Ripple reduction circuit based on input feedforward and loop control and coating power supply

A loop control and control circuit technology, applied in the power supply field, can solve the problems of high cost, untimely dynamic response of fast input or output, and poor real-time performance of digital control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The control strategy of conventional semiconductor coating power supply and photovoltaic coating power supply is generally AC rectification to DC+isolated voltage-regulated pulse output, or use PFC circuit + isolated voltage-regulated pulse output, resulting in the output of external alternating current with 100Hz or 300Hz after being rectified by the rectifier The DC voltage with low-frequency ripples reduces the efficiency of the power supply, and it is easy to generate harmonics on the back-end electrical equipment, resulting in damage to the back-end electrical equipment. The existing technology cannot achieve ultra-high-performance dynamic response in the process of suppressing low-frequency ripple, and cannot solve the problem of chip damage caused by excessive signal amplitude extracted by the differential extraction circuit in the filtering and phase-shifting process.

[0065] In view of the above problems, the embodiment of the present application provides a rip...

Embodiment 2

[0077] For ease of understanding, an embodiment of a ripple reduction circuit based on input feedforward and loop control is provided below for illustration. In practical applications, a circuit that couples the voltage loop control circuit and the filtering phase-shifting limiting circuit for further design.

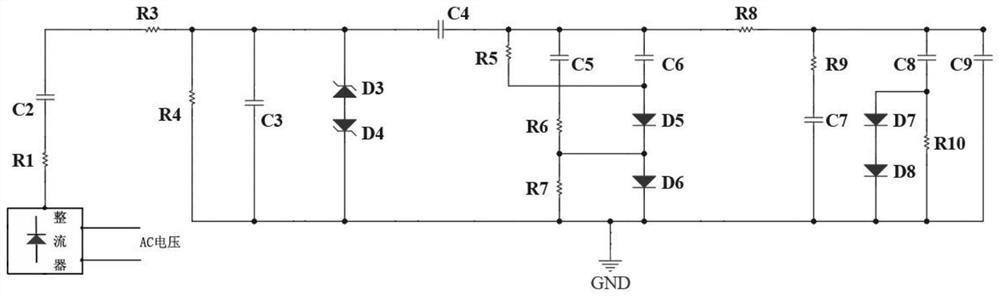

[0078] see figure 2, Embodiment 2 of the ripple reduction circuit based on input feedforward and loop control shown in the embodiment of the present application includes:

[0079] The differential extraction circuit includes a resistor R1 and a capacitor C2, the resistor R1 and the capacitor C2 are connected in series, and the resistor R1 is connected to the positive output terminal of the rectifier.

[0080] The filtering phase-shifting circuit includes a resistor R3, a resistor R4 and a capacitor C3, the resistor R3 and the capacitor C2 are connected in series, the resistor R4 and the resistor R3 are connected in series, the resistor R4 and the capacitor C3 are conn...

Embodiment 3

[0087] For ease of understanding, an embodiment of a ripple reduction circuit based on input feedforward and loop control is provided below for illustration. In practical applications, the working mode of the boost circuit will be determined by a pulse width modulation signal generator, and also Prevent the MOS transistor Q1 and MOS transistor Q2 in the boost circuit from being turned on at the same time, causing damage to the back-end electrical equipment.

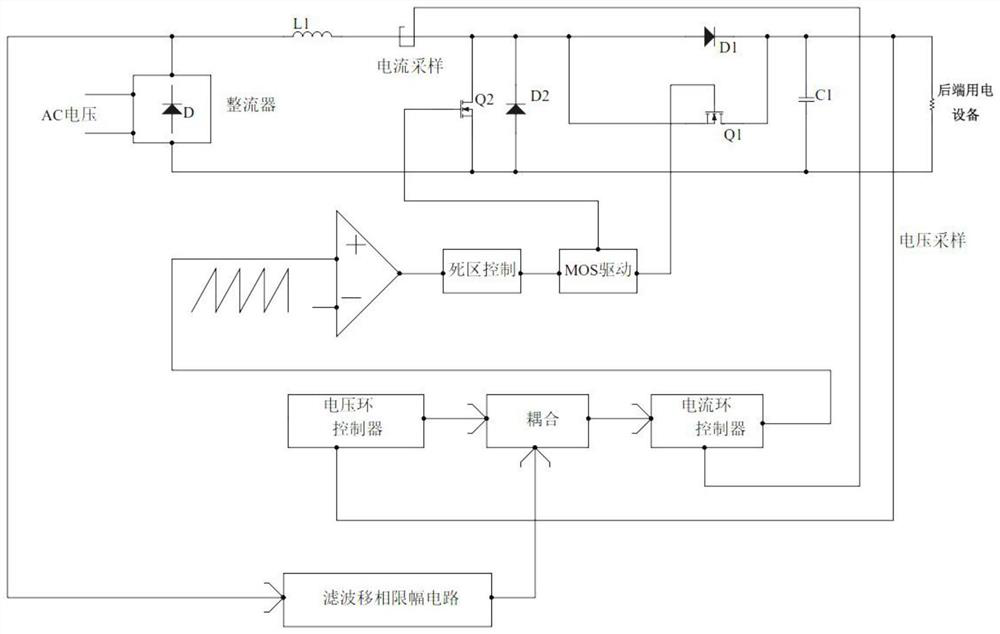

[0088] see figure 1 , Embodiment 3 of the ripple reduction circuit based on input feedforward and loop control shown in the embodiment of the present application includes:

[0089] Dynamic voltage signal input pulse width modulation signal generator, pulse width modulation signal generator includes: comparator T1, MOS transistor drive circuit and pulse width modulation signal generation circuit;

[0090] The pulse width modulation signal generating circuit is used to output a triangle wave;

[0091] The comparator T1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com