Radiation shielding electronic packaging material and preparation method for same

An electronic packaging material and radiation shielding technology, applied in shielding, circuits, electrical components, etc., can solve problems such as low yield, complicated molding process, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

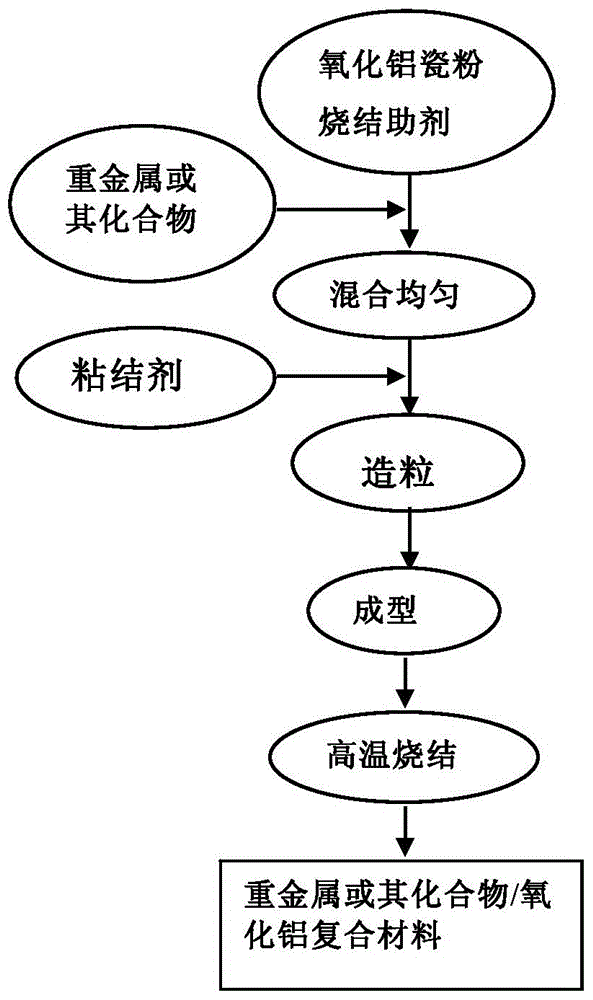

Method used

Image

Examples

Embodiment 1

[0026] The composition of the composite powder is: 14g of tungsten powder, 25g of 95 alumina porcelain powder, and 2.0g of silicon dioxide; ethanol is used as a dispersion medium and mixed evenly. After drying, 1.1 g of 7.0 wt % phenolic resin solution was added as a binder, mixed and granulated to obtain tungsten / alumina composite particles. The tungsten / alumina composite particles were dry-pressed and then sintered in a high-temperature tube furnace at a high temperature of 1400°C for 200 minutes to obtain a tungsten / alumina composite packaging material.

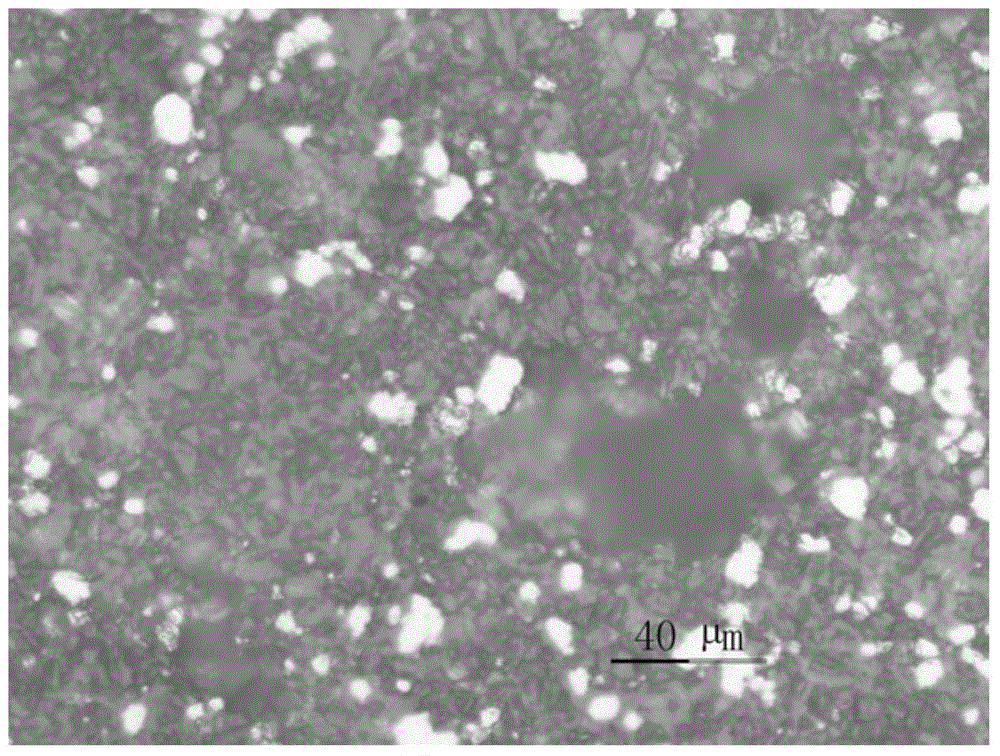

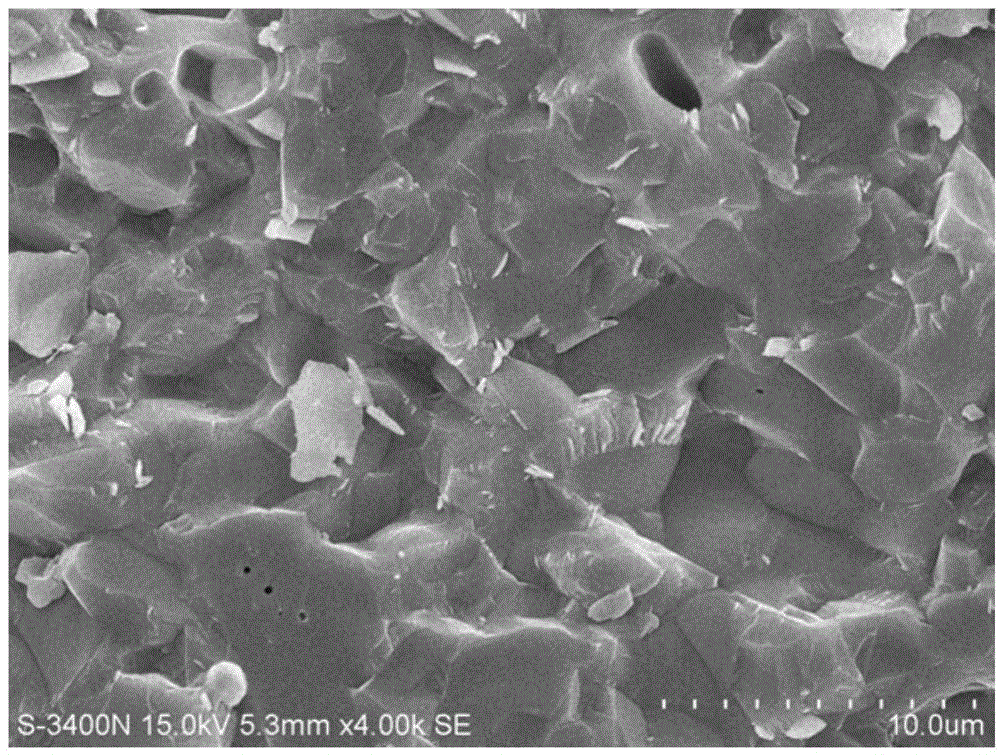

[0027] figure 2 , image 3 and Figure 4 The metallographic microscope image of the obtained composite packaging material, the scanning electron microscope image of the material section, and the X-ray diffraction image of the material are respectively shown.

Embodiment 2

[0029] The composition of the composite powder is: 63g of tantalum powder, 30g of 95 alumina ceramic powder, 0.5g of silicon dioxide, and 1.1g of yttrium oxide; methanol is used as a dispersion medium and mixed evenly. After drying, 1.2 g of 9.0 wt % polyvinyl alcohol solution was added as a binder, mixed and granulated to obtain tantalum / alumina composite particles. The tantalum / alumina composite particles were dry-pressed and then sintered in a high-temperature tube furnace at a temperature of 1400°C for 100 minutes to obtain a tantalum / alumina composite packaging material.

Embodiment 3

[0031] The composition of the composite powder is: 30g of bismuth oxide powder, 15g of 95 alumina ceramic powder, 0.8g of calcium oxide, and 0.8g of silicon dioxide; acetone is used as a dispersion medium and mixed evenly. After drying, 2.8 g of 4.0 wt % polyvinyl alcohol solution was added as a binder, mixed and granulated to obtain bismuth oxide / alumina composite particles. Bismuth oxide / alumina composite particles were dry-pressed and then sintered in a high-temperature tube furnace at a temperature of 1500°C for 200 minutes to obtain a bismuth oxide / alumina composite packaging material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com