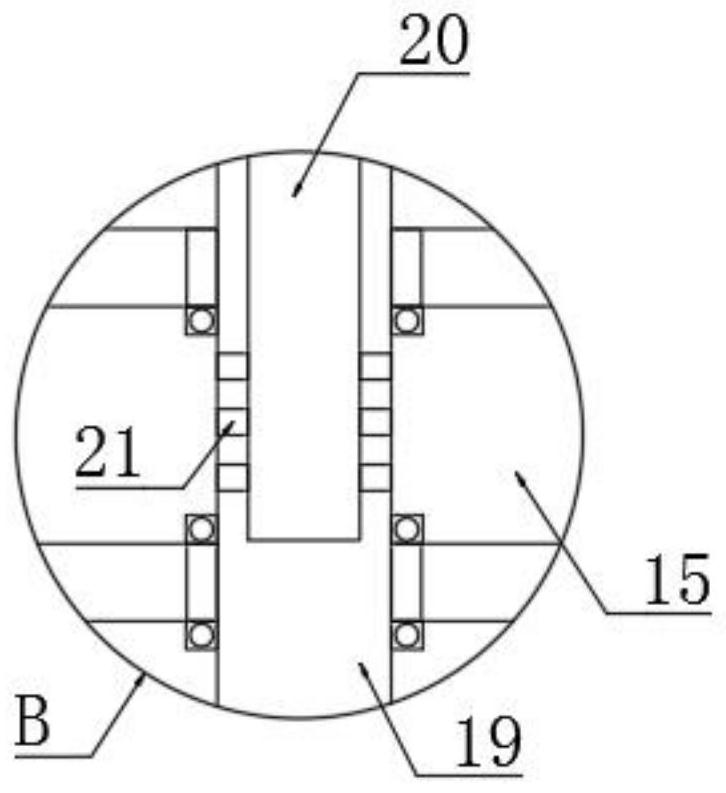

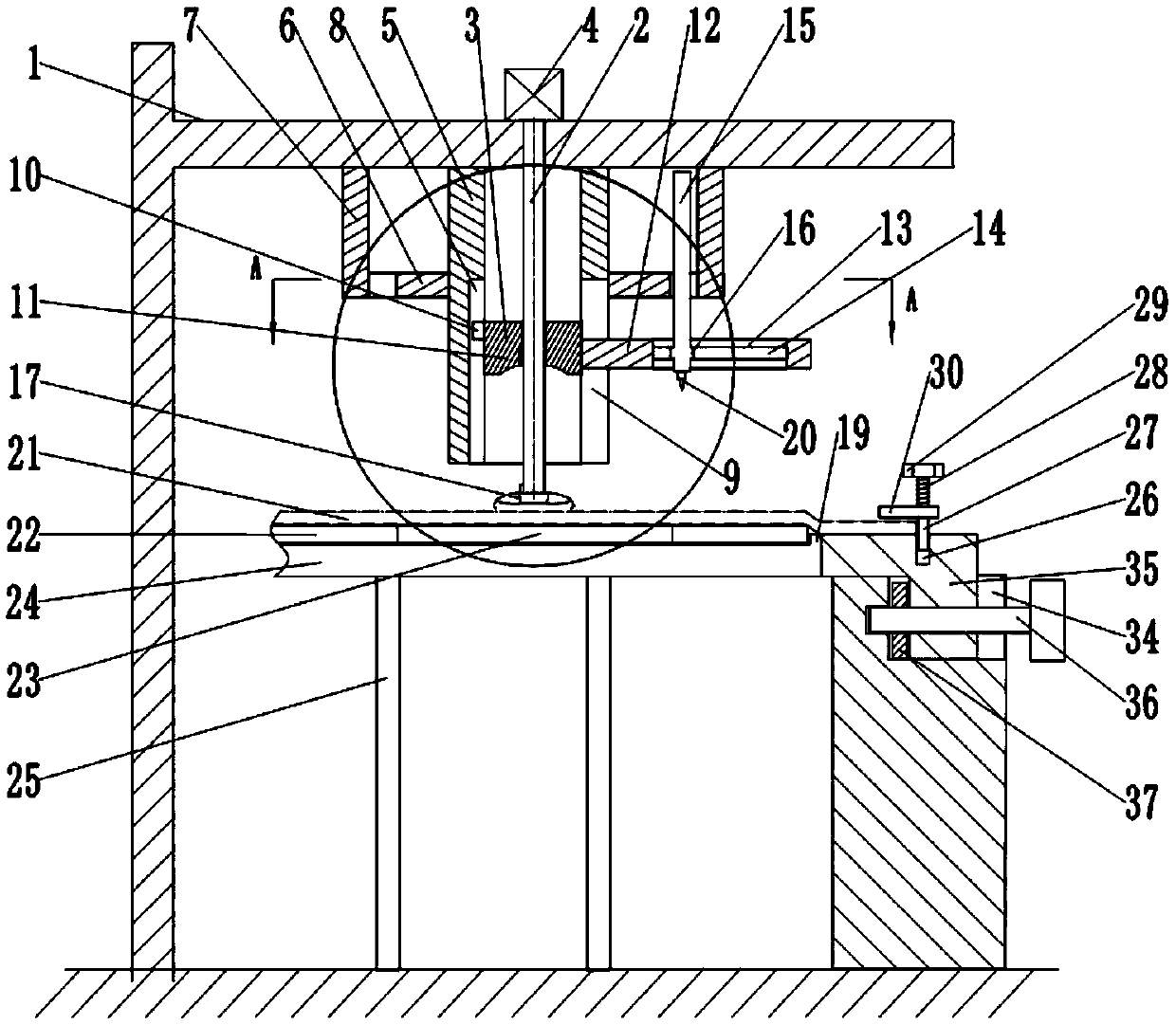

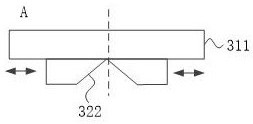

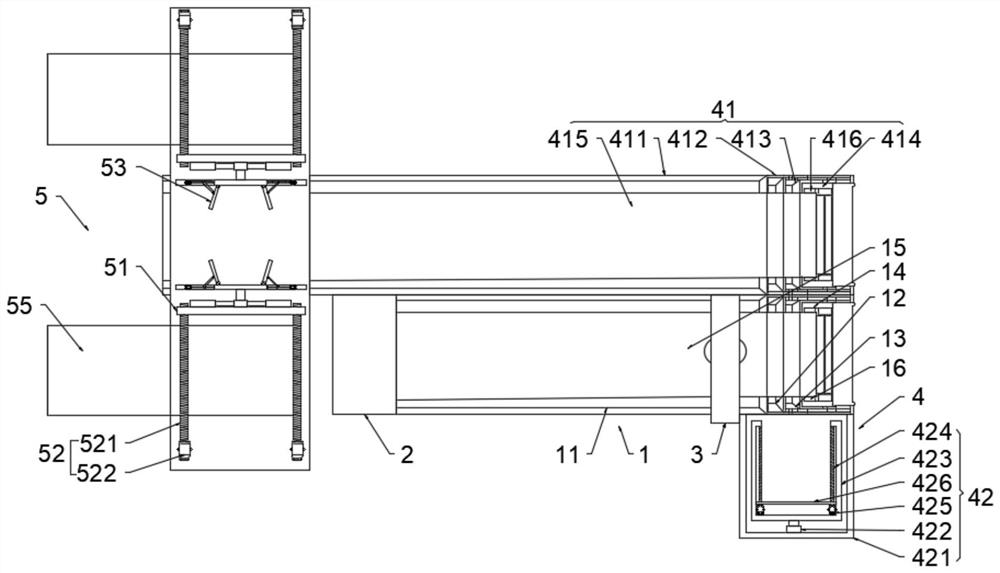

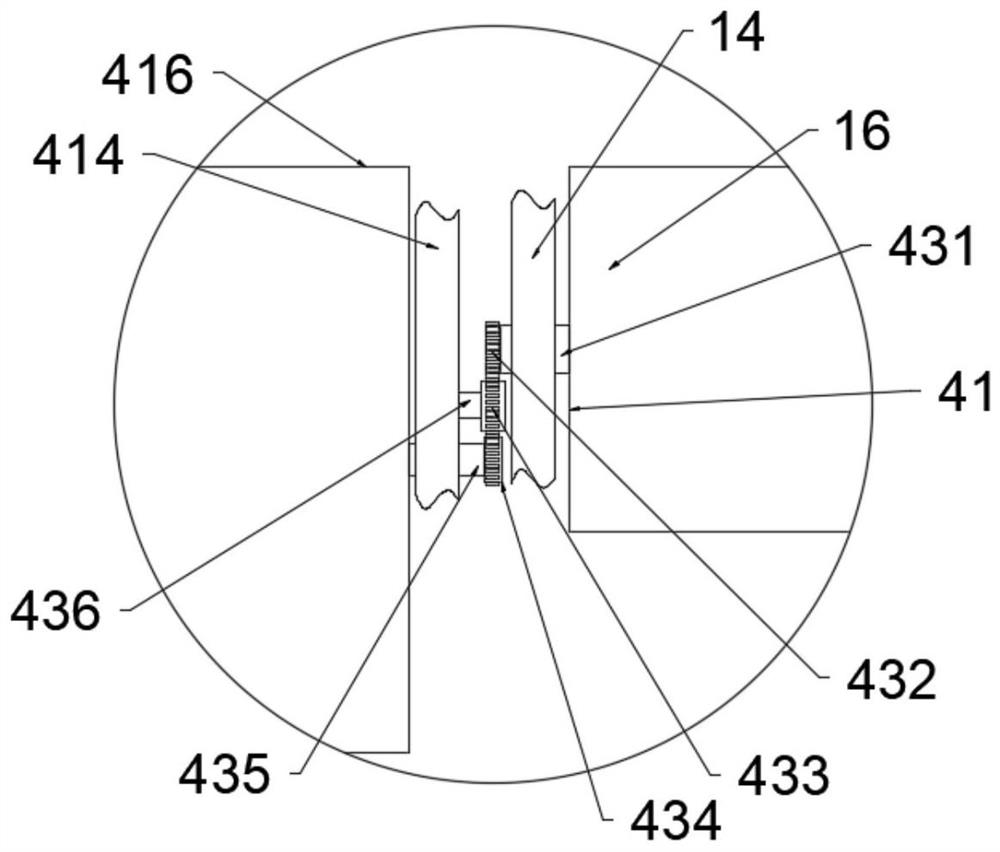

Screen stretching method for platemaking

The invention relates to platemaking equipment, in particular to a screen stretching method for platemaking. The screen stretching method comprises the steps that (1), a screen is pre-fixed, wherein the four sides of the screen are clamped and stretched to four directions so that the four sides of the screen are located at the same horizontal height and the tension on each position of the screen is uniformly distributed; (2), tension degree is adjusted to make the tensioning force of the screen be uniformly distributed; (3), screen sticking glue is adopted for fixing the screen, and specifically, the screen sticking glue used for fixing the screen on a screen frame coats the screen frame; (4), the screen and a steel mesh are separated, wherein an upward micro-shape change is generated on the screen located above the steel mesh, so that a certain gap is formed between the screen and the steel mesh, and a blade can conveniently cut the screen; and (5), the screen is cut, wherein the blade is started and made to cut the screen along the inner circumference of the screen sticking glue, so that the screen right above the steel mesh is cut off. According to the scheme, the screen stretching method capable of automatically and rapidly cutting the screen flat is provided.

Owner:宁波隆锐机械制造有限公司

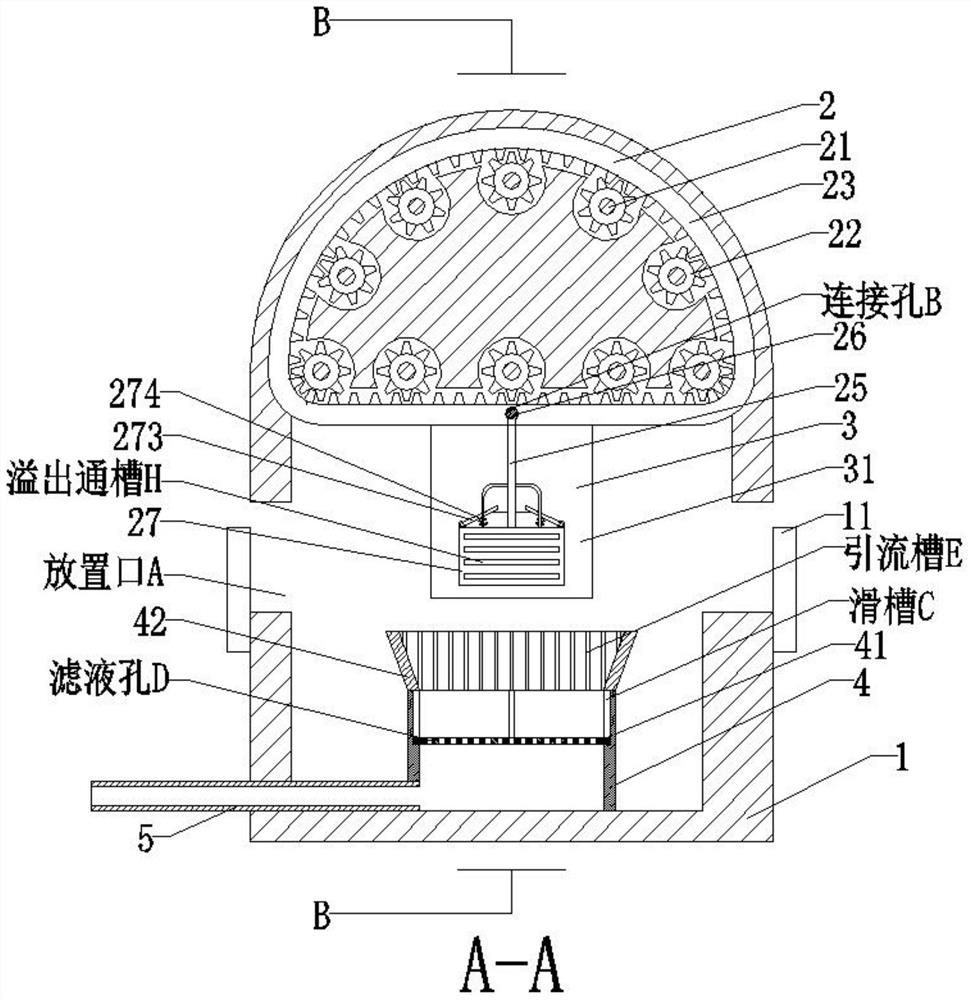

Pretreatment hazardous waste storage bin

ActiveCN113368933AIncrease lossVulnerable to health hazardsGrain treatmentsProcess engineeringBattery electrolyte

The invention relates to a pretreatment hazardous waste storage bin. The pretreatment hazardous waste storage bin comprises a bin body, a conveying assembly, a crushing assembly, a collecting box and a flow guide pipe, wherein the conveying assembly is arranged above the bin body, the crushing assembly is arranged on the outer side of the conveying assembly, the crushing assembly is arranged on the inner wall of the bin body, the collecting box is arranged below the crushing assembly, the flow guide pipe is connected to the collecting box, and the flow guide pipe penetrates through the bin body. According to the pretreatment hazardous waste storage bin, the problems existing in the recovery treatment of waste battery electrolyte can be solved, wherein the problems are that a, when existing waste battery electrolyte is subjected to recovery treatment, a battery is often crushed in a manual hammering mode, the crushing efficiency is low, and the human health is prone to being harmed; and b, when the existing waste battery electrolyte is poured into the collecting box, the situation that the electrolyte splashes frequently occurs, the splashed electrolyte drops outside a collecting vessel, and the loss of the electrolyte is increased.

Owner:佛山市铂朗环境科技有限公司

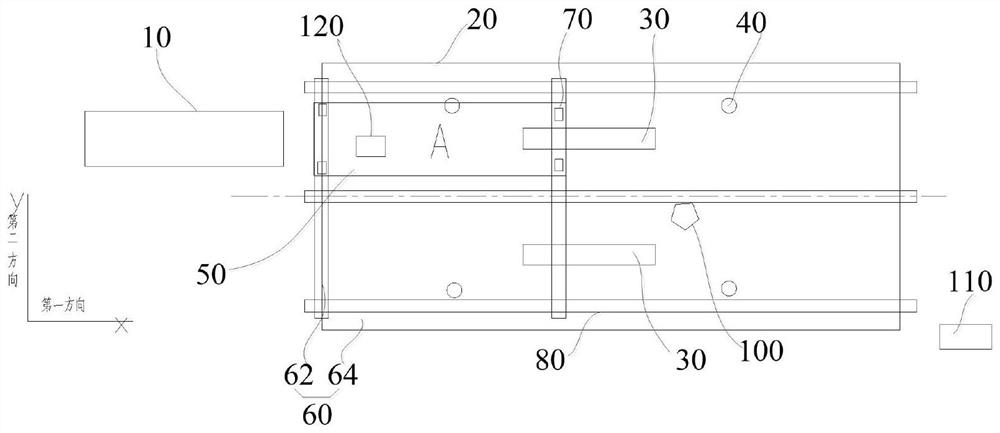

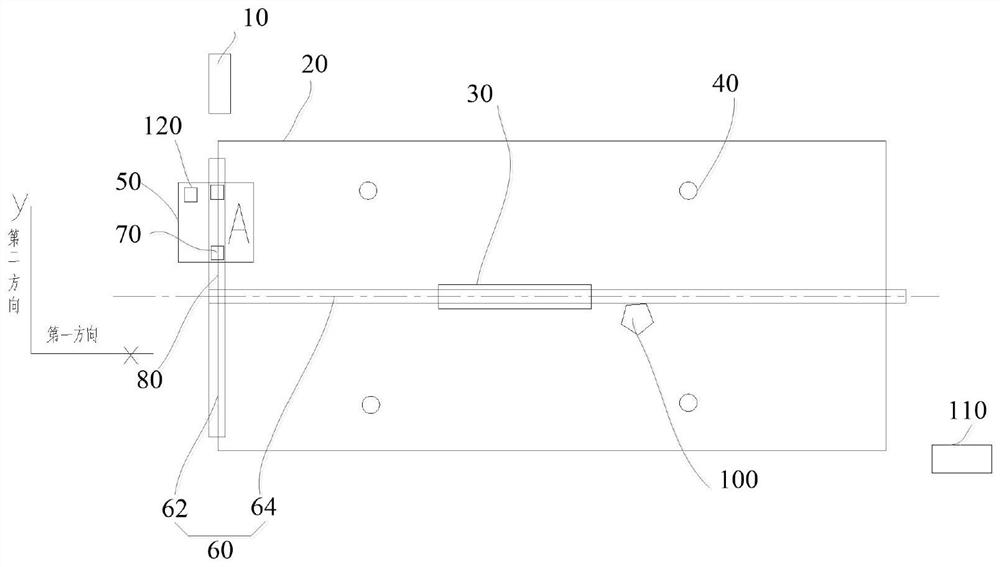

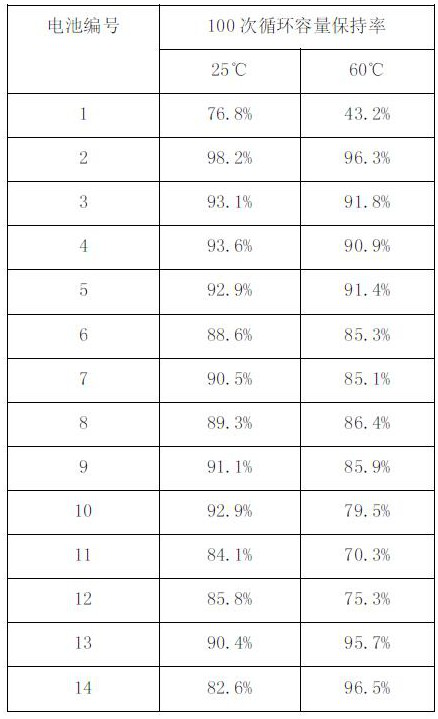

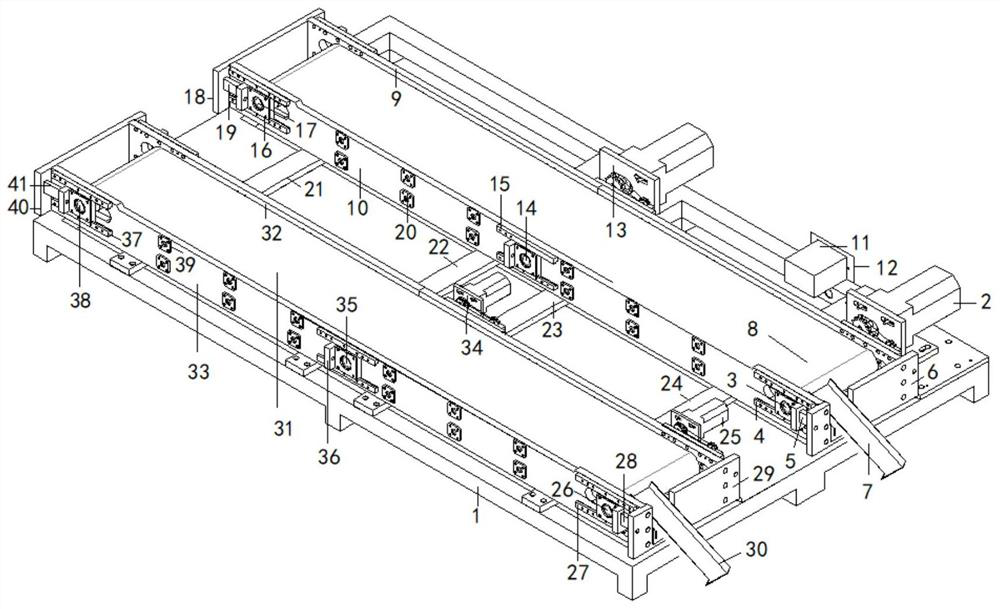

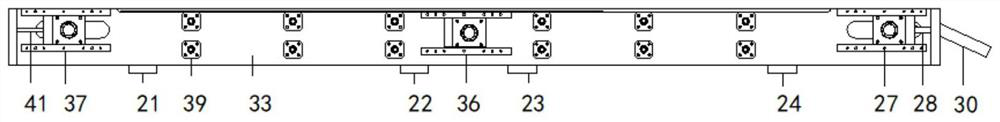

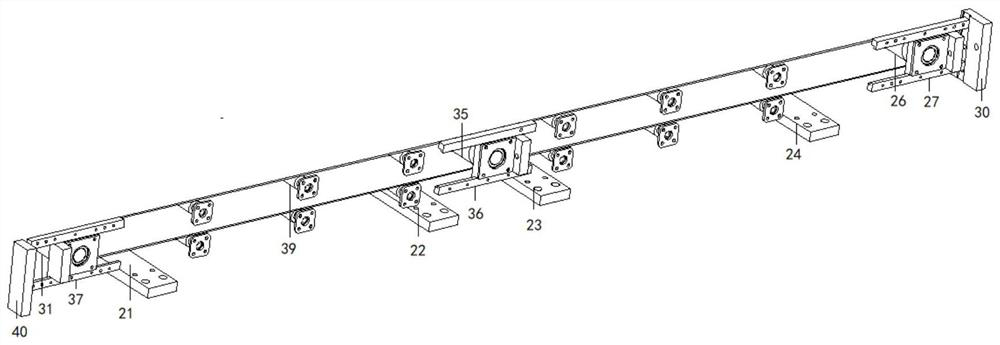

Material receiving system and asphalt mixing plant

InactiveCN111749080ARealize automatic feedingAvoidance of damageRoads maintainenceControl systemAgricultural engineering

The invention provides a material receiving system and an asphalt mixing plant. The material receiving system comprises a mobile platform, a control system and an image recognition device, wherein themobile platform is located below a material receiving port and used for bearing a material receiving vehicle; the control system is connected with the mobile platform and controls the mobile platformto move; and the image recognition device is connected with the control system, and the image recognition device is used for shooting and recognizing the charging condition in the material receivingvehicle and sending the recognized information to the control system so as to enable the control system to adjust the material receiving position. According to the technical scheme of the invention, in the material receiving process of the material receiving vehicle, the image recognition device can judge the loading position in a hopper of the material receiving vehicle, when uneven loading occurs in the hopper, the image recognition device sends information to the control system, and the control system can adjust the material receiving position of the material receiving vehicle conveniently,so that the situation that the hopper is partially filled with materials and overflows is avoided, and thus the loading and transporting efficiency of the material receiving vehicle is guaranteed.

Owner:SANY AUTOMOBILE MFG CO LTD

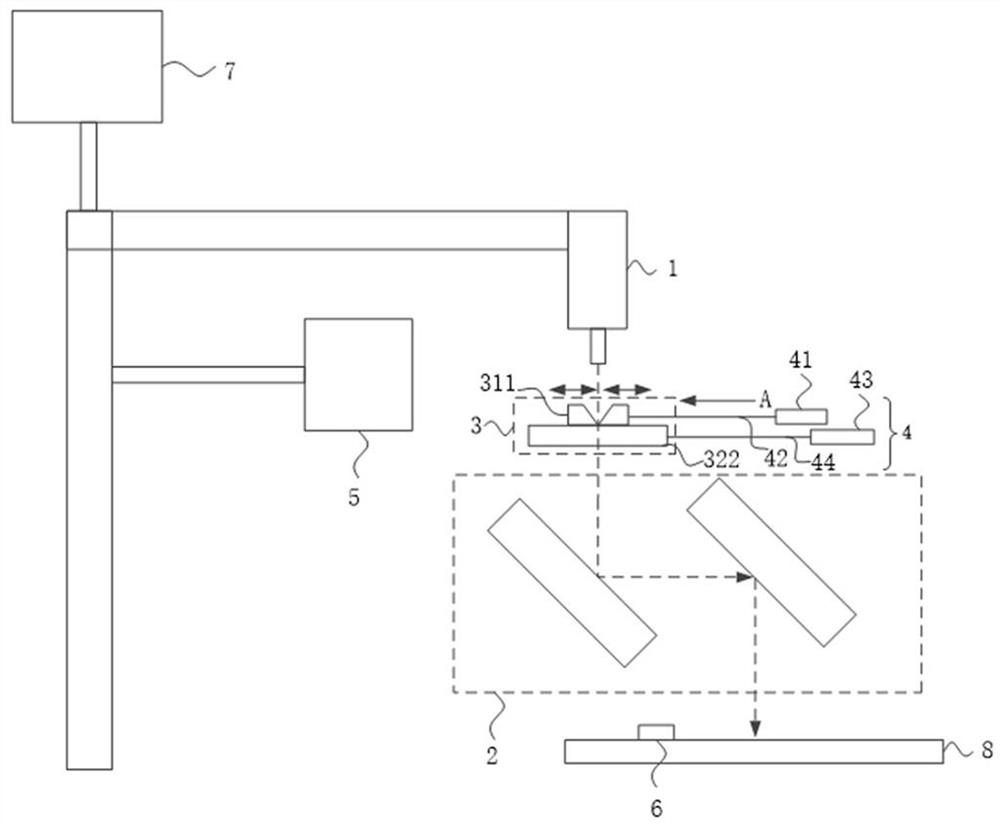

Laser repair device

InactiveCN111922515AChange spot sizeNarrow down the shooting rangeLaser beam welding apparatusLaser transmitterLight guide

The invention provides a laser repair device. The laser repair device comprises a laser emitter, a light guiding assembly and a slit structure. The slit structure comprises a first group of light blocking sheets and a second group of light blocking sheets which are overlaid on the laser emitting path. The first group of light blocking sheets comprises two first light blocking sheets which are located on the same plane and can oppositely move. The second group of light blocking sheets comprise two second light blocking sheets which are located on the same plane and can oppositely move. The twofirst light blocking sheets form a first slit. The two second light blocking sheets form a second slit. The first slit and the second slit intersect. The intersection point of the first slit and the second slit is located on the laser emitting path. The slit structure is used for allowing the laser beam emitted by the laser emitter to pass through and controlling the radial dimension of the laserbeam. The laser repairing device can effectively control the size of the spot of the laser, improve the repair accuracy and prevent pixels around a repaired area from being damaged.

Owner:苏州科韵激光科技有限公司

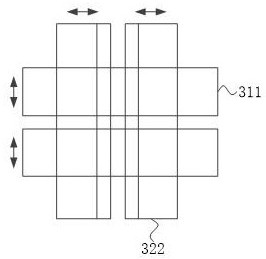

Lithium battery electrolyte additive, electrolyte and lithium battery

ActiveCN112448038AImprove circulation capacityEvenly dispersedSecondary cellsOrganic electrolytesPhysical chemistryUrethane acrylate

The invention belongs to the technical field of batteries, and particularly relates to a lithium battery electrolyte additive, an electrolyte and a lithium battery. The lithium battery electrolyte additive is prepared by the following method: (1) uniformly mixing urethane acrylate and an acrylic monomer; (2) adding paraffin and diatomite into the mixture treated in the step (1), and uniformly mixing; (3) adding 2, 2-dimethoxy-2-phenyl acetophenone and graphite powder into the mixture obtained in the step (2), uniformly mixing, and granulating; (4) adding a lithium halide diatomite graphite mixture into the product treated in the step (3), and uniformly mixing; and (5) curing under ultraviolet irradiation to obtain the lithium battery electrolyte additive. The lithium battery electrolyte additive can significantly improve the cycle capacity retention rate of the battery.

Owner:贵州光瑞新能源科技有限公司

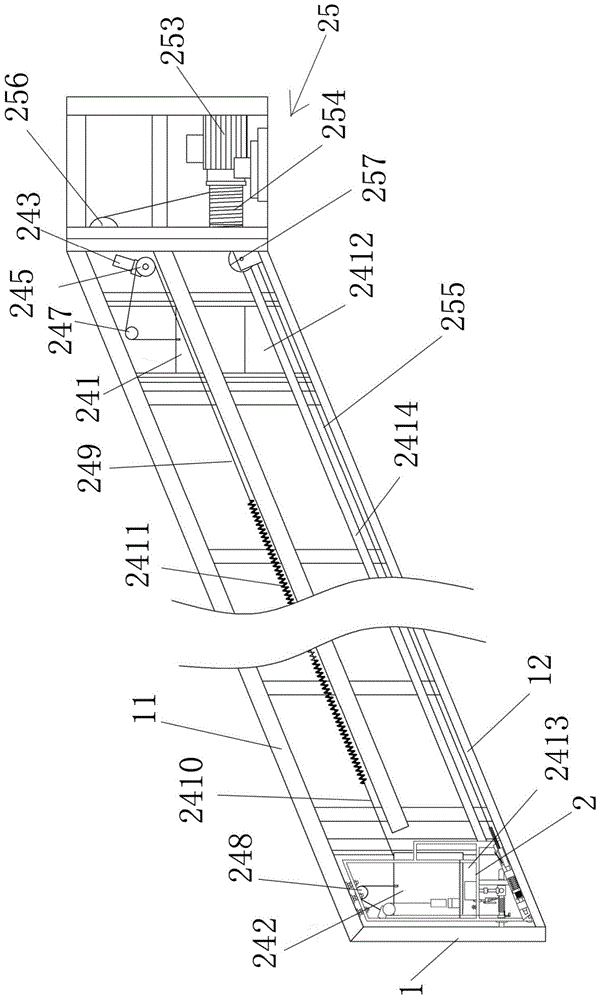

Mining belt conveyor with automatic adjusting function and based on Internet-of-Things technology

The invention discloses a mining belt conveyor with an automatic adjusting function and based on the Internet-of-Things technology. The mining belt conveyor comprises a belt conveyor body, a conveyingbelt is arranged in the belt conveyor body, multiple supporting legs are connected to the side, away from the conveying belt, of the belt conveyor body, and an angle adjusting mechanism is connectedto the end, away from the belt conveyor body, of the conveying belt. The angle adjusting mechanism comprises an adjustable support, a connecting rotating shaft is connected between the adjustable support and the belt conveyor body, a protective shell is arranged on the outer side of the connecting rotating shaft, and a turning wheel is connected to the side, close to the conveying belt, of the protective shell. The corresponding angle adjusting mechanism is additionally arranged on the mining belt conveyor so that the mining belt conveyor can perform corresponding angle adjustment according tothe actual use condition, the convenience of the mining belt conveyor in the use process is remarkably improved, the labor intensity of workers for adjusting the mining belt conveyor is greatly relieved, the service life of the mining belt conveyor is prolonged, and the use cost of the mining belt conveyor is reduced.

Owner:徐州市新龙腾矿山机械制造有限公司

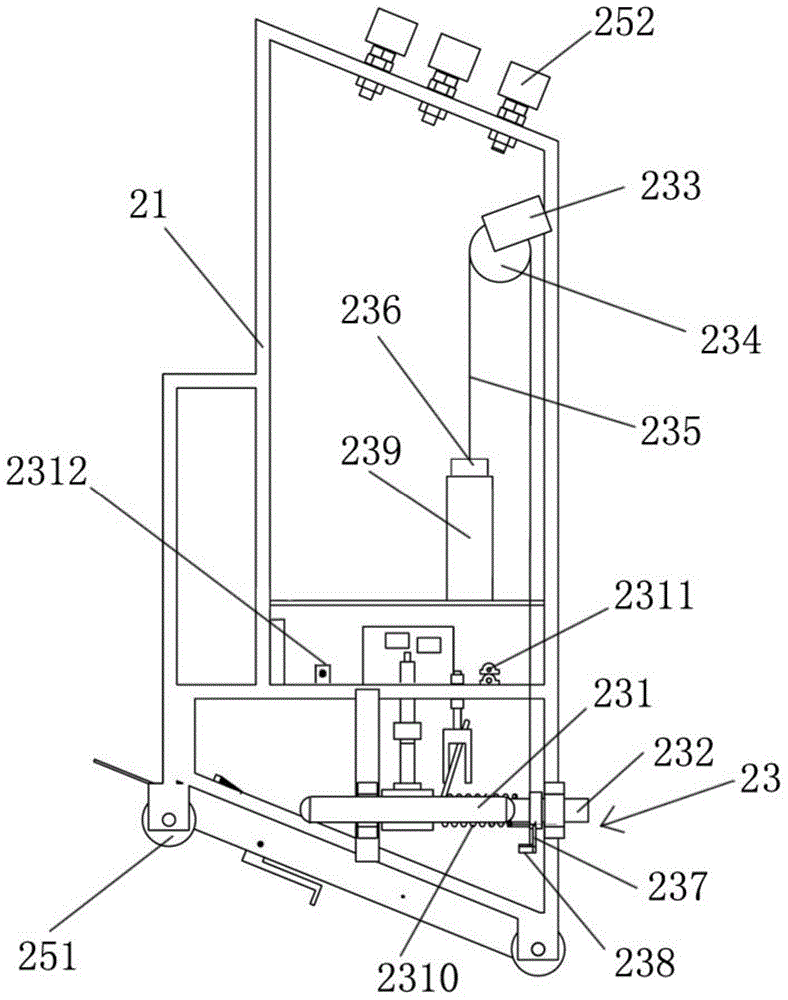

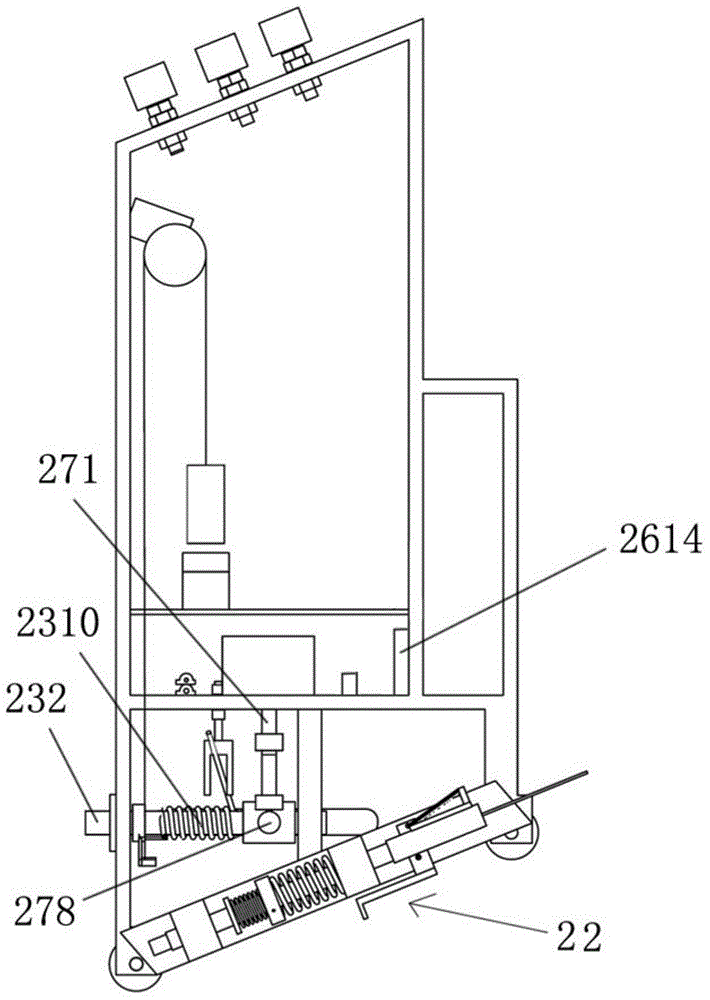

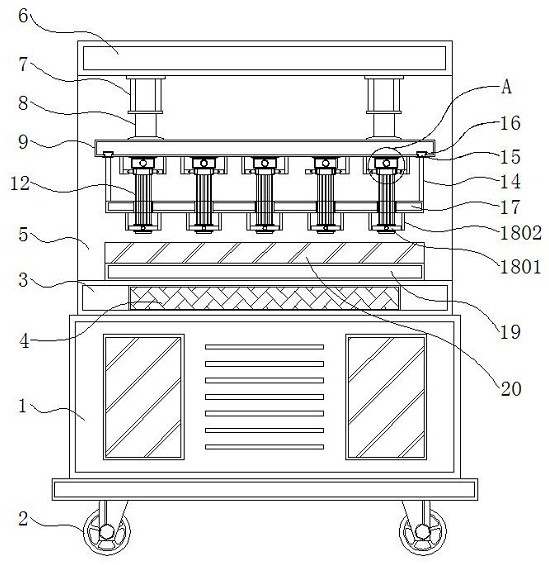

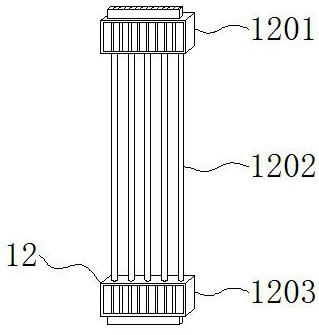

Convenient-to-adjust connection terminal power-on detection device with safety protection structure

InactiveCN112147456AGood up and downEasy to detectElectric connection testingMeasurement instrument housingEngineeringStructural engineering

The invention discloses a convenient-to-adjust connection terminal power-on detection device with a safety protection structure, and relates to the technical field of connection terminal detection. The device comprises a machine body, a connection terminal mechanism, a first positioning mechanism and a second positioning mechanism, wherein moving wheels are arranged on the two sides of the lower part of the machine body; a hollow table is fixed above the machine body; a power connection box is arranged in the hollow table; a back plate is welded on the rear side of the upper part of the hollowtable; a top plate is fixed above the back plate; an air cylinder is arranged on the lower side of the front part of the top plate; a piston rod is arranged below the air cylinder; a lifting plate isfixed below the piston rod; and a mounting box is fixed on the lower side of the lifting plate. The device has the beneficial effects that the device can be arranged on the outer side of the upper part of a power-on test board through a protective outer frame of a transparent structure to carry out safety protection on the power-on test board, and meanwhile, the protective outer frame is made ofan insulating material, so that the risk of electric shock caused by the fact that an operator approaches the power-on test board can be avoided.

Owner:重庆数智源智能装备科技有限公司

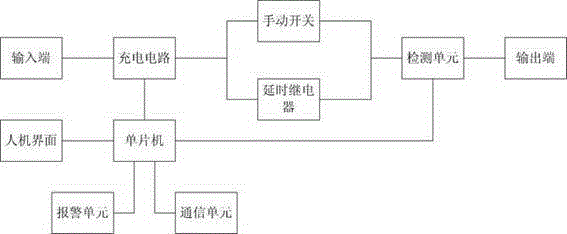

Intelligent electrical vehicle charger with communication function and alarm function

InactiveCN105048552AImprove performanceExtended service lifeBatteries circuit arrangementsElectric powerMicrocontrollerMicrocomputer

The invention discloses an intelligent electrical vehicle charger with a communication function and an alarm function. The intelligent electrical vehicle charger mainly comprises a single chip microcomputer, an input end, a charging circuit, a switch unit, a detection unit and an output end, wherein the input end, the charging circuit, the switch unit, the detection unit and the output end are sequentially connected with one another; the single chip microcomputer is respectively connected with the charging circuit and the detection unit; the switch unit comprises a manual switch and a time-delay relay; the manual switch is respectively connected with the charging circuit and the detection unit; the time-delay relay is respectively connected with the charging circuit and the detection unit; and the single chip microcomputer is also respectively connected with a communication unit, an alarm unit and a man-machine interface. According to the intelligent electrical vehicle charger, the charging starting time can be independently selected according to the user requirements; and the intelligence electrical vehicle charger can be independently powered off after fully charging, so as to realize intelligent control. Meanwhile, one manual switch is added; the manual switch can be adopted by the user according to the requirements; and the intelligent electrical vehicle charger can immediately charge and stop charging, so that the intelligent electrical vehicle charger is relatively flexible and convenient to use; and by a dual-switch mode, the charger can continue to work when the other switch is damaged, so that the stability of the charger is increased.

Owner:南京译海网络科技股份有限公司

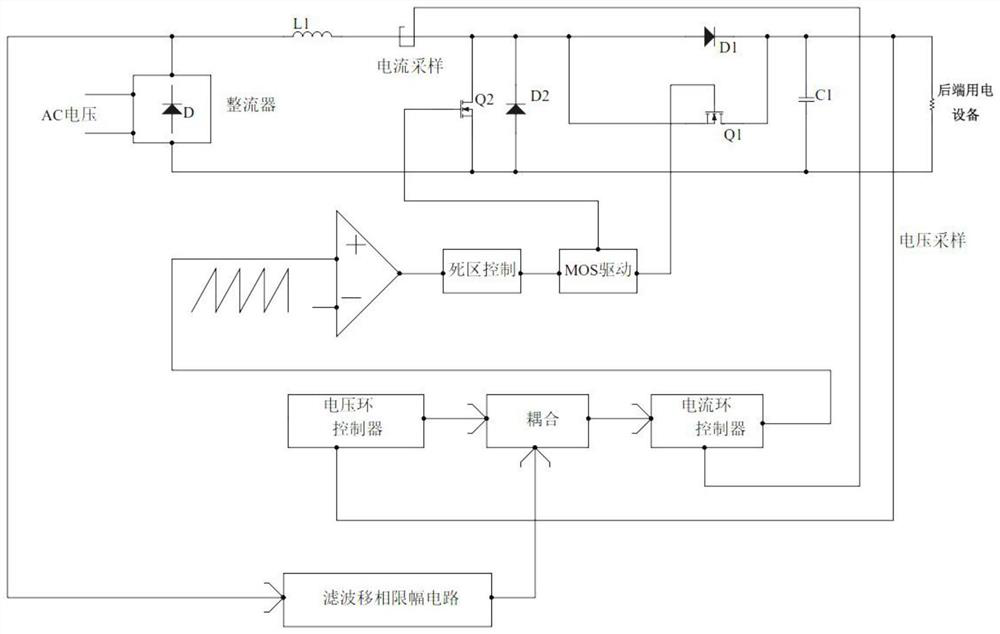

Ripple reduction circuit based on input feedforward and loop control and coating power supply

PendingCN114172355AAvoidance of damageGuaranteed to workEfficient power electronics conversionDc-dc conversionUltra high speedLoop control

The invention relates to a ripple reduction circuit based on input feedforward and loop control. The circuit comprises a rectifier, a voltage loop control circuit, a filtering phase-shifting amplitude limiting circuit and a booster circuit, the output end of the rectifier is connected with the input end of the filtering phase-shifting amplitude limiting circuit; a first coupling voltage output by the voltage loop control circuit is coupled with a second coupling voltage output by the filtering phase-shifting amplitude limiting circuit to obtain a coupling voltage signal; processing the coupling voltage signal through a current loop controller to obtain a dynamic voltage signal; the filtering phase-shifting amplitude limiting circuit comprises a differential extraction circuit, a filtering phase-shifting circuit, an amplitude limiting circuit and a filtering phase-shifting coupling circuit; the voltage loop control circuit comprises a voltage loop controller and a voltage loop coupling circuit; and the output end of the current loop controller is connected with the pulse width modulation signal generator. According to the scheme, low-frequency ripples can be restrained, the system can achieve ultra-high-speed response, the high-performance requirement is met, and the situation that rear-end electric equipment is damaged is avoided.

Owner:固赢科技(深圳)有限公司

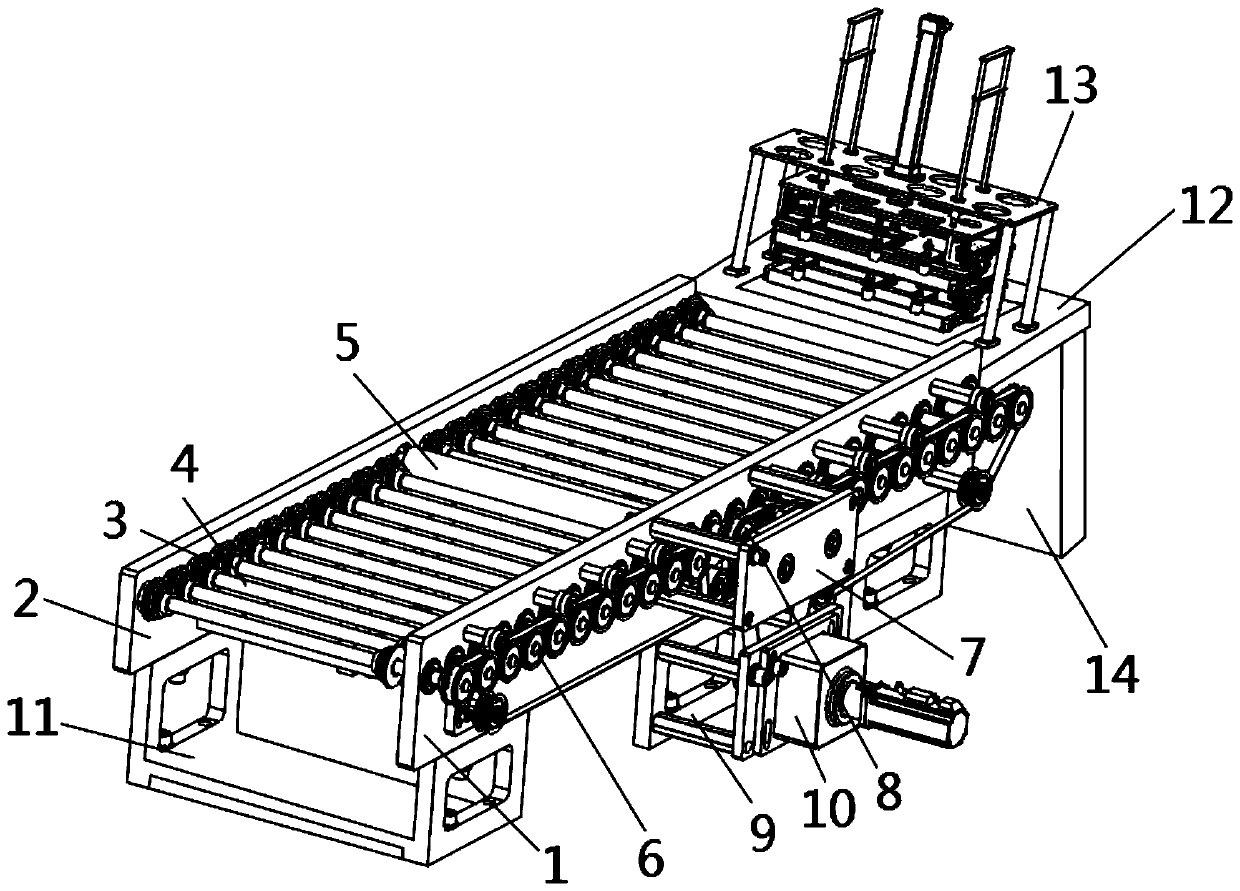

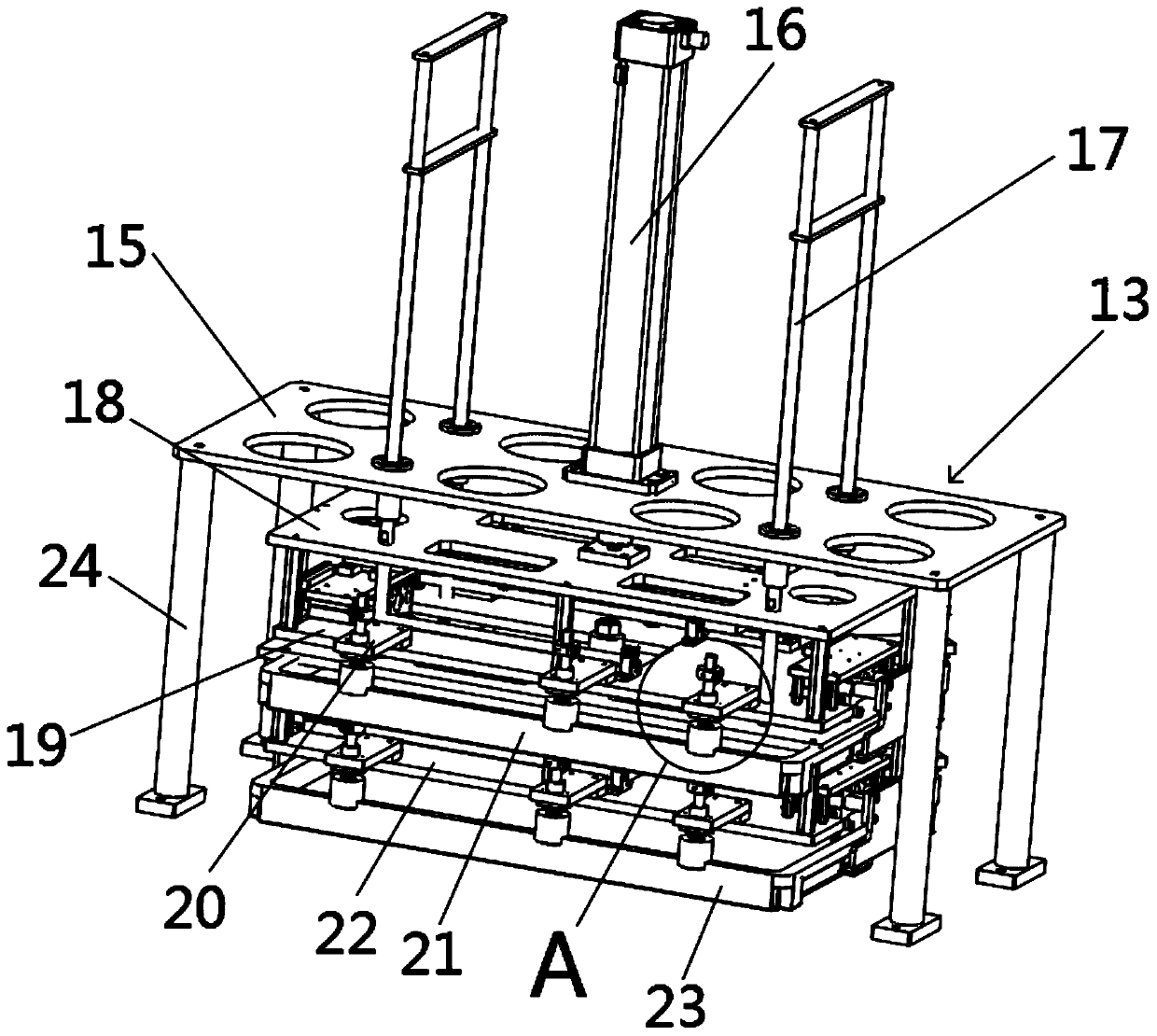

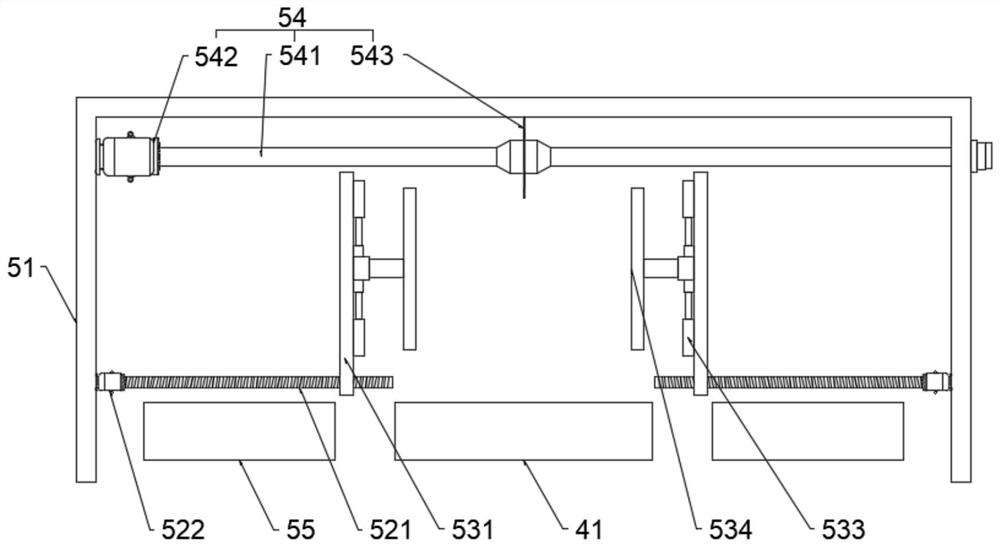

Speed regulatable and tightenable express transfer assembly line and application method

ActiveCN113148560AAvoidance of damagePlay a role in speeding upConveyorsControl devices for conveyorsAssembly lineStructural engineering

The invention discloses a speed regulatable and tightenable express transfer assembly line which comprises a base, wherein the other side of the upper end of the base is connected with a first driving mechanism, one side of the first driving mechanism is connected with a first roller, one side of the first roller is connected with a first fixing mechanism, one side of the first fixing mechanism is connected with a first telescopic block, one side of the first telescopic block is connected with a first concave baffle plate, one end of the first concave baffle plate is connected with a first receiving groove and the other end of the first concave baffle plate is connected with a first conveyor belt. By designing the first driving mechanism, the second driving mechanism, a third driving mechanism, a fourth driving mechanism, the first conveyor belt, a second conveyor belt, a first sliding wheel, a second sliding wheel, six rollers, six fixing mechanisms and four telescopic blocks, the speeds of the first conveyor belt and the second conveyor belt can be regulated, such that the conveying speeds of the first conveyor belt and the second conveyor belt can be improved or the speeds are reduced, and therefore, the express transfer time is saved to a certain extent.

Owner:上海申雪供应链管理有限公司

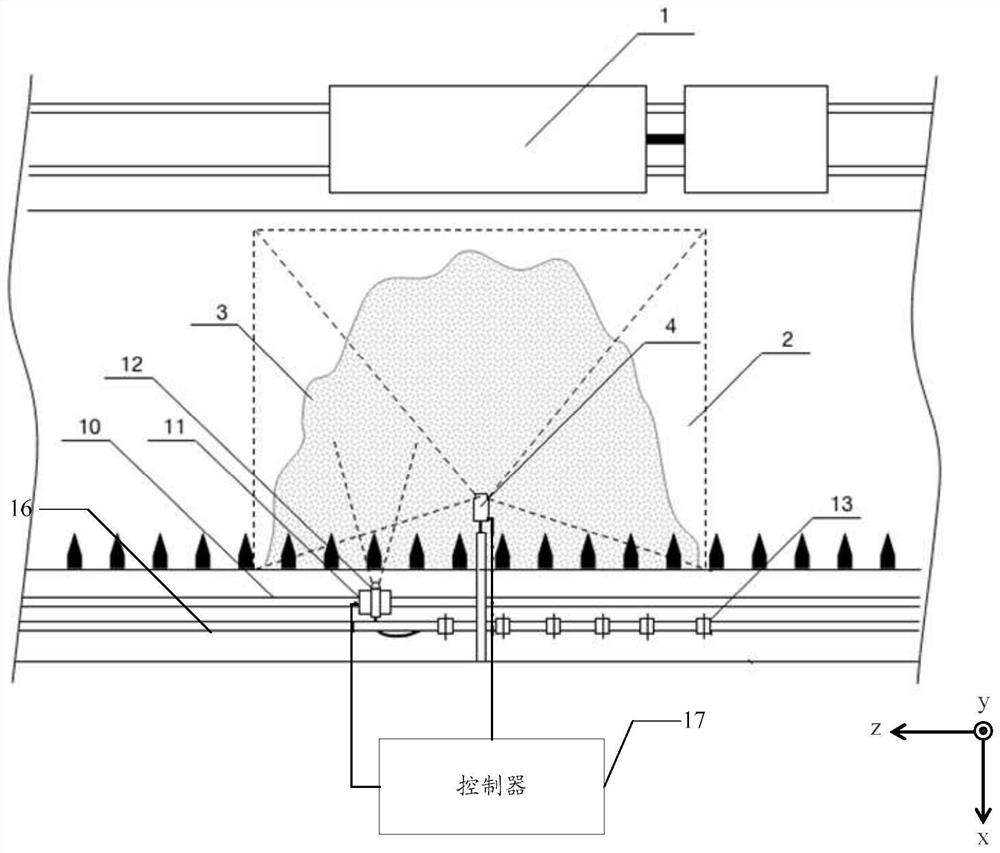

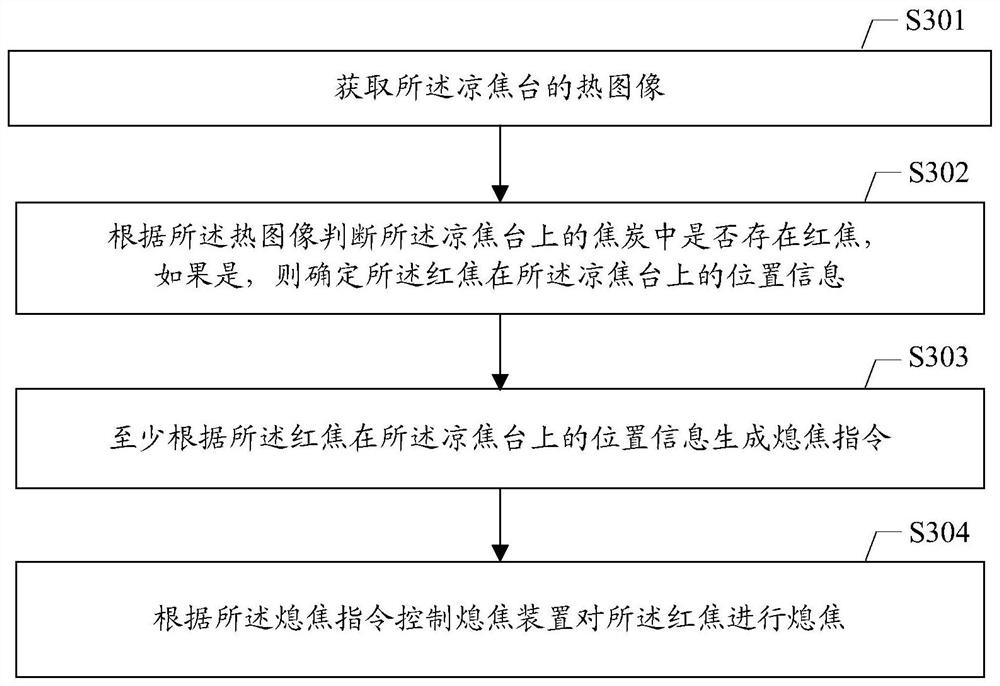

Coke quenching control method and device for coke cooling table, terminal and coke quenching system

PendingCN114133940AAvoid missed judgmentsAbnormal detection in timeCoke quenchingCoke oven safety devicesMetallurgyProcess engineering

The invention discloses a coke quenching control method and device for a coke cooling table, a terminal and a coke quenching system. The method comprises the following steps: acquiring a thermal image of the coke cooling table; judging whether red coke exists in the coke on the coke cooling table or not according to the thermal image, and if yes, determining the position information of the red coke on the coke cooling table; generating a coke quenching instruction at least according to the position information of the red coke on the coke cooling table; and controlling the coke quenching device to quench the red coke according to the coke quenching instruction. According to the scheme of the invention, the red coke on the coke cooling table can be comprehensively subjected to secondary coke quenching.

Owner:HUA DATA TECH (SHANGHAI) CO LTD

Automatic assembling device for express sorting telescopic machine

PendingCN114455275AEasy to reassembleReduce express delivery lossControl devices for conveyorsSupporting framesSoftware engineeringAssembly machine

The invention discloses an automatic assembling device for an express sorting extendable conveyor, which comprises an extendable conveyor, an assembling machine, a detecting mechanism, a recycling mechanism and an unpacking mechanism, the assembling machine is used for packaging and strip pasting of expresses, and the detecting mechanism is used for detecting package damage and strip pasting completeness of warehoused express packages. And the recycling mechanism is used for conveying unqualified express packages back to the unpacking mechanism according to the detection result of the detection mechanism, and the unpacking mechanism is used for disassembling packages of the express packages recycled by the recycling mechanism. The detection mechanism is arranged at the discharging end of the telescopic machine, and the express packages are conveyed back to the unpacking mechanism through the recycling mechanism when the detection mechanism detects that the packages or the joint strips are abnormal, so that the situation that the express packages are damaged in the transportation process of the express sorting telescopic machine is avoided; and outer packages of the express packages are disassembled and recycled through the unpacking mechanism, reassembly of the express packages and recycling of damaged packages are facilitated, and the situation of express package damage is reduced.

Owner:芜湖市创赫钢结构有限公司

A method of using a wire mounting seat

InactiveCN112234568BAchieve fasteningAvoid pulling and disconnectingAnimal repellantsSpatial arrangements/dispositions of cablesSnow removalSnowpack

The present invention discloses a wire installation seat and its usage method, including the installation board, which is opened in the installation board with four pores with upper and lower openings.Settings, the installation board is set with two bird -removing bird -removing bird -repellent devices with the center vertical line of the installation board.The two emergency drop devices are set up between reserved wires between the emergency drop device, which realizes the tightening of the wires, and it can fall off when the wire rod is dumped.As a result, when the power -off is also realized, when the snow falls on the wire, the snow on the wire shakes off the wire by shaking, avoiding excessive snow, causing damage to the damage to the wires and telephone poles.

Owner:李惠铭

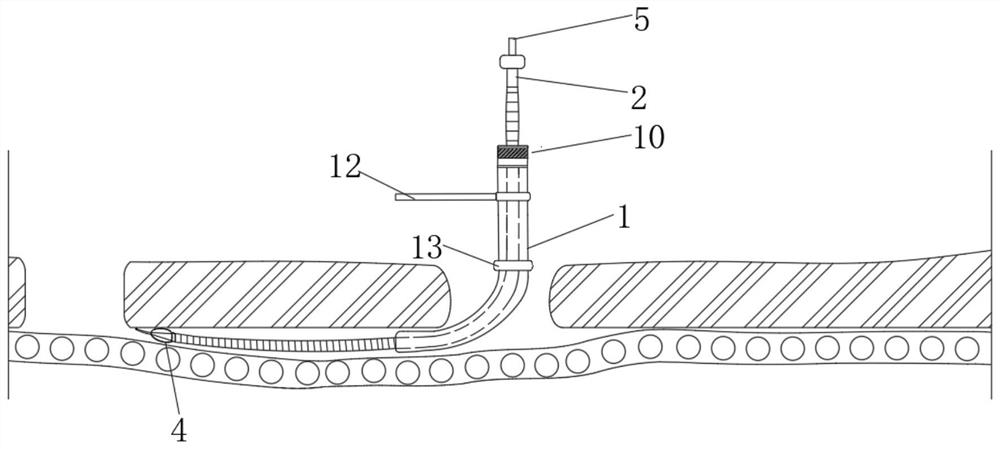

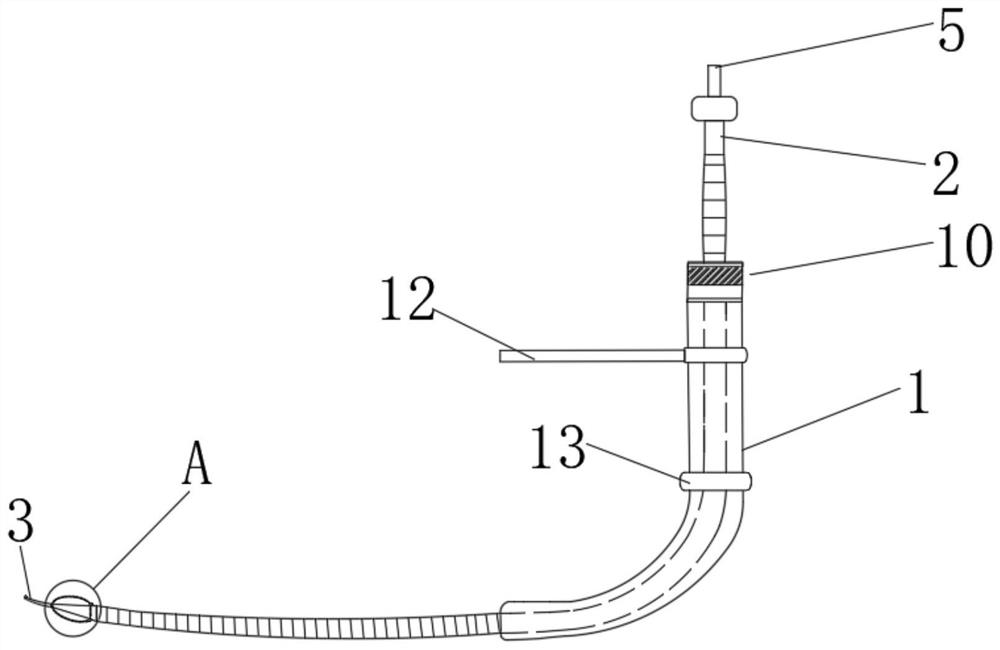

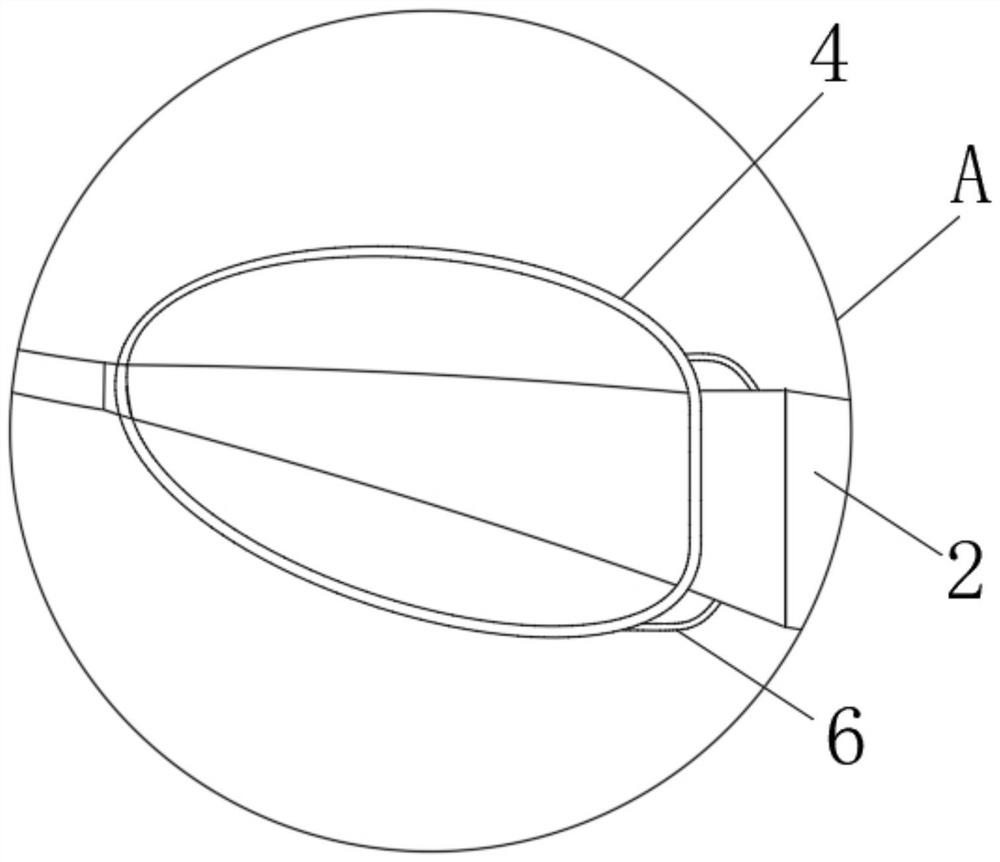

A skull dura separation device

The invention discloses a skull dura separation device, comprising an arc sheath and an inner core, the inner core is movably connected inside the arc sheath, one end of the inner core is provided with a tip head, and the outer surface of the inner core is close to the tip One side of the head is provided with a spreading bag, the other end of the inner core is fixedly connected with an injection head, and one side of the pointed head is tilted upward at an angle of 15 degrees. The skull dura mater separation device, when the craniotomy is drilled, the device is inserted under the skull and on the dura, and the direction is changed to be parallel to the skull surface through the radian sheath, and the dura is separated from the skull by pushing the inner core. It is convenient to separate the dura mater. During the insertion process, the medical staff can know the depth of the insertion of the two through the nicks on the surface of the inner core and the curved sheath and the evaluation sheet, and the staff can use the injection tube to inflate through the injection head, The expansion bag is inflated and separated by the force of its expansion.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

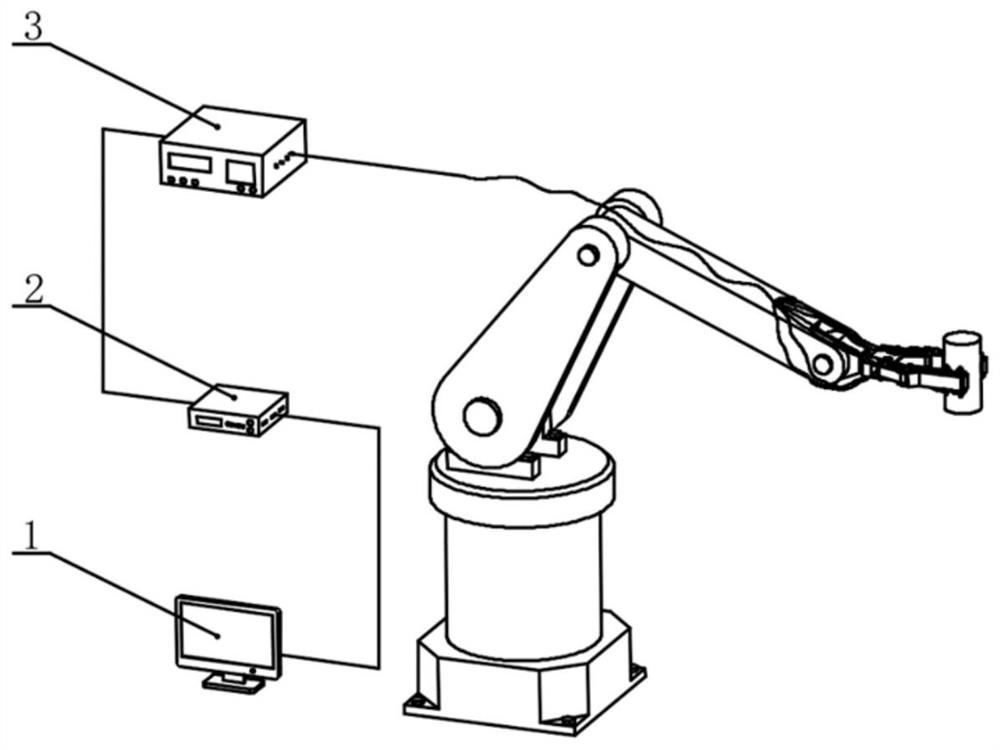

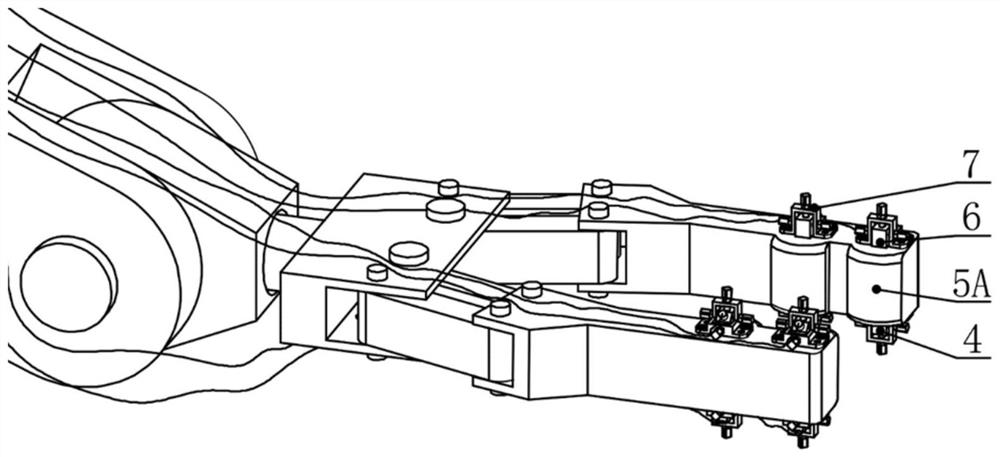

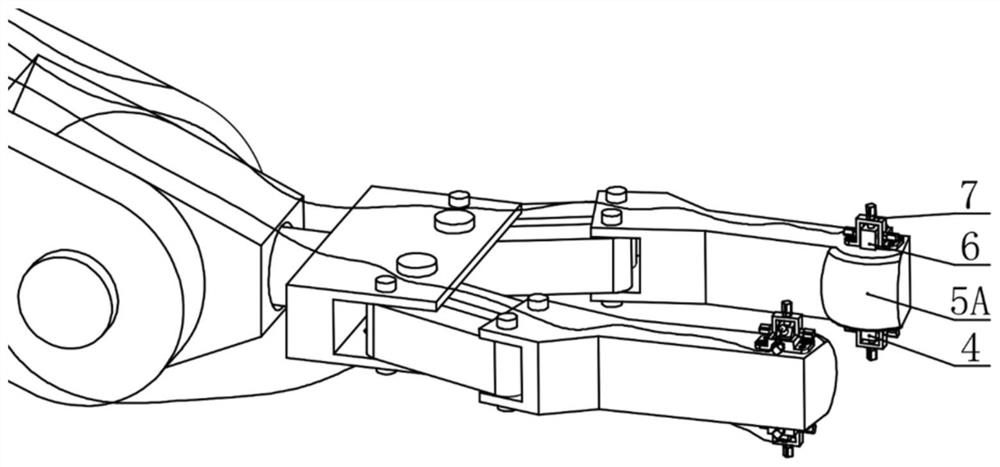

Manipulator tail end and method based on intelligent sensing of ultrasonic surface wave contact stress

PendingCN112405569ALarge clamping forceAvoid stressForce measurementApparatus for force/torque/work measurementData acquisitionIndustrial manipulator

The invention relates to a manipulator tail end and method based on intelligent sensing of ultrasonic surface wave contact stress. The manipulator tail end and method are suitable for real-time monitoring of local contact stress of the tail end when an industrial manipulator grabs an object. The manipulator tail end comprises a specially-made manipulator columnar or spherical tail end, an ultrasonic transmitting and receiving probe, probe supports, adjusting bolts and nuts, an ultrasonic transmitting and receiving device, a data acquisition card and a computer. The probe supports are installedon the upper plane and the lower plane of the manipulator tail end, and the adjusting bolts and nuts on the probe supports are used for adjusting and fixing the position of the probe. The probe, theultrasonic transmitting and receiving device, the data acquisition card and the computer are sequentially connected. During work, the ultrasonic transmitting and receiving device sends out an electricsignal to stimulate the ultrasonic transmitting probe to generate surface waves; the surface waves are transmitted along the surface of the manipulator tail end, and the receiving probe receives thesurface waves, converts the surface waves into an electric signal and transmits the electric signal back to the ultrasonic transmitting and receiving device; and the data acquisition card samples anddigitizes the sent and received signals, by the computer, data storage and calculation analysis are achieved to obtain change of the surface wave transmission time, real-time monitoring of the local contact stress of the manipulator tail end is achieved, and the industrial manipulator which is cold originally has the capacity of sensing the contact stress.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com