A device for removing nitrate nitrogen in resin desorption liquid and its application process

A technology of desorption liquid and nitrate nitrogen, which is applied in water/sewage multi-stage treatment, biological water/sewage treatment, oxidized water/sewage treatment, etc. Small area, compact device structure, chemical oxygen demand reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

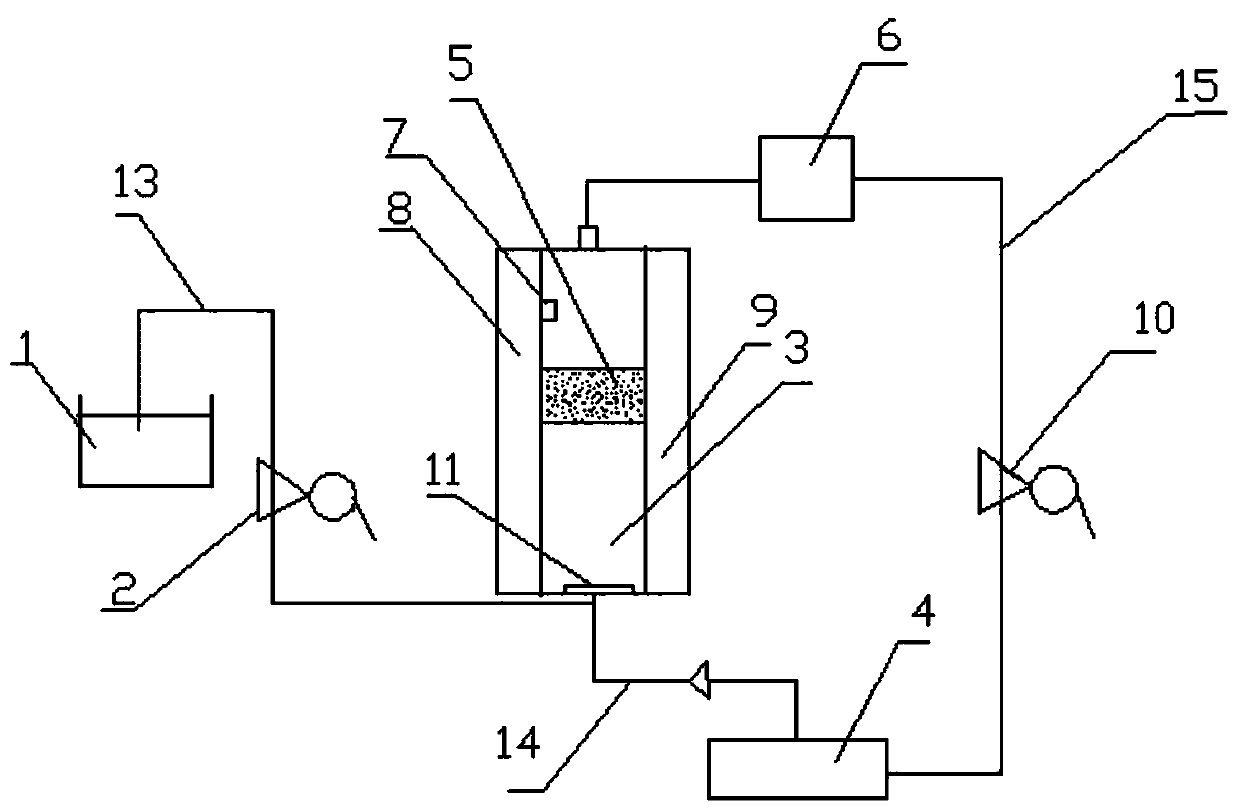

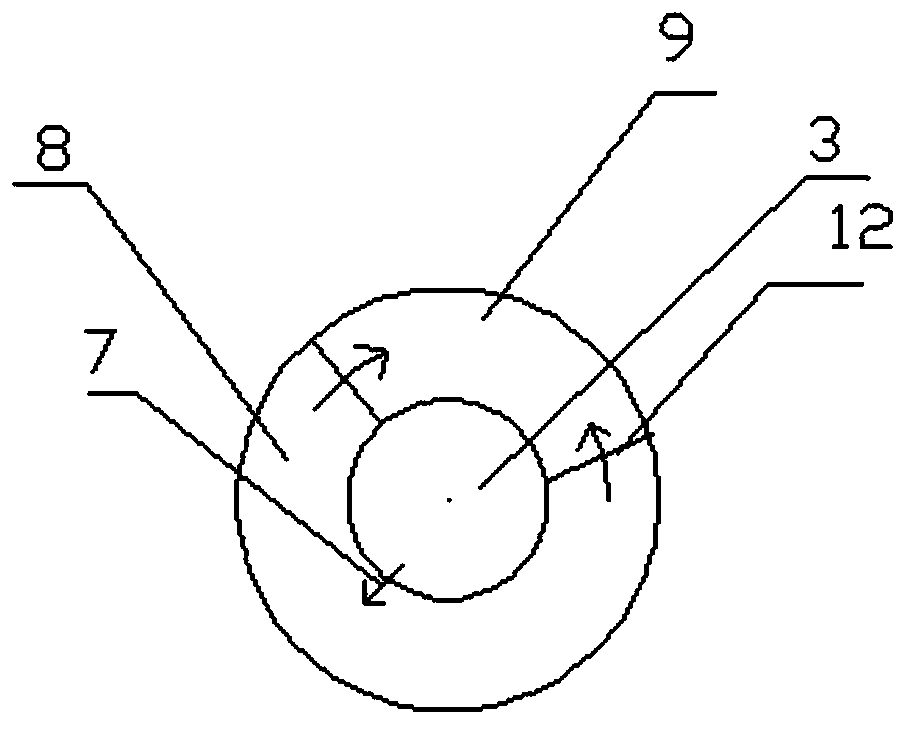

[0032] Such as figure 1 As shown, a device for removing nitrate nitrogen in the resin desorption liquid, including a reactor, an aeration device 11, a water inlet tank 1 and an ozone dosing device 4, is characterized in that: the reactor is a concentric cylindrical structure, The inner layer of the reactor of the concentric cylindrical structure is an ozone contact reactor 3, and the outer layer is an anoxic reactor 8 and a sludge settler 9 spaced apart, and the bottom of the anoxic reactor 8 and the sludge settler 9 The upper end of the ozone contact reactor 3 is provided with a water outlet 7 communicating with the anoxic reactor 8, and the lower end of the ozone contact reactor 8 is filled with an ozone reaction catalytic packing 5, and the ozone contact reactor 3 is connected through a connecting pipe One 13 is connected with the water inlet tank 1, and the ozone contact reactor 3 is connected with the ozone dosing device 4 through the connection pipe two 14, and the devic...

Embodiment 2

[0041] Utilize the device among the embodiment 1 to remove the technology of nitrate nitrogen in the resin desorption liquid as follows:

[0042]Mix 10L wastewater with influent COD of 1000mg / L and nitrate nitrogen concentration of 100mg / L and ozone from the ozone dosing device in the lower part of the ozone contact reactor, and then enter the 12.5L ozone contact reactor through the aeration device , under the condition of pH between 4 and 5, after a hydraulic retention time of 3 hours, the wastewater overflows from the outlet at the upper end of the ozone contact reactor to the anoxic reactor with a volume of 16.5L. In the anoxic reactor, The denitrifying bacteria denitrify with the wastewater in the anoxic reactor under the condition of pH between 7 and 8. After 20 hours of hydraulic retention time, they enter the sludge settler for precipitation, and the settled wastewater can be discharged. In the present embodiment, the COD value of the treated wastewater is reduced to 19...

Embodiment 3

[0044] Utilize the device among the embodiment 1 to remove the technology of nitrate nitrogen in the resin desorption liquid as follows:

[0045] Mix the 12L wastewater with an average influent COD of 2000mg / L and a nitrate nitrogen concentration of 300mg / L and the ozone from the ozone dosing device in the lower part of the ozone contact reactor, and then enter the ozone contact reaction with a volume of 12.5L through the aeration device In the reactor, under the condition of pH between 4 and 5, after 2 hours of hydraulic retention time, the wastewater overflows from the water outlet at the upper end of the ozone contact reactor to the anoxic reactor with a volume of 16.5L. In the reactor, the denitrifying bacteria will denitrify with the wastewater from the anoxic reactor under the condition of pH between 7 and 8. After 15 hours of hydraulic retention time, they enter the sludge settler for precipitation, and the wastewater after precipitation can be emission. In the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com