Pretreatment hazardous waste storage bin

A hazardous waste and pretreatment technology, applied in grain processing and other directions, can solve the problems of dripping outside the collection vessel, hazardous waste entering the external environment, and easy harm to human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

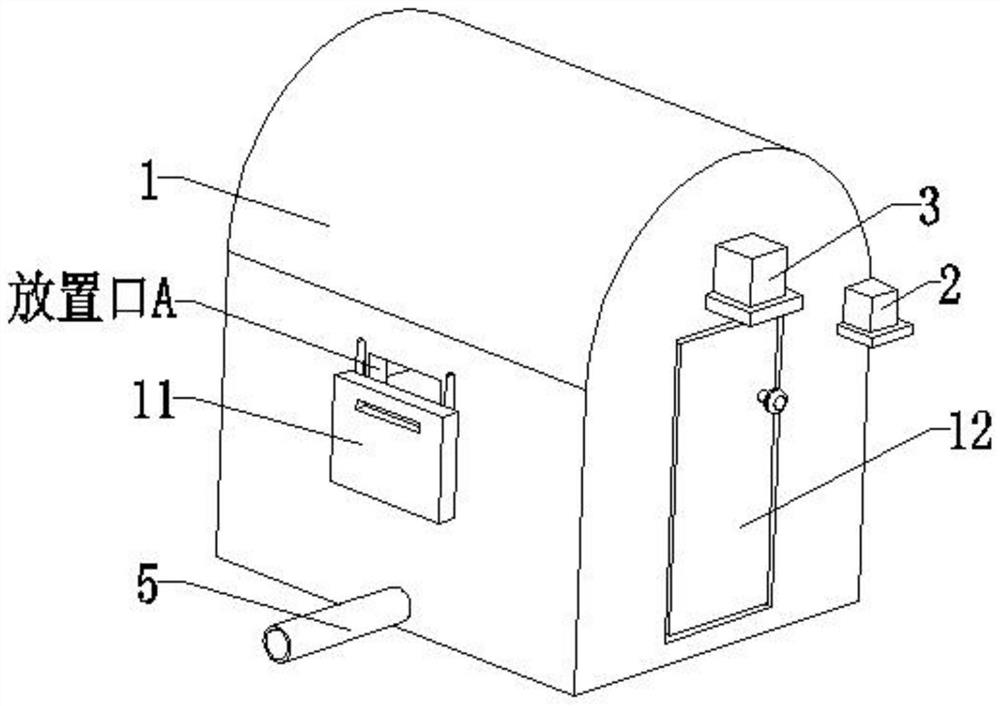

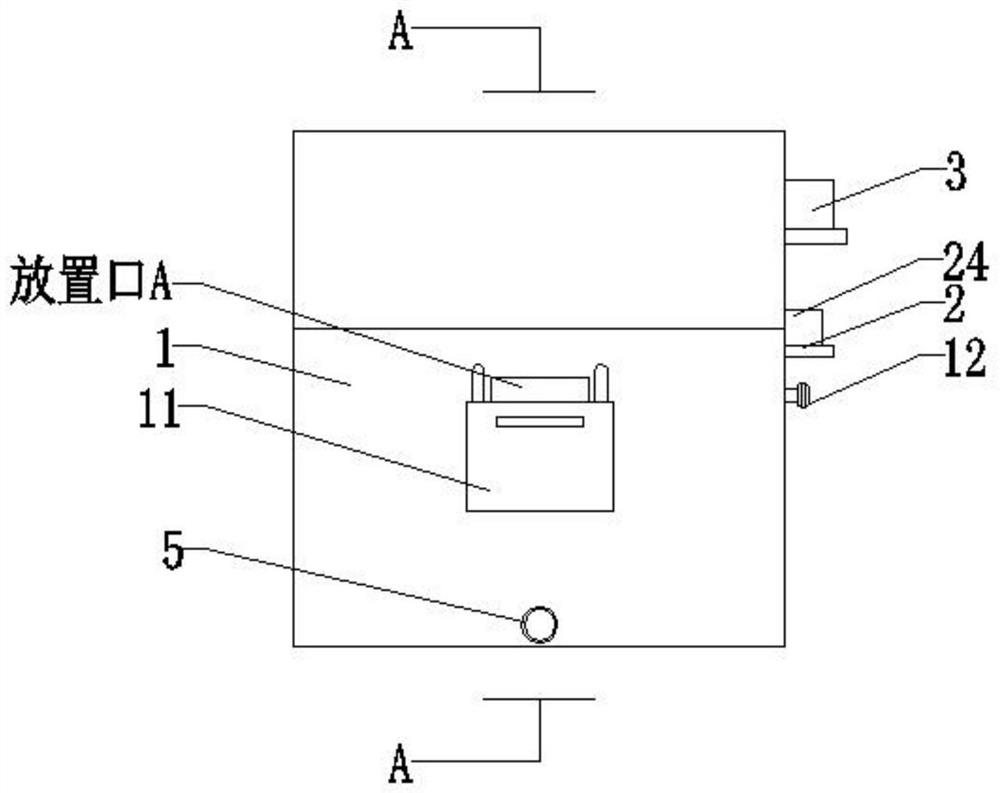

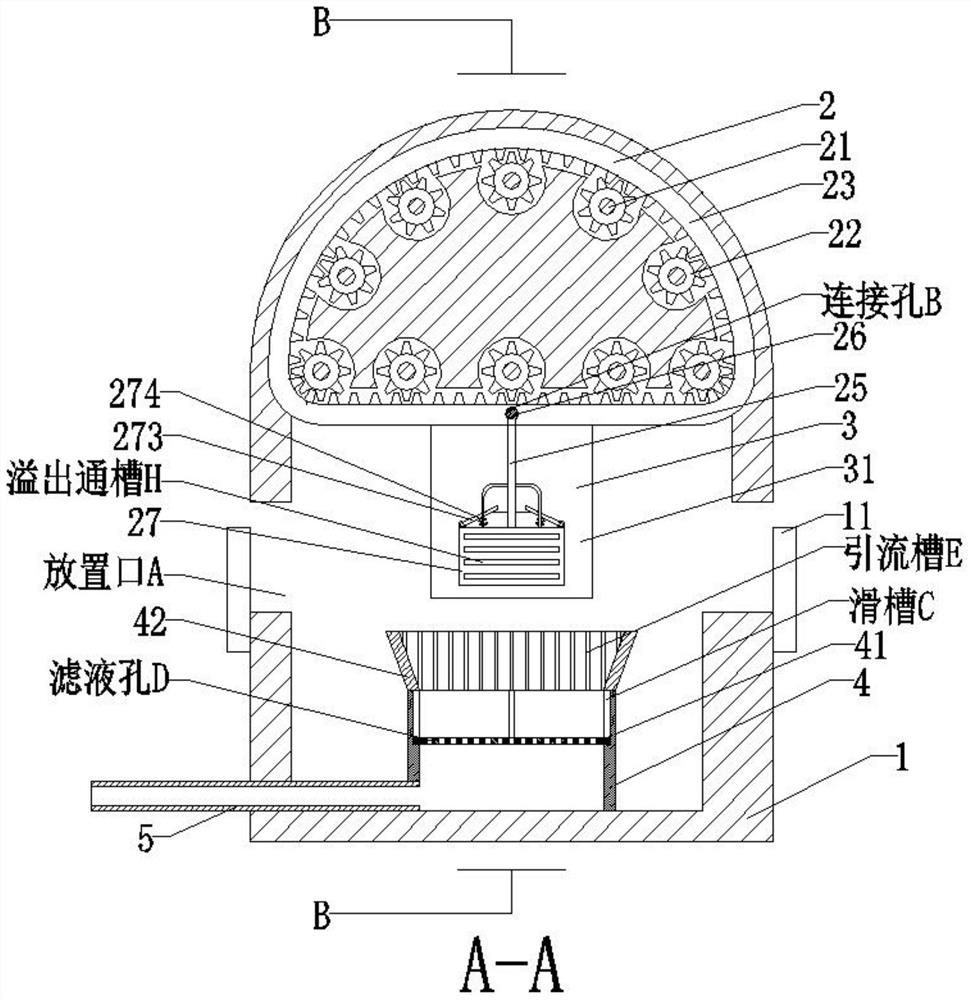

[0030] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

[0031] A pretreatment hazardous waste storage bin, including a bin body 1, a conveying assembly 2, a crushing assembly 3, a collection box 4 and a diversion pipe 5, a conveying assembly 2 is installed above the bin body 1, and a crushing assembly 3 is arranged outside the conveying assembly 2 , the crushing assembly 3 is installed on the inner wall of the bin body 1, a collection box 4 is arranged below the crushing assembly 3, and a diversion tube 5 is connected to the collection box 4, and the diversion tube 5 passes through the bin body 1, wherein:

[0032] The left and right sides of the bin body 1 are symmetrically provided with a placement port A, and a sliding baffle 11 is installed on the placement hole A through a sliding connection, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com