Speed regulatable and tightenable express transfer assembly line and application method

An assembly line and speed regulation technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

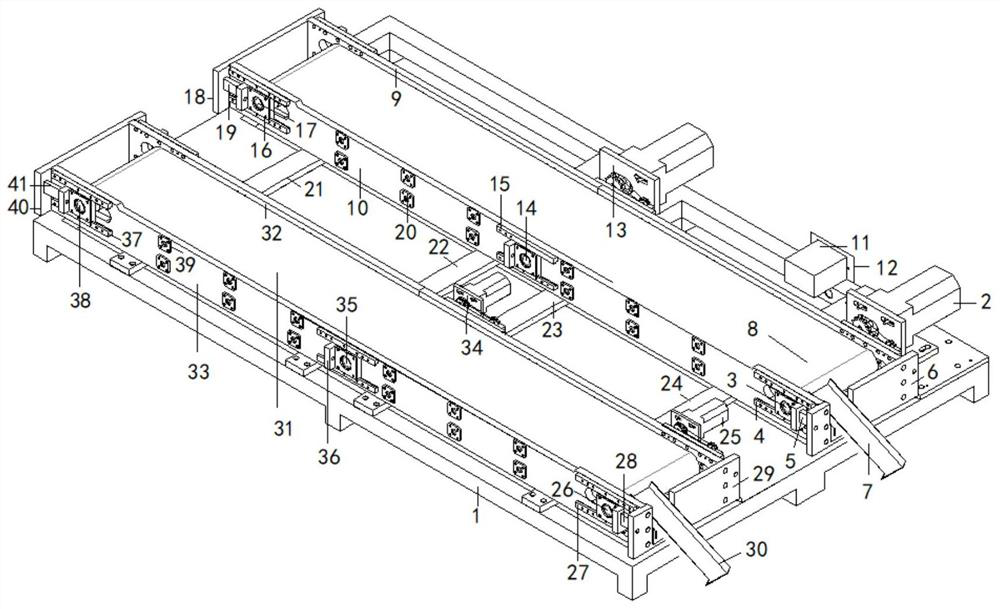

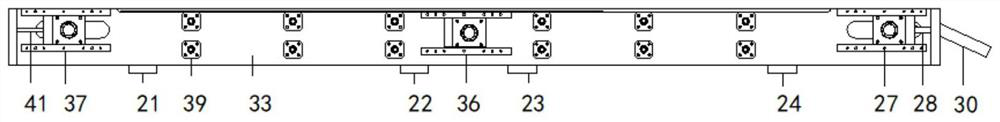

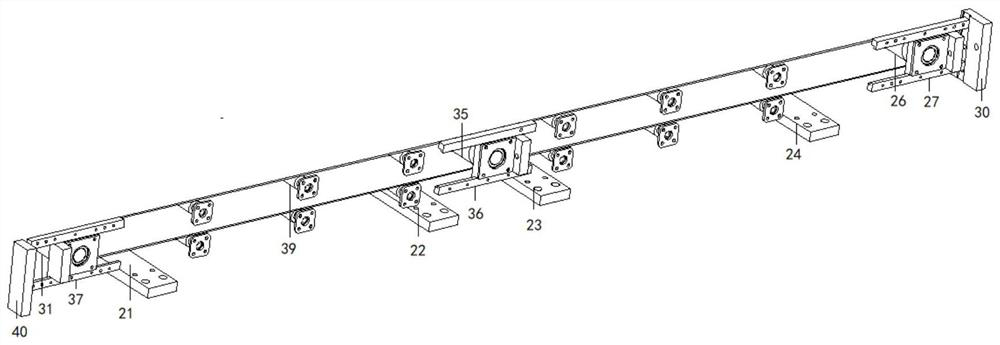

[0038] Such as Figure 1-9 As shown, the speed-adjustable and tightenable express transmission line includes a base 1, the other side of the upper end of the base 1 is connected with a first driving mechanism 2, one side of the first driving mechanism 2 is connected with a first roller 3, and the first One side of the roller 3 is connected with a first fixing mechanism 4, and the first fixing mechanism 4 plays a fixed role, one side of the first fixing mechanism 4 is connected with a first telescopic block 5, and one side of the first telescopic block 5 is connected There is a first concave baffle 6, one end of the first concave baffle 6 is connected with a first receiving chute 7, and the first receiving chute 7 plays a role of collecting express delivery, and the other end of the first concave baffle 6 is connected to There is a first conveyor belt 8, a first baffle plate 9 is installed on one side of the first conveyor belt 8, and the first conveyor belt 8 plays the role of...

Embodiment 2

[0048] The method of using the speed-adjustable and tightenable express delivery line is as follows:

[0049] Step 1: After turning on the power, press the switch button 1204, so that the power box 11 can provide current to the internal machinery of the adjustable speed and tightenable express transmission line, so that the entire assembly line starts to run, and then press the fifth button 1206 Make the four telescopic blocks start to shrink, and the first roller 3, the third roller 17, the fourth roller 26 and the sixth roller 38 will be driven to expand along with the four telescopic blocks 1206. Roller 3, the third roller 17, the fourth roller 26 and the sixth roller 38 do the expansion movement to tighten the first conveyor belt 8 and the second conveyor belt 31, and at the same time the expansion movement of the first roller 3 and the fourth roller 26 will drive the first drive The two-way gear 2005 in the mechanism 2 and the third driving mechanism 25 moves around;

[...

Embodiment 3

[0055] After turning on the power, press the switch button 1204, so that the power supply box 11 can provide current to the internal machinery of the adjustable speed and tightenable express transmission line, so that the entire assembly line can start running, and then press the fifth button 1206 to make the four The telescopic block starts to shrink, and the first roller 3, the third roller 17, the fourth roller 26 and the sixth roller 38 will be driven to expand along with the four telescopic blocks. The tension of the first conveyor belt 8 and the second conveyor belt 31, along with the first roller 3, the third roller 17, the fourth roller 26 and the sixth roller 38, will make the first conveyor belt 8 and the second conveyor belt 31 tense At the same time, the expansion movement of the first roller 3 and the fourth roller 26 will drive the two-way gear 2005 in the first drive mechanism 2 and the third drive mechanism 25 to move around, and the first drive mechanism 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com